Roofing rigid waterproof layer structure and construction method thereof

A rigid waterproof and multi-layer structure technology, which is applied to roof cladding, roofing, and roofs using flat/curved panels, etc., can solve the problems of easy aging of waterproof coiled materials and caulking materials, long-term moisture in the waterproof layer that cannot be discharged, and dust accumulation on the floor Waterlogging and other problems, to achieve the effect of good development prospects, simple structure, small compression volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

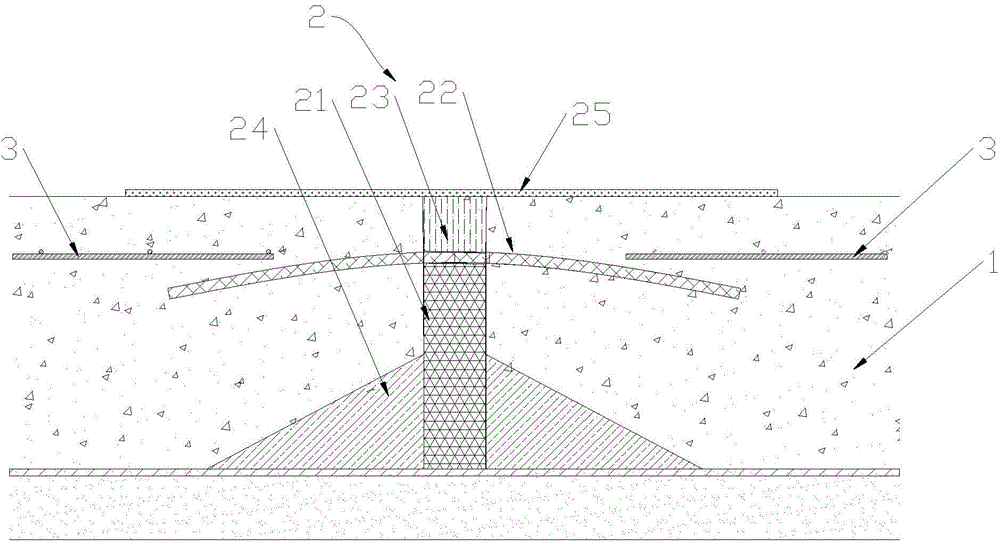

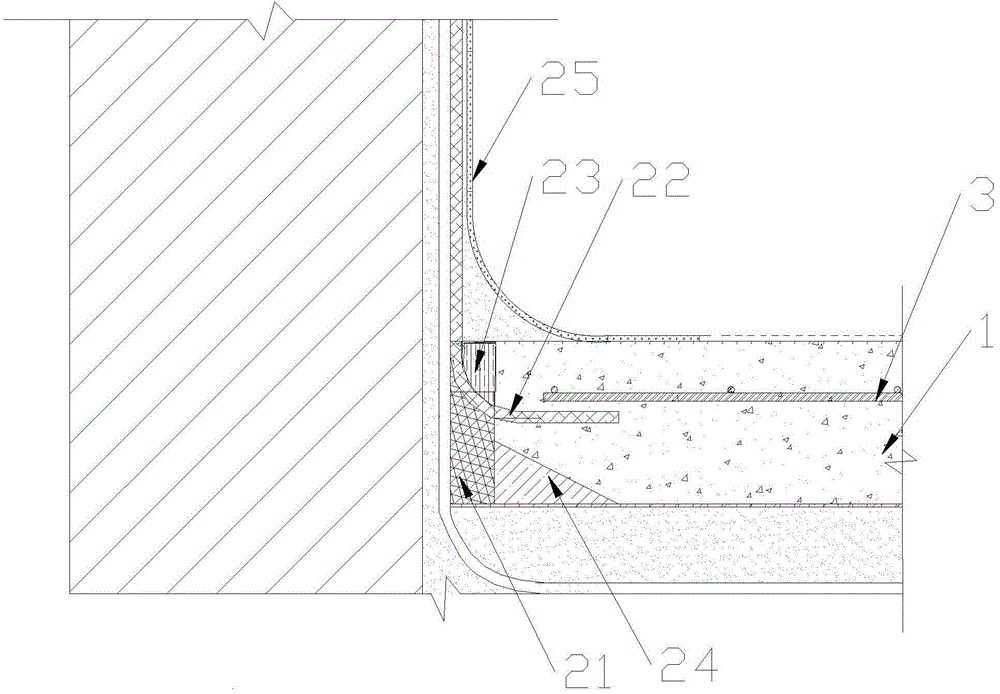

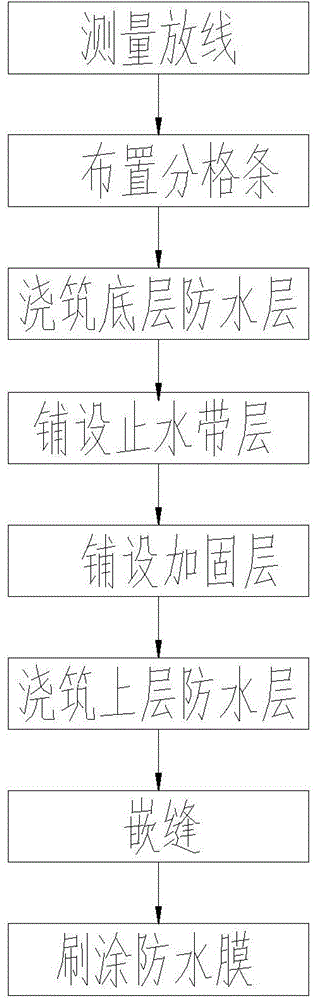

[0029] Such as image 3 Shown, the invention provides a kind of construction method of roof rigid waterproof layer structure, concrete steps are as follows:

[0030] (1) Measuring and setting-out: the control line of the grid joint is popped up at the deformation-sensitive parts such as the support end of the roof panel with large deformation and easy deformation, the roof turning point, the junction of the waterproof layer and the protruding roof structure, and several control lines are horizontal and vertical. The roof is divided into multiple rectangular areas by staggering. At the same time, corresponding marking lines should be made on the wall. The distance between any two adjacent control lines should be within 3-6m. No more than 3m.

[0031] (2) Arranging grid strips: Select qualified phenolic boards or other materials with a thickness of 10-30mm, and cut them into grid strips with a width of 35-40mm (design board thickness minus 10mm), and set the board To thicken t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com