Corrugated box beam

A wave box and box girder technology, applied in the direction of bridges, structural elements, building components, etc., can solve the problems of building stability and seismic performance damage, reduce building integrity, and poor bonding, etc., to achieve enhanced collapse resistance Ability, suppression of local buckling or overall instability, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: A corrugated box girder

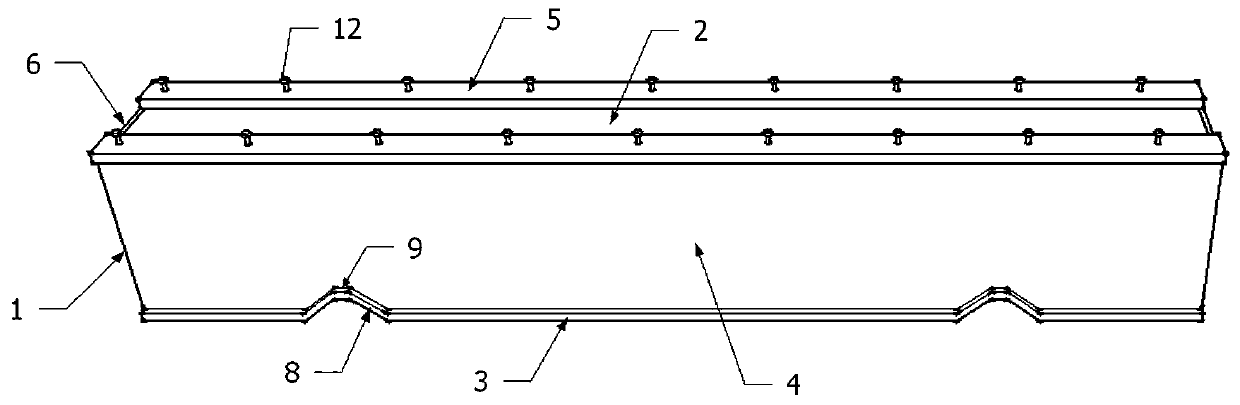

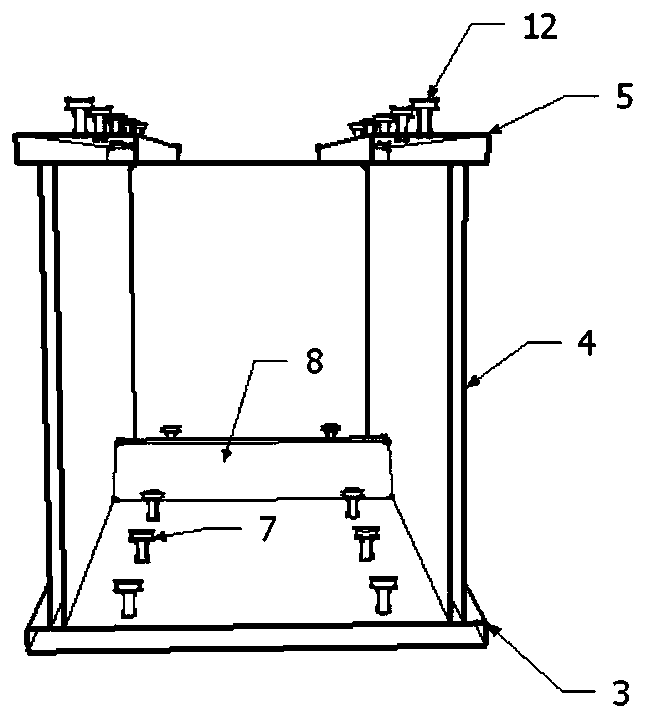

[0051] Such as Figure 1-3 , a corrugating box girder comprising a steel frame 1 and rectangular concrete 2 filled inside the steel frame 1;

[0052] The steel skeleton 1 includes a corrugated floor 3, two webs 4 distributed along the length direction of the beam and vertically connected to the corrugated floor 3, and two webs 4 parallel to the corrugated floor 3 and vertically connected to the two webs 4 respectively. Cover plate 5, and two partition plates 6 located at both ends of the box girder and vertically connected to the corrugated bottom plate 3, web plate 4 and cover plate 5 at the same time;

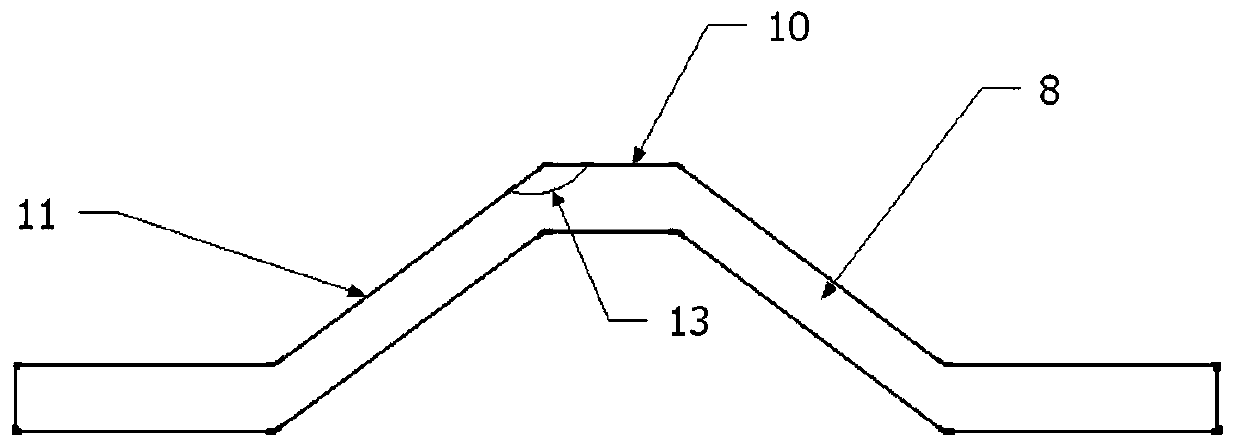

[0053] The wave bottom plate 3 is connected with a number of first bolts 7 built into the rectangular concrete 2 and the wave bottom plate 3 is provided with an inverted "U"-shaped wave 8; the inverted "U"-shaped wave 8 is not in contact with the The plates 4 are connected; the inverted "U" wave 8 is separated from the rectangu...

Embodiment 2

[0067] Embodiment 2: A construction method of corrugated box girder

[0068] Specific steps are as follows:

[0069] (1) Perform corrugation on the corrugated bottom plate 3 and arrange the first bolts 7 on the corrugated bottom plate 3, cut the web 4 according to the design of the inverted “U” wave 8, and cut the web 4 Vertically welded on both sides of the corrugated bottom plate 3, no welding is performed at the 8 inverted "U"-shaped waves, the cover plate 5 is vertically welded on the top of the web plate 4, and the partition plate 6 is vertically welded to the corrugated bottom plate 3 and the web plate 4. The two ends of the cover plate 5 obtain the steel skeleton 1;

[0070] (2) Cover the non-stick film 9 on the inverted "U" wave 8, and pour rectangular concrete 2 inside the steel skeleton 1 to obtain the corrugated box girder.

Embodiment 3

[0071] Example 3: Detection of a corrugated box girder

[0072] Specific steps are as follows:

[0073] Use C40 ordinary concrete as the material of the rectangular concrete, Q345 steel as the material of the steel skeleton, select the first bolt and the second bolt of the model of M20*90 outer hexagonal hot-dip galvanized bolts, and select the non-stick film of plastic material, according to the embodiment 1-2. Prepare a corrugated box girder.

[0074] The span of the corrugated box girder is 5m, and the section size is 250mm×500mm; the section size of the corrugated bottom plate is 250mm×10mm; the section size of the web plate is 480mm×6mm; the size of the cover plate is 75mm×8mm; the size of the partition It is 200mm×500mm×10mm; there are two inverted “U”-shaped waves on the corrugated bottom plate, and the distance between the center of one inverted “U”-shaped wave and the closer partition is one-fifth of the beam length , the distance between another inverted "U" wave a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com