Preparation method of low-modulus and high-strength resin adhesive film

A high-strength, resin glue technology, applied in the direction of epoxy resin glue, adhesive, film/sheet adhesive, etc., can solve problems such as crack resistance, low impact resistance, poor impact resistance, and easy cracking , to achieve the effect of reducing tensile modulus, easy reaction steps, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

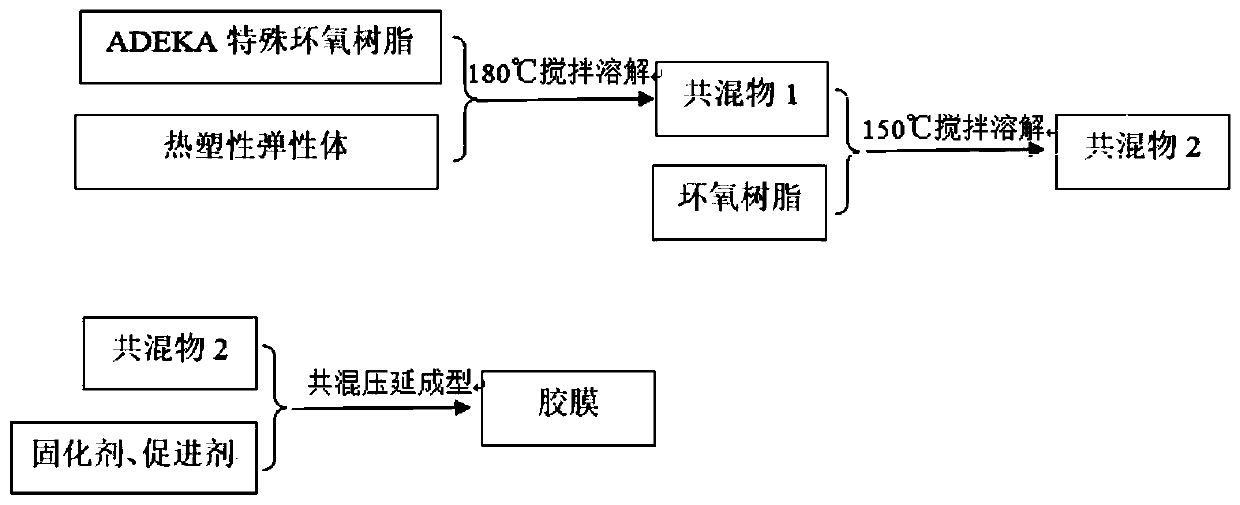

[0031] This is achieved through the following steps:

[0032] Step a. Weigh 100g of ADEKA special epoxy resin and add it into the glass beaker, and add 3g of thermoplastic polyurethane elastomer component inside, the addition amount is 3% of the total mass of ADEKA special epoxy resin. Put the mixed system in an oil bath and raise the temperature to 180°C, and stir it with a timing electric stirrer for about 90 minutes until the thermoplastic polyurethane elastomer component is completely dissolved and dispersed to obtain a blend;

[0033] Step b, take 8g of ordinary bisphenol A type epoxy resin, the addition amount is 8% of the total mass of ADEKA special epoxy resin, adjust the temperature of the blend prepared in step a to 150 ° C, and weigh the ordinary Add bisphenol A epoxy resin to it, and stir with a timing electric mixer for about 90 minutes until the common bisphenol A epoxy resin components are completely dissolved and dispersed to obtain a clear and transparent blen...

Embodiment 2

[0038] Proportion: ADEKA special epoxy resin 100g; thermoplastic polyurethane elastomer 7g; ordinary bisphenol A epoxy resin 8g; dicyandiamide 4g; UR300 organic urea 2g.

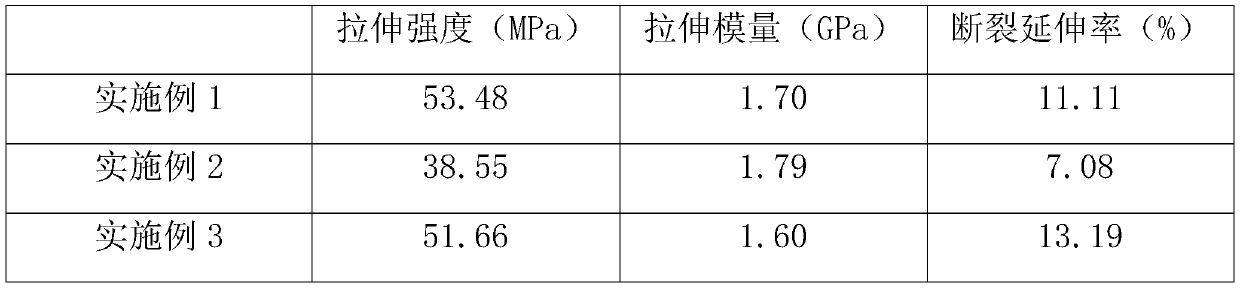

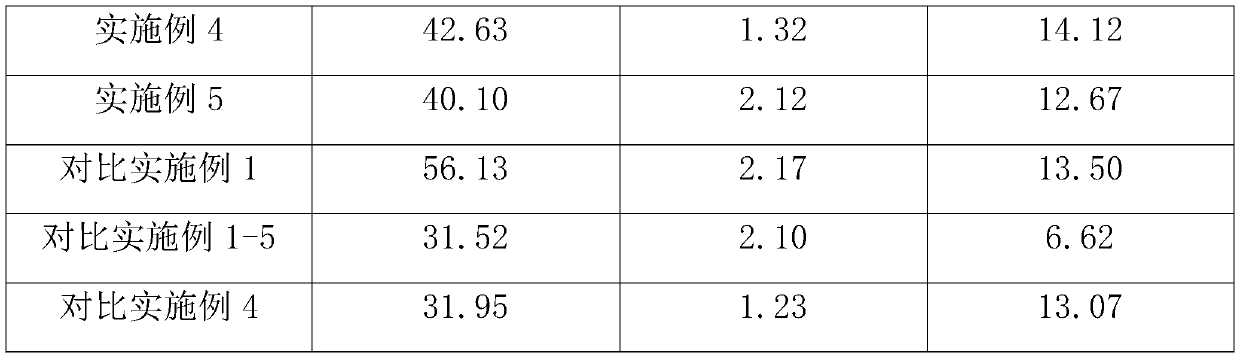

[0039] The specific preparation method, curing method and mechanical property test of the resin film provided in this example are the same as in Example 1. The tensile strength, tensile modulus and elongation at break of the obtained resin film cured product are shown in Table 1.

Embodiment 3

[0041] Proportion: ADEKA special epoxy resin 100g; thermoplastic polyurethane elastomer 15g; ordinary bisphenol A epoxy resin 8g; dicyandiamide 4g; UR300 organic urea 2g.

[0042] The specific preparation method, curing method and mechanical property test of the resin film provided in this example are the same as in Example 1. The tensile strength, tensile modulus and elongation at break of the obtained resin film cured product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com