Support substrate for surface protection film and surface protection film

A surface protection film and substrate technology, which is applied in applications, household components, household appliances, etc., can solve the problems of easy shrinkage of supporting substrates, and achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

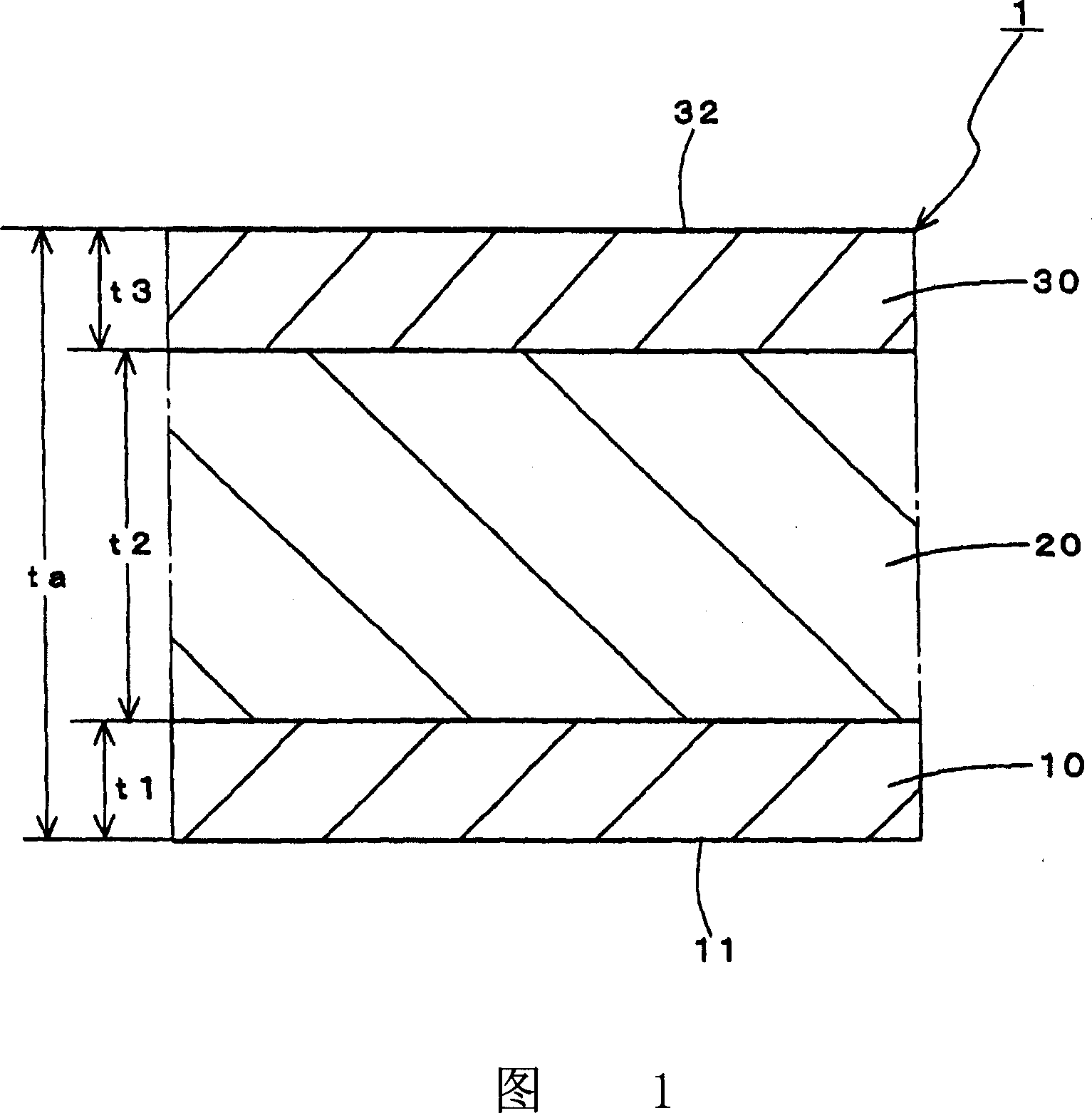

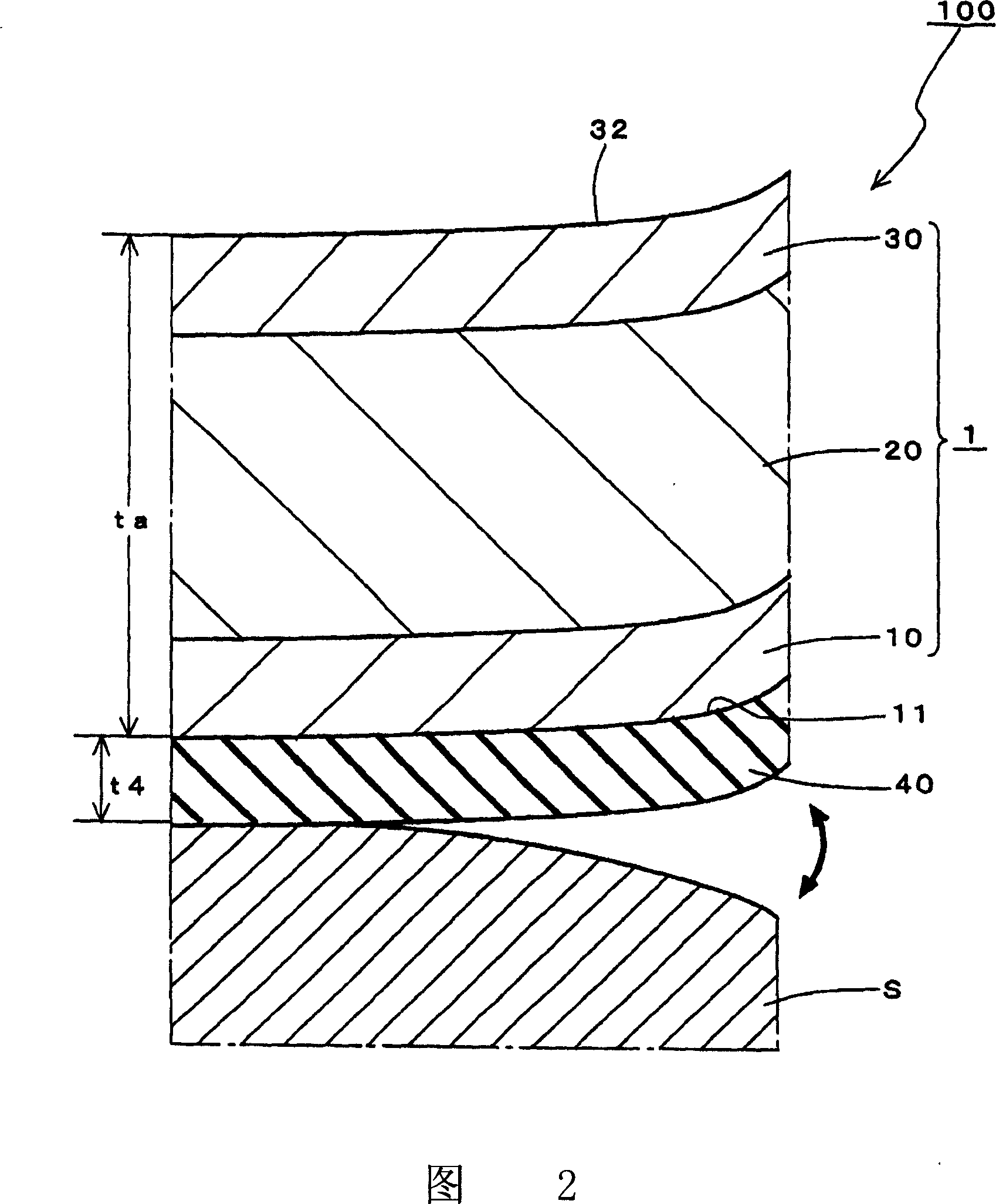

[0035] The present invention will be described in detail below with reference to the accompanying drawings. FIG. 1 is a schematic cross-sectional view showing a support substrate for a surface protection film according to an embodiment of the present invention; FIG. 2 is a schematic cross-sectional view showing a surface protection film according to an embodiment of the present invention.

[0036] As described in the first aspect of the invention, the support substrate for a surface protection film of the present invention is formed of at least two or more film layers having different physical properties. Simultaneously, an outermost film layer corresponding to the outermost surface of the other side is formed with respect to one side surface of the support base material.

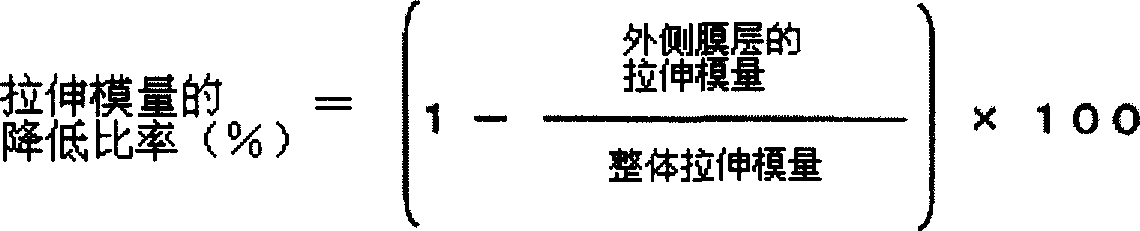

[0037] The tensile modulus measured based on JIS-K-7127 (2000) of the outermost film layer shows a value lower than the tensile modulus of the support base material as a whole, preferably a value lower than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com