A method for arranging the injection unit of the injector of a two-component liquid rocket engine

A liquid rocket and engine technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc. It can solve the problems that the accuracy of the jet is greatly affected, atomization and mixing are difficult, and machining methods are difficult to ensure accurate alignment. , to achieve the effect of improving mixing efficiency and high area utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

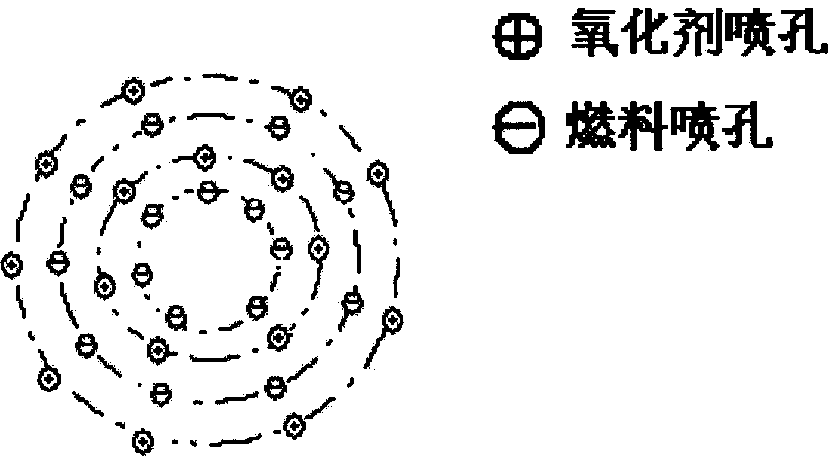

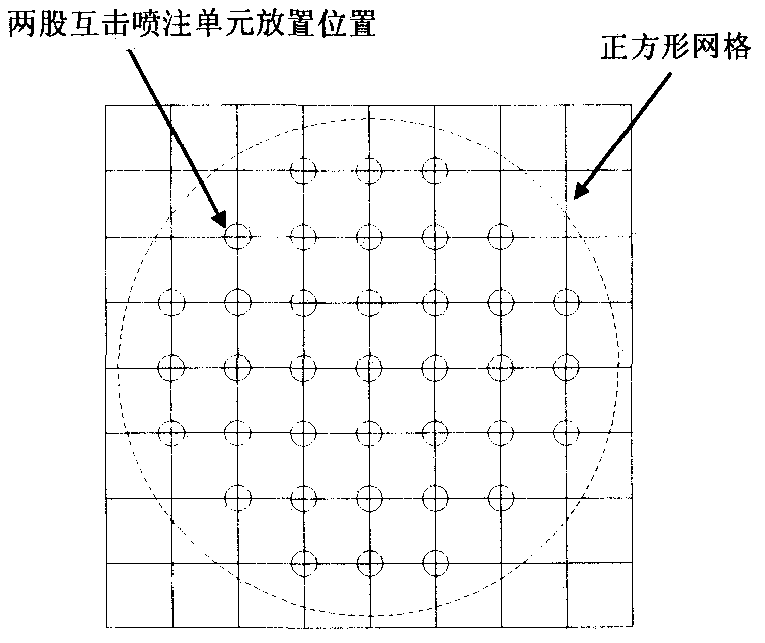

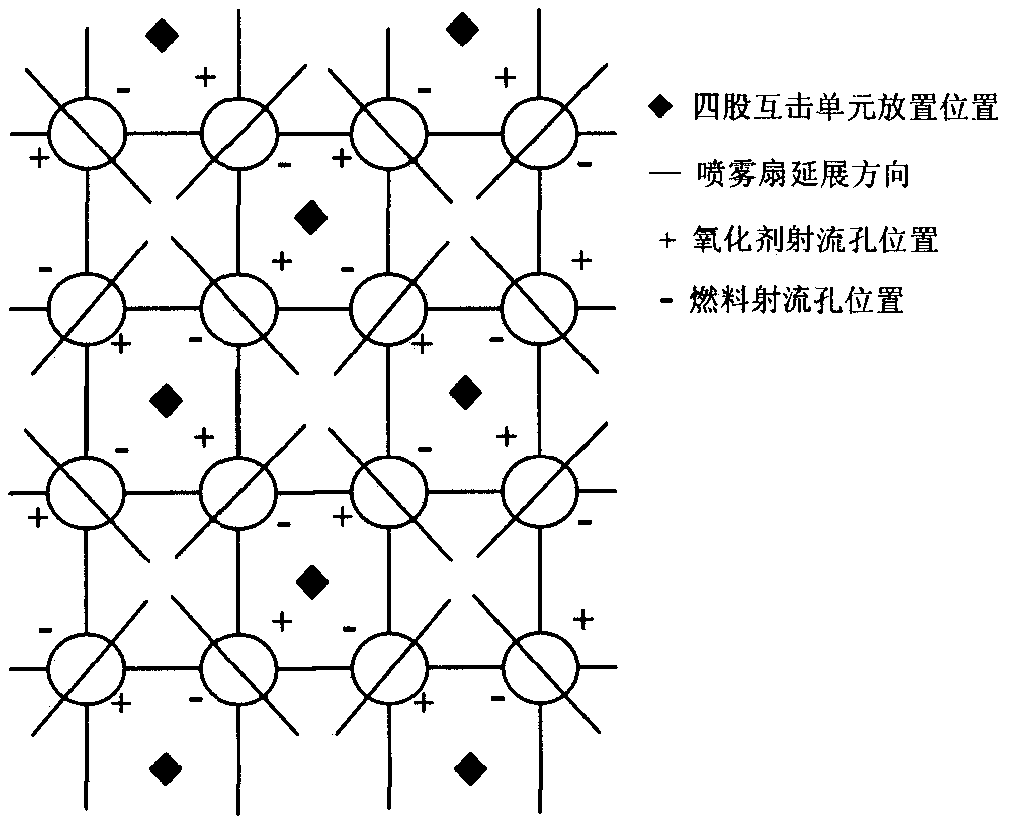

[0019] Such as figure 1 Shown is a schematic diagram of the arrangement of concentric circles of the injection units of the bicomponent liquid rocket engine injector in the prior art. In the figure, the arrangement method of the injection units in the prior art is to arrange the injection units in several concentric circles On each concentric circle, only injection holes of the same type of propellant components can be arranged, and the spray fan formed by these units can only be deployed along the concentric circle. And the present invention proposes such as Figure 2 ~ Figure 4 The arrangement method shown is to arrange the injection unit at the node and center of the square grid, and let the spray fan formed by the injection unit spread out in two directions of 45 degrees and 135 degrees, so that the same grid content The four-sided spray fan is used, and then the propellant component types of the nozzle holes in each injection unit are arranged in a staggered manner, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com