Low-tensile-modulus one-component moisture cured polyurethane sealant and preparation method thereof

A technology of polyurethane sealant and tensile modulus, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of inability to seal and waterproof, reduce tensile strength, and failure of elongation at break To achieve the ideal value and other problems, to achieve the effect of excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

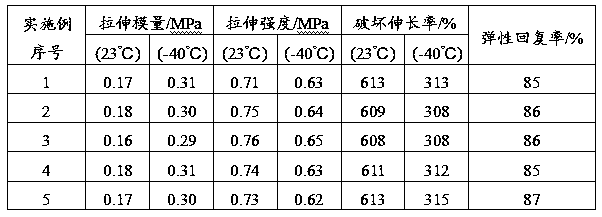

Examples

Embodiment 1

[0019] A low tensile modulus one-component moisture-curing polyurethane sealant, which is composed of the following raw materials by weight: 15 parts of isophorone diisocyanate, 45 parts of two-functional polyether polyol, three-functional polyol 10 parts of ether polyol, 0.4 part of dibutyltin dilaurate, 22 parts of calcium carbonate, 6 parts of hydrophobically modified fumed silica, 0.6 part of oxazolidinone, and 1 part of black iron oxide.

[0020] The preparation method of the low tensile modulus polyurethane sealant of the present embodiment is as follows:

[0021] Step 1. Add 45g of difunctional polyether polyol and 15g of trifunctional polyether polyol into the stirred tank, vacuumize the stirred tank and heat it to 110°C for dehydration for 2 hours;

[0022] Step 2: Cool down the stirred tank to 40°C, add 15g of isophorone diisocyanate and mix evenly, then add 0.4g of dibutyltin dilaurate, raise the temperature to 90°C for 2 hours, then cool down to room temperature; ...

Embodiment 2

[0026] A low tensile modulus one-component moisture-curing polyurethane sealant, which is composed of the following raw materials by weight: 21 parts of isophorone diisocyanate, 38 parts of two-functional polyether polyol, three-functional polyol 17 parts of ether polyol, 0.15 part of dibutyltin dilaurate, 26 parts of calcium carbonate, 5.5 parts of hydrophobically modified fumed silica, 1.2 parts of oxazolidinone, and 0.8 part of black iron oxide.

[0027] The preparation method of the low tensile modulus one-component moisture-curing polyurethane sealant of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0029] A low tensile modulus one-component moisture-curing polyurethane sealant, which is composed of the following raw materials by weight: 23 parts of isophorone diisocyanate, 33 parts of two-functional polyether polyol, three-functional polyol 19 parts of ether polyol, 0.25 part of dibutyltin dilaurate, 29 parts of calcium carbonate, 9 parts of hydrophobically modified fumed silica, 1.4 parts of oxazolidinone, and 0.6 part of black iron oxide.

[0030] The preparation method of the low tensile modulus one-component moisture-curing polyurethane sealant of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com