Novel maintenance-free screw post-disassembly type direct-drive extrusion device and operation method thereof

An extrusion device and maintenance-free technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems that the reducer is not in line with the development of the times, the space requirements of the workshop are large, and the product line conversion cycle is long. , to achieve the effect of improving the overall transmission efficiency, reducing raw material consumption, and high overall operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

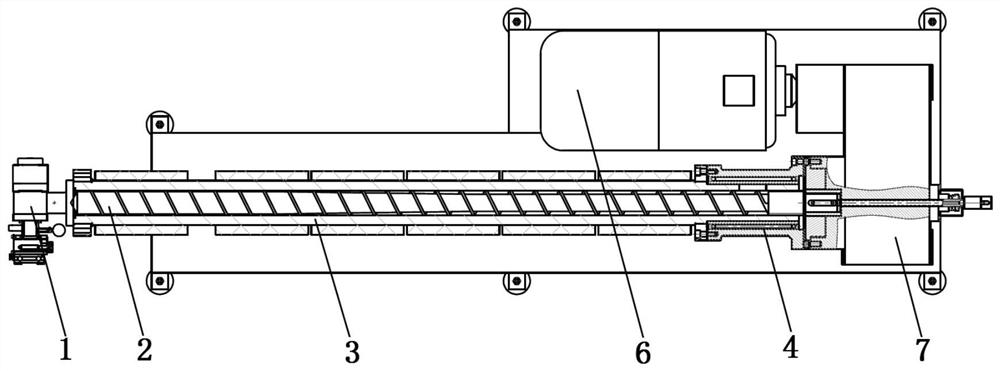

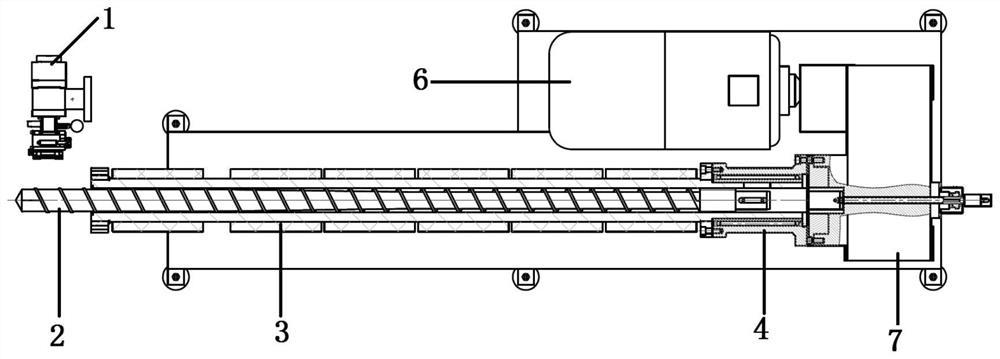

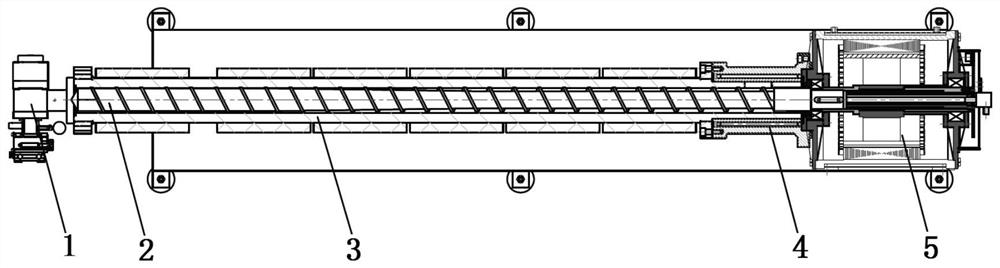

[0072] The new maintenance-free screw rear disassembly type direct drive extrusion device adopted in this embodiment includes: extrusion device head 1, extrusion screw 2, machine barrel 3, feeding part 4, hollow direct drive torque motor 5; Direct drive torque motor 5 comprises: motor main body 51; Motor shaft 52, it is positioned at described motor main body 51 inside, is hollow structure, is provided with stop nut 55 between described motor shaft 52 and described motor main body 51, can prevent The motor shaft 52 moves axially; the extrusion screw fitting 53 is located in the hollow structure of the motor shaft 52, and the extrusion screw fitting 53 and the motor shaft 52 are connected and fixed by connecting bolts 54 ; The motor driver drives and controls the rotational speed of the motor shaft 52;

[0073] The connection relationship of the above components is as follows:

[0074] One end of the extrusion screw 2 is connected to the extrusion screw adapter 53 inside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com