Patents

Literature

59results about How to "Does not affect deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

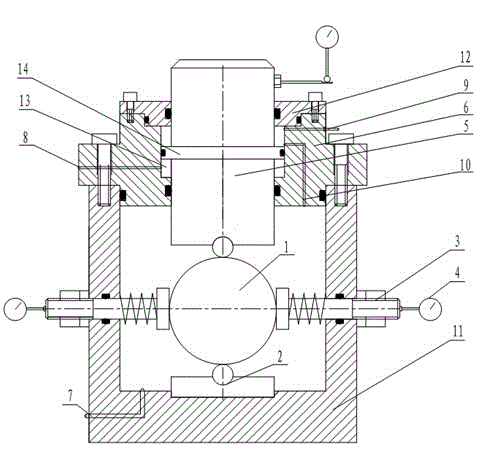

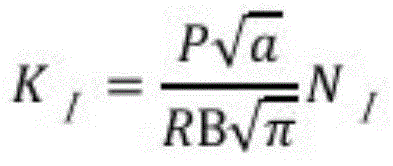

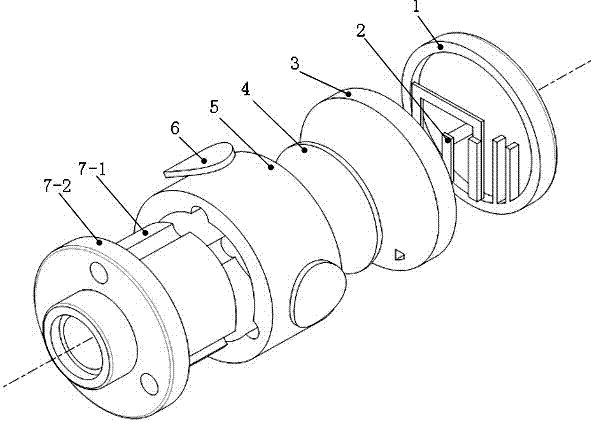

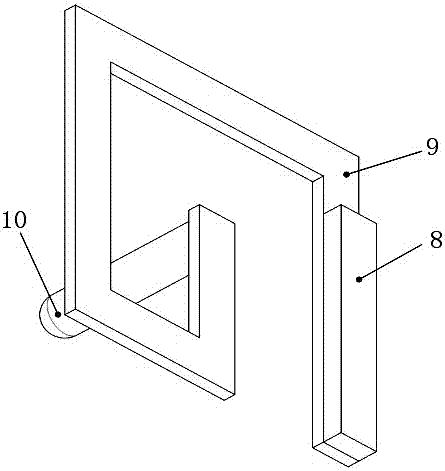

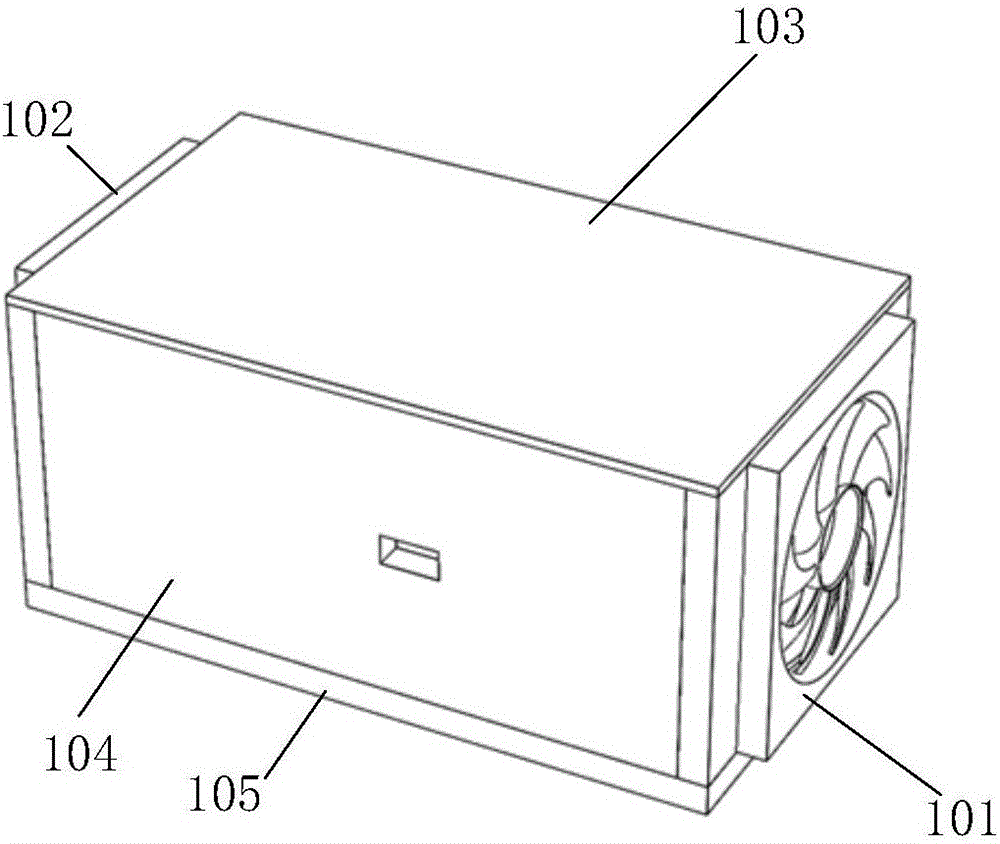

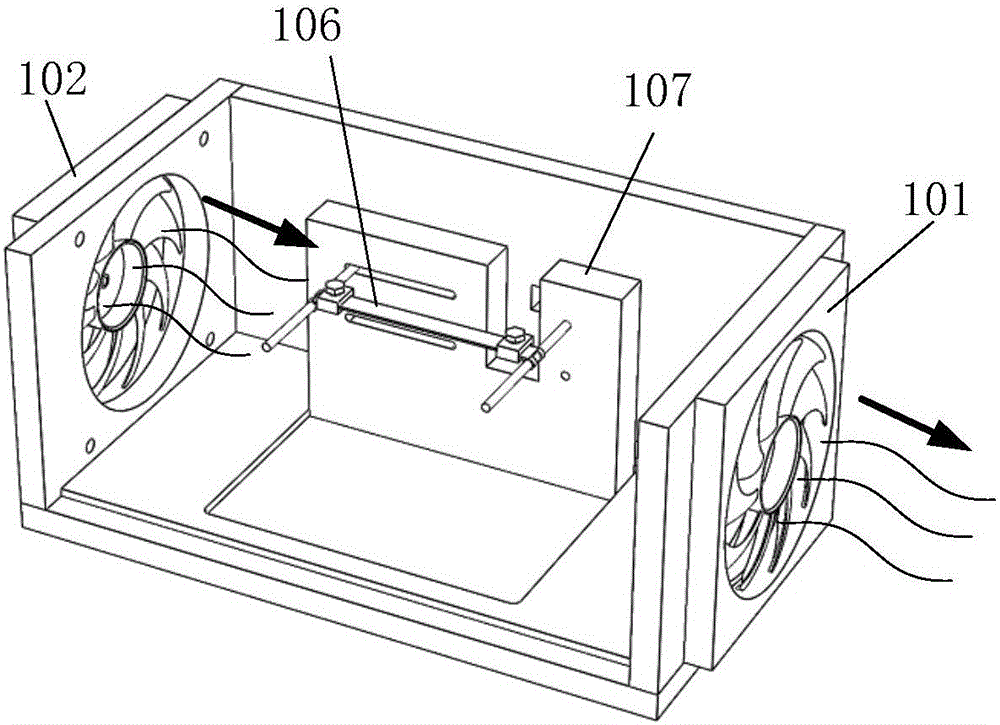

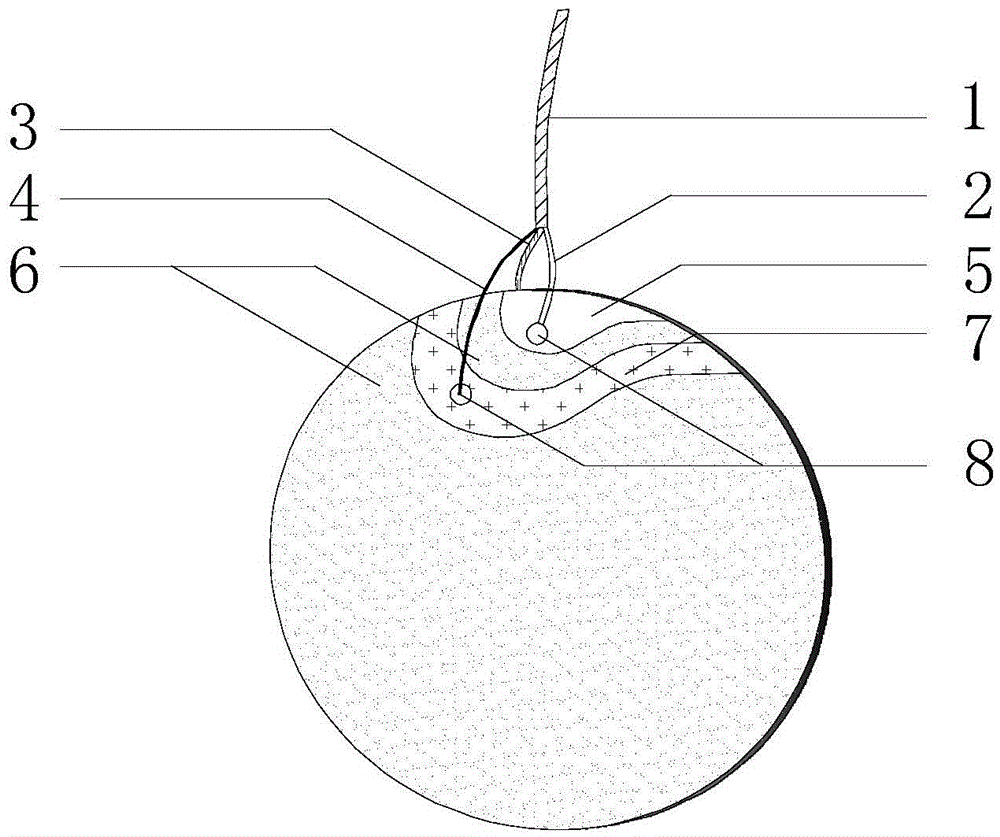

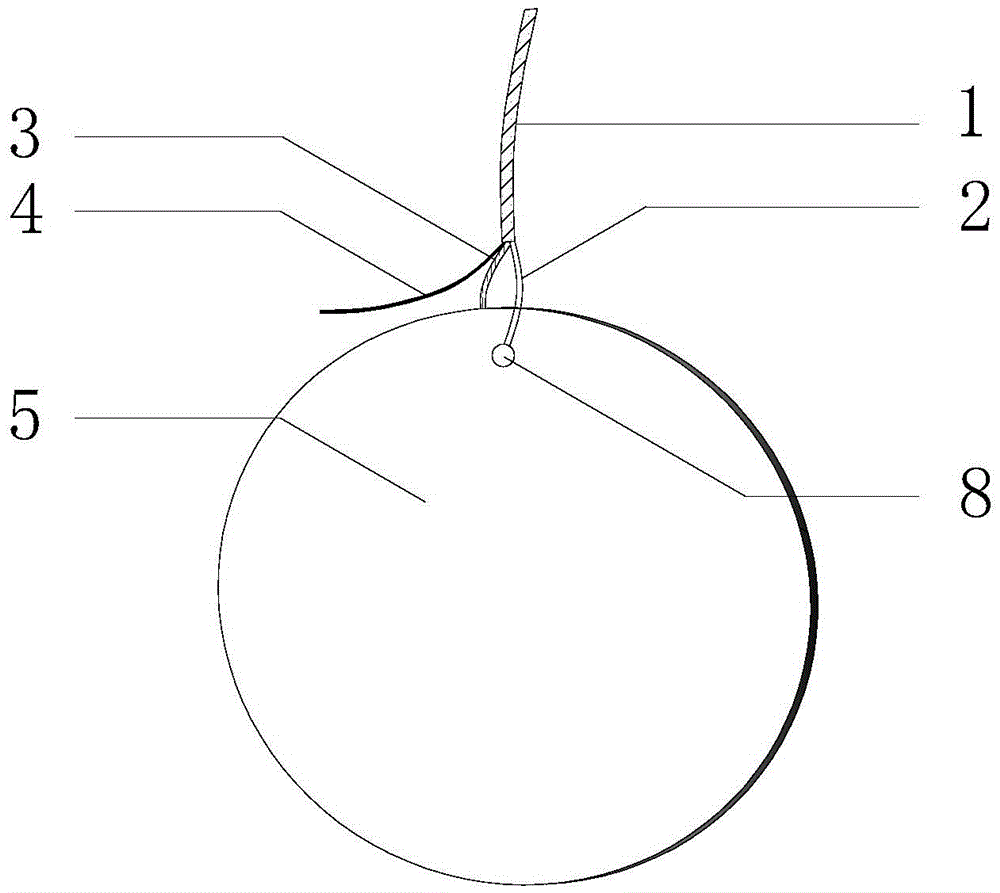

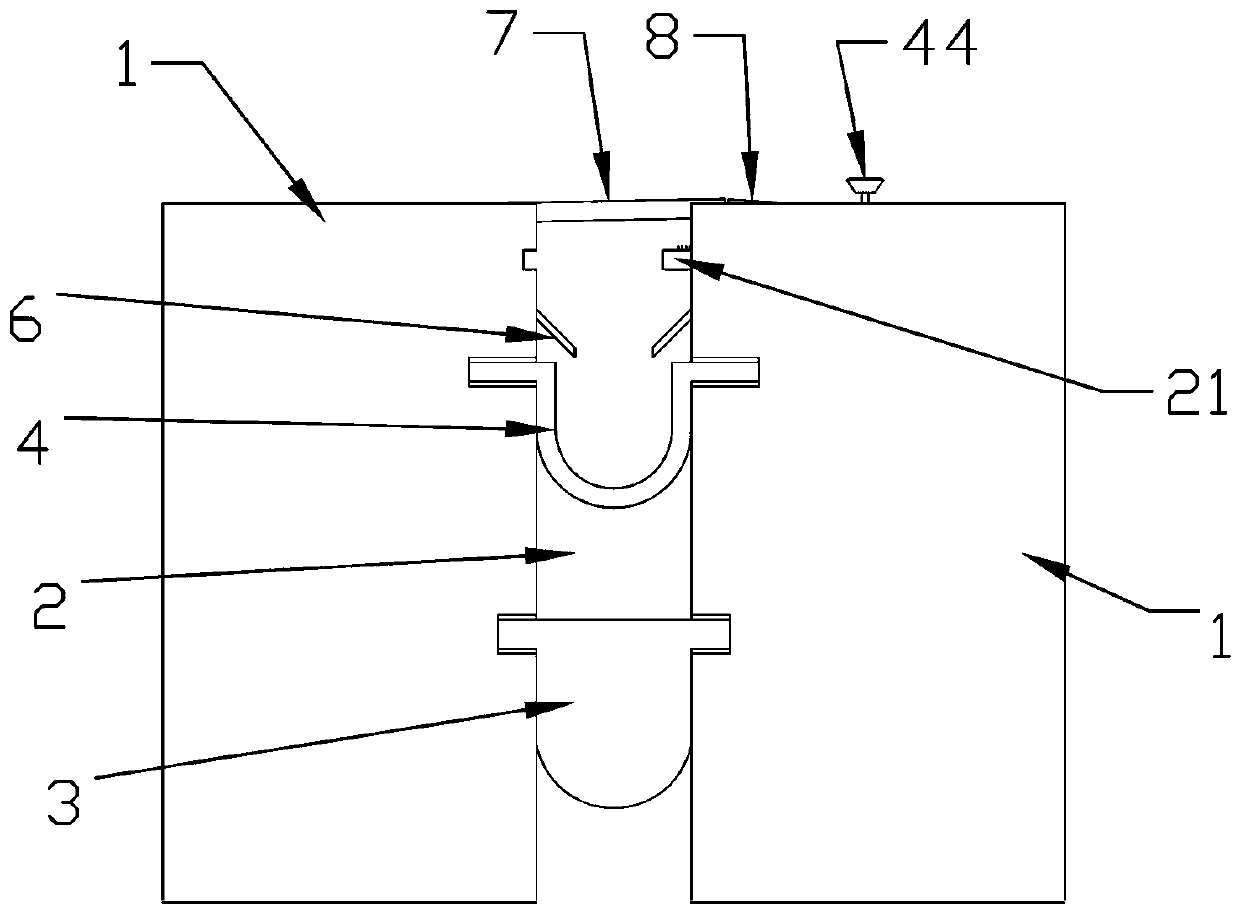

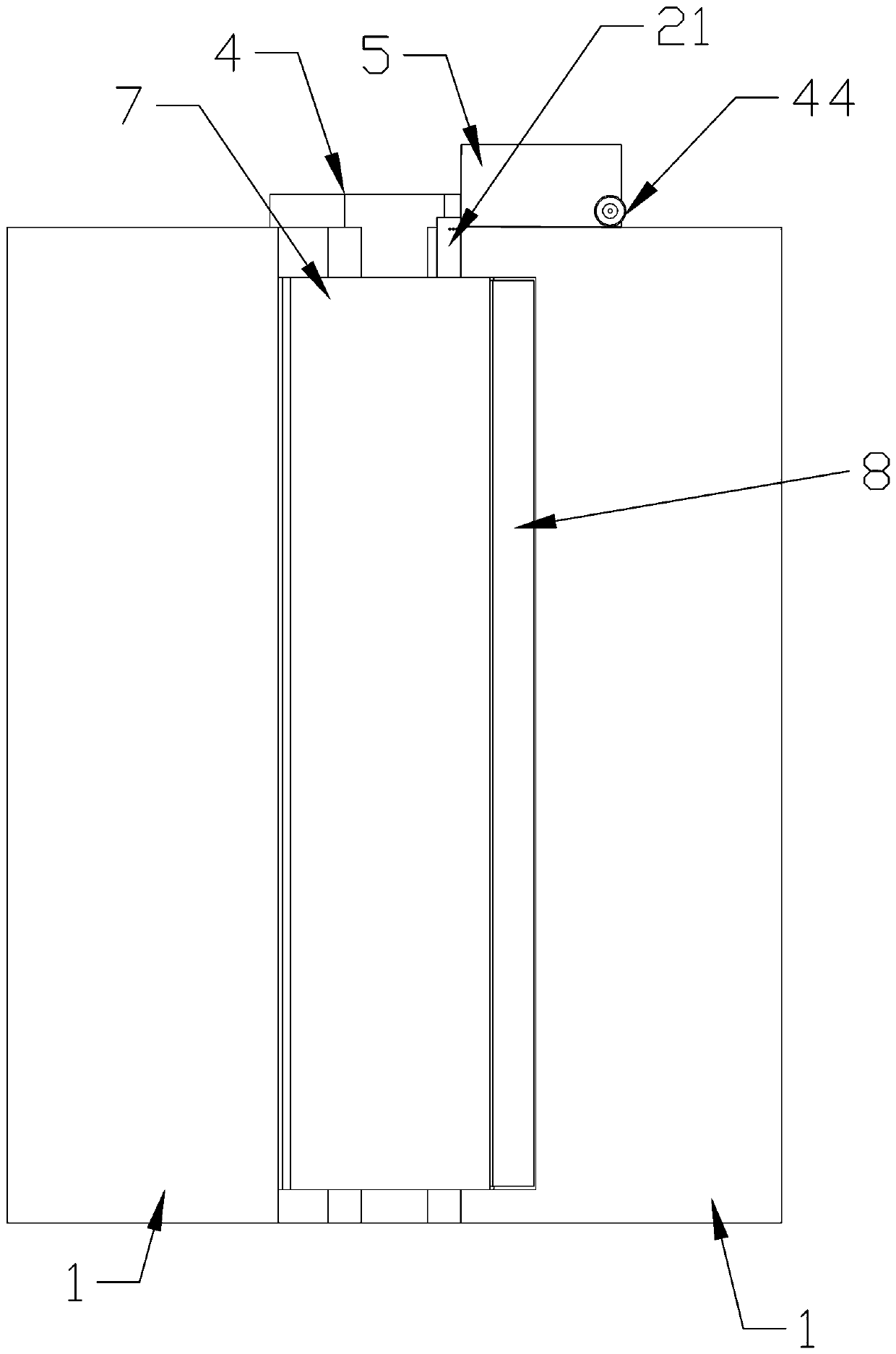

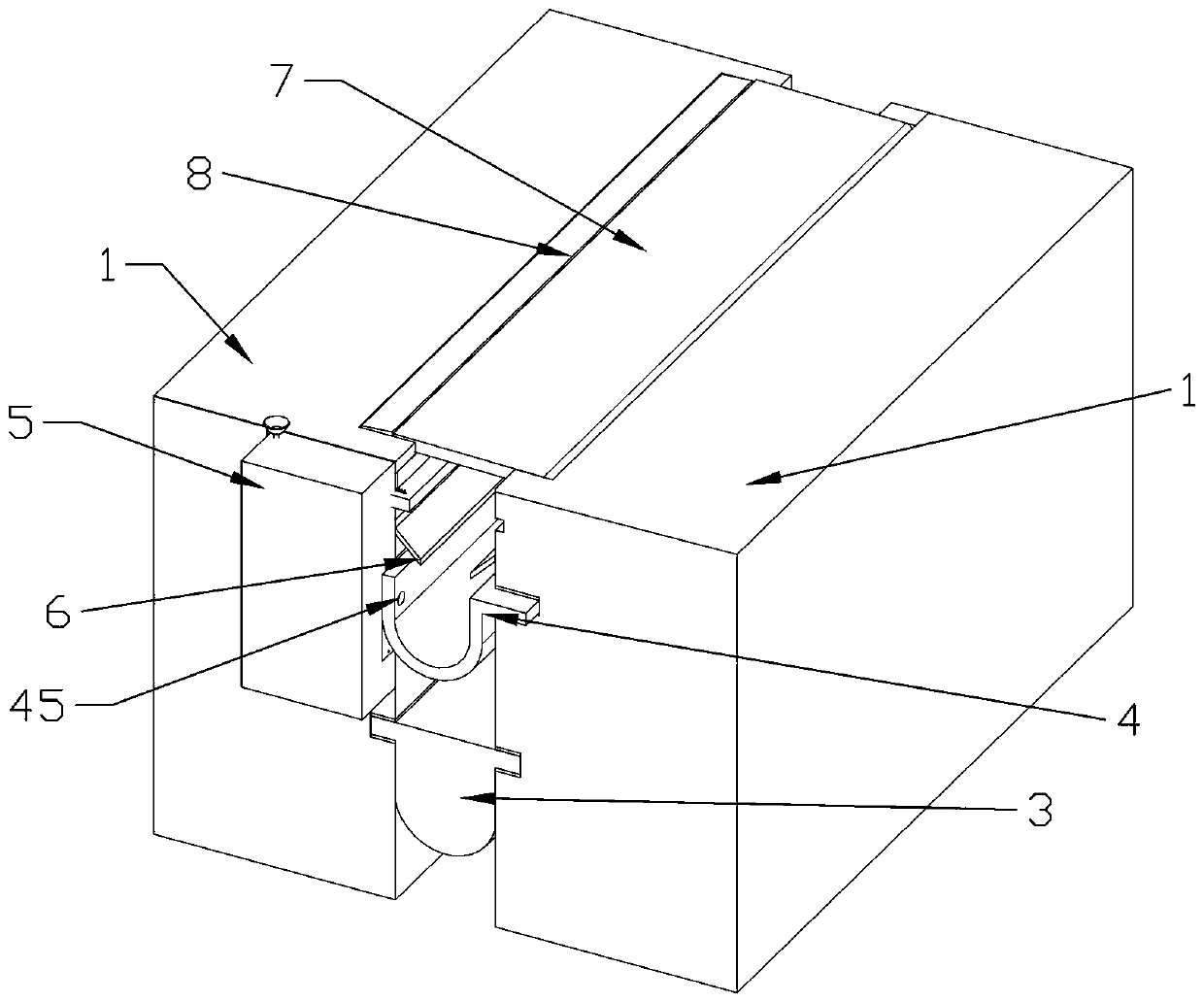

Device for testing fracture toughness of rock

InactiveCN103604702ADoes not affect deformationEasy loading and unloading processMaterial strength using tensile/compressive forcesAxial displacementRock engineering

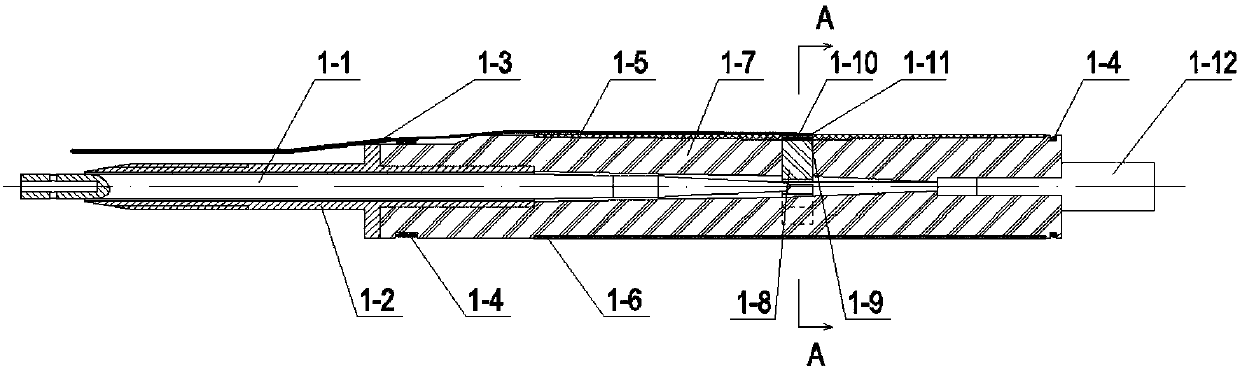

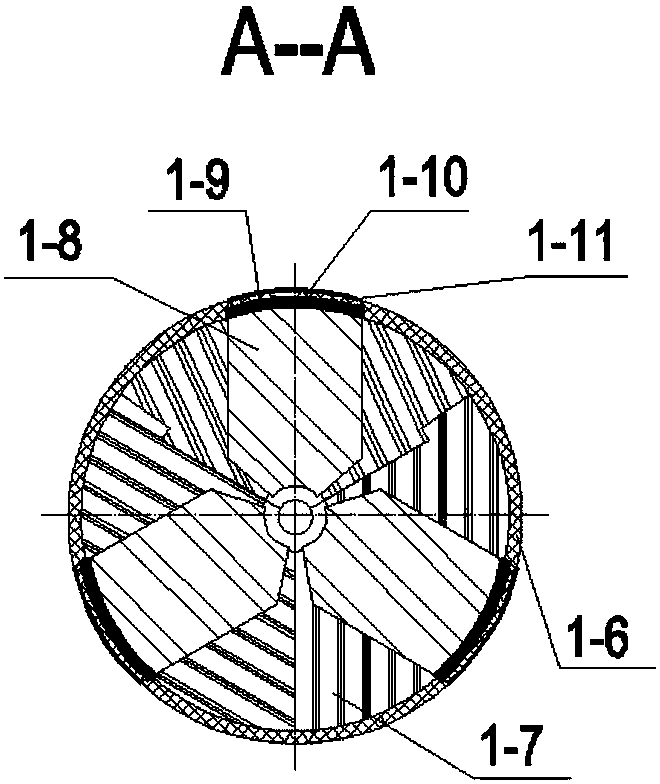

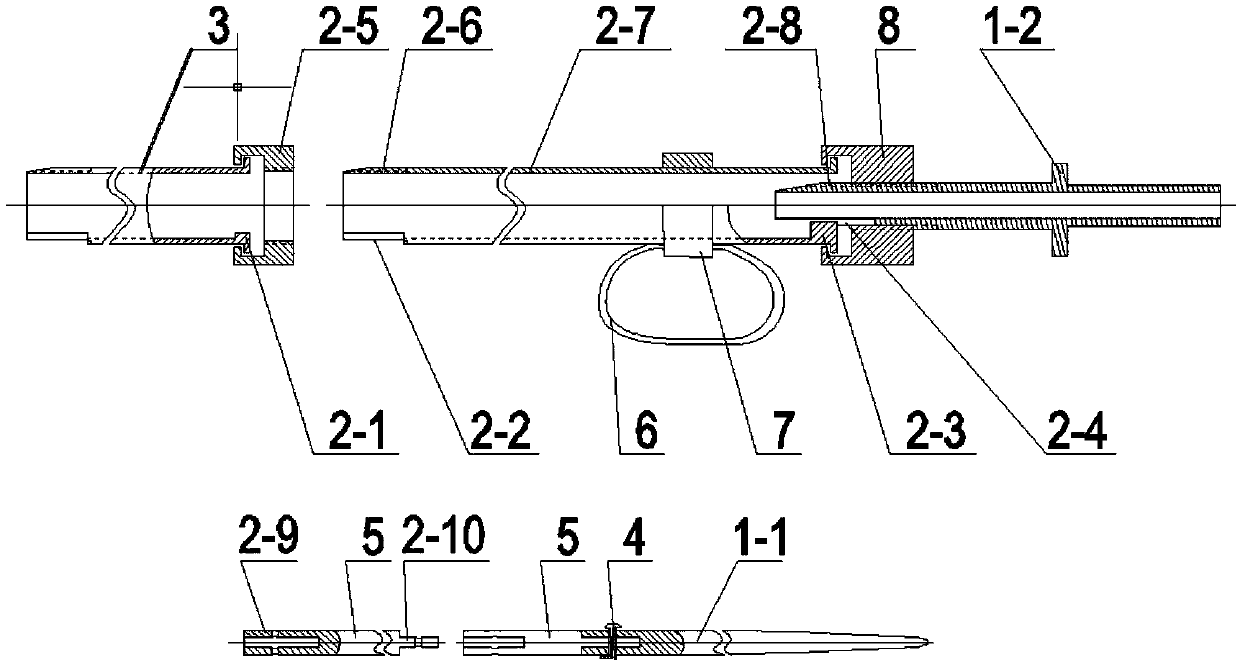

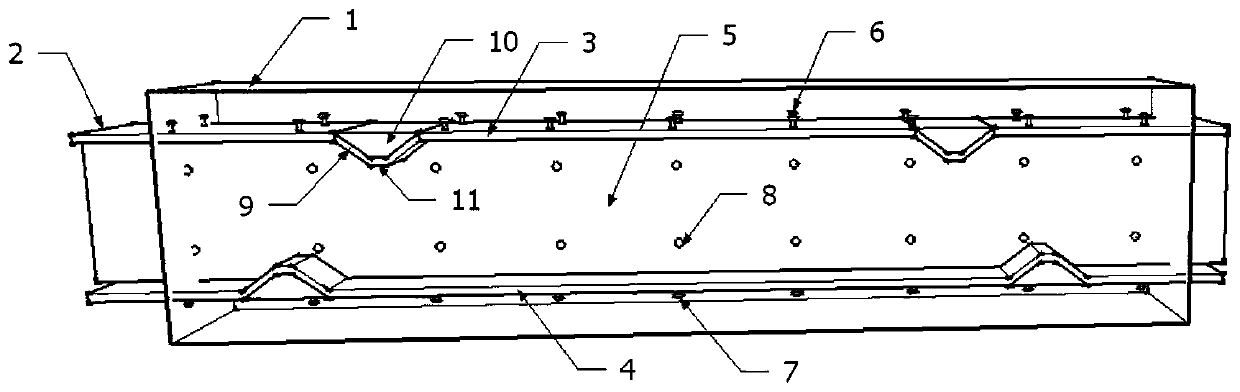

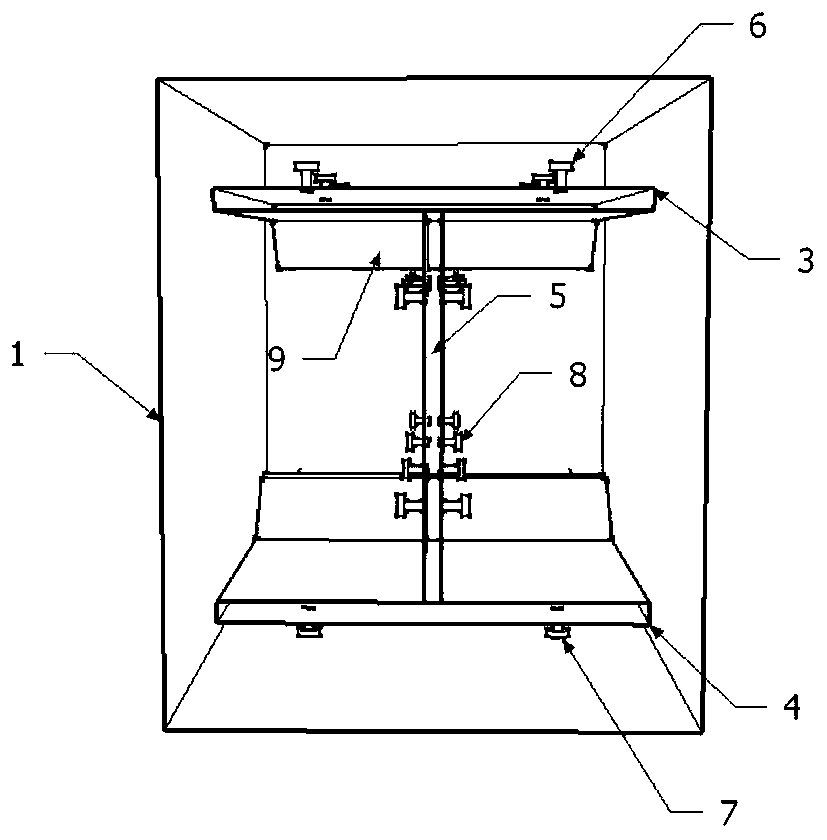

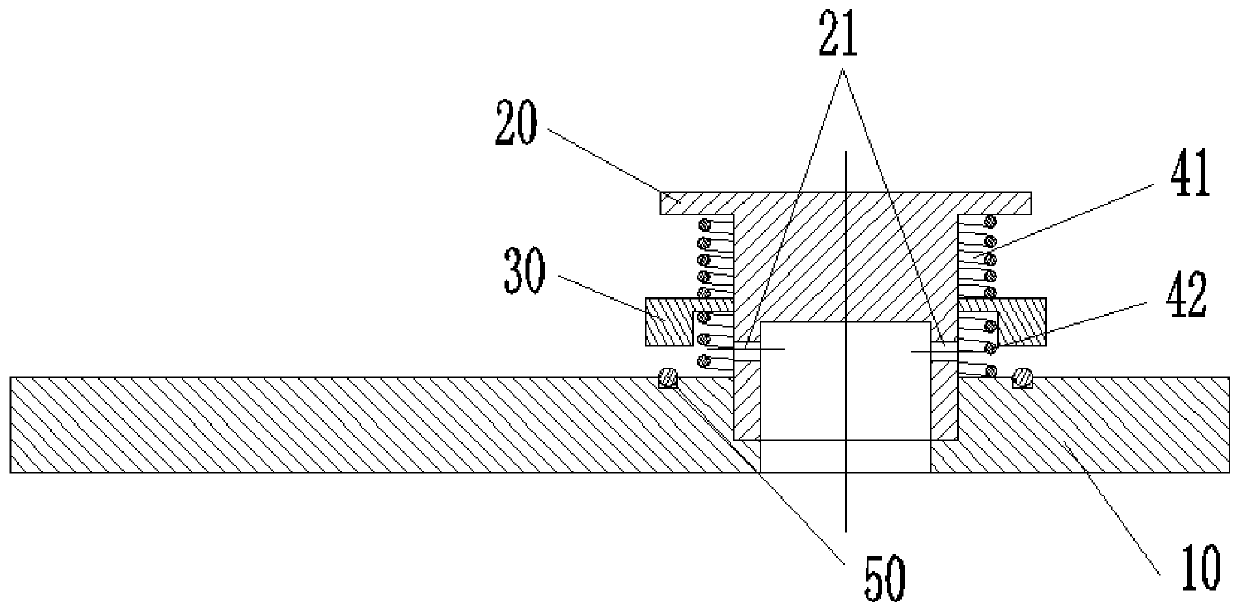

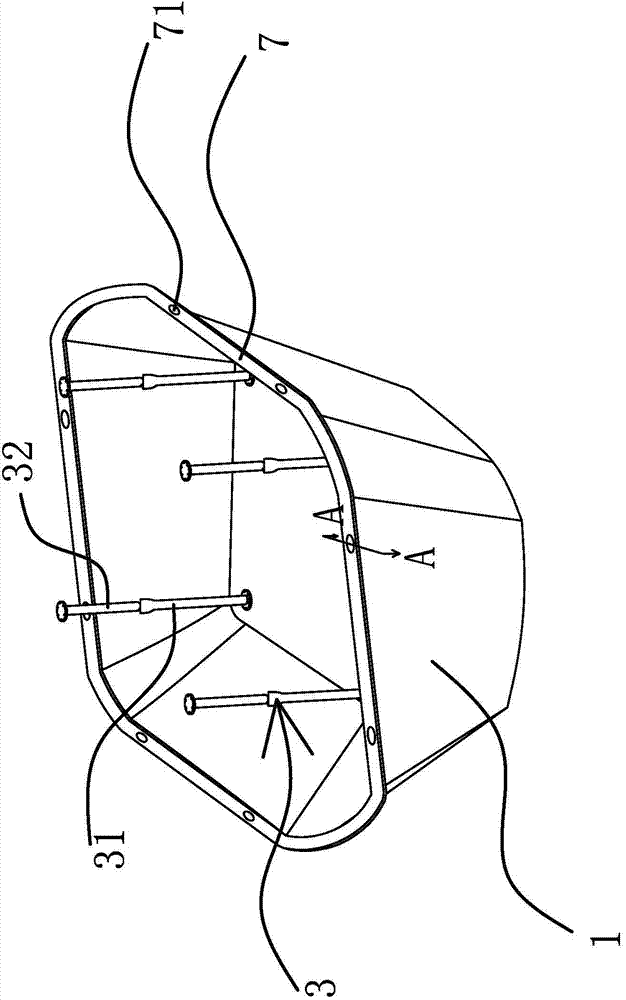

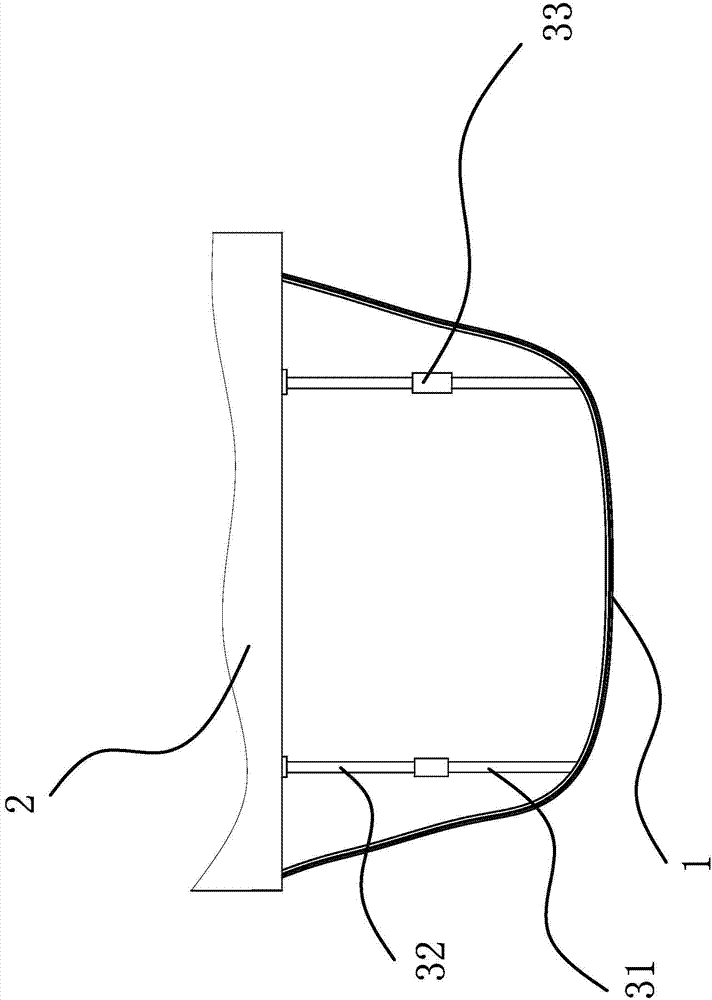

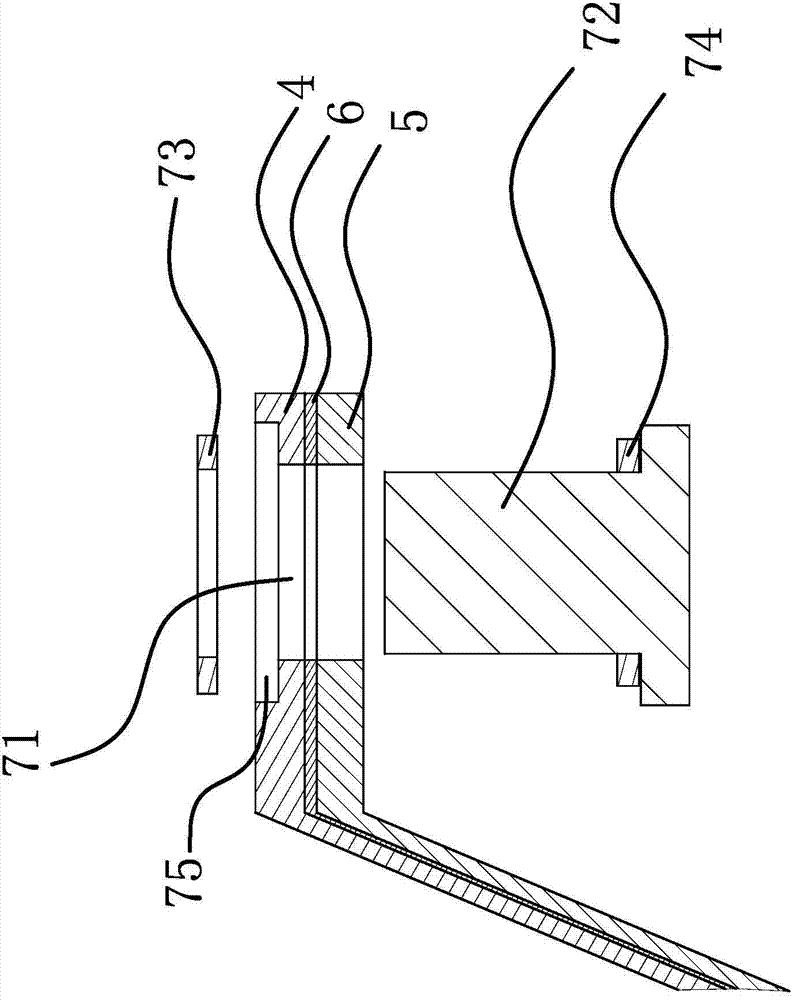

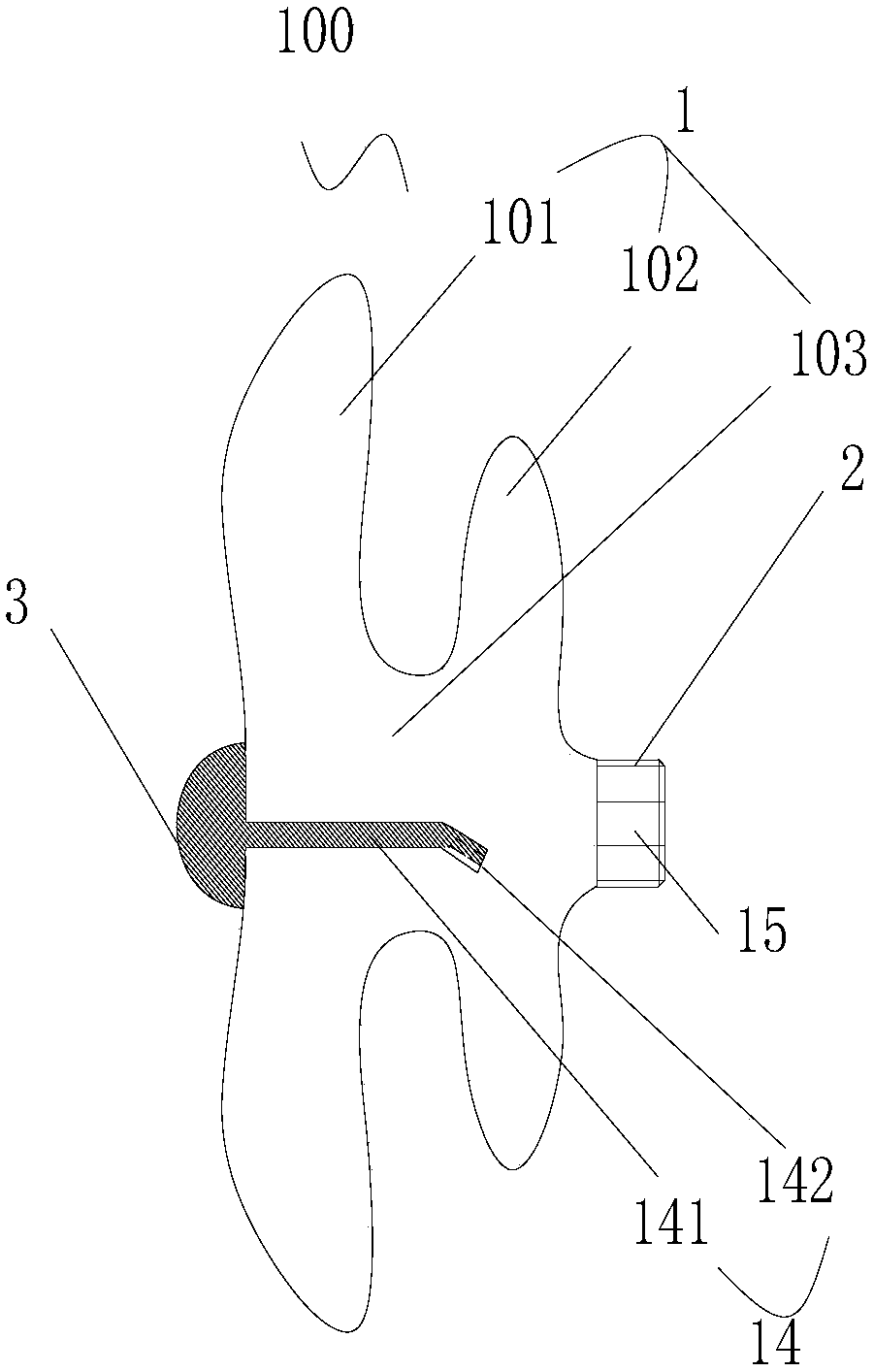

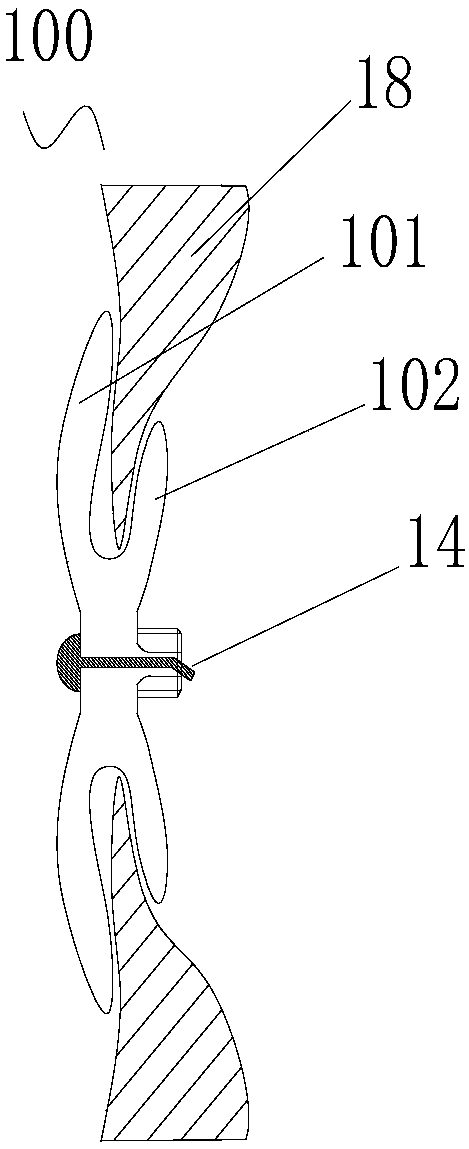

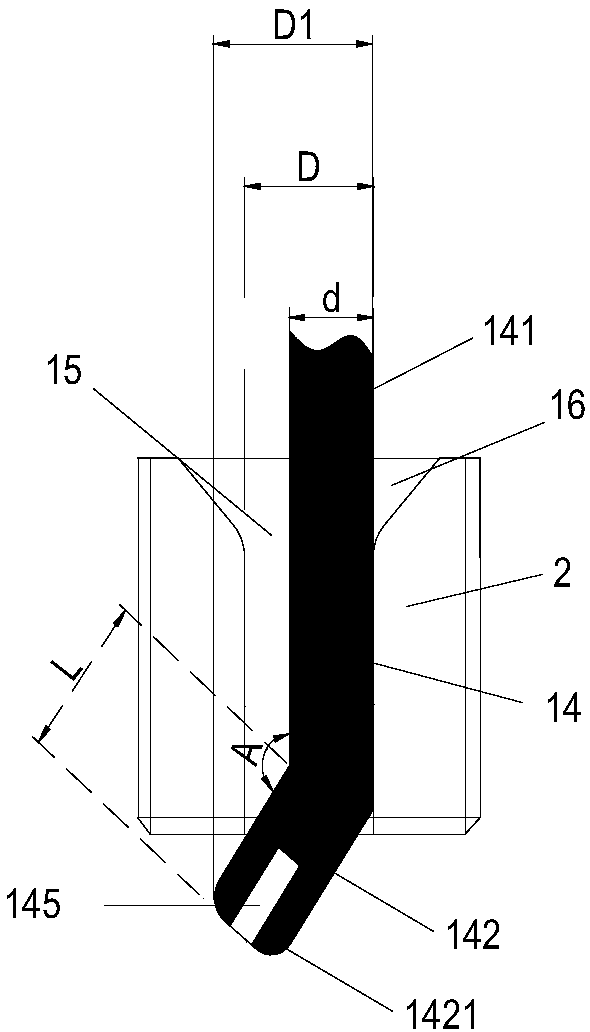

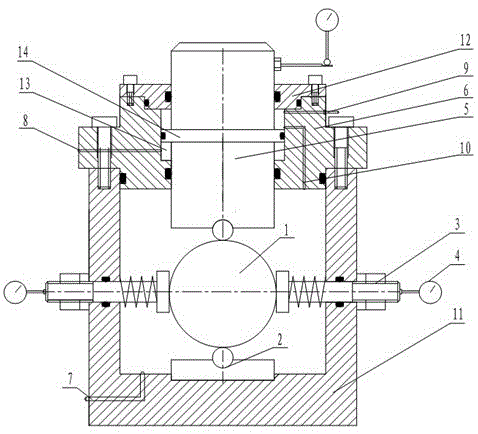

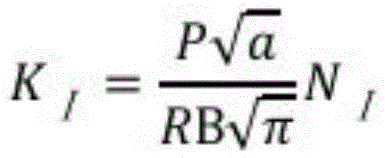

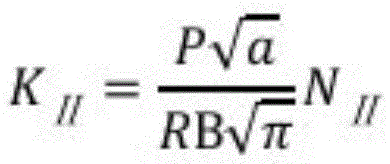

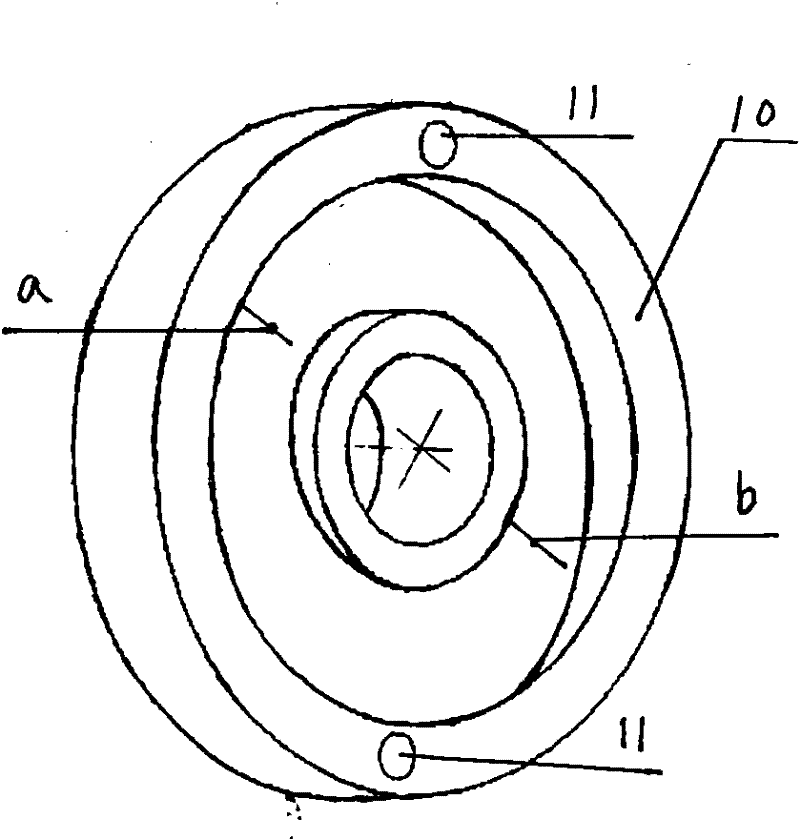

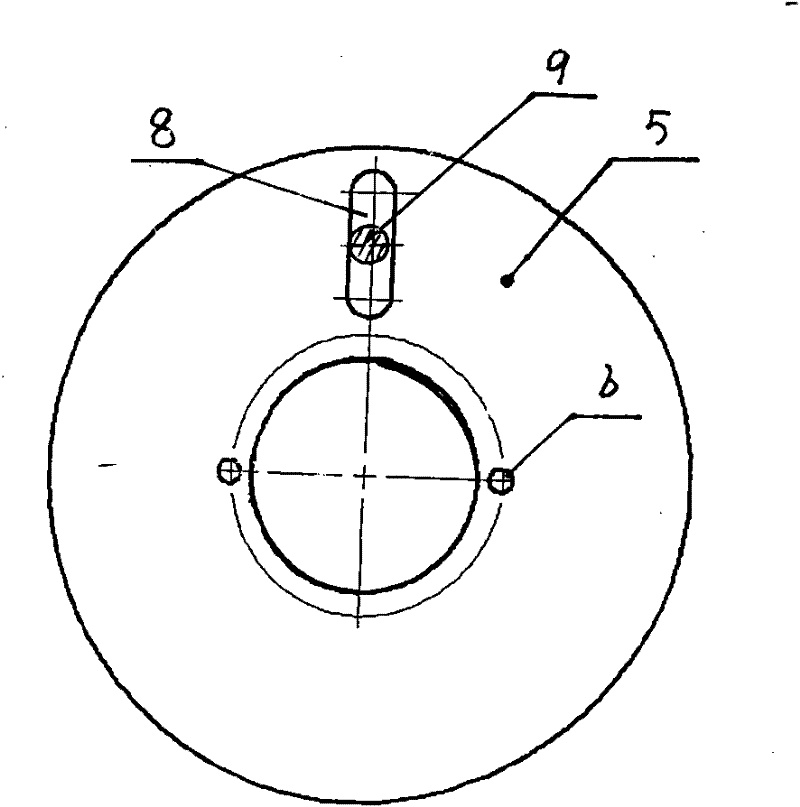

The invention relates to a device for testing fracture toughness of rock and especially relates to a device for testing fracture toughness of rock under the action of confining pressure, and belongs to the technical field of rock engineering. Through use of a confining pressure application device in the original Brazilian disc test device, a simple direct loading splitting test way of the existing test device is changed; and through use of a spring positioning device, a sealing device and a self-balancing device arranged in the box, and use of a dial indicator, an oil filling port and an exhaust port as matching devices, lateral and axial displacement change is recorded and the liquid in the box is controlled so that stable confining pressure is formed. After a sample is put into the box, the sample is fixed by the spring positioning device, and the self-balancing device is used for preventing the influence produced by the confining pressure on a loading shaft so that sample loading can be controlled conveniently. The device can realize a splitting test on a rock sample under the confining pressure, can calculate fracture toughness of the rock sample, has a reasonable design, is convenient for operation and is suitable for fracture toughness determination on various types of rock.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

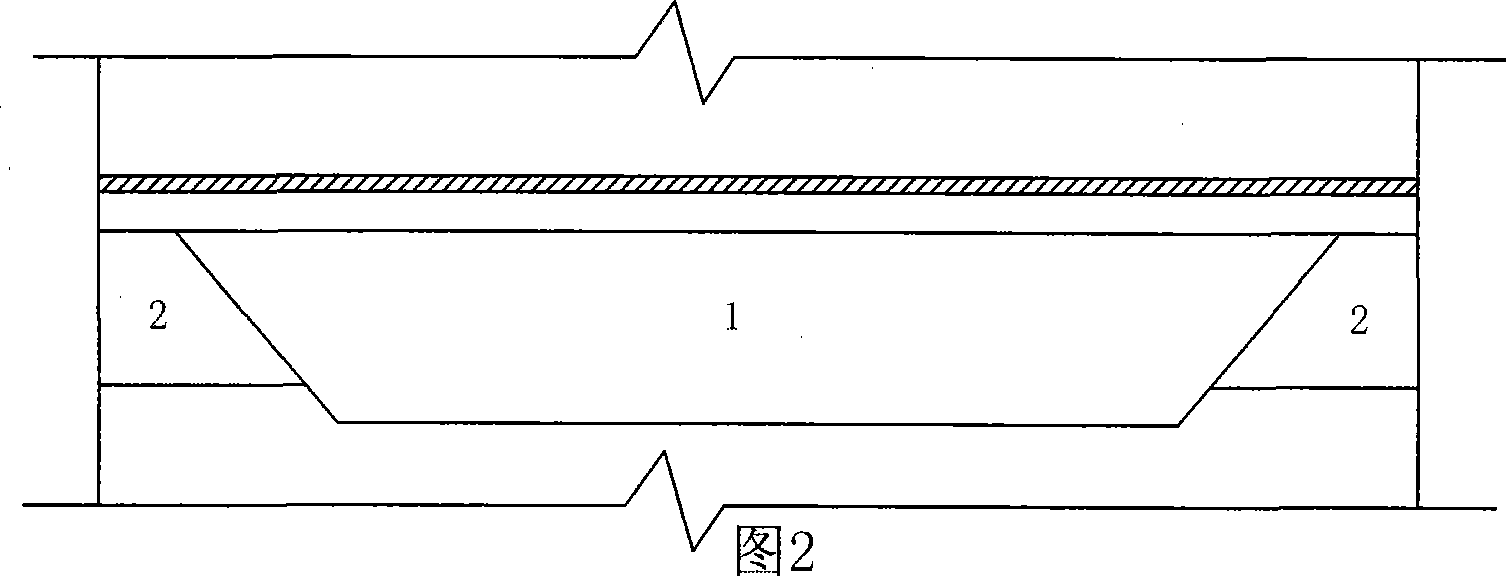

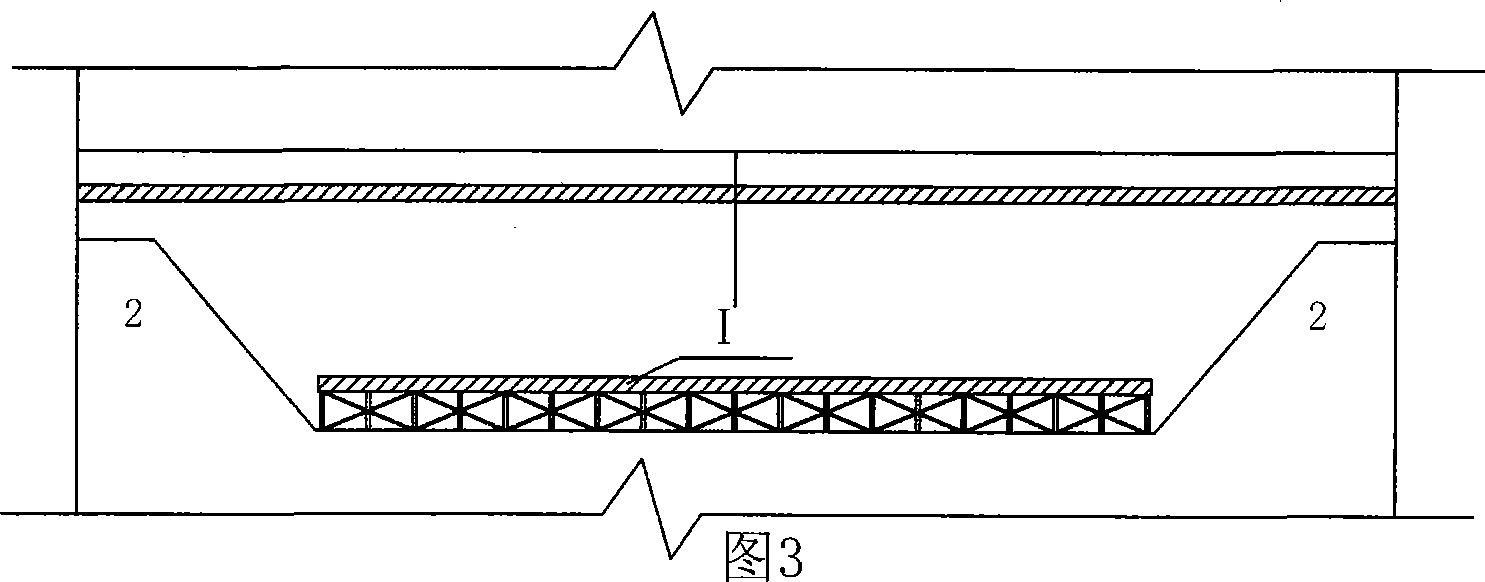

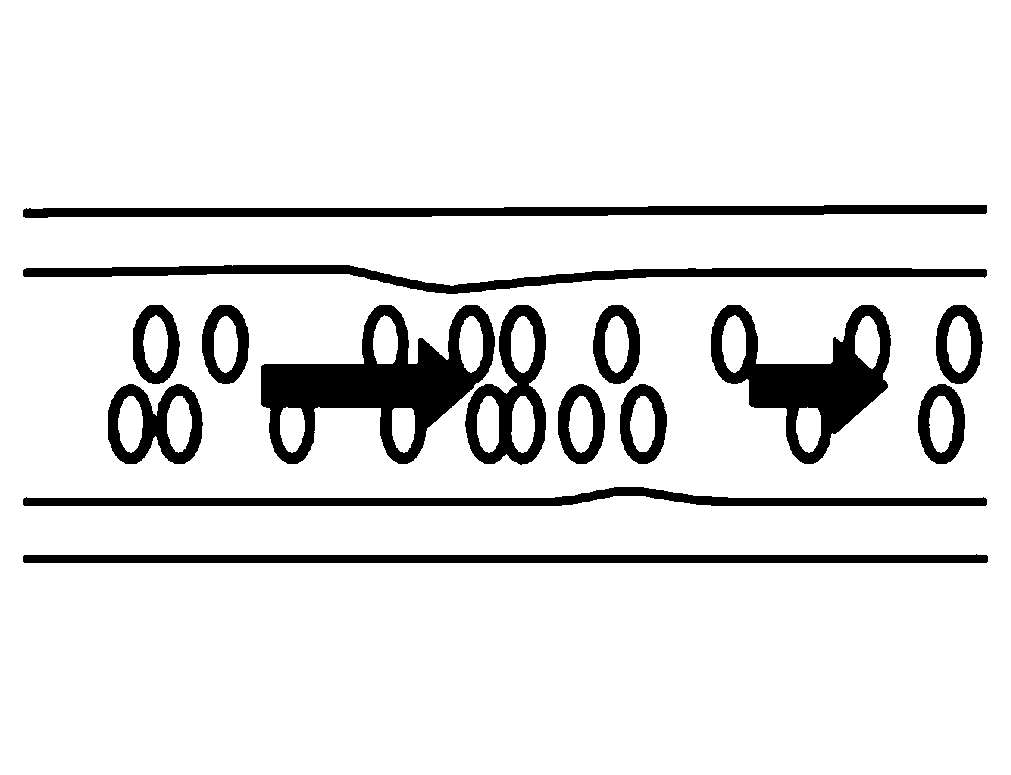

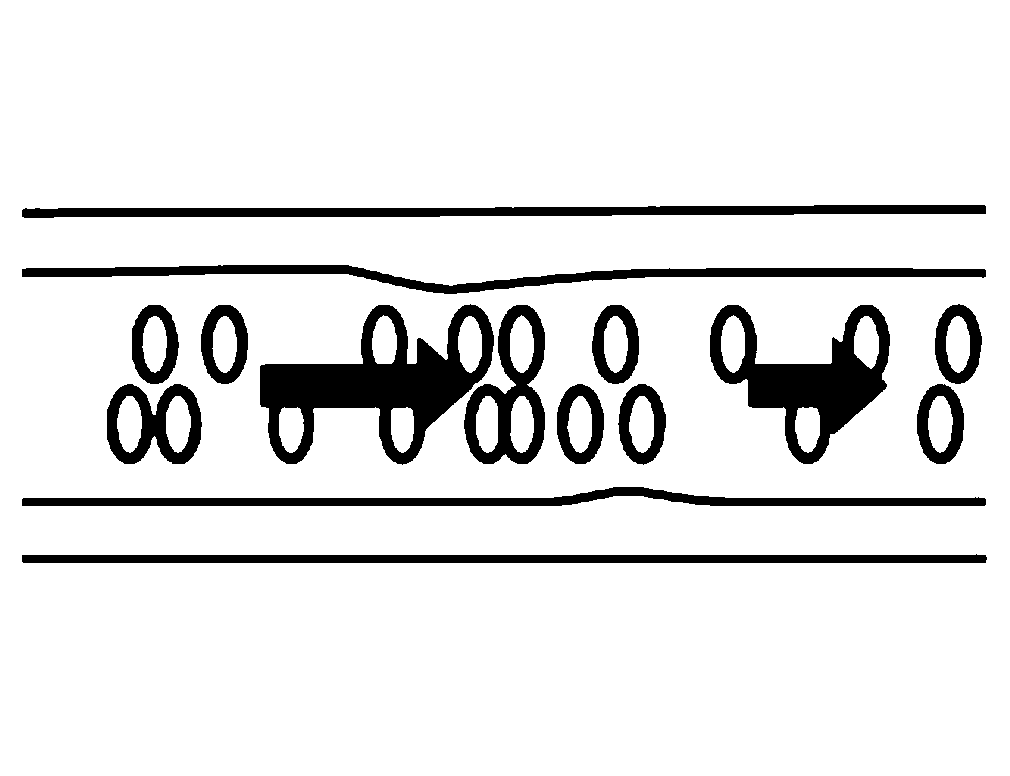

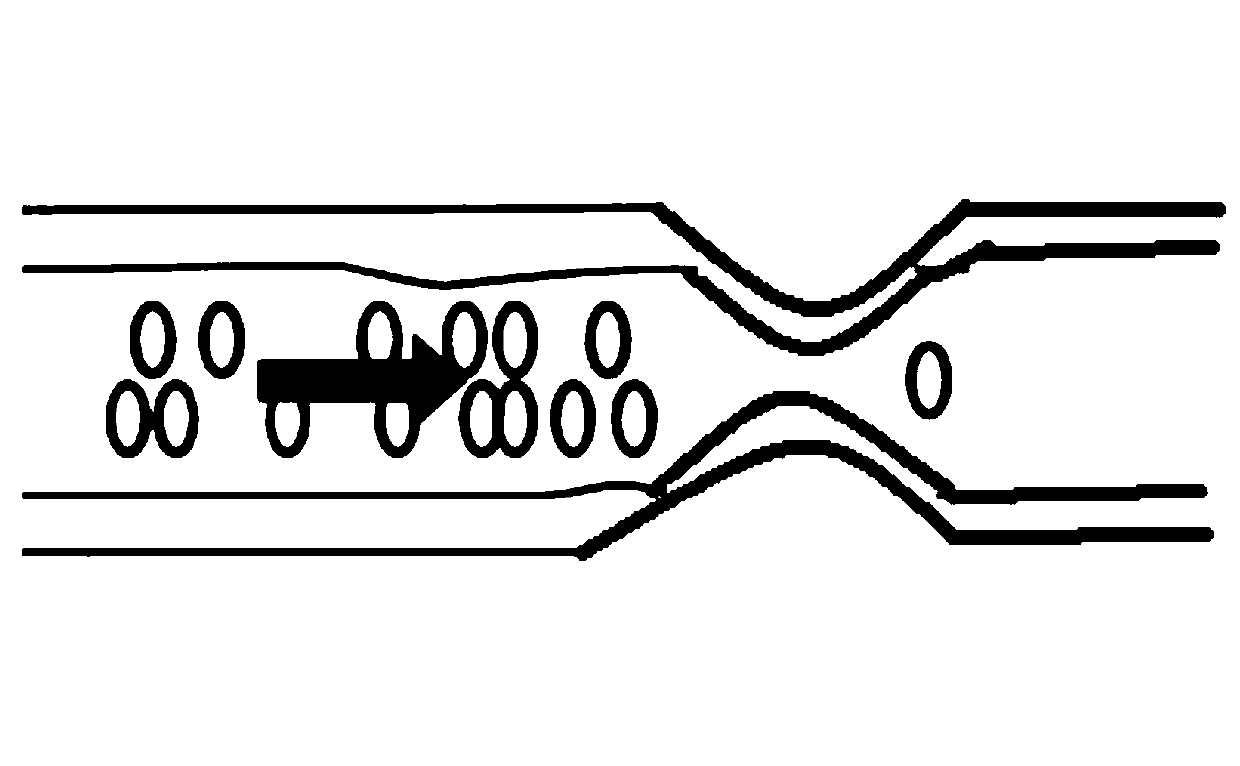

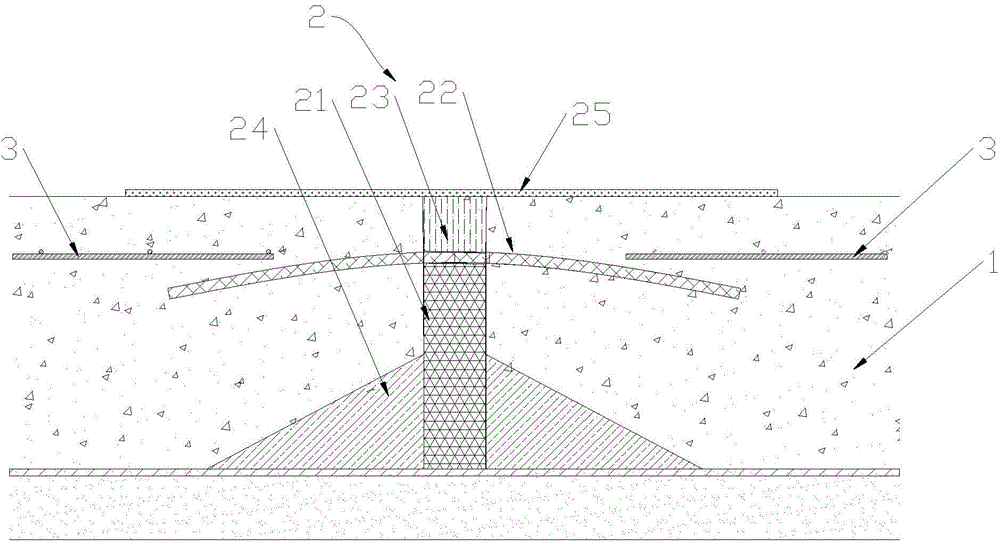

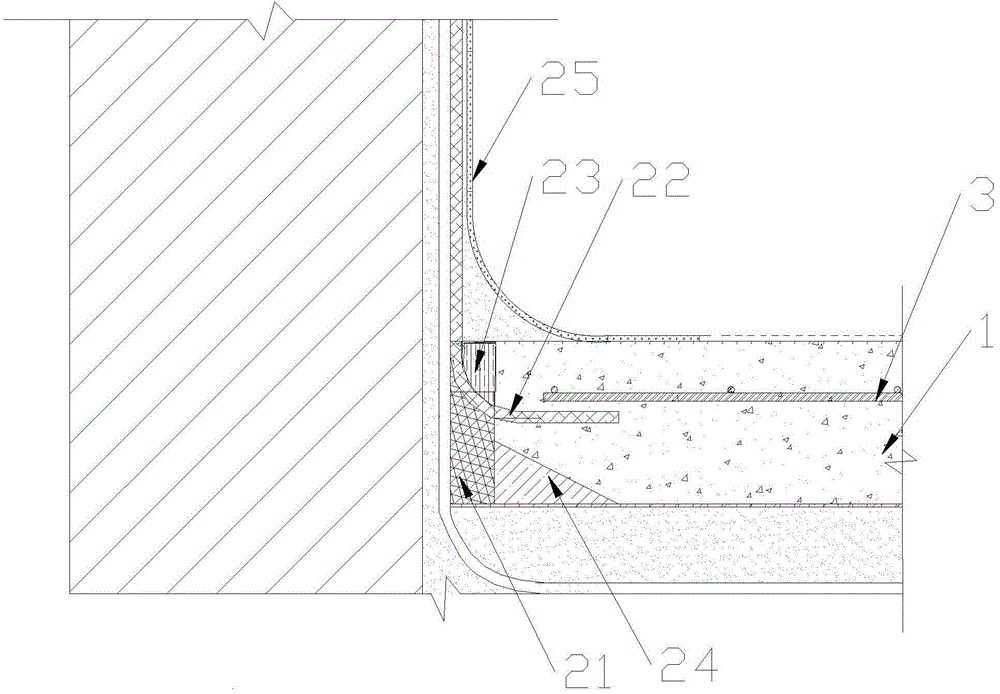

Middle plate construction method of wide pit top-down construction

The invention relates to underground construction, in particular to a construction method for a median plate under the condition of construction of a wide foundation pit by the reverse construction method. The method comprises the following steps: an earthwork in the middle is excavated first, and tables are preserved near an enclosing structure to control deformation of the enclosing structure; when concrete slabs are subjected to placing, a reinforced concrete slab in the middle is constructed first and tables on both sides are excavated after subdividing when the reinforced concrete slab in the middle reaches the strength; and concrete slabs on both sides near the enclosing structure are symmetrically constructed after subdividing. The construction method has reasonable excavating and placing sequence, is favorable for controlling deformation of the foundation pit, saves the construction period, and is convenient to construct.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

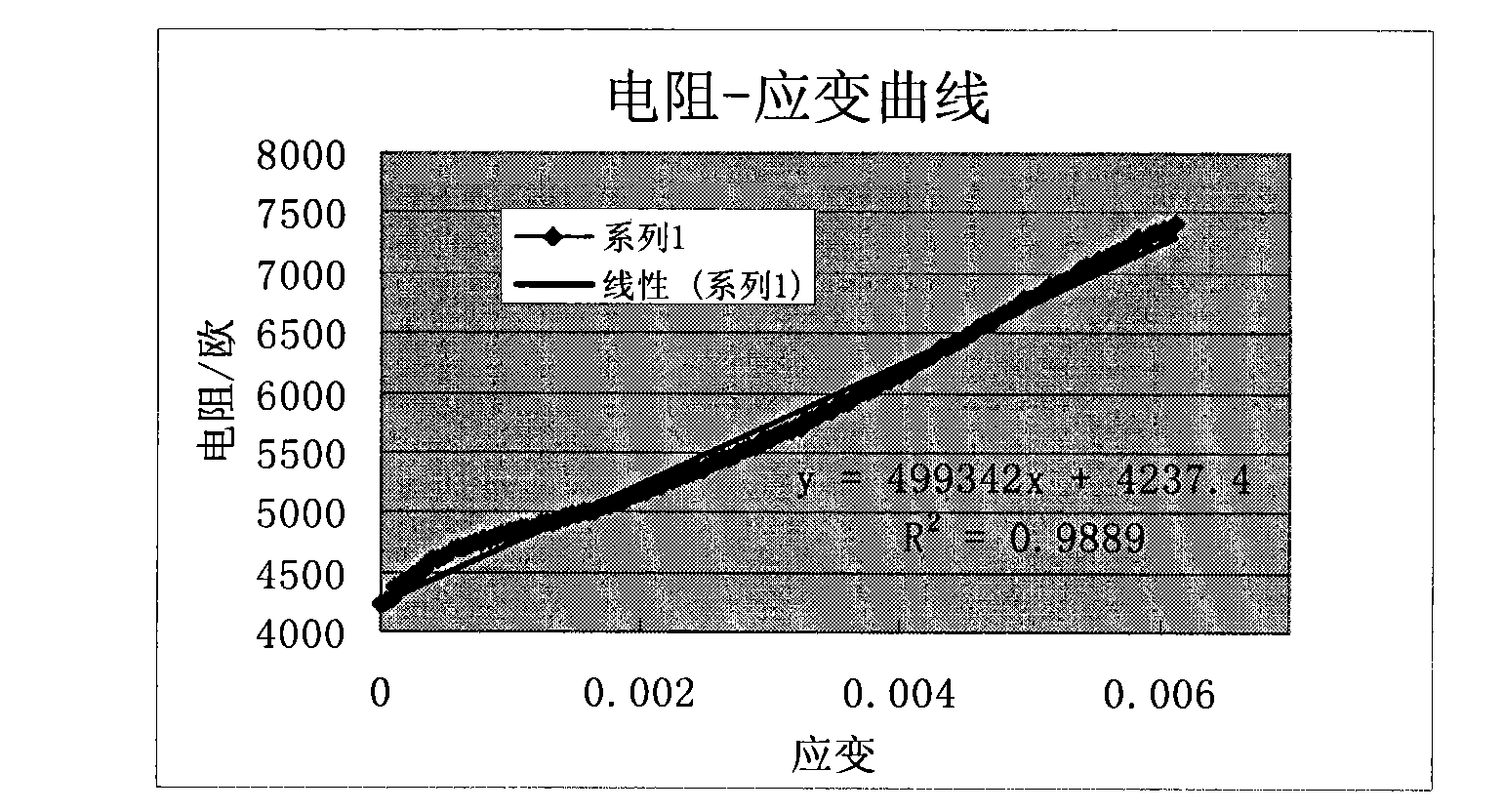

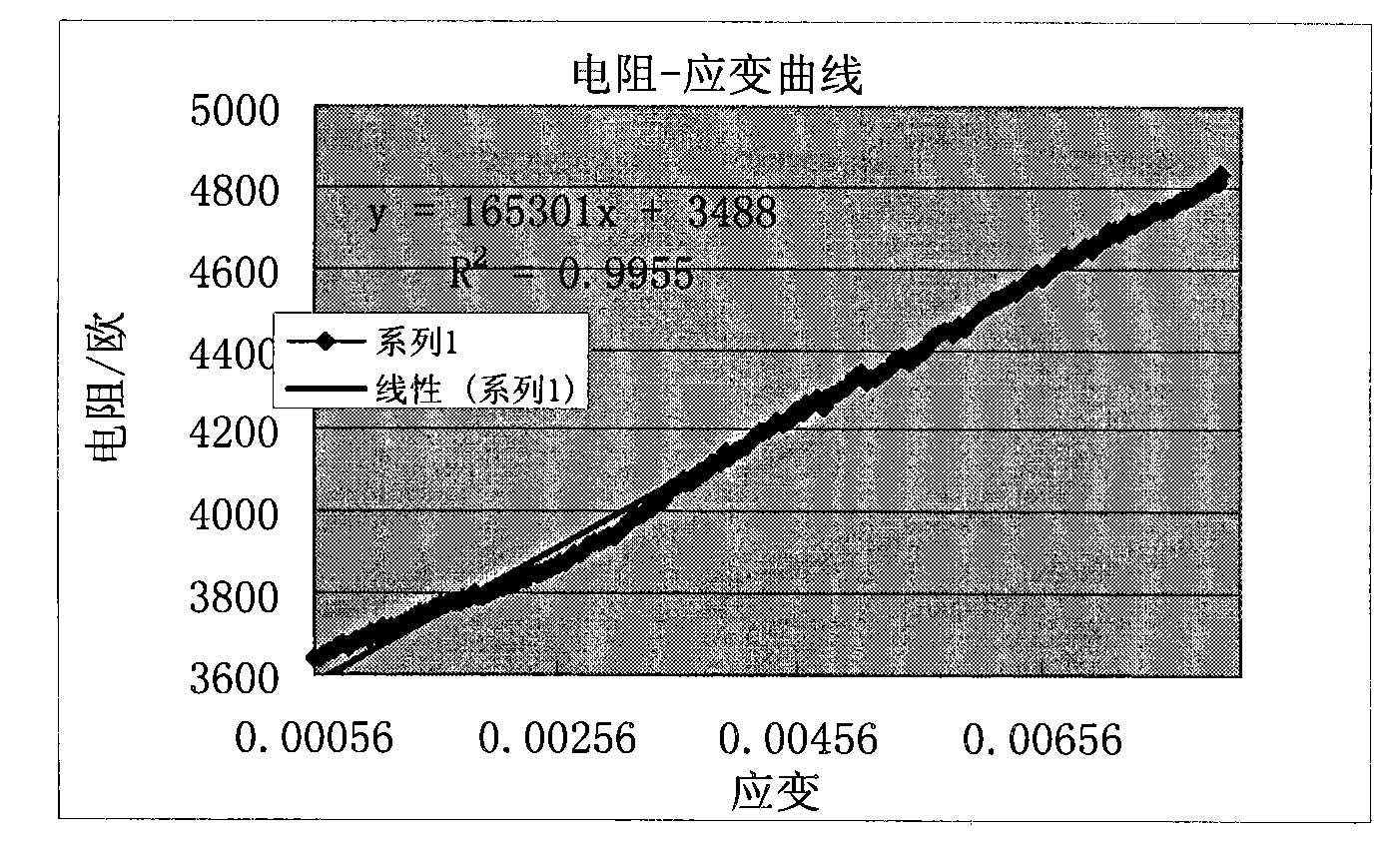

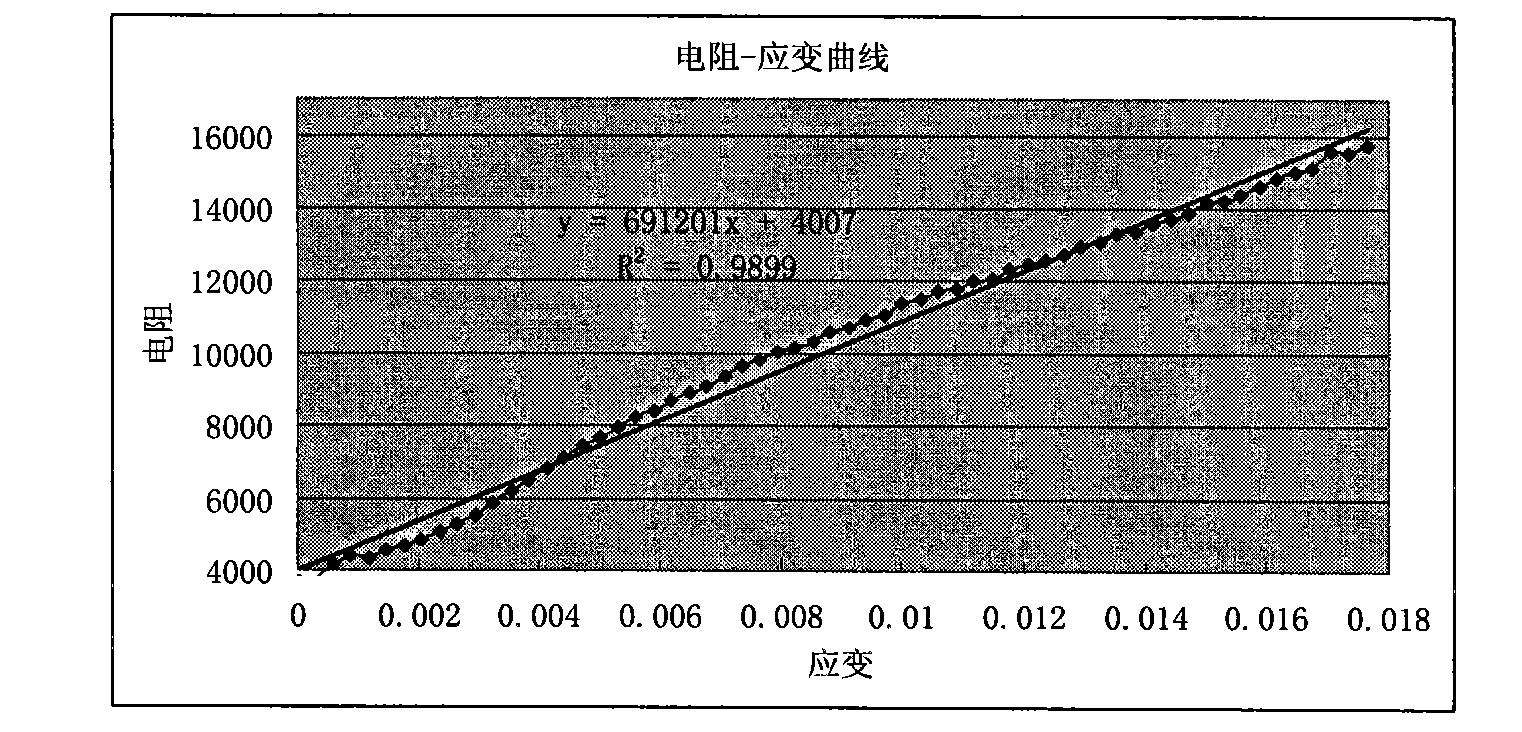

Sensitive material for tensile deformation test and preparation method thereof

InactiveCN101914290AGood flexibilityLow tensile modulusElectrical/magnetic solid deformation measurementFiberNano sio2

The invention relates to a sensitive material for a tensile deformation test and a preparation method thereof. The method comprises the following steps of: stirring and mixing liquid-state silicon rubber, chopped carbon fiber, conductive carbon black, nano-SiO2, a curing agent and a coupling agent serving as raw materials at normal temperature and under normal pressure in turn; removing air bubbles by vacuumizing; and molding. The obtained sensitive material for the tensile deformation test has high flexibility and very small tensile modulus and does not affect the deformation of a test structure or a test material in a testing process; and simultaneously, the sensitive material has the advantages of high sensitivity, performance stability, simple preparation method, wide raw material source and low manufacturing cost.

Owner:CHINA UNIV OF MINING & TECH

Korotkoff-sound-based blood pressure measurement method and blood pressure measurement and cardiovascular system evaluation system

PendingCN110840429ASimple structureReduce distractionsCatheterDiagnostic recording/measuringHuman bodyArterial velocity

The invention discloses a korotkoff-sound-based blood pressure measurement method and a blood pressure measurement and cardiovascular system evaluation system, aiming to solve the problems of inaccurate blood pressure measurement and large influences of individual differences on measurement results in the prior art. Through combination of information detection at radial arteries with intelligent pressurization and pressure relief techniques, signal sources are stable, accurate capture of korotkoff sounds is ensured, and accordingly, the stability and reliability of the measurement results areimproved. Cardiovascular parameters of a human body can be calculated according to basic information of the human body and the measurement results, information of the human body, such as age, height,gender, weight and arm length, is entered, and a series of measured cardiac function parameters such as PWV (pulse wave velocity), heartbeat, heart output and blood viscosity are acquired through algorithm processing, so that an examinee is assisted in evaluating the state of his / her cardiovascular system.

Owner:云鸿创新信息科技(武汉)有限公司

Semi-inclusion direct surface-mounting ground stress relief test device and method

ActiveCN108414129ADoes not affect deformationEliminate measurement errorsForce measurement by permanent gauge deformationClimate change adaptationSurface mountingEngineering

The invention provides a semi-inclusion direct surface-mounting ground stress relief test device and method. According to the device and method, measuring errors of stress-strain transmission, broughtby an inclusion layer and an adhesive layer of a hollow inclusion type strain gauge are eliminated, and a waterproof protection function of strain foils and lines by the strain gauge is reserved. Thedevice comprises a support, a support member connected with the support, and a rubber cylinder arranged at the periphery of the support member in a sleeved manner, the support member is formed by splicing of at least 3 arc blocks, each arc block is provided with a groove hole for installing a strain bundle push block from an inner bore to an exterior, the exterior of the strain bundle push blockis an arc structure, the plurality of arc blocks and the strain bundle push blocks are spliced to form a cylinder structure, and the rubber cylinder is arranged on an outer wall of the cylinder structure formed by the support member and the strain bundle push blocks in a sleeved manner. An outer end wall of each strain bundle push block is provided with a non-deformation layer, the rubber cylinderis provided with an opening for installing a strain bundle, and the non-deformation layer and the opening of the rubber cylinder are bonded; and a compensating gauge or a temperature sensor is bondedto the non-deformation layer, and strain bundle rubber and the strain bundle are bonded thereon in sequence.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Multi-kinetic energy tactile sensor and measuring method

ActiveCN107238452ASimple structureMiniaturizationForce measurement using piezo-resistive materialsApparatus for force/torque/work measurementContact forceHardness

The invention discloses a multi-kinetic energy tactile sensor and a measuring method. The multi-kinetic energy tactile sensor is composed of a hardness detecting unit, a voltage-sensitive varistor sheet, a rubber pipe and a connector. The hardness detection unit is intended for detecting the hardness of a tissue which is in contact with the end of an instrument. The voltage-sensitive varistor sheet is intended for detecting the contact force when the end of the instrument and side wall is in contact with an tissue or blood vessel. Compared with prior art, according to the invention, the multi-kinetic energy tactile sensor is advantaged by capability of detecting tissue hardness, and the contact force of the end of the instrument and the side wall, having simple structure, being beneficial to minimization, being free from contact force upon detecting hardness, and being applied to hardness measurement of biological tissues. The tactile sensor can provide safety in the field of interventional operation, provide key information for disease diagnosis of biological tissues, and can facilitate the development in the field of interventional operation.

Owner:江苏有熊安全科技有限公司

Thermosensitive clothes material with temperature adjusting function and preparation method thereof.

ActiveCN105479887ADoes not affect deformationReduce voltageGarment special featuresLamination ancillary operationsElectrical resistance and conductanceControl signal

The invention relates to a thermosensitive clothes material with temperature adjusting function and a preparation method thereof. A circuit layer which is prepared based on PTC (positive temperature coefficient) effect is applied to the thermosensitive material, so that the thermosensitive material has the temperature adjusting function; at the same time, a minisize pressure sensor is arranged in the circuit layer for detecting side pressure caused by a thermal resistance which expands due to heating, and the minisize pressure sensor outputs control signals and actively reduces the voltage which is applied to the thermal resistance. According to the arrangement, energy of power supply is better utilized, and environmental protection and energy consumption reduction are realized.

Owner:ZHEJIANG CHAOFAN GARMENT CO LTD

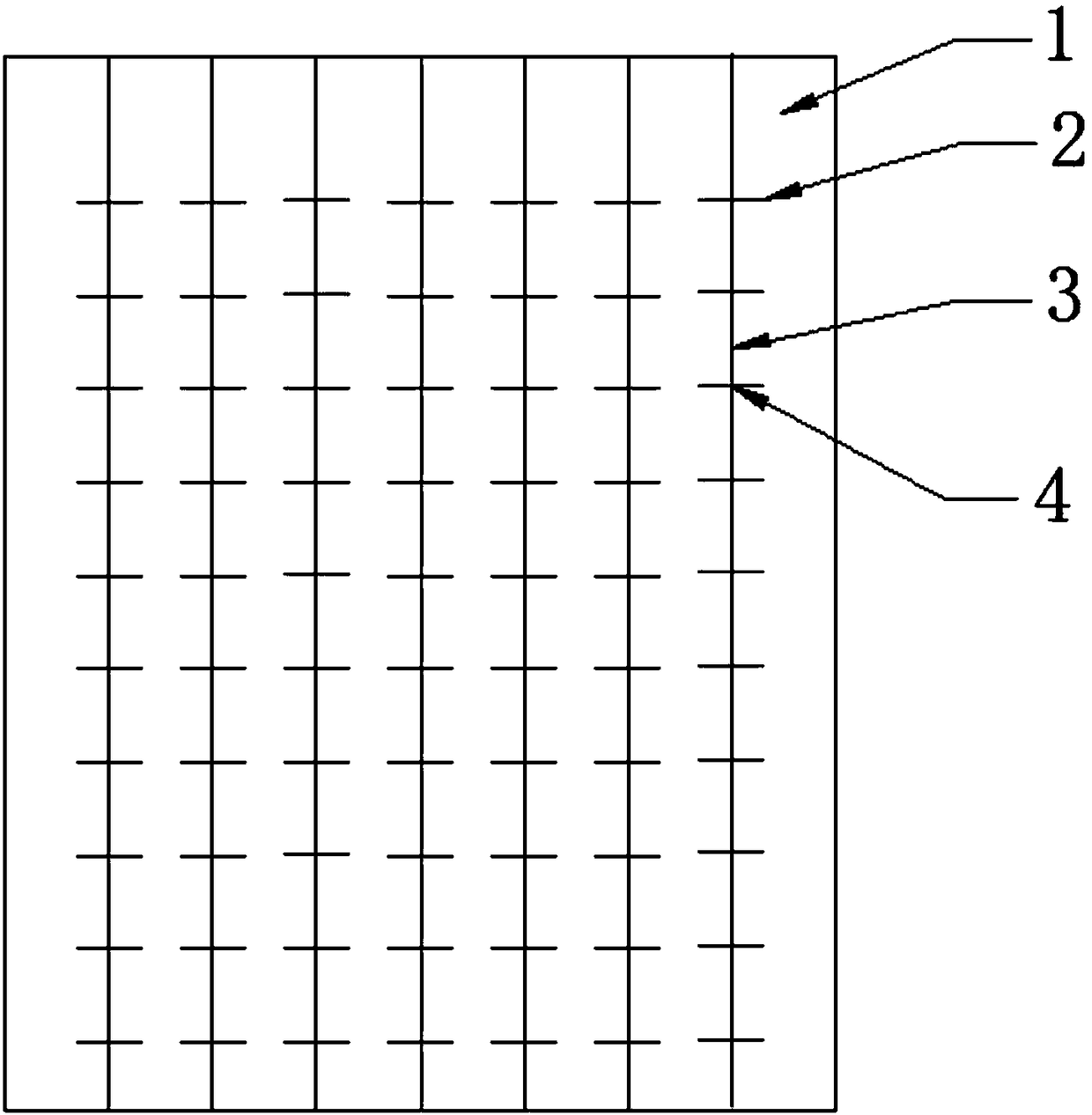

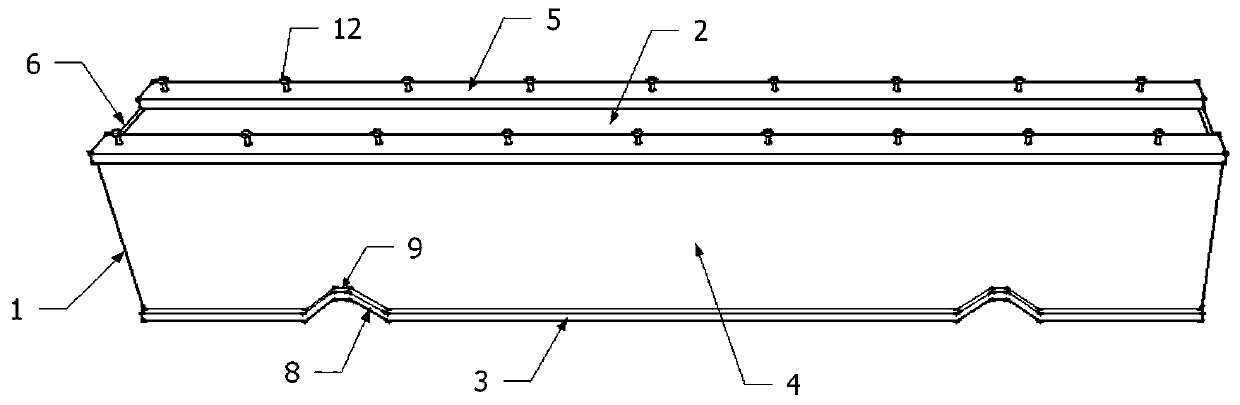

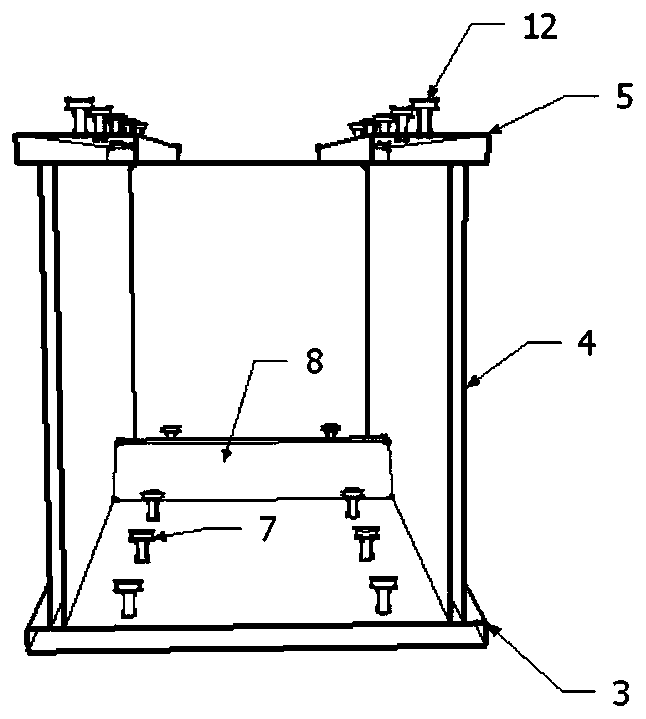

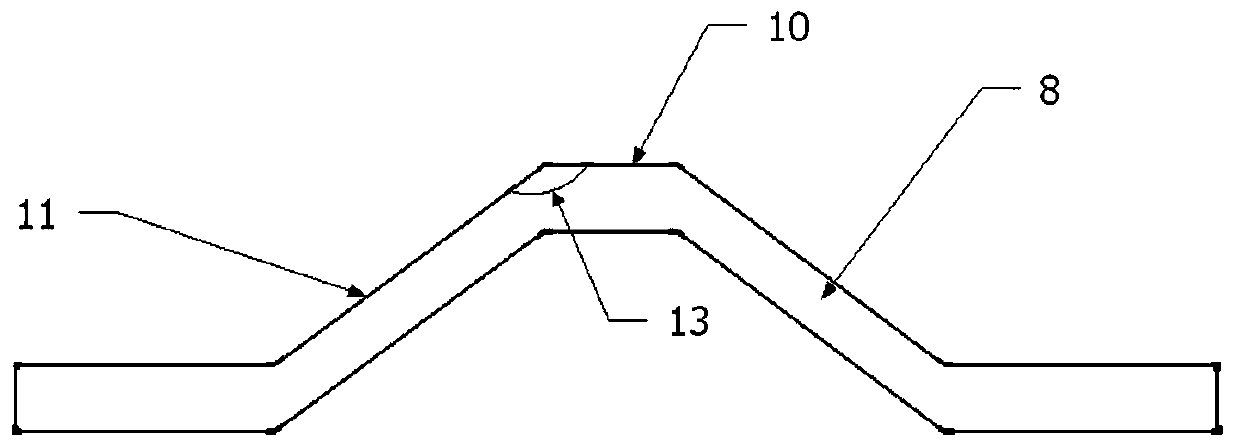

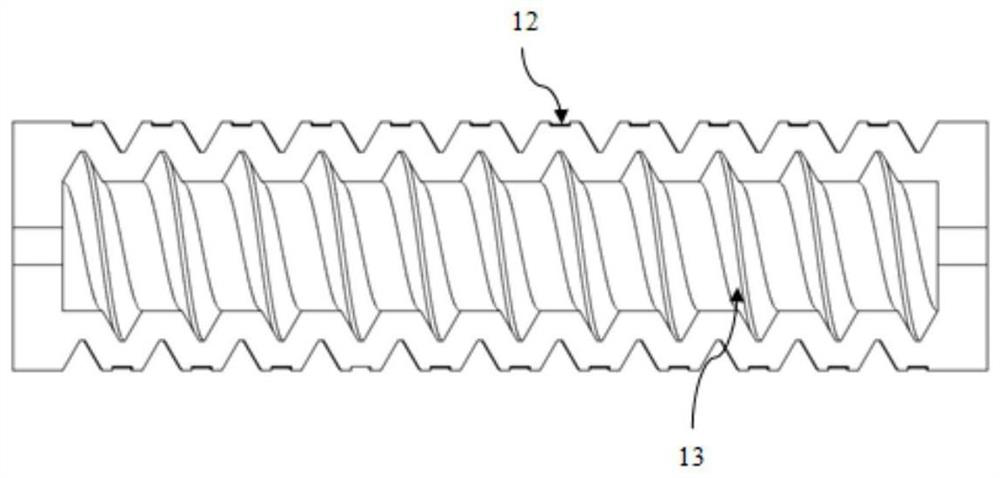

Corrugated box beam

ActiveCN109763415AImprove deformation abilityImprove collapse resistanceLoad-supporting elementsBridgesInverted uLarge earthquakes

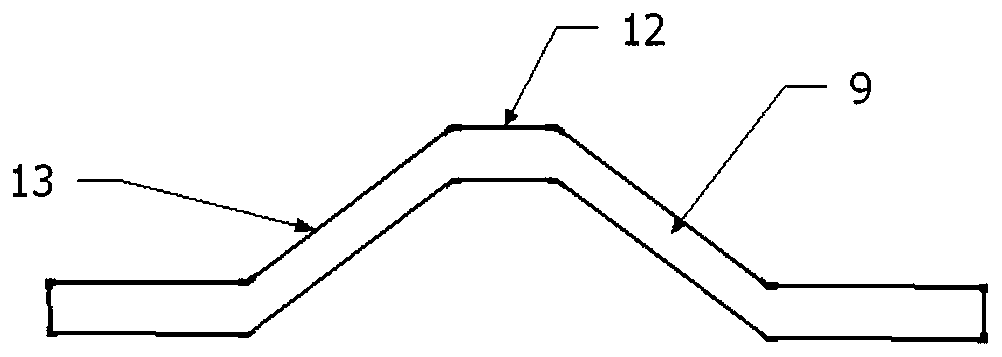

The invention discloses a corrugated box beam, and belongs to the technical fields of construction and structural engineering. A corrugated bottom plate of the corrugated box beam provided by the invention bends and corrugates at inflection points near beam-column joints to form inverted U-shaped wavy protrusions, and the inverted U-shaped wavy protrusions deform greatly in the process of straightening under load, so that the deformation capacity of the corrugated box beam under earthquake action is greatly increased, and the collapse resistance capacity of the corrugated box beam under largeearthquakes is greatly enhanced; in addition, corrugated parts of the corrugated box beam are covered with non-stick films, so that the corrugated box beam is not bonded to concrete locally, and no affect is caused on the deformation of the inverted U-shaped wavy protrusions, the deformation capacity of the corrugated box beam under the earthquake action is further increased, and the collapse resistance capacity of the corrugated box beam under the large earthquakes is greatly enhanced.

Owner:JIANGNAN UNIV

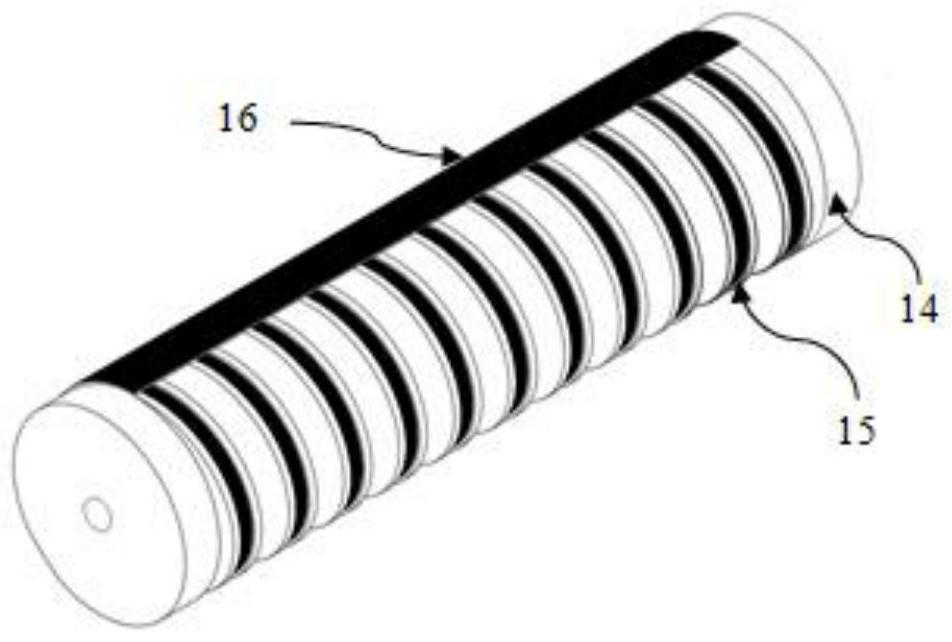

Corrugated steel-concrete composite beam

ActiveCN109763603AImprove deformation abilityImprove collapse resistanceLoad-supporting elementsBridge materialsEngineeringPlastic hinge

The invention discloses a corrugated steel-concrete composite beam and belongs to the technical field of building and structural engineering. According to the corrugated steel-concrete composite beam,a corrugated beam section generates an obvious plastic hinge under the action of a major earthquake; a midspan section generates a crack first, and then the corrugated part is straightened. Therefore, the bending bearing capacity of the section of the corrugated part is enhanced, and then the yielding section of the beam is transferred to the midspan; the bearing force of the beam can also continue to be increased; when the midspan section is yielded, the deformation of the beam continues to be increased, and the bearing force is not increased any more till the beam is destroyed; through theadoption of the design, the corrugated steel-concrete composite beam is destroyed in prior to a column under the action of the earthquake so that the strong column and the weak beam are really realized; when the span of the corrugated steel-concrete composite beam is 5 m and the section dimension of the corrugated steel-concrete composite beam is 250mm*450mm, the ultimate bending bearing capacityof the corrugated steel-concrete composite beam can reach 212 kN.m, and the deflection limit of the corrugated steel-concrete composite beam can reach 59 mm.

Owner:JIANGNAN UNIV

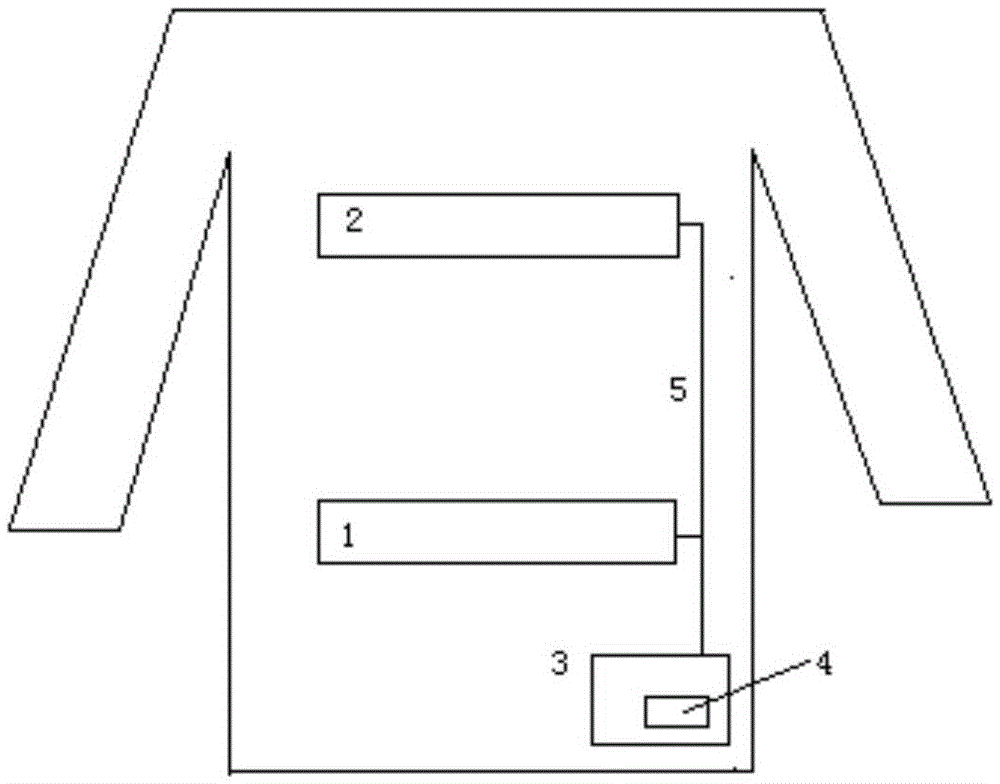

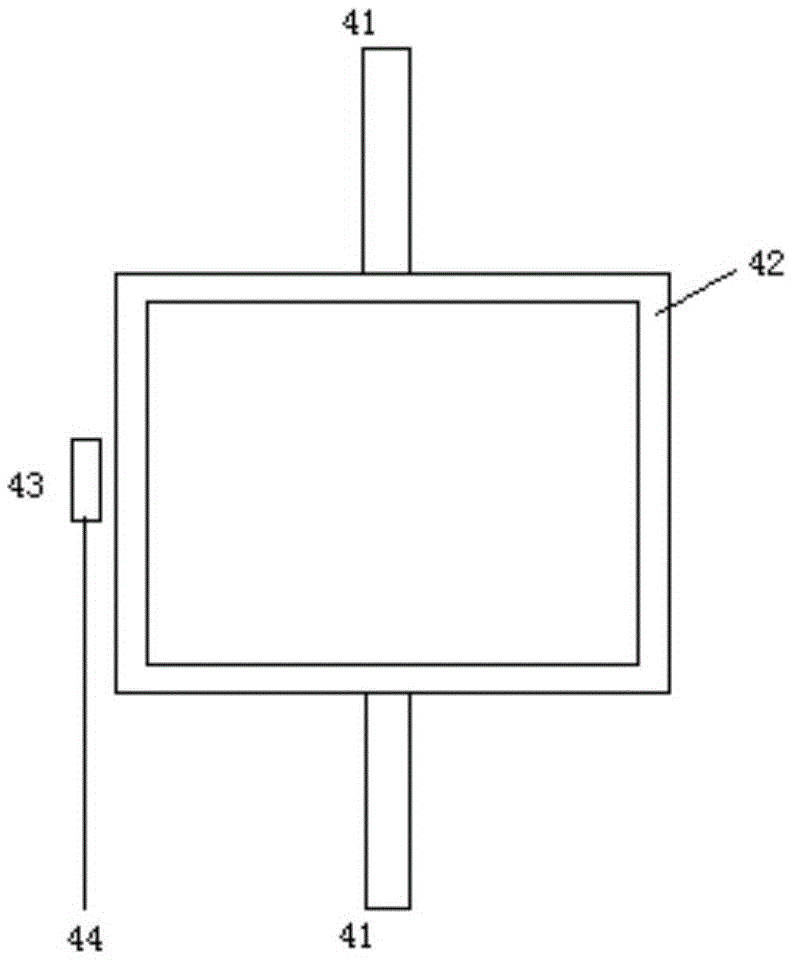

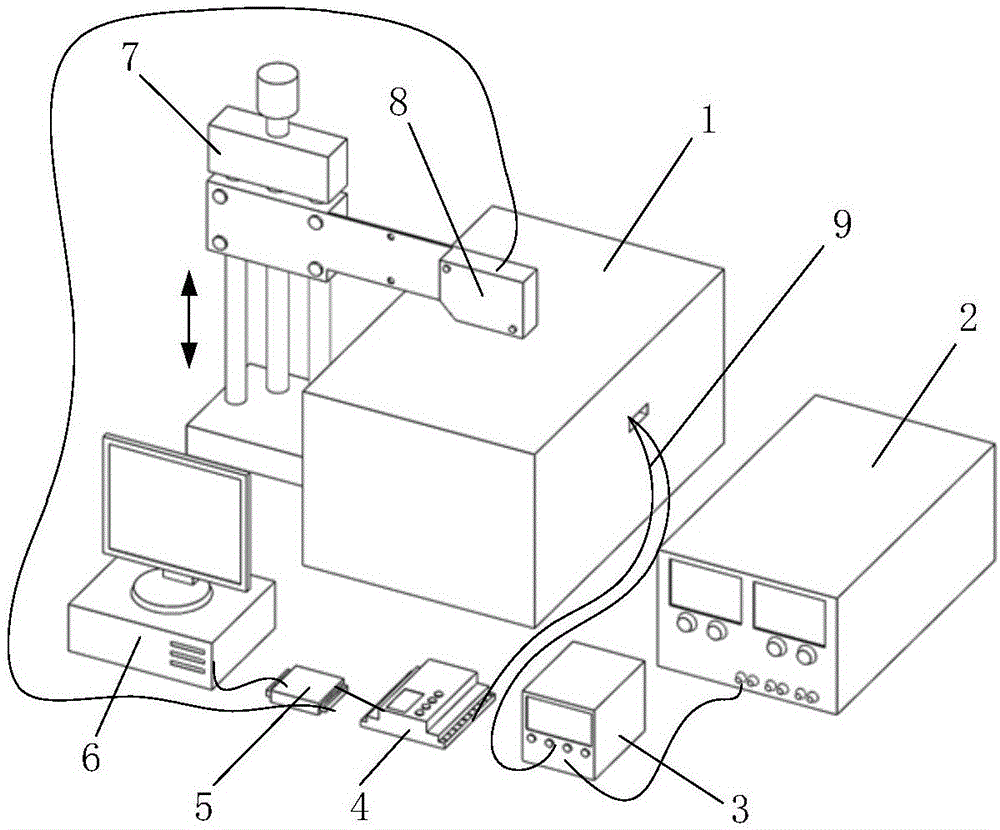

Shape memory alloy thermal circulation stability and function fatigue property testing system

ActiveCN106680310ADoes not affect deformationHeating up fastInvestigating phase/state changeData acquisitionShape-memory alloy

The invention discloses a shape memory alloy thermal circulation stability and function fatigue property testing system which comprises a temperature control box, a sample bracket, a thermal circulation temperature control system and a data acquisition system, wherein the temperature control box is of a hexahedron hollow structure; a flexible polyimide heating film of the thermal circulation control system is adhered to the bottom of a stripped shape memory alloy sample; an anode / cathode lead of the flexible polyimide heating film is connected with a heating end of a time relay; the time relay is connected with a direct-current voltage-stabilizing power supply; a thermocouple signal conditioning module and a laser tube displacement sensor of the data acquisition system are connected with a data acquisition card; the data acquisition card is connected with a computer; one end of a K-type thermocouple is connected with a thermocouple signal conditioning module; and the other end of the K-type thermocouple is connected with the flexible polyimide heating film. By adopting the shape memory alloy thermal circulation stability and function fatigue property testing system, shape and temperature variation of a shape memory alloy in the thermal circulation process can be displayed and stored in real time through data acquisition and processing, and the function fatigue property of the shape memory alloy in the thermal circulation process can be relatively well evaluated through analysis.

Owner:SOUTH CHINA UNIV OF TECH

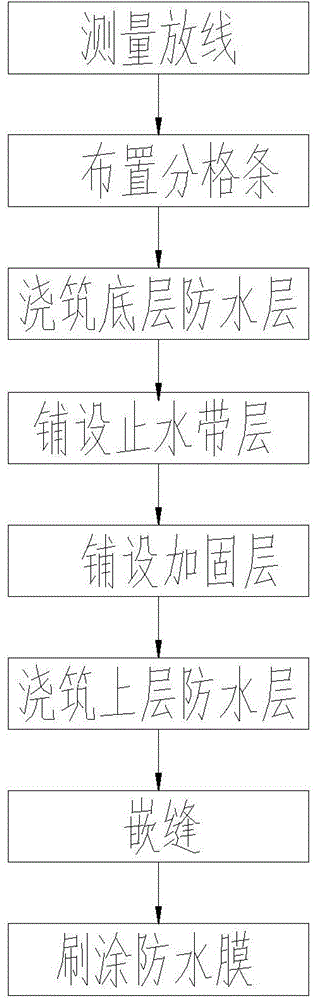

Roofing rigid waterproof layer structure and construction method thereof

InactiveCN104929322AAvoid loss of waterproof functionImprove waterproof performanceRoof covering using slabs/sheetsBuild-up roofsSurface layerEngineering

The present invention relates to a roofing rigid waterproof layer structure and a construction method thereof. A rigid waterproof layer is obtained through processes of surveying and setting out, arranging a dividing strip layer, pouring a bottom layer waterproof layer, laying a waterstop belt layer and pouring an upper layer waterproof layer and the like, and a plurality of dividing joint structures are staggered in the rigid waterproof layer. The roofing rigid waterproof layer structure has the beneficial effects that a dividing joint is separated from external environment by a waterstop belt, and the top of the waterstop belt is provided with the dividing joint and a waterproof coating protective layer; construction progress is accelerated, cost is saved to a certain degree, concrete moulding effect is good, and the surface is flat without ponding cold ponds; and after joint material and waterproof coating are aged and not waterproof, due to the fact that the waterstop belt is disposed and the surface layer dividing joint is relatively shallow, moisture is not easy to leak and can be rapidly evaporated, temperature telescoping deformation of the concrete rigid waterproof layer is satisfied, waterproof performance of the dividing joint is largely enhanced, and service life period of roofing waterproof is prolonged.

Owner:高峰

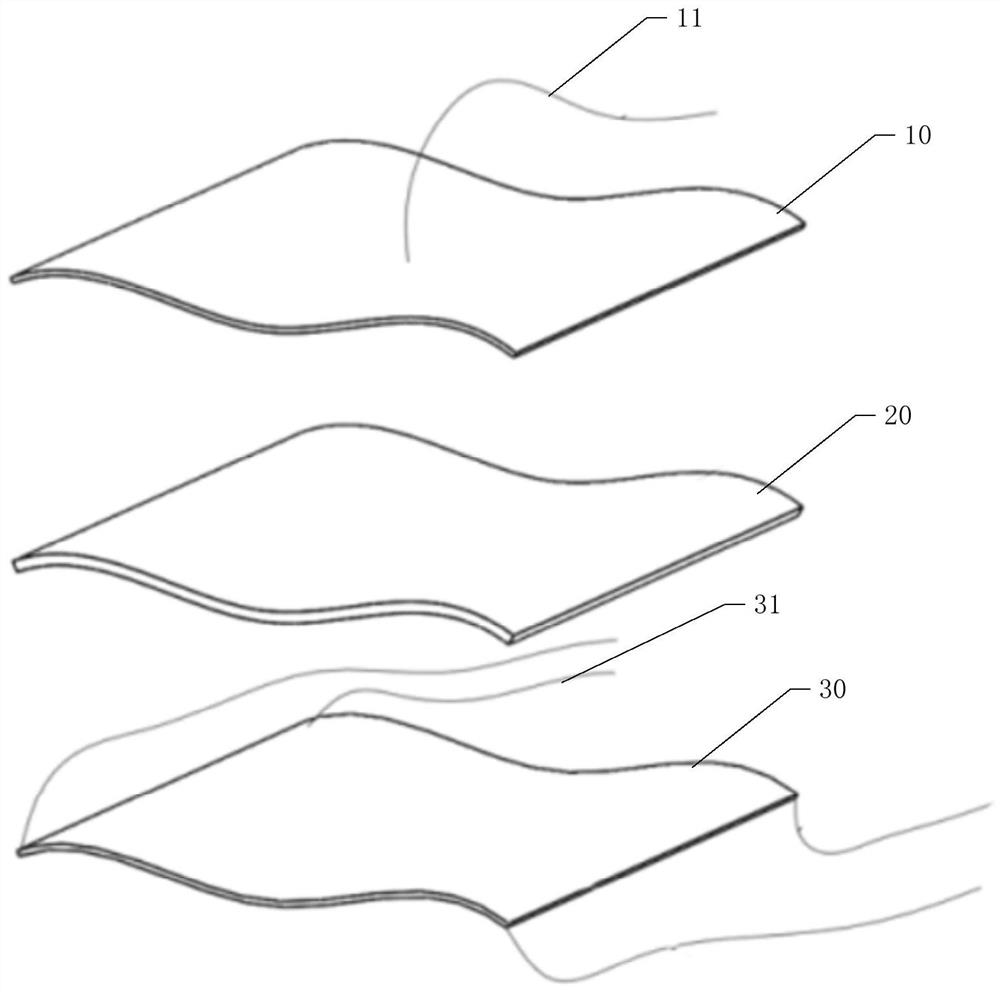

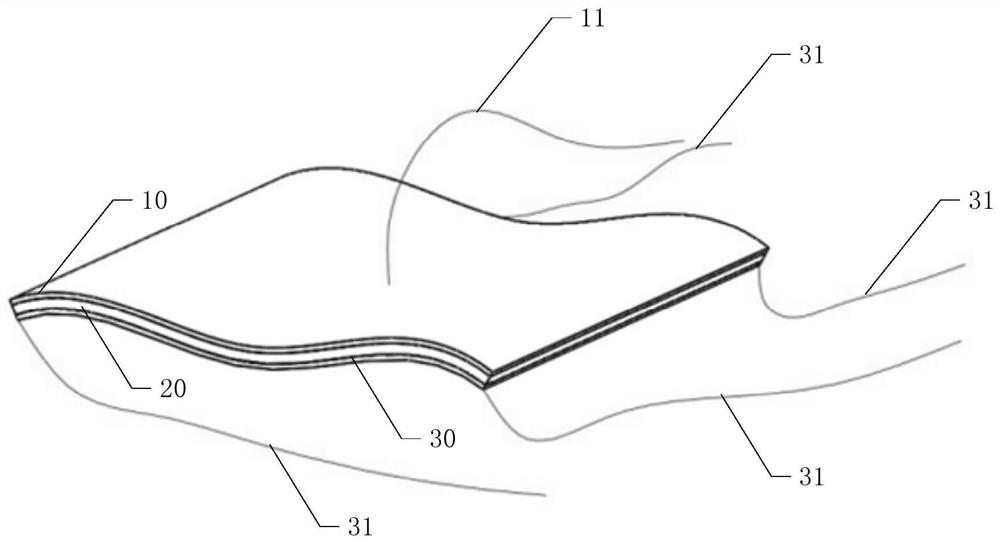

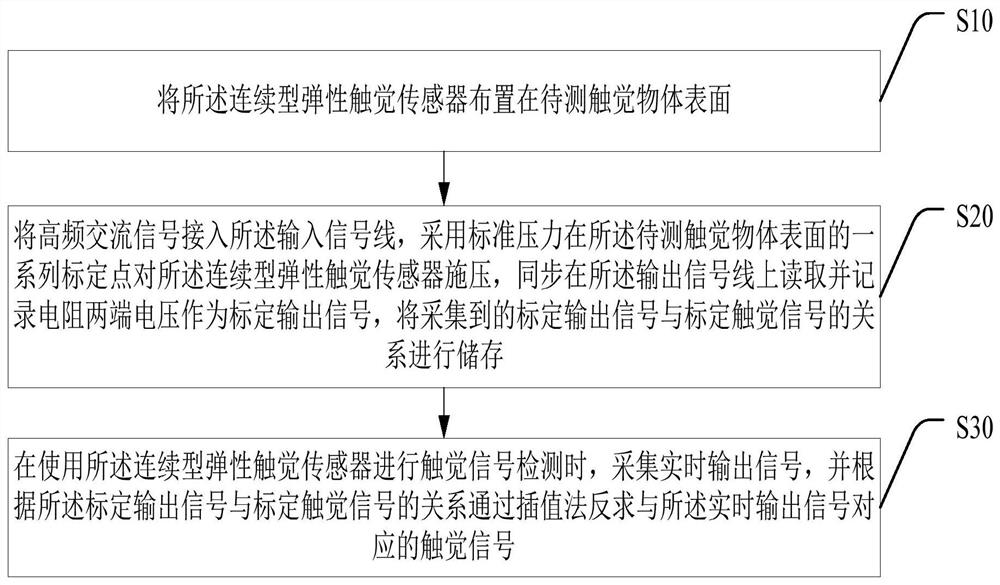

Continuous elastic tactile sensor and detection method thereof

ActiveCN111982379AGood adaptabilitySimple structureForce measurementMeasurement of force applied to control membersElectrically conductiveTactile sensor

The invention discloses a continuous elastic tactile sensor and a detection method thereof. The continuous elastic tactile sensor comprises a first elastic conducting layer, an elastic insulating layer and a second elastic conducting layer which are sequentially arranged in a stacked mode from top to bottom. At least one input signal line is arranged in the center of the first elastic conducting layer, at least two output signal lines are arranged on the edge of the second elastic conducting layer, and output resistors are connected to the output signal lines in series. The continuous elastictactile sensor provided by the invention adopts an elastic material for preparing a sensor, has better adaptability to the surface of a flexible and elastic deformation object, and does not influencethe deformation of a measured surface; the structure is greatly simplified while the contact position and the pressure intensity of a measured surface with a large area are detected, the number of needed signal leads is extremely small, and arrangement is facilitated and influences on deformation of a measured object are avoided.

Owner:PENG CHENG LAB

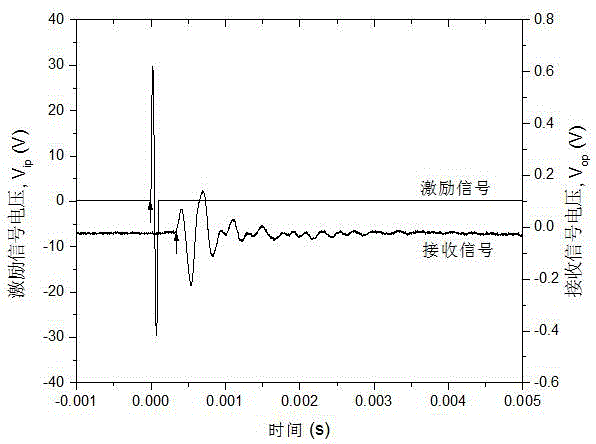

Minitype piezoelectric telescopic element, compression wave measurement device and compression wave measurement method for centrifuge testing

ActiveCN105651605AImprove area utilizationLarge longitudinal amplitudeSubsonic/sonic/ultrasonic wave measurementMaterial strength using tensile/compressive forcesEpoxyMeasurement device

The invention discloses a minitype piezoelectric telescopic element, a compression wave measurement device and a compression wave measurement method for centrifuge testing. The minitype piezoelectric telescopic element comprises a tubular substrate and a processed piezoelectric ceramic piece, wherein the positive lead and the negative lead of a signal shielding wire are connected with the surfaces of two sides of the piezoelectric ceramic piece respectively, an inner epoxy resin layer, a conductive copper tape and an outer epoxy resin layer cover the surface of each of two sides of the piezoelectric ceramic piece, the grounding line of the signal shielding wire is connected with the conductive copper tape, and the piezoelectric ceramic piece is fixed on one end surface of the tubular substrate. The compression wave measurement device comprises a pair of minitype piezoelectric telescopic elements, a signal generator, a power amplifier, a principal axis slip ring of the centrifuge, a charge amplifier, an oscilloscope and the minitype piezoelectric telescopic element. According to the invention, good electromagnetic shielding effect is achieved, electromagnetic interference in the centrifuge is eliminated, the excited compression wave has strong bundling directivity, a reliable signal can be obtained in a strong interference environment, and the telescopic element has high compression wave excitation efficiency, and can be used in a high attenuation nearly-saturated water body.

Owner:ZHEJIANG UNIV

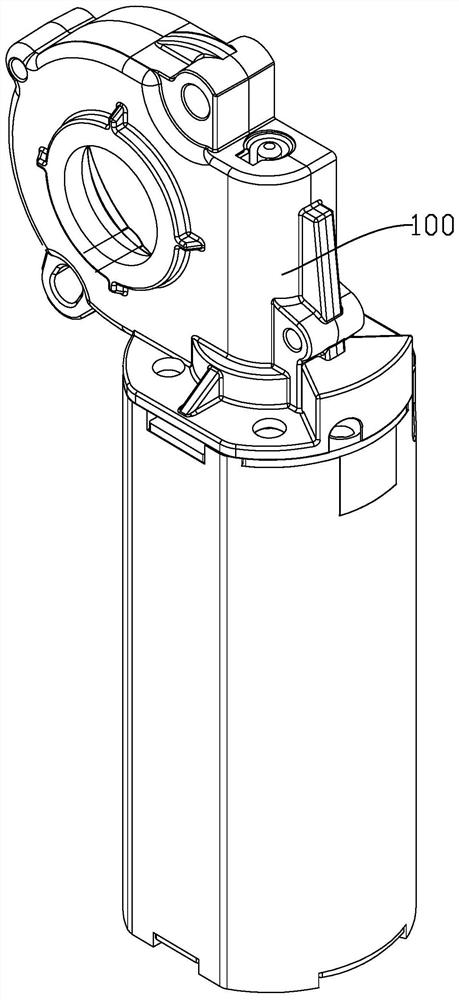

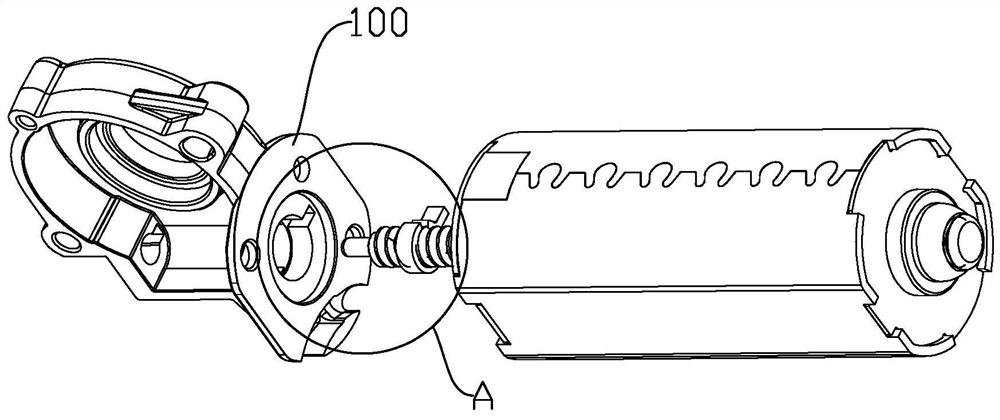

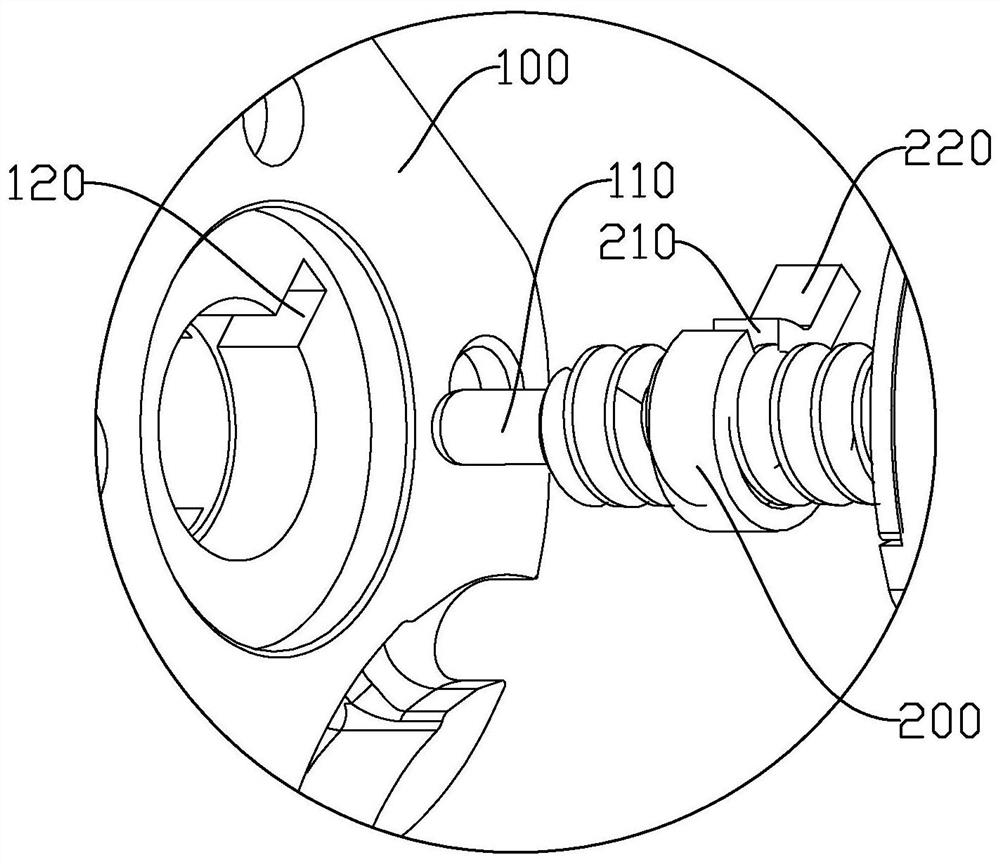

Self-locking device suitable for motor and linear actuator

The invention discloses a self-locking device suitable for a motor and a linear actuator, and belongs to the field of motors. The motor has self-locking performance, good stability, low noise in the operation process and good user experience feeling. The self-locking device suitable for the motor comprises an end cover installed on the motor and a friction ring arranged on a motor driving shaft in a sleeving mode. A notch is formed in the friction ring, a limiting part is arranged on the periphery of the friction ring, and the end cover is matched with the limiting part so that the friction ring can tightly hold the driving shaft when the driving shaft rotates in the first direction.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Exhaust assembly and compressor with same

PendingCN111396294AGuaranteed reliabilityTroubleshoot technical issues with poor reliabilityPositive displacement pump componentsPositive-displacement liquid enginesControl theoryValve seat

The invention provides an exhaust assembly and a compressor with the same. The exhaust assembly comprises a valve seat, a valve bonnet and a sliding block; the valve seat is provided with an exhaust port; the valve bonnet is arranged at the exhaust port, an inner cavity of the valve bonnet communicates with the exhaust port, and an exhaust hole is formed in the side wall of the valve bonnet, so that gas at the exhaust port is exhausted from the exhaust hole through the inner cavity of the valve bonnet; and the sliding block is arranged on the valve bonnet in a sliding and sleeving mode, and the sliding block is provided with a shielding position for shielding the exhaust hole and an exhaust position for avoiding the exhaust hole. By means of the technical scheme provided by the exhaust assembly and the compressor with the same, the technical problem that in the prior art, an exhaust assembly is poor in reliability can be solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

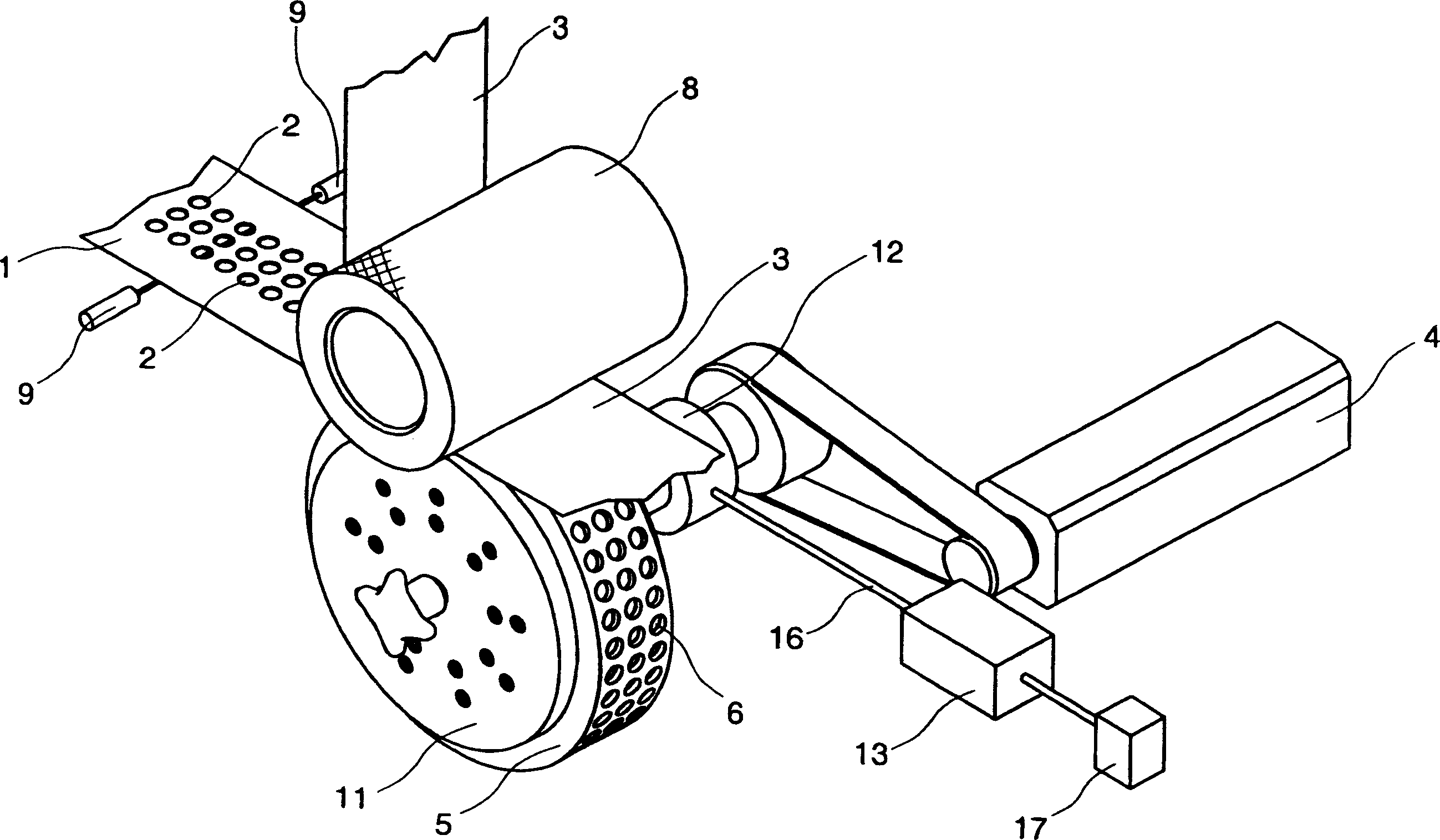

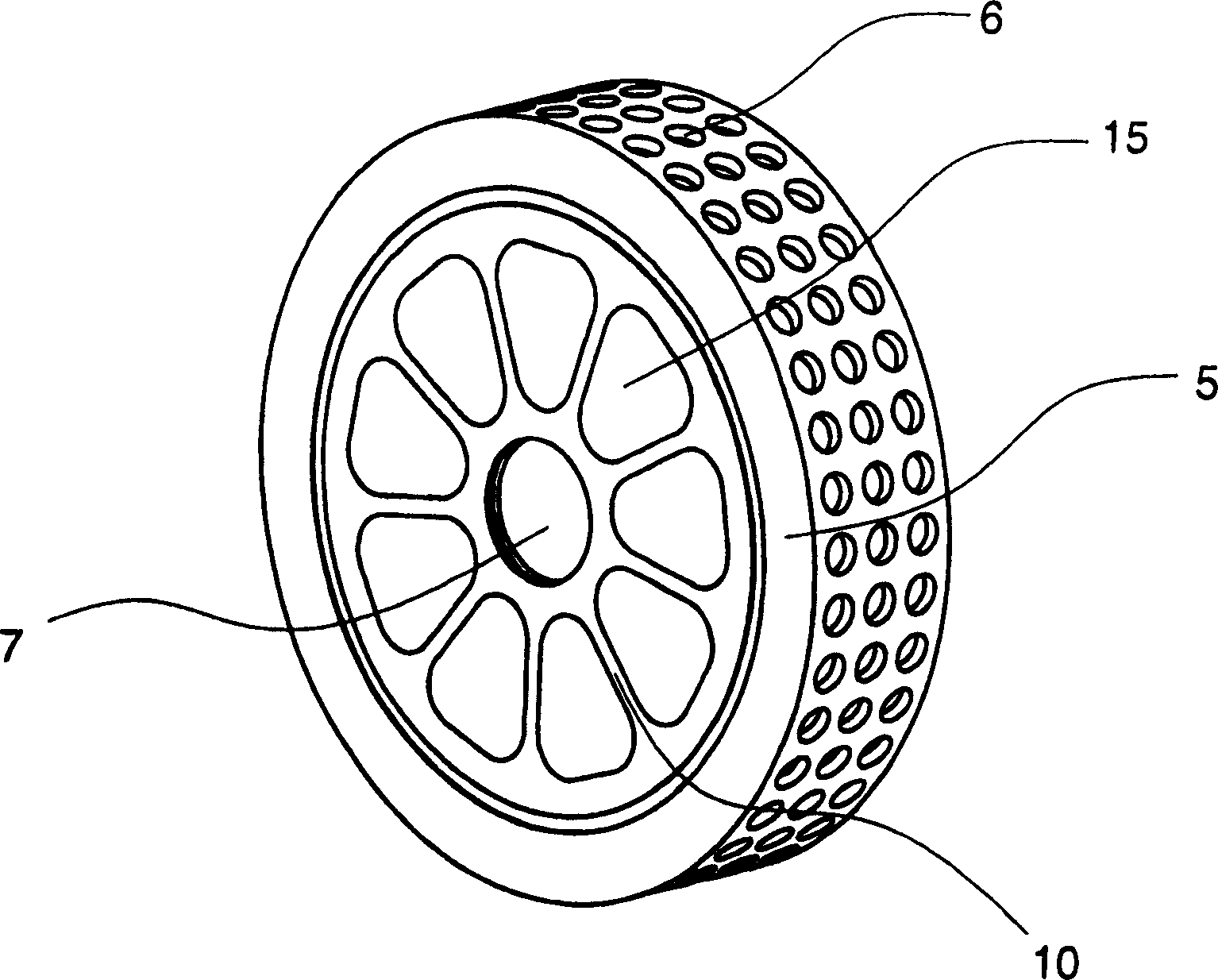

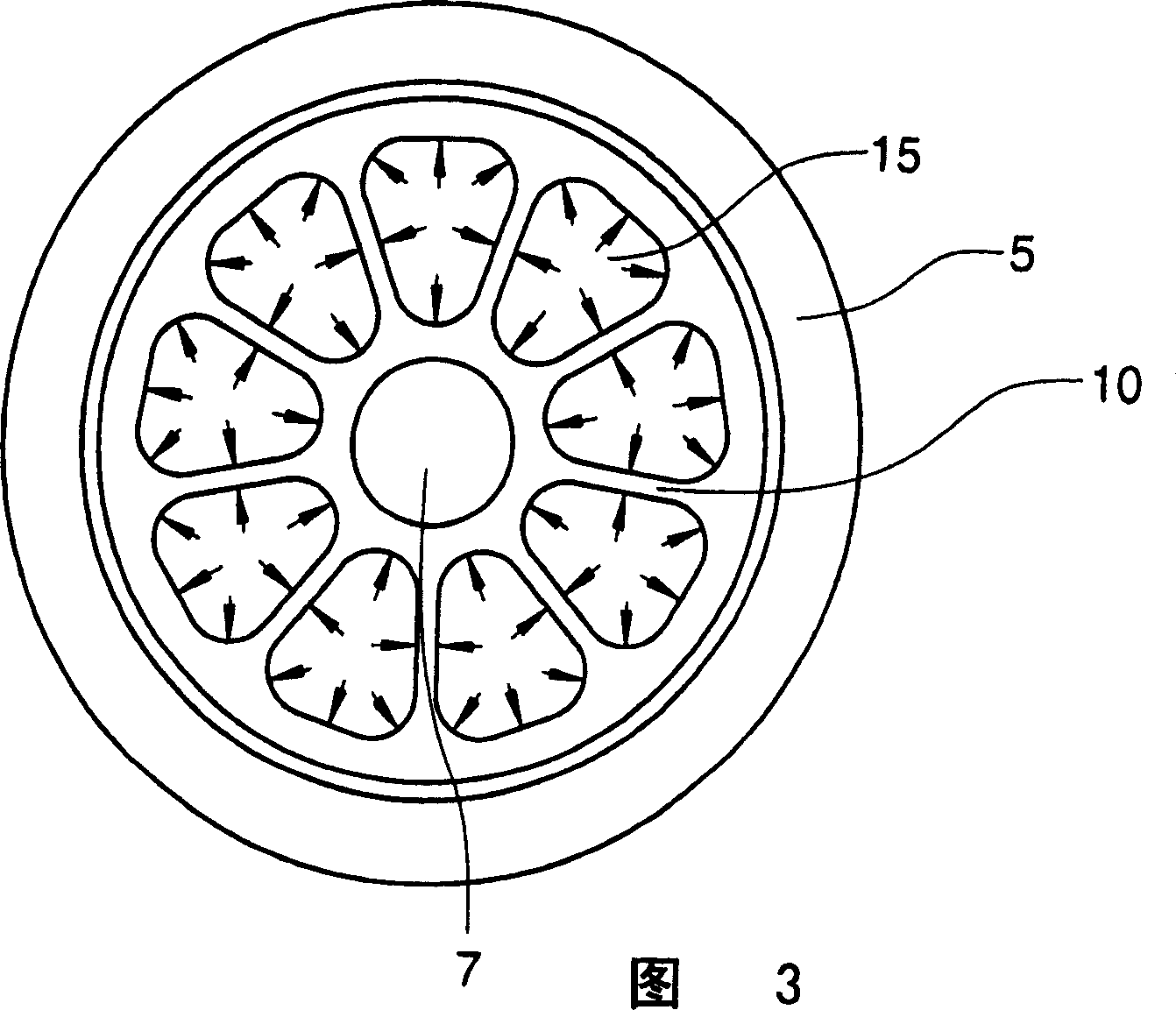

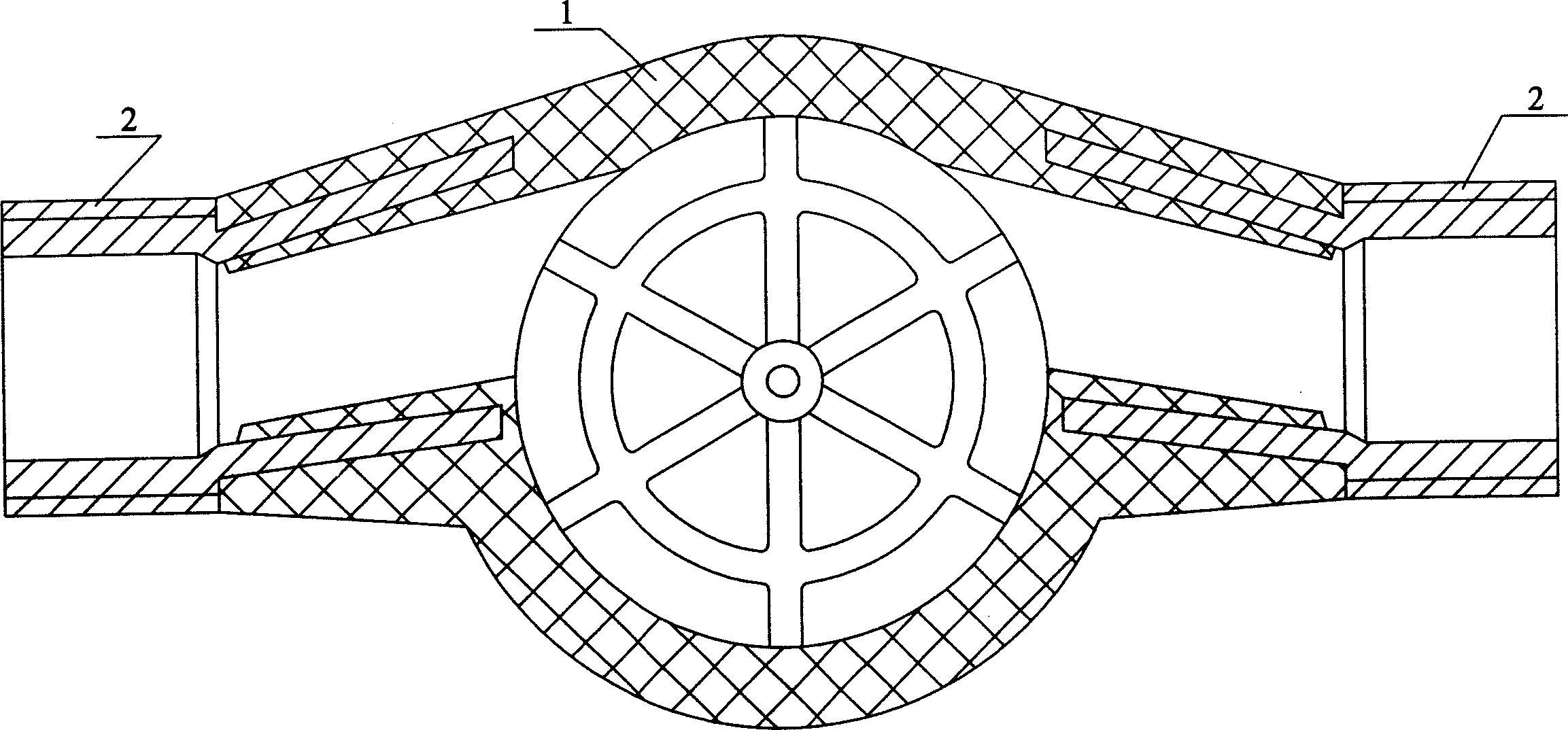

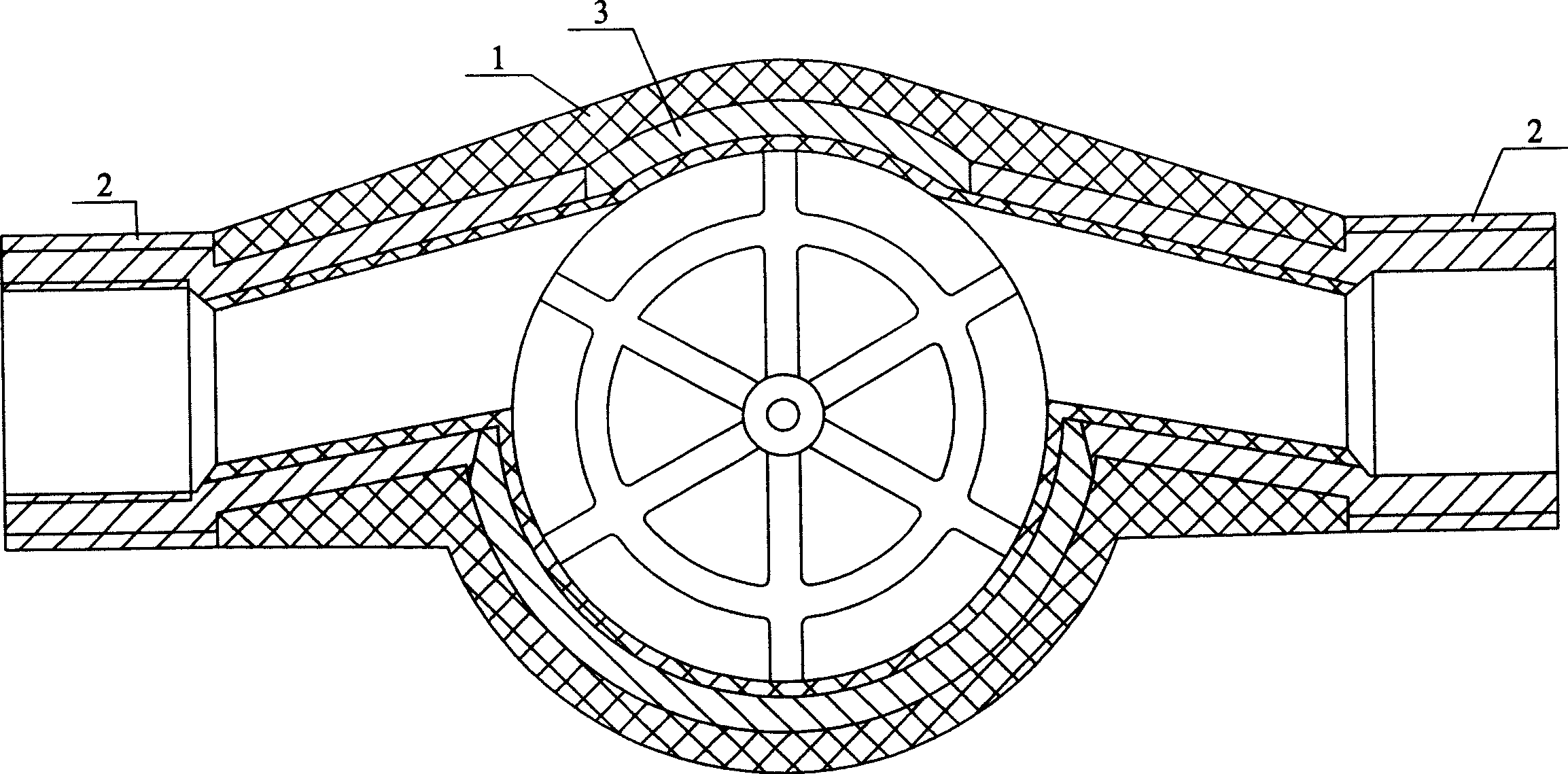

Device for sealing a cup comprising foil with a cover sheet

InactiveCN1854018ALarge diameter changeAvoid deformationWrapper twisting/gatheringDomestic articlesMechanical engineeringEngineering

The invention relates to a device for sealing a molded film (1) with a preferably filled basin (2) with a covering film (3), having a Feed roller (5) with recess (6) for pot (2) and a sealing roller (8) running above it, between which the forming film (1) and cover film can be guided (3), a pressure chamber (15) is set in the feed roller (5), which is connected to a pressure medium source (17) through a pressure medium conduit (16), so that the change of the circumference of the feed roller (5) Accurate correlation of the positions of the pelvis (2) and the recess (6) is achieved.

Owner:UHLMANN PAC SYST

Oil pan of automobile engine

ActiveCN103573328AImprove buffering effectReduce the difficulty of assemblyNon-rotating vibration suppressionSynthetic resin layered productsEnergy absorptionCylinder block

The invention provides an oil pan of an automobile engine, and belongs to the technical field of automobiles. The oil pan solves the technical problem that an existing engine oil pan does not have good buffering or energy absorption effect. The oil pan of the automobile engine comprises a flexible shell connected to the lower end of an engine cylinder body, the upper end of the shell is fixedly connected with the lower end of the engine cylinder body, and a supporting structure capable of supporting the bottom of the shell is further arranged between the bottom of the shell and the engine cylinder body. The oil pan of the automobile engine has the advantages of having good buffering and energy absorption effects while being impacted and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Synthesis method of controlled alloy for minimally invasive dental pulp treatment nickel-titanium instrument

InactiveCN109504969AHas strong oxidizing propertiesNot easy to corrodeTeeth fillingMetallic material coating processesBerberineSynthesis methods

The invention discloses a synthesis method of a controlled alloy for a minimally invasive dental pulp treatment nickel-titanium instrument. The method comprises the following steps that S1, the surface of a nickel-titanium alloy is subjected to free-of-nickel treatment; S2, the surface of the nickel-titanium alloy is subjected to coating; and S3, the nickel-titanium alloy is activated. According to the method, a plurality of micropores are formed in the nickel-titanium alloy subjected to surface free-of-nickel treatment, after the surface is subjected to the coating, a plurality of tiny cavities are formed between the nickel-titanium alloy and polytetrafluoroethylene, and finally the activation step is carried out, so that berberine can be soaked in the cavities between the nickel-titaniumalloy and the polytetrafluoroethylene; and the berberine in the cavities can release slowly, due to the fact that the berberine has a certain sterilization effect, when the berberine slowly releases,the minimally invasive dental pulp treatment can be facilitated.

Owner:QINGDAO STOMATOLOGICAL HOSPITAL

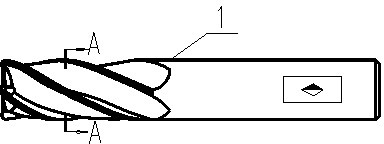

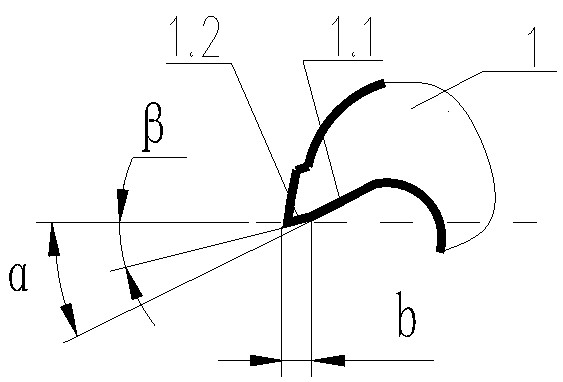

Manufacturing method of high-strength end mill cutting edge and double-front-angle end mill

InactiveCN102642045AAvoid hard point wearIncrease cooling spaceMilling cuttersMachining processManufacturing engineering

The invention discloses a manufacturing method of a high-strength end mill cutting edge and a double-front-angle end mill. To manufacture a cutting edge of an end mill (1) with a spiral groove, a main front angle (1.1) is firstly manufactured on the cutting edge of the end mill (1), an auxiliary front angle (1.2) is then manufactured on the main front angle (1.1), and the angle (alpha) of the main front angle (1.1) is greater than the angle (beta) of the auxiliary front angle (1.2). The cutting edge disclosed by the invention not only can effectively improve the end mill cutting edge strength and the processing fineness, but also has the advantages of simple processing technology, relatively low manufacturing cost and relatively long service life.

Owner:XINAN TOOLS GUIZHOU PROV

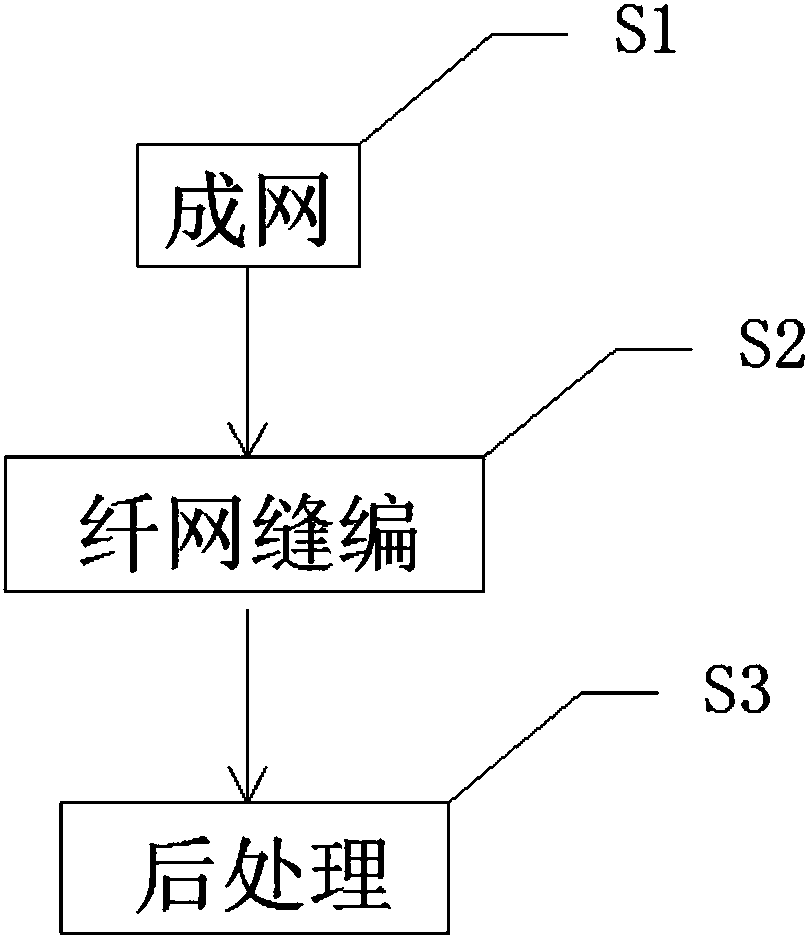

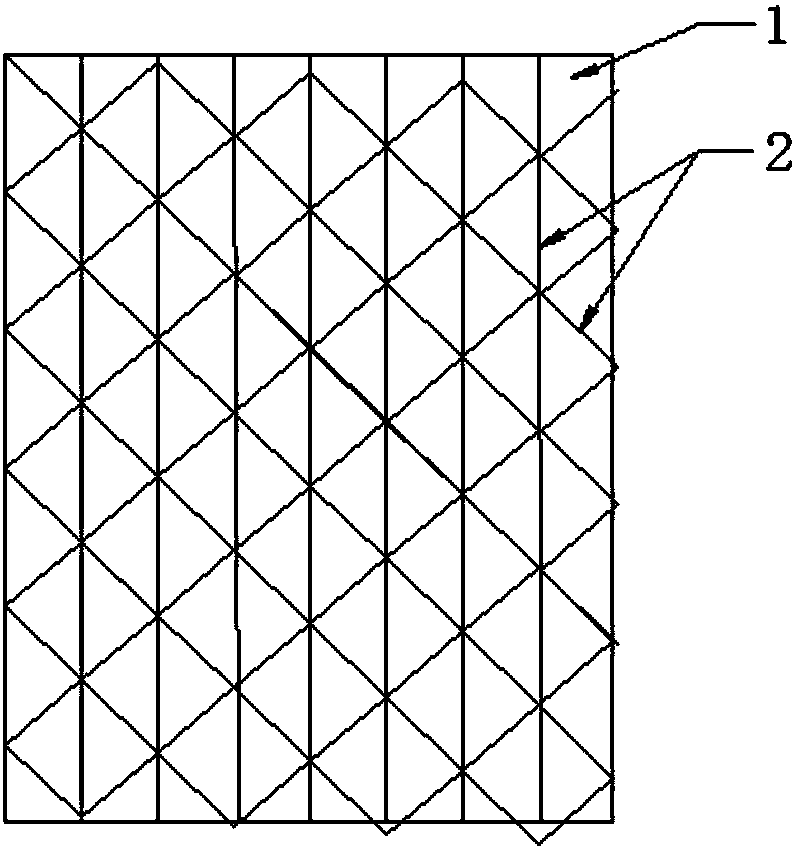

Manufacturing method of elastic non-woven fabric, elastic non-woven fabric and elastic product

ActiveCN108468150AImprove ductilityOvercome the disadvantage of being easy to form unidirectional elasticityWarp knittingCardingNetwork structure

The invention provides a manufacturing method of an elastic non-woven fabric. The method comprises the following steps of 1, formation of a net, wherein a fiber raw material is subjected to processesof loosening, mixing, carding and net laying to form the fiber net of a network structure; 2, knitting of the fiber net, wherein a plurality of composite filaments are introduced into the fiber net made in step 1, the composite filaments repeatedly penetrate through the fiber net and form thread rings on the front and back faces of the fiber net, and the thread rings are mutually encircled according to a stitching rule of knitting textures on the front face of the fiber net; 3, post-treatment, wherein the fiber net made in step 2 is subjected to heat treatment. A thread ring structure formed by the composite filaments is utilized, so that the non-woven fabric has better ductility. Since the thread rings have the deformation ability in the longitudinal and transverse directions, the elasticnon-woven fabric has elasticity not only in the transverse direction but also in the longitudinal direction, the elasticity of the elastic non-woven fabric is not in one direction, and the disadvantage of easily forming the elasticity in one direction by means of a conventional elastic non-woven fabric preparation method is overcome.

Owner:海宁纺织综合企业有限公司

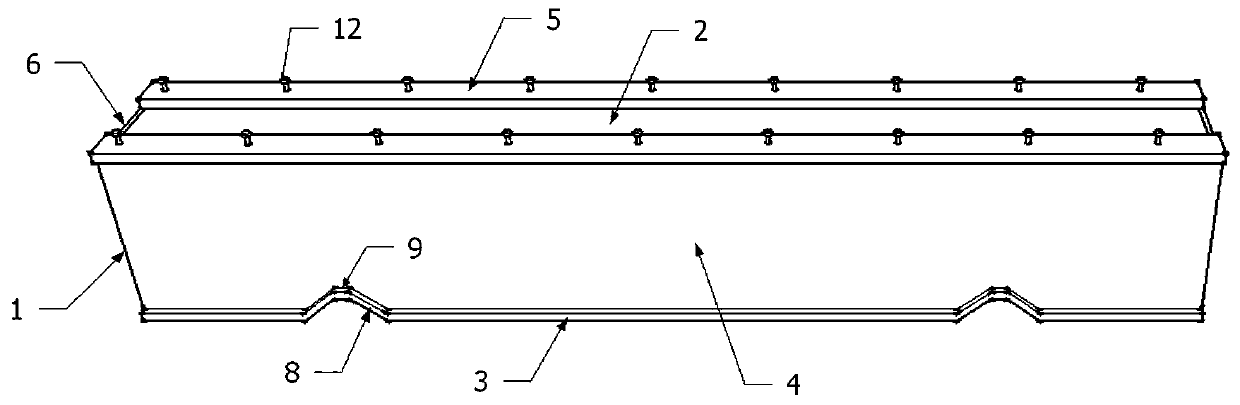

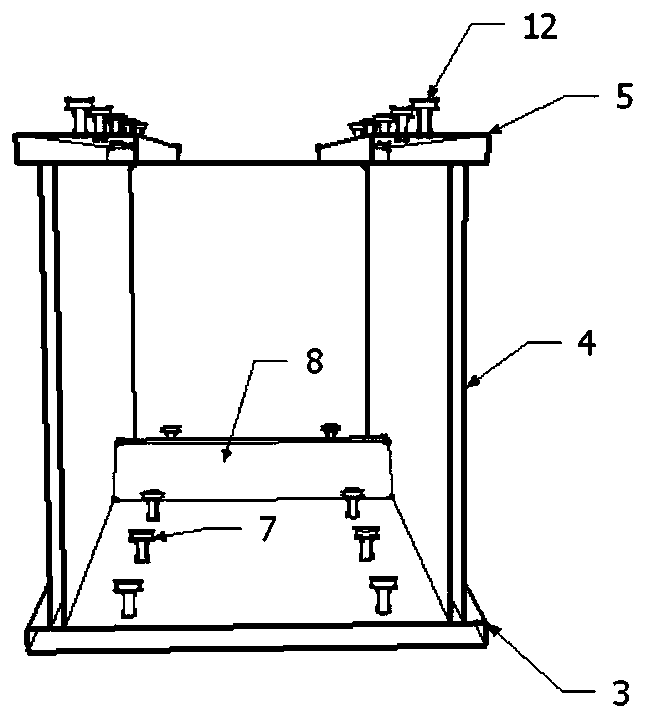

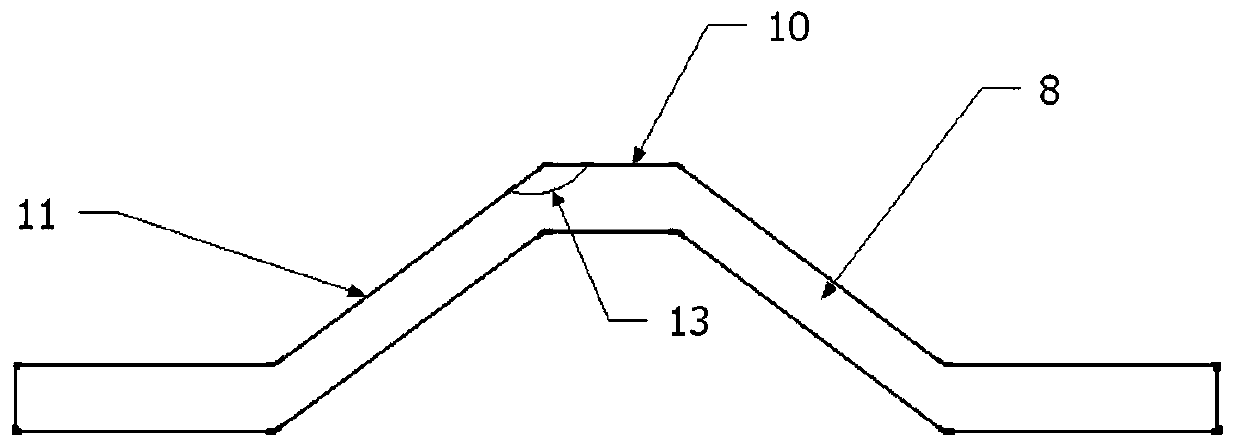

A wave box girder

ActiveCN109763415BImprove deformation abilityImprove collapse resistanceLoad-supporting elementsBridgesClassical mechanicsStructural engineering

The invention discloses a corrugated box beam, and belongs to the technical fields of construction and structural engineering. A corrugated bottom plate of the corrugated box beam provided by the invention bends and corrugates at inflection points near beam-column joints to form inverted U-shaped wavy protrusions, and the inverted U-shaped wavy protrusions deform greatly in the process of straightening under load, so that the deformation capacity of the corrugated box beam under earthquake action is greatly increased, and the collapse resistance capacity of the corrugated box beam under largeearthquakes is greatly enhanced; in addition, corrugated parts of the corrugated box beam are covered with non-stick films, so that the corrugated box beam is not bonded to concrete locally, and no affect is caused on the deformation of the inverted U-shaped wavy protrusions, the deformation capacity of the corrugated box beam under the earthquake action is further increased, and the collapse resistance capacity of the corrugated box beam under the large earthquakes is greatly enhanced.

Owner:JIANGNAN UNIV

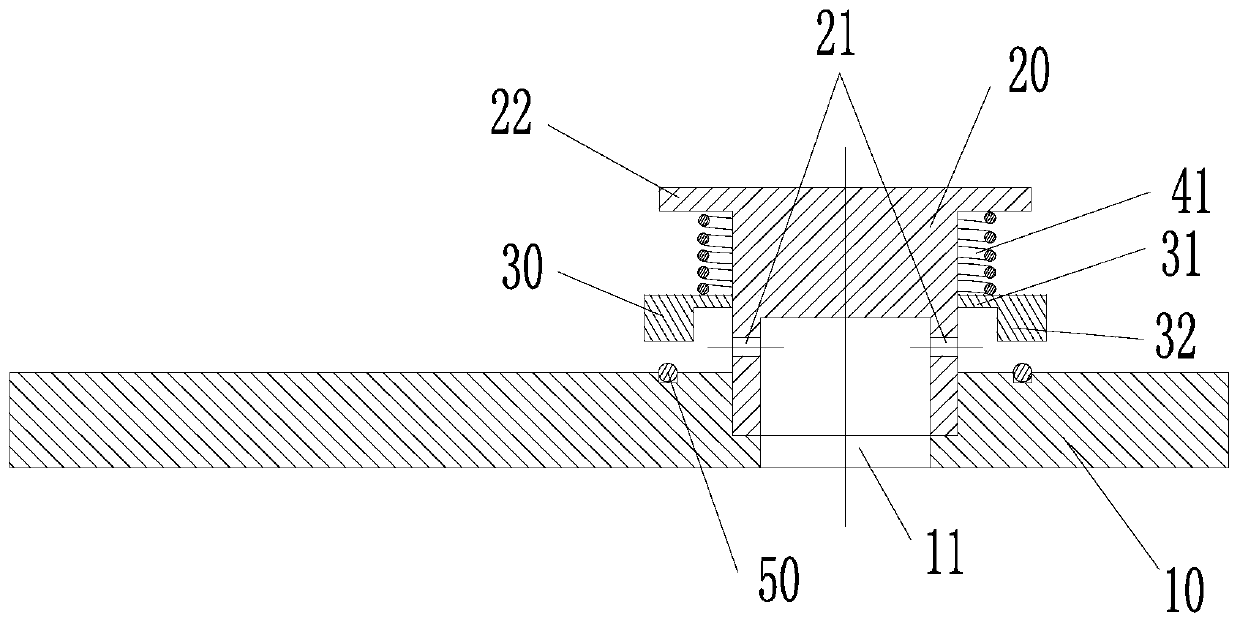

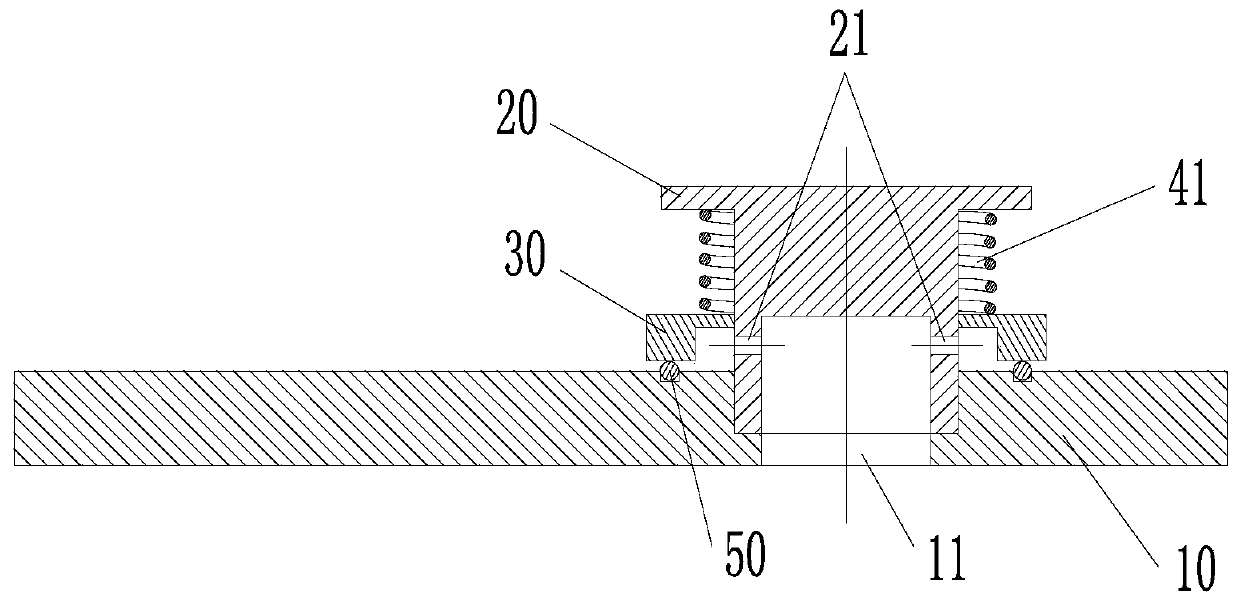

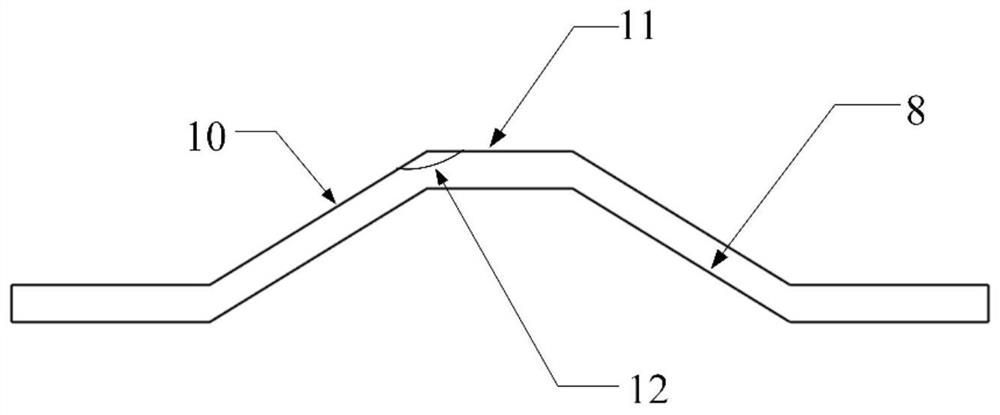

Packer and sealing device

The invention discloses a packer and a sealing device. The packer comprises a mesh-shaped packer body with a cavity and a proximal bolt head, the proximal bolt head is provided with a locking hole penetrating through the cavity, and the packer further comprises a locking member, the distal end of the locking member is in contact with the distal end of the packer body, the locking member is an elastic member, the locking member includes a connecting portion connected to the packer body and a first bending portion, the first bending portion is provided with a first bending angle, the diameter ofthe circumscribed circle projected by the first bending portion on the cross section perpendicular to the longitudinal direction thereof is smaller than the diameter of the smallest inscribed circleof the locking hole, the projection width of the first bend portion on the plane perpendicular to the longitudinal central axis of the locking hole is larger than the diameter of the maximum inscribedcircle of the locking hole. The packer has the advantages of simple structure, easy size control of the locking member, convenient processing, and simplified the preparation process and the locking operation. At the same time, the locking member has high locking reliability, and is not easy to be broken, the locking operation process is reversible, and the locking process and the recycling process are simple and easy.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

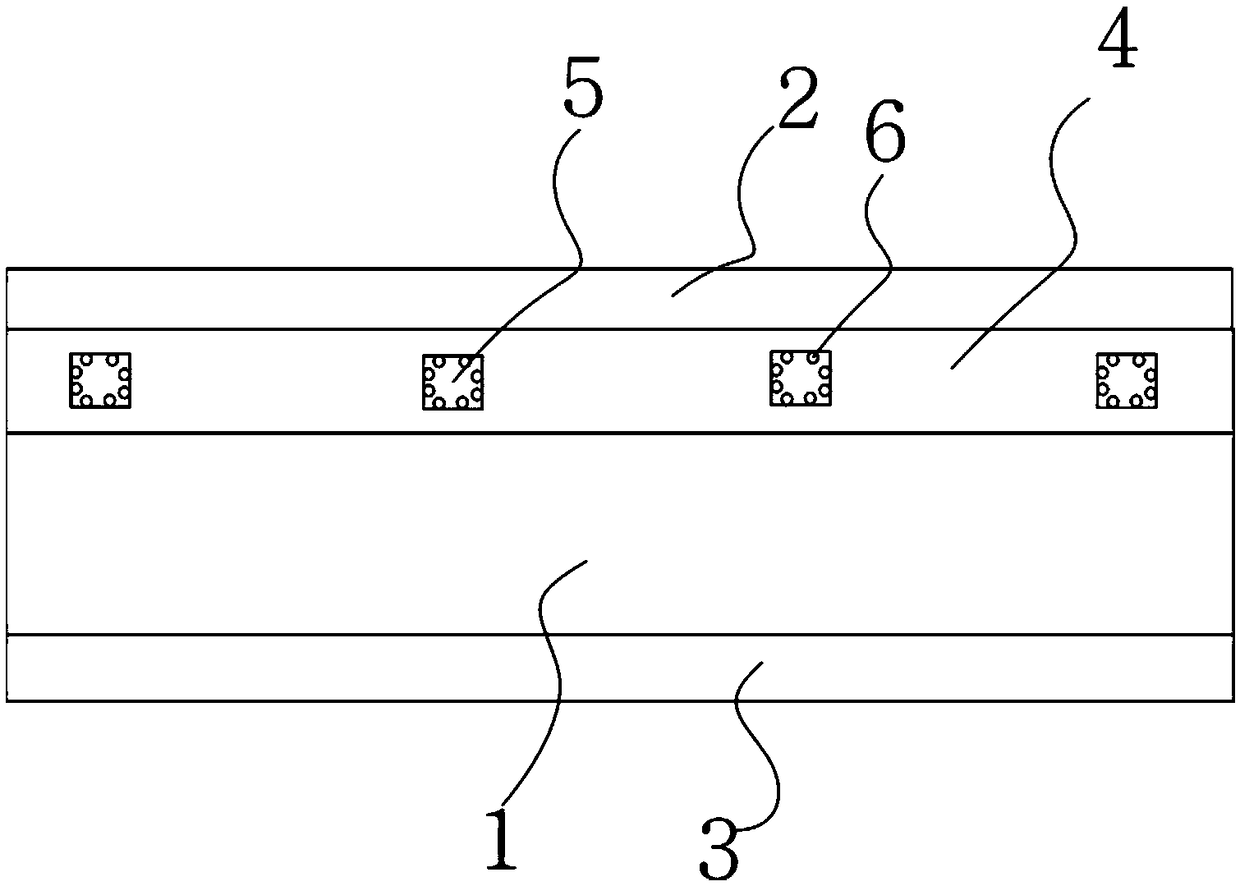

Waterproof thermal insulation board

InactiveCN108978910ADoes not affect deformationPrevent penetrationHeat proofingBuilding insulationsThermal insulationArchitectural engineering

The invention relates to a waterproof thermal insulation board which comprises a thermal insulation layer, a protective layer adheres the thermal insulation layer and an adhesive layer. A waterproof layer is adhered between the thermal insulation layer and the protective layer, a through groove is arranged inside the waterproof layer, and an inner wall of the through groove is provided with adsorbing particles. The waterproof thermal insulation board has a good waterproof effect.

Owner:TIANJIN YUSHEN ENERGY SAVING THERMAL INSULATION MATERIAL

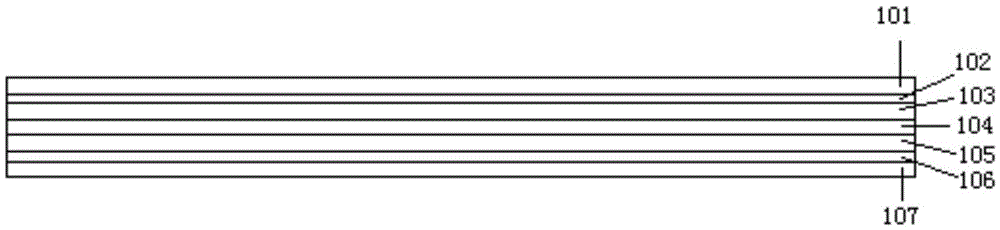

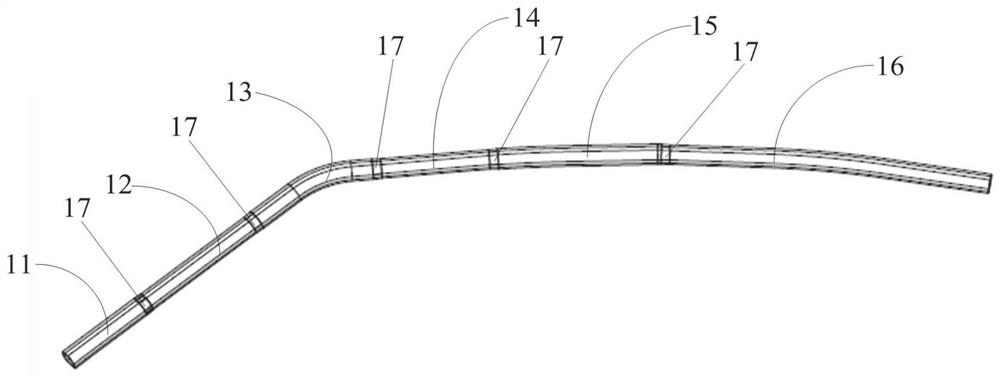

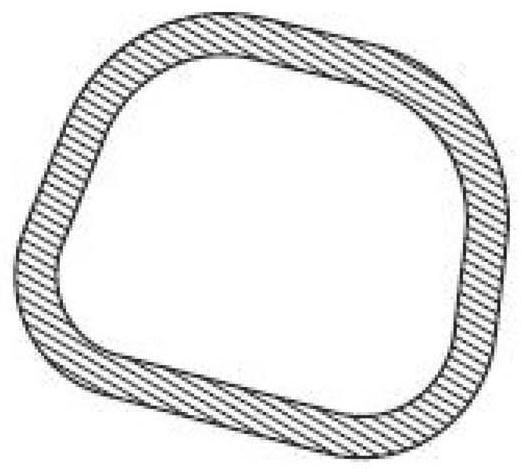

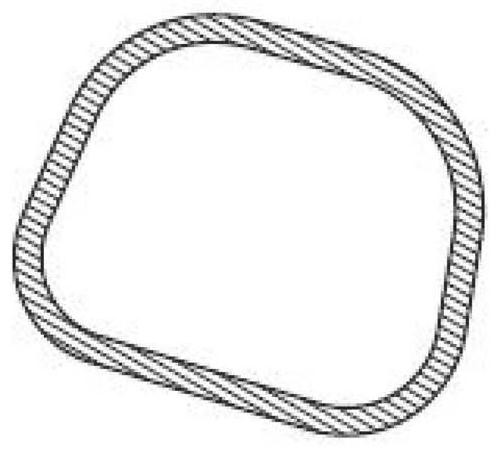

Reinforcing tube and manufacturing method thereof

ActiveCN112793670AEfficient use ofGuaranteed performanceSuperstructure subunitsFiberStructural engineering

In order to solve the technical problem that an existing A-column upper sidebeam reinforcement structure is large in weight, the invention provides a reinforcing tube and a manufacturing method of the reinforcing tube. The reinforcing tube is a carbon fiber composite tube and comprises a first section, a second section, a third section, a fourth section, a fifth section and a sixth section which are sequentially connected, wherein the thickness of the second section, the thickness of the fourth section and the thickness of the sixth section are equal, and the thickness of the first section, the thickness of the third section and the thickness of the fifth section are all larger than the thickness of the second section. The reinforcing tube is used for connecting a vehicle side wall outer plate and a vehicle side wall inner plate. The reinforcing tube is manufactured through a variable-thickness three-dimensional braiding process, and by fully utilizing the designability of a three-dimensional braided carbon fiber winding technology, the performance is guaranteed, meanwhile, extreme light weight is achieved, and the optimal structural design is achieved. The material thickness of the tubular beam is changed through design at different positions, the material thickness is increased at the main force bearing and connecting positions, and the material thickness is reduced at the secondary force bearing positions, so that the lighter weight is achieved under the same performance as that of a metal reinforcing piece.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

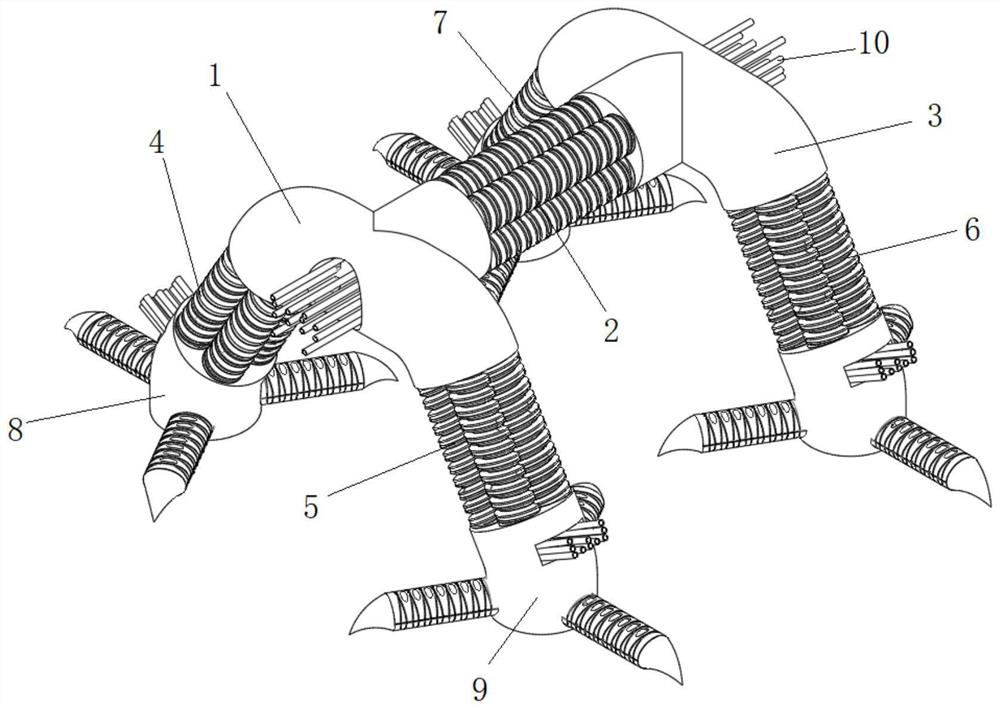

Pneumatically-driven four-footed soft wall-climbing robot

ActiveCN114771686AMany degrees of freedomIncrease flexibilityVehiclesPhysical medicine and rehabilitationEngineering

The invention discloses a pneumatically-driven four-footed soft wall-climbing robot. The pneumatically-driven four-footed soft wall-climbing robot comprises a shoulder connecting piece, a soft spine, a hip connecting piece, four soft legs and four soft feet. Each of the soft spine and the soft legs comprises four trunk expansion rods, each soft foot comprises three soft toes, the shoulder connecting piece and the hip connecting piece are connected through the soft spine, the shoulder connecting piece is connected with the two legs, and the hip connecting piece is connected with the other two legs. The soft spine, the soft legs and the soft toes are driven by an external air source and have multiple degrees of freedom. The robot is flexible in mechanism, high in environment adaptability, capable of going straight, turning, crossing obstacles and the like on uneven rough surfaces and high in crawling speed. In addition, the rigidity of the soft spine and the soft legs of the soft robot can be adjusted, and the soft robot has good bearing capacity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

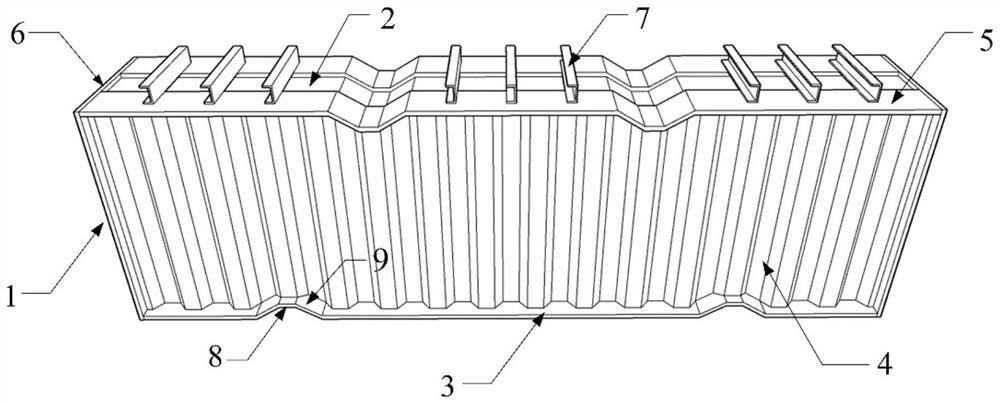

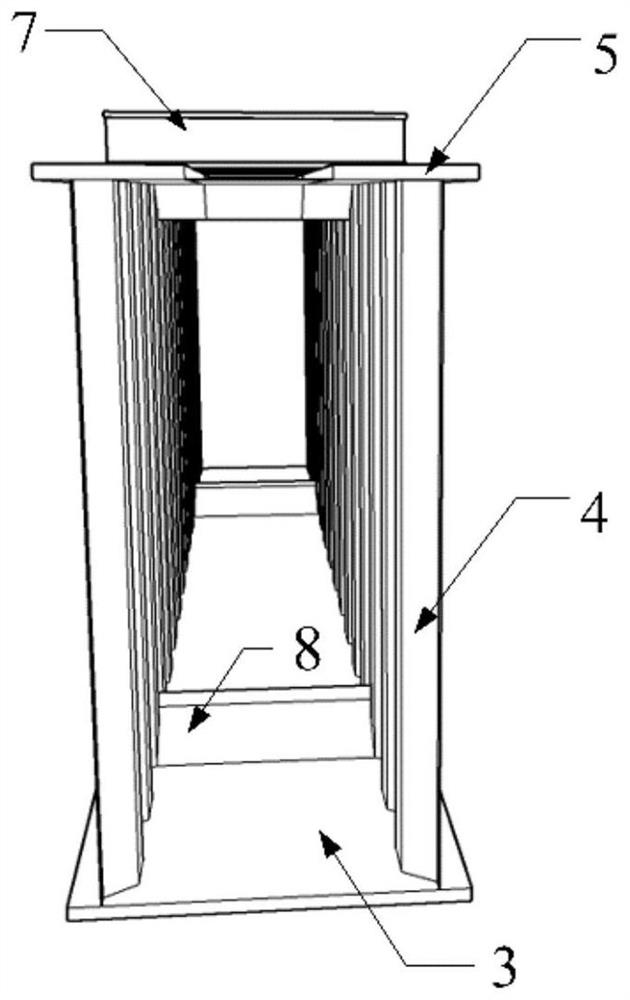

Ripple-forming externally-wrapped corrugated steel-concrete composite beam and construction method and application thereof

InactiveCN112482661AImprove deformation abilityImprove collapse resistanceGirdersJoistsLarge deformationMechanical engineering

Provided is a ripple-forming externally-wrapped corrugated steel-concrete composite beam. The composite beam comprises a steel framework (1) and wavy concrete (2); the steel framework (1) comprises abottom plate, a web plate, a top plate and an end plate; the beam is characterized in that the bottom plate is a corrugated bottom plate (3), the web plate is a corrugated web plate (4), and the top plate is a corrugated top plate (5); and a plurality of inverted U-shaped waves (8) are arranged on the corrugated bottom plate (3) and the corrugated top plate (5). Inverted-U-shaped wavy protrusionscan deform greatly in the loaded straightening process, so that the deformability of the composite beam under the earthquake action is improved, and the collapse resistance is enhanced; the wave starting position of the corrugated steel composite beam is covered with a non-sticky film, and the corrugated steel composite beam is not bonded with concrete locally, so that the deformation of the inverted-U-shaped wavy protrusions is not affected, and the deformability of the composite beam in an earthquake is further improved; and the bonding of two interfaces is increased through the corrugated web plate and shear-resistant channel steel, so that the situation that a steel plate and the concrete work together is guaranteed.

Owner:JIANGNAN UNIV

Water-proof structure for civil engineering expansion joint

ActiveCN110777649APrevent flowDoes not hinder deformationBridge structural detailsArchitectural engineeringWater flow

The invention provides a water-proof structure for a civil engineering expansion joint. A sealing plate embedded between two sections of bridges is used, and force accumulation torsional springs are subjected to self force accumulation for a passing vehicle through the force accumulation torsional springs so as to accumulate force for pushing the sealing plate is accumulated. During heavy rain, rain water flows into a water discharging plate in the expansion joint to enter a water receiving bucket. Through a clamping device, the internal force of the force accumulation torsional springs is released to push the sealing plate to seal the expansion joint between two sections of bridges, the rain water can not enter the lower end of the bridge through the expansion joint, and a pier on the lower end of the bridge can not be corroded. The water-proof structure disclosed by the invention is artful, can be produced on batch, performs a water-proof function on the expansion joint in the bridge, and protects the pier on the lower end of the bridge.

Owner:ZHENGZHOU UNIV OF IND TECH

A test device for testing rock fracture toughness

InactiveCN103604702BDoes not affect deformationEasy loading and unloading processMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention relates to a test device for testing rock fracture toughness, in particular to a test device for measuring rock fracture toughness under confining pressure. It belongs to the technical field of geotechnical engineering. The present invention adopts the addition of a confining pressure device in the original Brazilian disc test device, which changes the method of simply directly loading and splitting the test in the existing test device, and adds a spring positioning device, a sealing device and a self-balancing device in the box body , and is equipped with a dial indicator, oil filling port and exhaust port, etc., to record the lateral and axial displacement changes and control the liquid in the box to form a stable confining pressure. After putting the sample into the box, the spring positioning device is used to fix the sample, and the addition of a self-balancing device can make the loading shaft not affected by the confining pressure, which is convenient for controlling the loading of the sample. The device can realize the splitting test of the rock sample under the confining pressure, thereby calculating the fracture toughness of the sample. The design of the test device is reasonable, the operation is convenient, and it is suitable for the determination of the fracture toughness of various rocks.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Oscillating ink device of offset machine

InactiveCN101927596BGuaranteed transmission accuracyExtend your lifePrinting press partsLeft halfThrust bearing

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

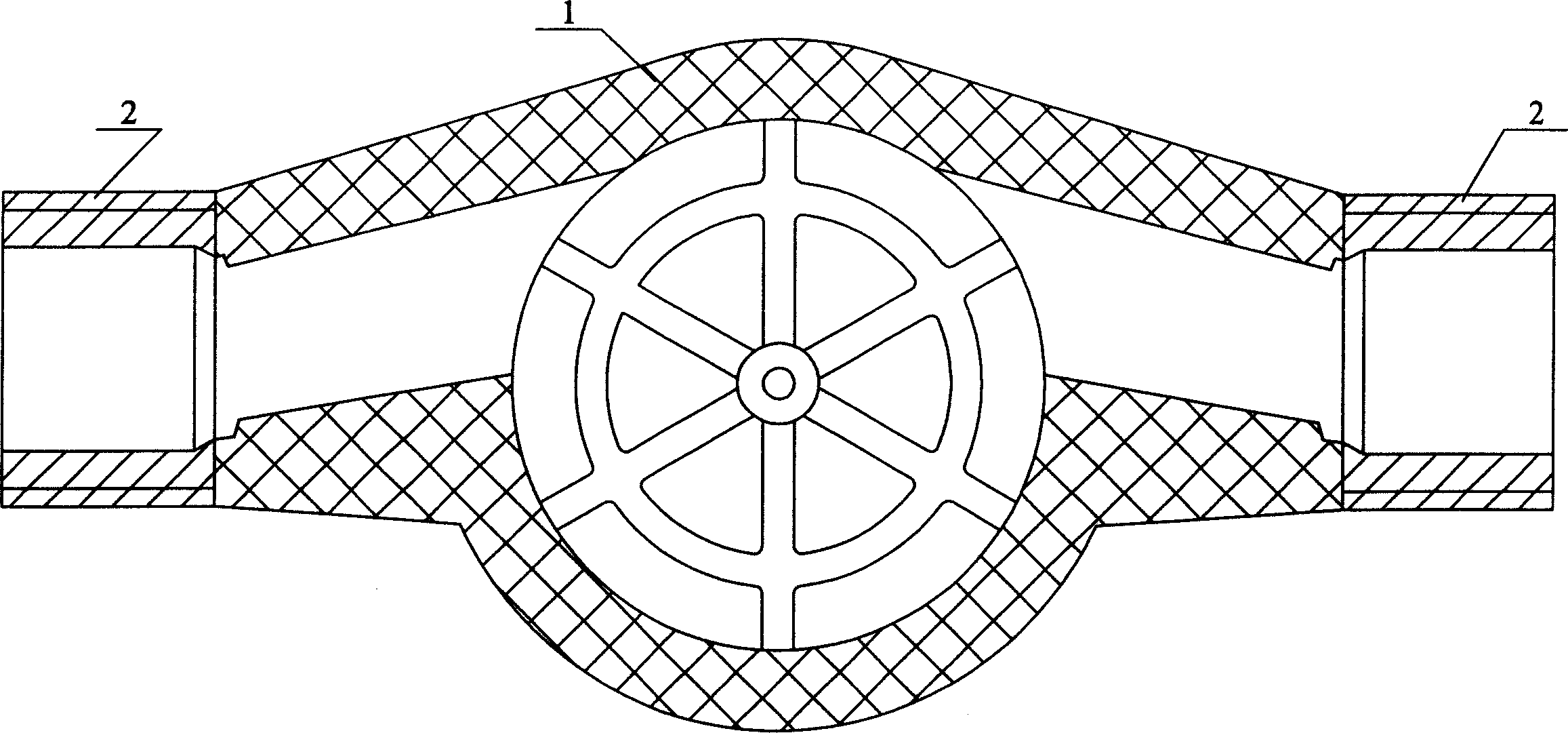

Flow instrument housing

The invention discloses shell of flow meter, which comprises plastic out shell (1) and connecting pipe fitting (2) connected to both sides of out shell (1). The out shell (1) and connecting pipe fitting (2) interconnect to each other and become an one part by injection molding. Connecting pipe fitting (2) is used to connect flow meter to liquid or gas transmission pipe with its impeller set directly in out shell (1); the inside surface of out shell (1) can be injection molding to structure and shape to support and locate the impeller; when the temperature of liquid or gas changes, plastic out shell (1) changes little and has no influence to impeller rotation and the measurement precision. The cost of plastic out shell is less than that of copper.

Owner:陶晓滨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com