Ripple-forming externally-wrapped corrugated steel-concrete composite beam and construction method and application thereof

A technology of concrete and composite beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of building stability and seismic performance damage, composite beams lose bearing capacity, and reduce building integrity, etc., to achieve enhanced collapse resistance, The effect of overcoming the insufficient shear bearing capacity and increasing the shear capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A corrugated steel-concrete composite beam covered with waves

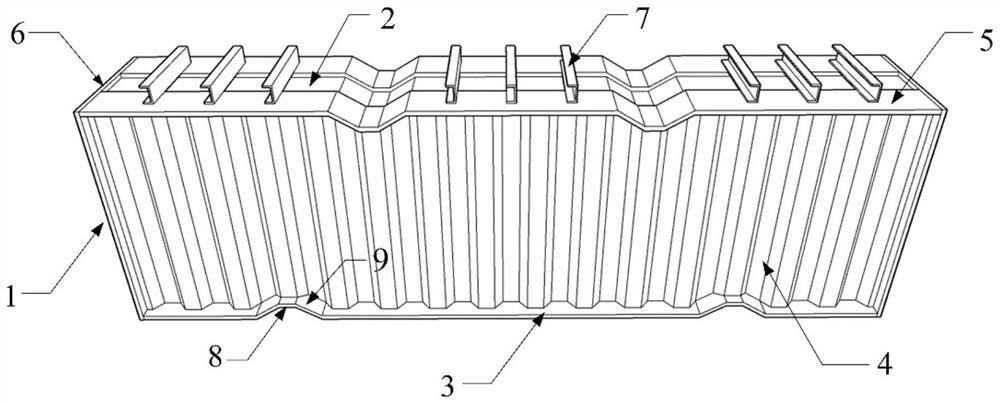

[0044] like Figure 1-3 , a corrugated steel-concrete composite beam covered with waves, comprising a steel skeleton 1 and corrugated concrete 2 filled inside the steel skeleton 1 .

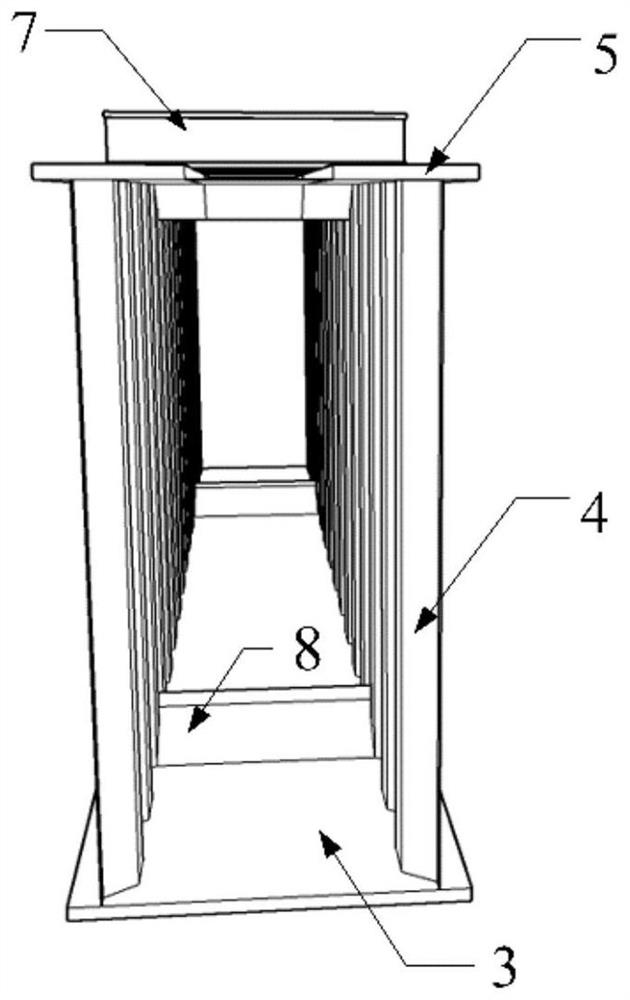

[0045] The steel skeleton 1 includes a corrugated bottom plate 3, two corrugated steel webs 4 distributed along the beam length direction and vertically connected to the corrugated bottom plate 3, parallel to the corrugated bottom plate 3 and vertically connected to the two corrugated webs 4 respectively two corrugated top plates 5, and two end plates 6 which are located at both ends of the composite beam and are vertically connected to the corrugated bottom plate 3, the corrugated web 4 and the corrugated top plate 5; the corrugated top plate 5 is welded with several Shear channel steel 7.

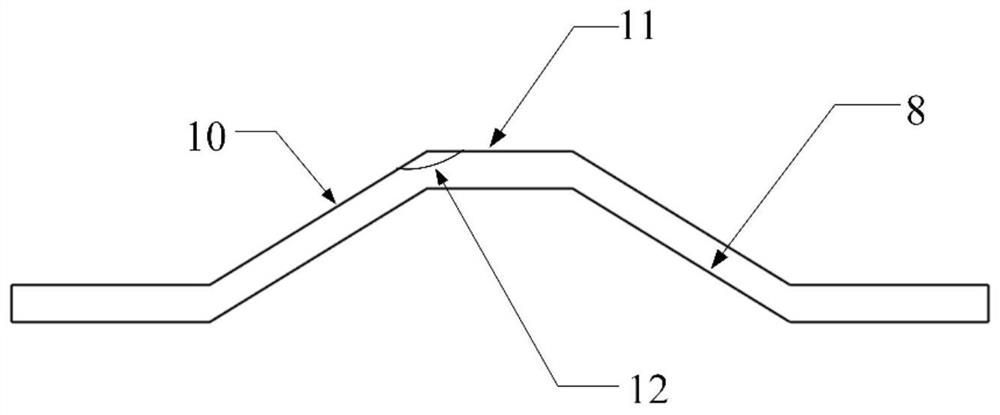

[0046] The corrugated bottom plate 3 is provided with an inverted "U"-shaped wave 8; the inverted "U"-shaped wave 8 is not ...

Embodiment 2

[0049] Example 2: Construction method of corrugated steel-concrete composite beam with corrugated outsourcing

[0050] Specific steps are as follows:

[0051] (1) Making steel skeleton 1

[0052] Corrugation is carried out on the corrugated bottom plate 3 and the corrugated top plate 5, and a notch matching the inverted “U”-shaped wave 8 is cut on the corrugated web 4 corresponding to the inverted “U”-shaped wave 8. The cut corrugated web 4 is vertically welded on both sides of the corrugated bottom plate 3, and no welding is performed at the inverted "U"-shaped corrugation 8. The corrugated top plate 6 is vertically welded above the corrugated web 4, and the inverted “U”-shaped wave 8 on the corrugated top plate 6 is not welded. Weld the shear channel steel 7 to the two corrugated top plates 5, the welding method of the shear channel steel 7 is: between the inverted "U" wave 8 or between the inverted "U" wave 8 and the end plate 6 Three shear-resistant channel steels 7 are...

Embodiment 3

[0055] Example 3: Detection of corrugated steel-concrete composite beams with corrugated outsourcing

[0056] Specific steps are as follows:

[0057] Using C40 ordinary concrete as the corrugated concrete material, Q345 as the steel material, and non-stick film of plastic material, referring to Examples 1-2, a corrugated steel-concrete composite beam covered with corrugation was prepared. Among them, the span of the corrugated steel-concrete composite beam covered with corrugations is 3.6m, and the section size is 200mm×520mm; the section size of the corrugated bottom plate is 220mm×4mm; the section size of the web plate is 450mm×3mm; It is 80mm×6mm; the size of the end plate is 220mm×460mm×6mm; there are two inverted “U” waves on the corrugated bottom plate, one of which is between the center of the inverted “U” wave and the closer end plate The distance between the other inverted "U" wave and the closer end plate is one-fifth of the beam length; the wave top plate is also p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com