Single-ingredient oxime removal type low-modulus room-temperature vulcanization neutral silicone weather-resistant sealant and preparation method thereof

A room temperature vulcanization and deoxime-type technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of increasing elongation, slow surface dry speed, reducing modulus, etc., and achieve high elasticity and elastic recovery rate, good adhesive performance, and high elastic recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

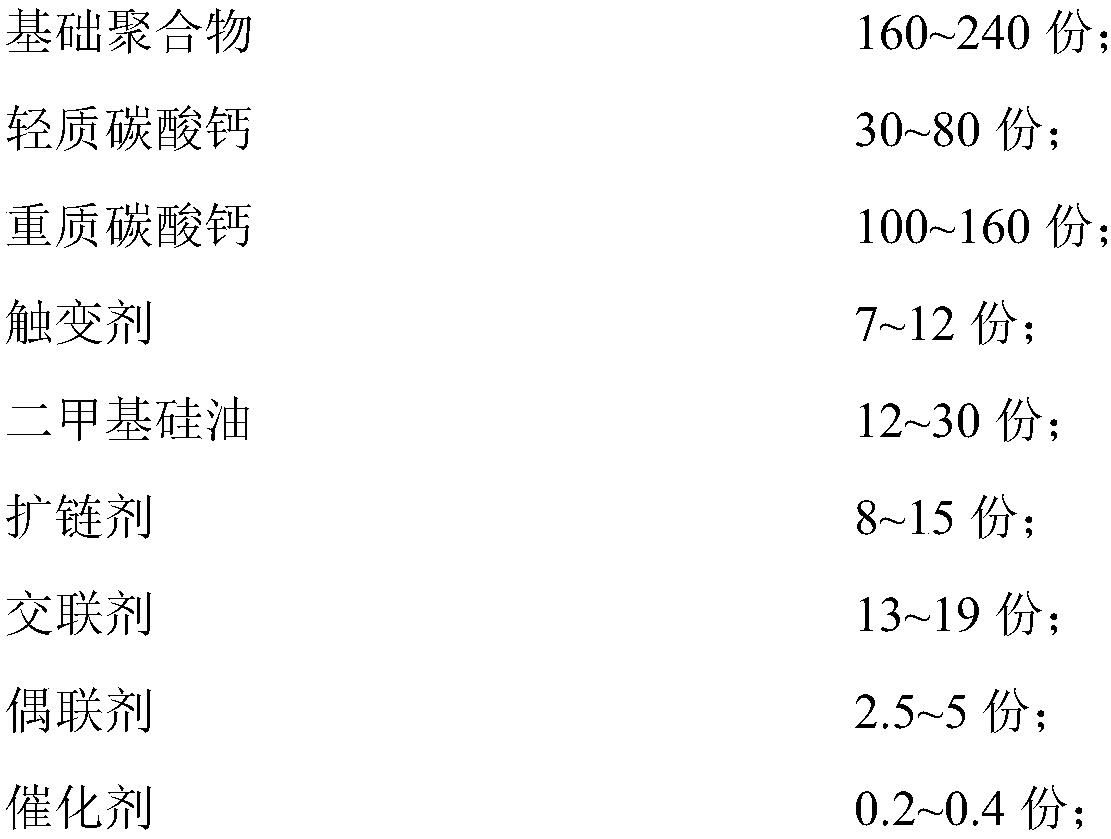

[0048] Preparation of one-component deoxime type low modulus room temperature vulcanization neutral silicone weathering sealant:

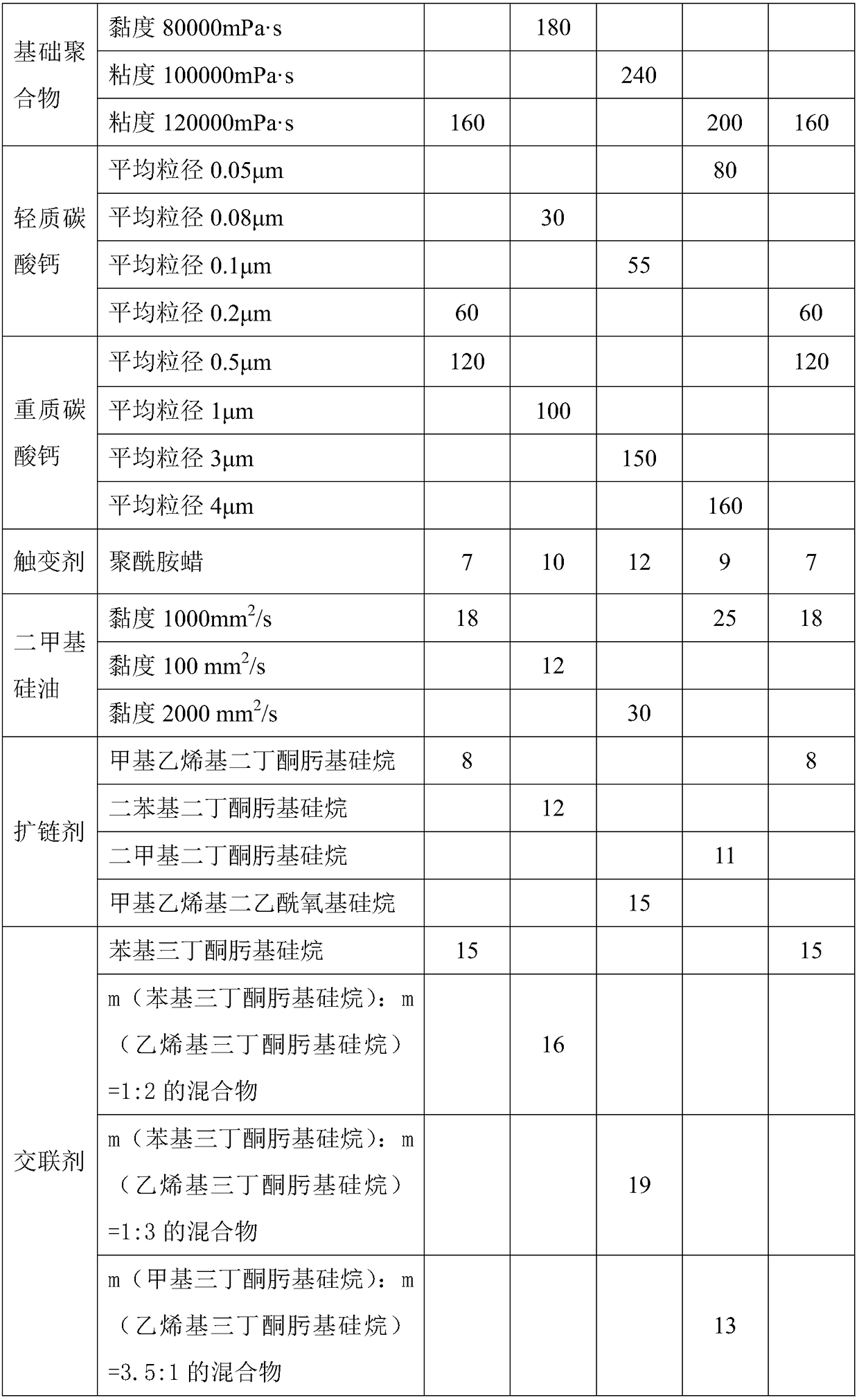

[0049] The raw material consumption of embodiment 1~5 is as shown in table 1;

[0050] Reaction conditions are as shown in table 2 in the preparation step of embodiment 1~5;

[0051] Preparation steps:

[0052] S1. Mix α, ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil and chain extender at T1 (℃) temperature and stir for t1 (min), then add light calcium carbonate and heavy calcium carbonate 1. The thixotropic agent is stirred and dehydrated for t2 (min) at T2 (°C) and the vacuum degree is P1 (MPa), and the base material is obtained after cooling;

[0053] S2. At room temperature, add the base material of S1. into a planetary stirring tank, then add a crosslinking agent, a coupling agent and a catalyst, and react t3 (min) at a vacuum degree of P2 (MPa) and a rotational speed of r (rpm). , the one-component room temperature vulcanization ...

Embodiment 5

[0084] The modulus, elastic recovery rate and elongation adhesion of Example 5 all meet the "GB / T 22083-2008 Building Sealants Classification and Requirements" and "GB / T 14683-2017 Silicone and Modified Silicone Building Sealants The performance requirements for low modulus sealants in Adhesives. However, because it uses a conventional small molecule coupling agent as a tackifier, only an intermediate with 3 silanol groups is produced after hydrolysis. When the tensile adhesiveness test was carried out, interfacial failure occurred at an elongation of about 400%, whereas in Example 1, cohesive failure occurred. It shows that the viscosity-increasing effect of oligomer is better than that of small molecule silane coupling agent.

[0085] The test results of Comparative Examples 1-2 and Example 1 show that the base polymer with a viscosity of 50000mPa s has a shorter molecular chain than that of the base polymer with a viscosity of 80000mPa s, resulting in a relatively large cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com