Middle plate construction method of wide pit top-down construction

A construction method and reverse method technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of unfavorable control of foundation pit deformation, control of enclosure structure deformation, and large loss during construction, so as to reduce unsupported exposure time , speed up the construction progress, the effect of speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

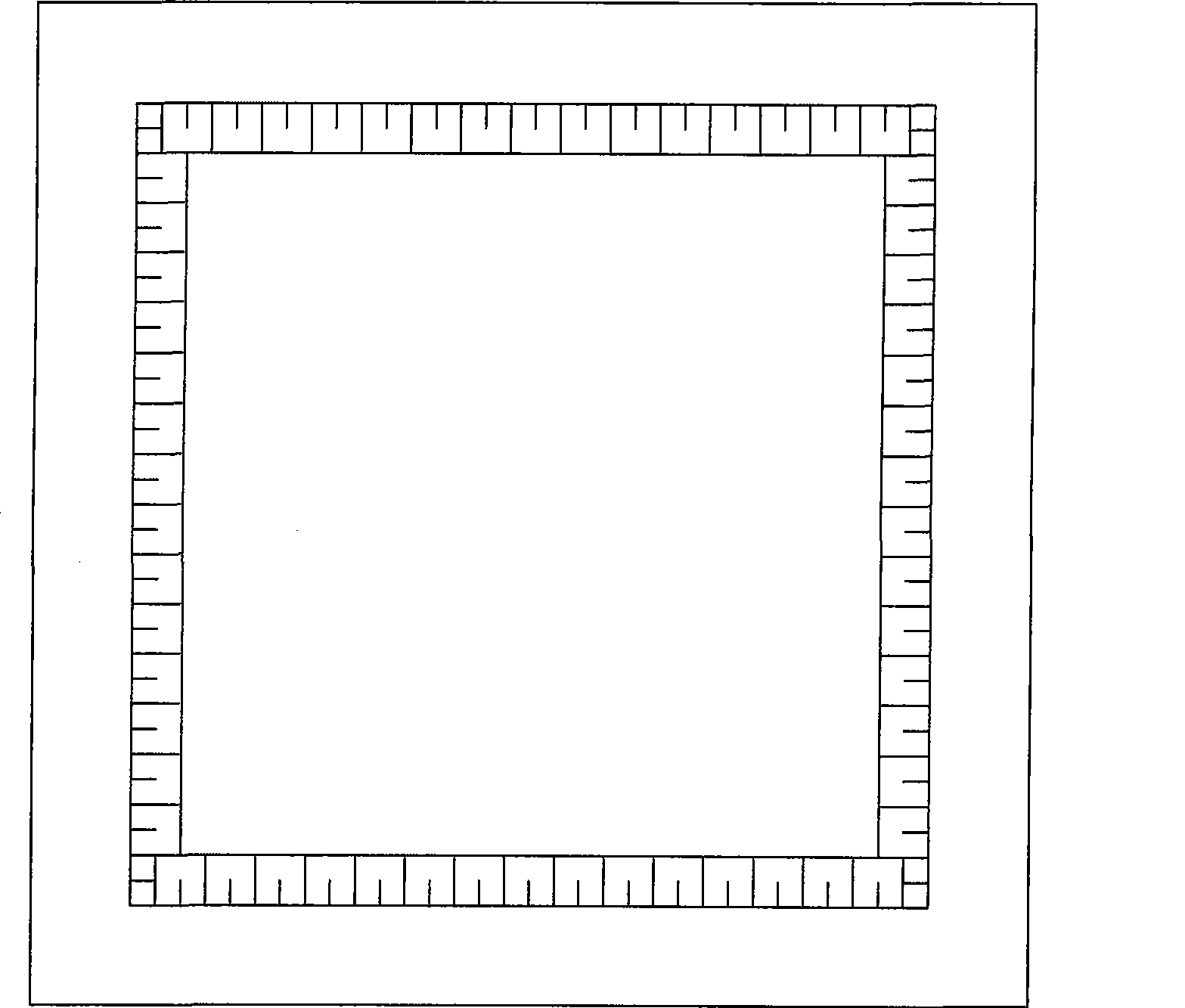

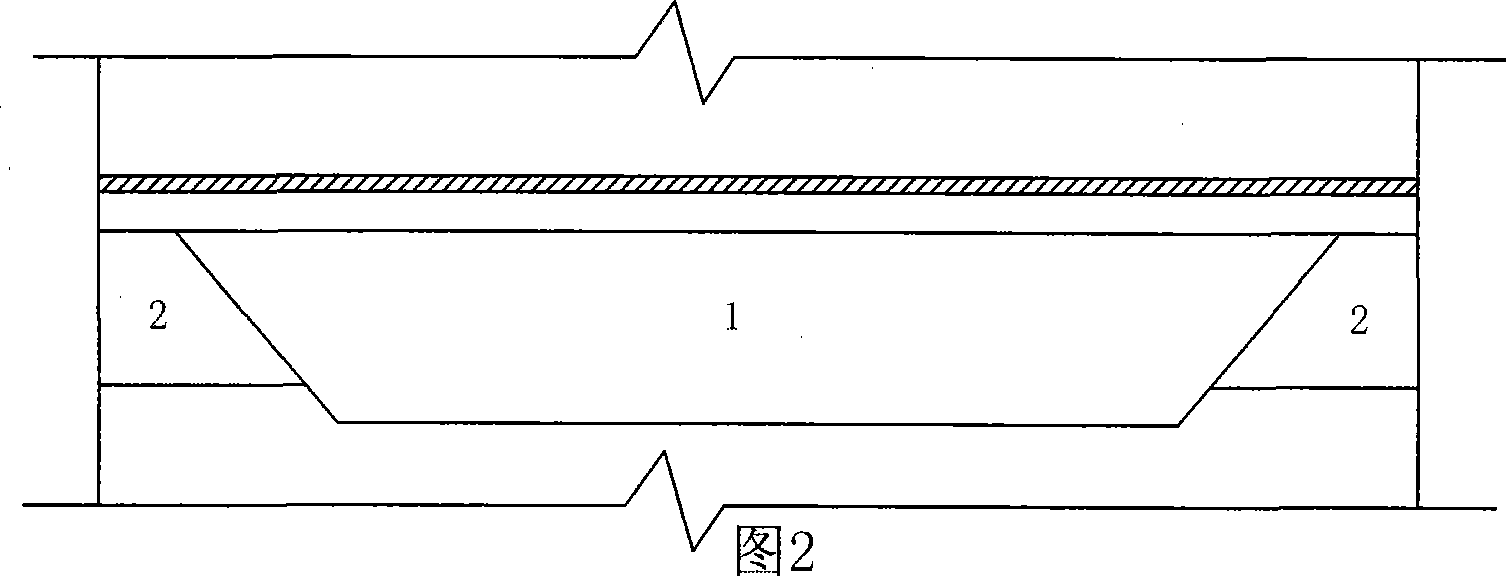

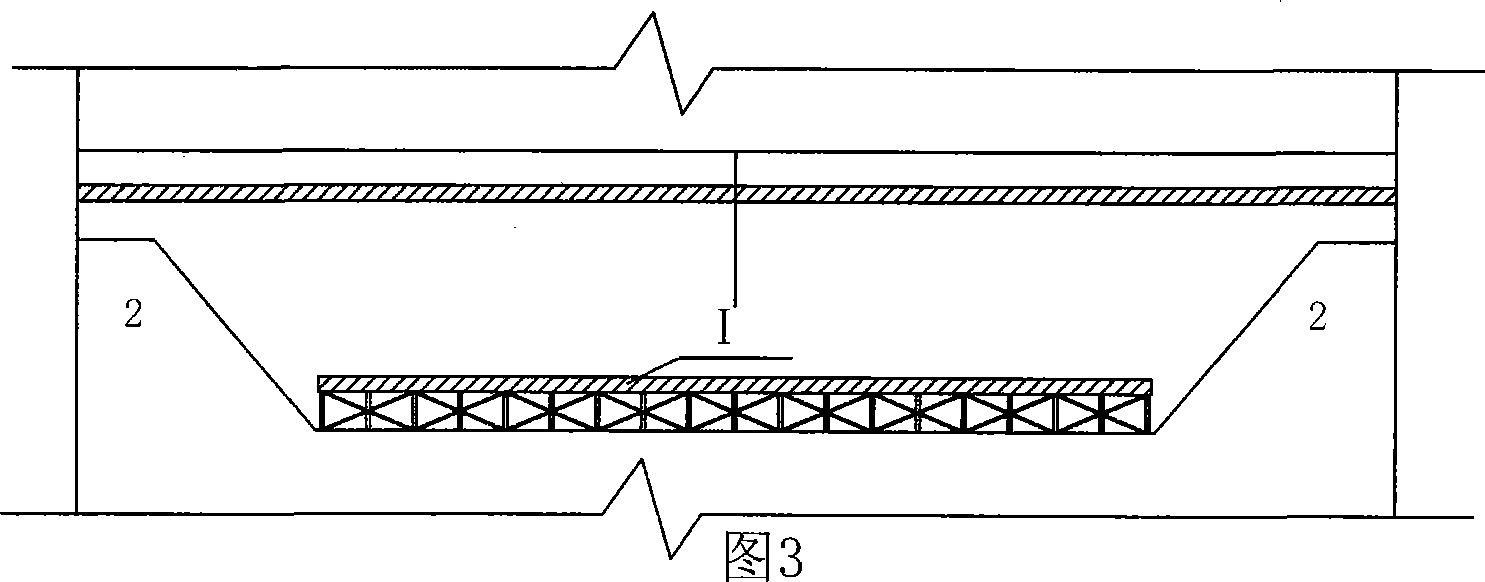

[0021] Such as Figure 1~6 , where the labels respectively indicate: soil 1 located in the center of the foundation pit, soil 2 located in the side span of the foundation pit, middle plate I located in the middle part, middle plate II located in the side span, and plate II-1 ~Plate II-5 represent the construction sequence of side span middle slab respectively.

[0022] In this embodiment, the soil 1 in the middle part of the foundation pit is excavated first, and the soil platform 2 with a width of 8 to 10 m is reserved near the enclosure structure, that is, the side span part. Match the length of the steel pipes, then pour the cushion in the middle part of the foundation pit, use 1.8-2.0m long steel pipe brackets to support the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com