Bio-based polyester modified polylactic resin, preparation method and processing forming method

A polylactic acid resin and polyester modification technology, applied in the fields of bio-based polyester modified polylactic acid resin and its preparation, high-reflection and high toughness polylactic acid modified resin and its preparation, can solve the impact strength and elongation at break The rate of improvement is not large, there is no surface reflectivity, the tensile strength of polylactic acid is decreased, etc., to achieve the effect of high pearlescent color reflection and good eco-friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

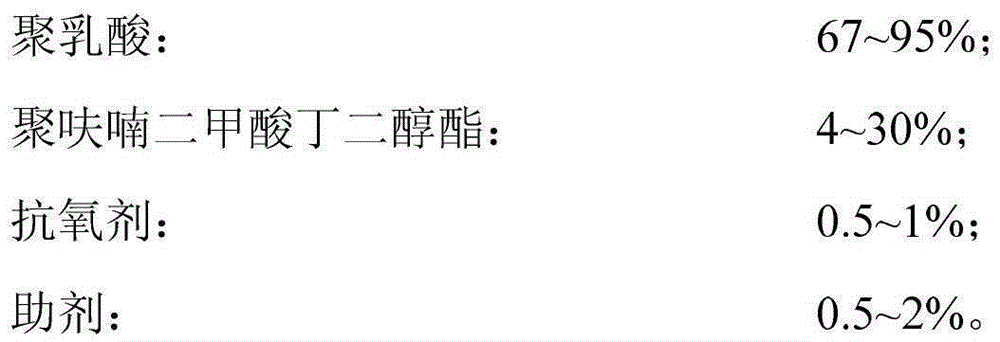

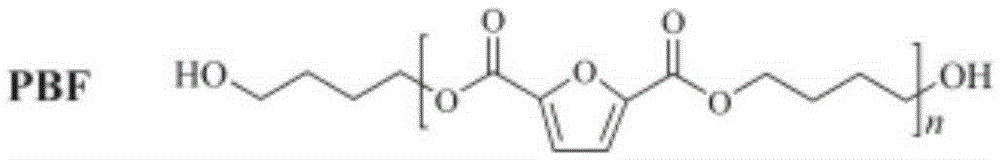

[0029] Another aspect of the present invention provides a method for preparing the high-reflection and high-toughness polylactic acid modified resin, comprising: fully drying polylactic acid and polybutylene furandicarboxylate at 80-100°C, and The dried polylactic acid, polybutylene furandicarboxylate, antioxidant and additives are banburyed and blended under the conditions of 175-200° C., 30-70 rpm, and 4-8 minutes.

[0030] As a preference, the aforementioned banbury blended product can also be put into a mold, preheated at 190-200°C for 3-6 minutes, for example 5 minutes, and hot-pressed at 12-16MPa for 2-4 minutes, for example After 3 minutes, a hot-press molded body, such as a highly reflective and high-toughness polylactic acid modified resin sheet, can be obtained.

[0031] As preferably, it is also possible to carry out extrusion granulation through a twin-screw extruder after fully drying polylactic acid, polybutylene furandicarboxylate, antioxidant and auxiliary agen...

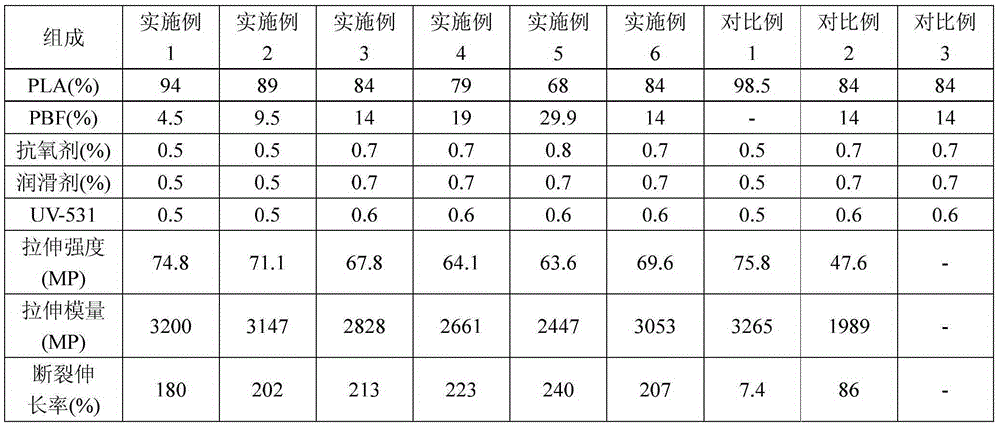

Embodiment 1

[0042] The polylactic acid PLA (4032D), the aforementioned PBF, antioxidant AT1010, lubricant PETS-3, and ultraviolet light absorber UV-531 after vacuum drying at 90°C for 2 hours are in a mass ratio of 94:4.5:0.5:0.5: 0.5 Banburying was carried out in a Brabender torque rheometer, the banburying temperature was 185°C, the rotating speed was 50 rpm, and the banburying time was 6 minutes to obtain a blend;

[0043] The obtained blend is put into a mold, preheated at 195° C. for 5 minutes, and hot-pressed at 15 MPa for 3 minutes to obtain a reflective high-toughness polylactic acid modified resin sheet.

Embodiment 2

[0045] The preparation process of this example is the same as that of Example 1, except that the mass ratio of PLA, PBF, antioxidant AT1010, lubricant PETS-3, and ultraviolet light absorber UV-531 is 89:9.5:0.5:0.5:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com