Oscillating ink device of offset machine

An offset printing press and ink roller technology, which is used in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of large and unadjustable string momentum, unadjustable string momentum, complex structure, etc., and achieves good ink string effect. , The structure is simple, the effect of improving the quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed description in conjunction with the attached drawings;

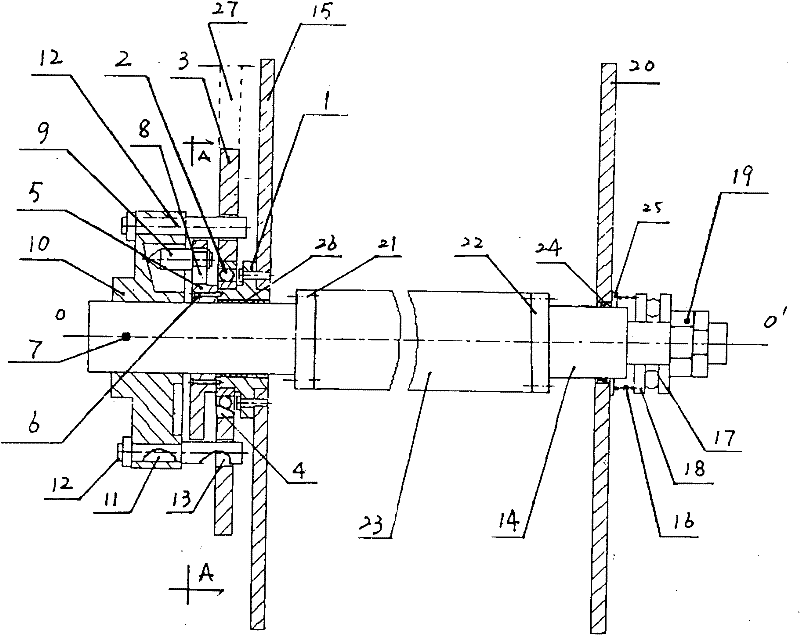

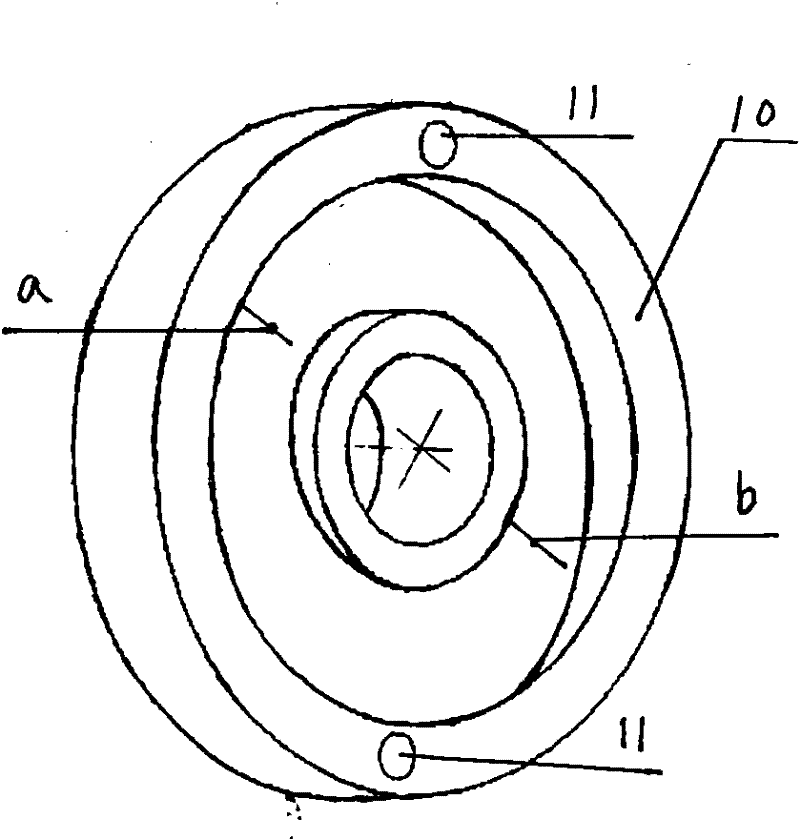

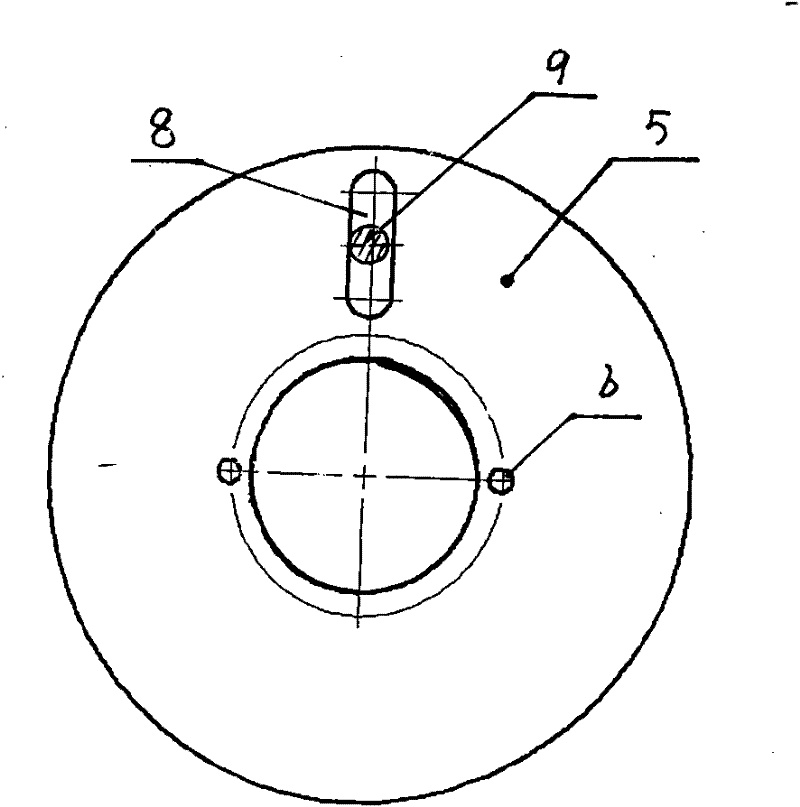

[0014] Such as figure 1 , 2 As shown, the left wall plate 15 is equipped with a bearing seat 1, the inner ring of the bearing 2 is installed on the bearing seat 1, the outer ring of the bearing 2 is installed in the center hole 4 of the inking gear 3, and the matching disc 5 is passed through the screw 6. Installed on the left end surface of the bearing seat 1; the cylindrical cam mechanism is that the left half shaft 7 slides through the left wall plate 15 and at the same time passes through the concentric matching center holes of the bearing seat 1 and the disc 5. The disc 5 has a The radial strip hole 8, in which a position-adjustable push rod 9 is installed, the left end of the push rod 9 is in contact with the contour on the end surface of the cylindrical cam 10, and the cylindrical cam 10 is installed at the end of the left half shaft 7, The cylindrical cam 10 has two symmetrically distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com