Minitype piezoelectric telescopic element, compression wave measurement device and compression wave measurement method for centrifuge testing

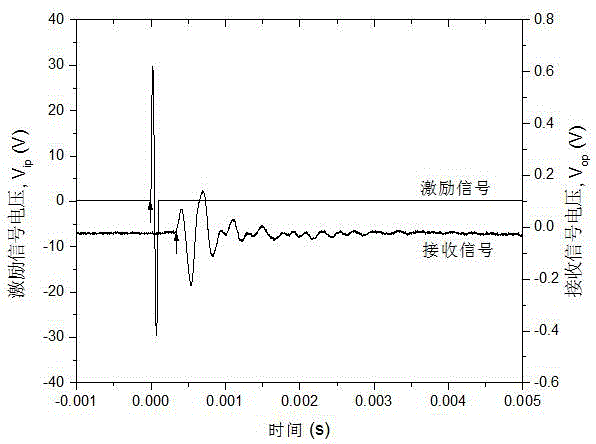

A technology of centrifuge and compression wave, which is applied in the direction of measuring device, using electric device, measuring ultrasonic/sonic wave/infrasonic wave, etc., can solve the problem that the measurement of the compression wave velocity of model soil samples cannot be effectively realized, and avoid geometric dissipation , simple device, large excitation displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

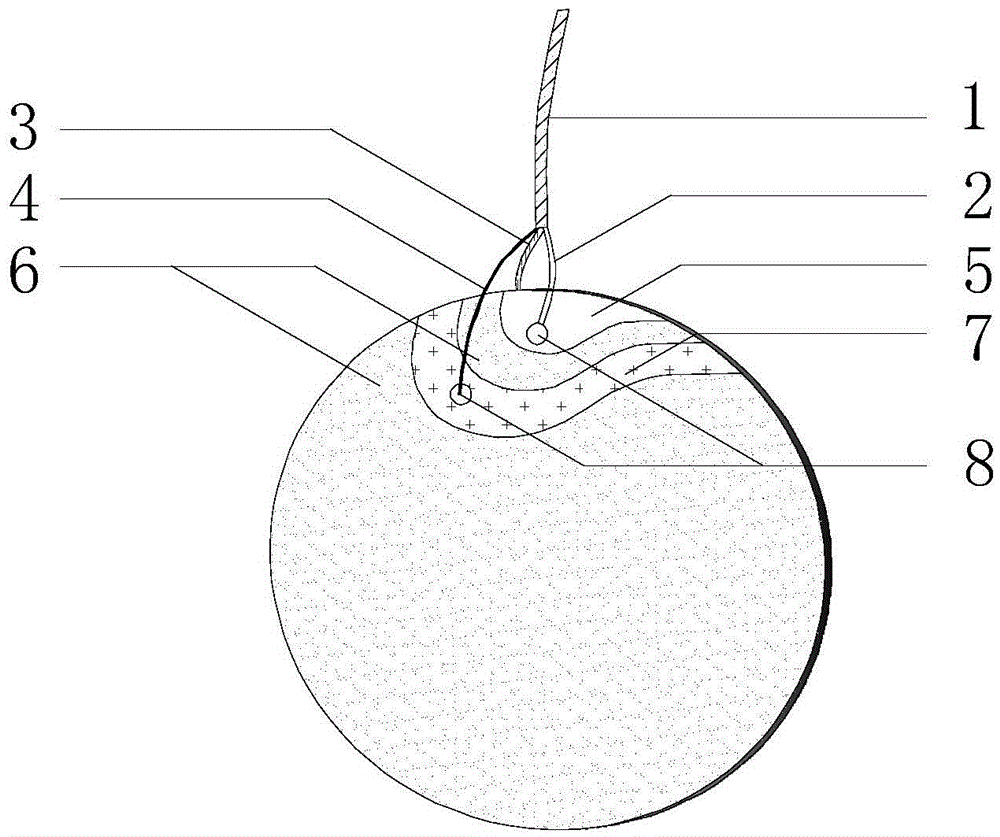

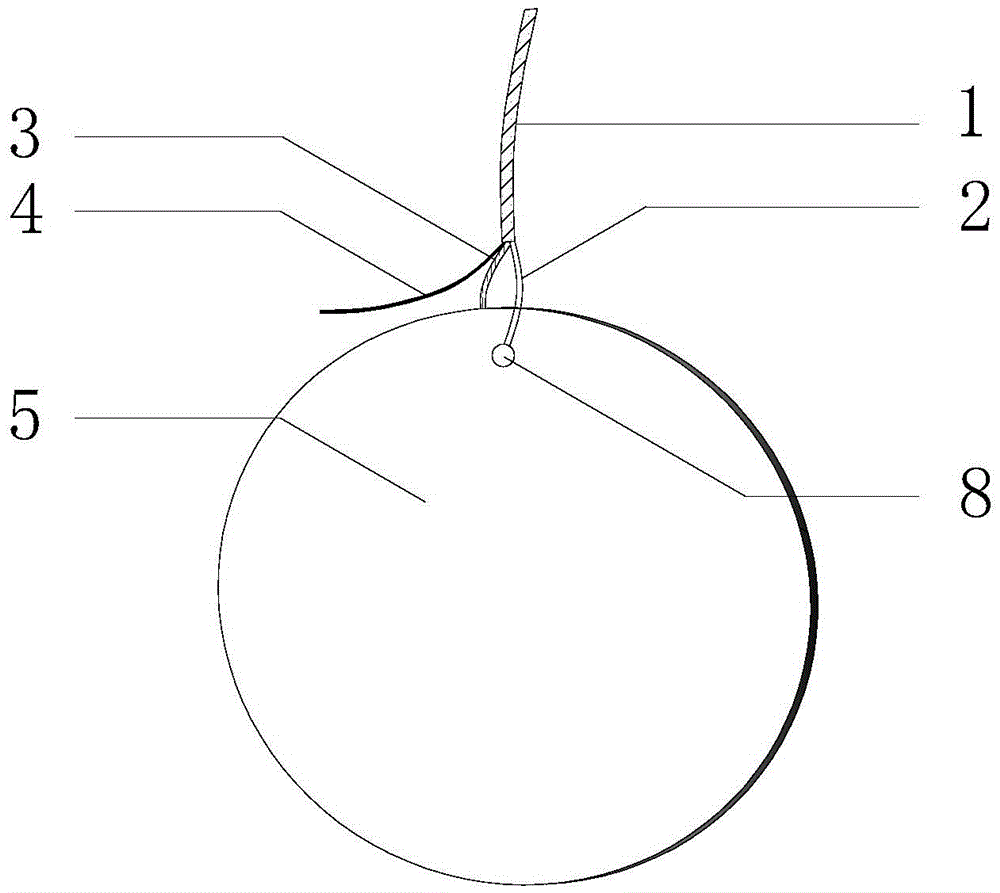

[0053] The present invention includes a tubular base 9 and a processed piezoelectric ceramic sheet 5, such as Figure 5 As shown, the side of the tubular structure of the tubular base 9 is provided with an axial strip groove, and the interior of the tubular base 9 is provided with an X-shaped support 10, such as image 3 As shown, the processed piezoelectric ceramic sheet 5 is fixed on one end surface of the tubular base 9 .

[0054] like figure 1 As shown, the processed piezoelectric ceramic sheet 5 includes a signal shielding wire 1 connected or wrapped on the piezoelectric ceramic sheet 5 , an epoxy resin layer 6 and a conductive copper tape 7 . like figure 2 As shown, the signal shielding wire 1 includes the positive wire 2 of the shielding wire, the negative wire 3 of the shielding wire, and the iron wire 4 of the shielding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com