Device for sealing a cup comprising foil with a cover sheet

A technology of forming film and covering film, which is applied in the field of forming film devices, can solve the problems of expensive and other problems, and achieve the effect of simple manufacture and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

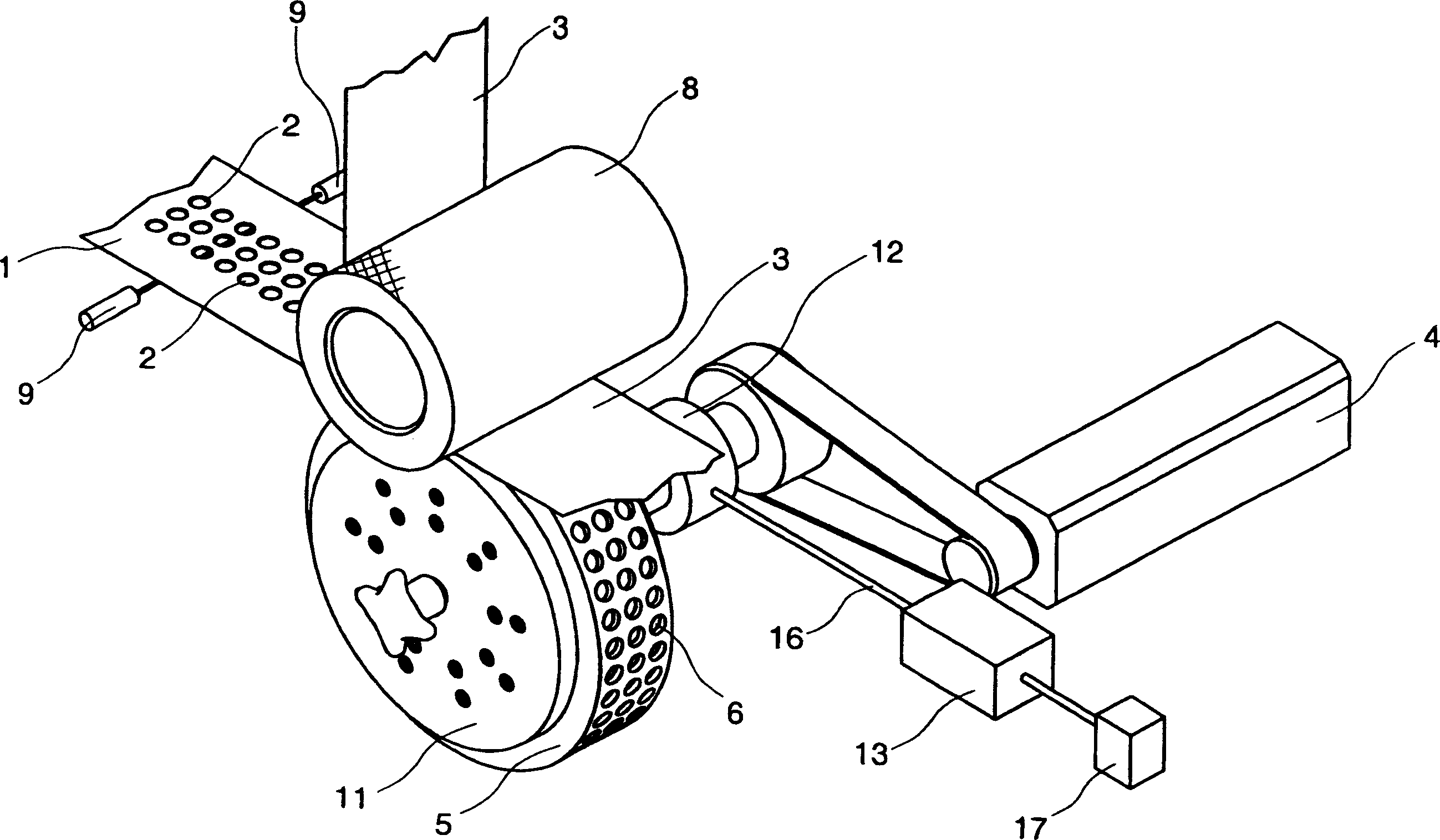

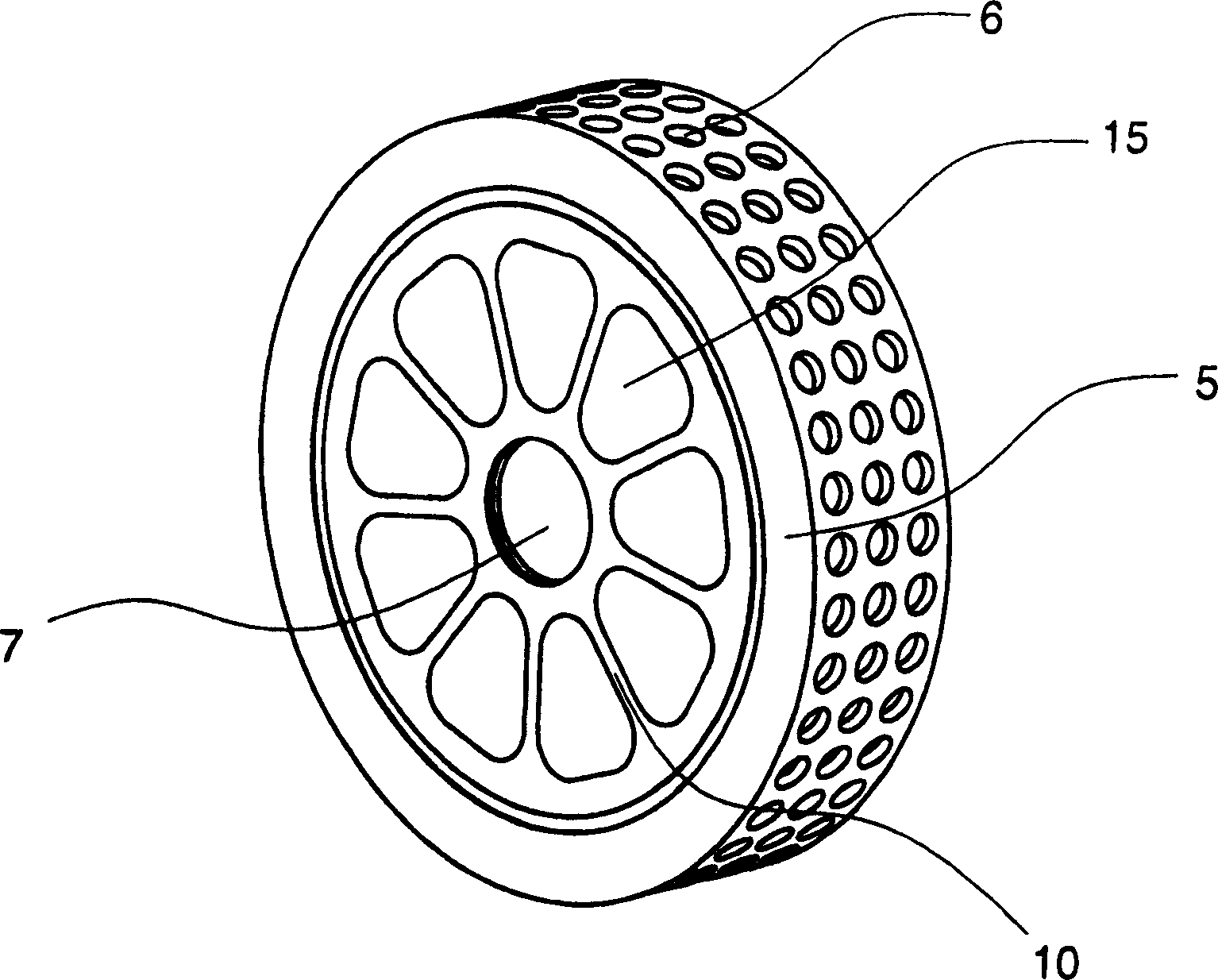

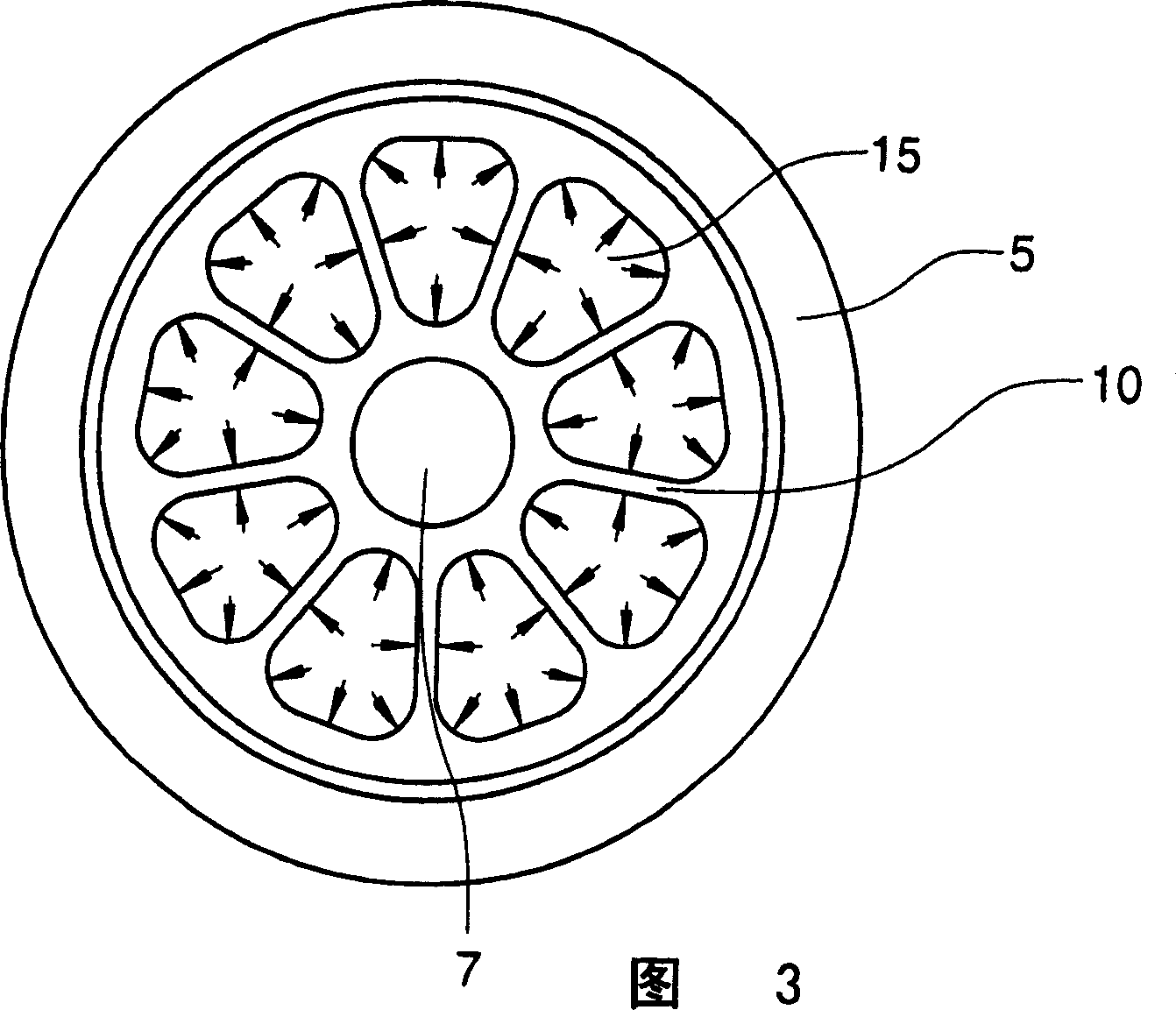

[0022] The drawing shows a device which is used for sealing a molded film 1 with a filled basin 2 with a covering film 3, wherein not only the forming film 1 but also the covering film 3 is not shown in the drawing Provided on the supply roll and guided if necessary by means of guide rolls between a heatable sealing roll 8 and a feed roll 5 . The feed roller 5 is drivable by means of a roller drive 4 and has recesses 6 for forming the pockets 2 of the film 1 on its peripheral surface. as specifically from figure 2 As can be seen in 3 and 3, a pressure chamber 15, which in the exemplary embodiment shown is several, is provided in the feed roller 5. The pressure chamber 15 is connected via a pressure medium line 16 to a pressure medium source 17 . The feed roller 5 consists of a material with a small modulus of elasticity (E-modulus), which is significantly smaller than, for example, the E- modulus. Plastics and among them especially polytetrafluoroethylene (PTFE) can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com