Automatic 3D film attaching device for mobile phone

A film sticking device and automatic technology, which is applied in packaging and other fields, can solve problems such as product capacity limitations and product quality difficulties, and achieve the effects of improving film sticking efficiency, convenient operation, and ensuring transmission accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

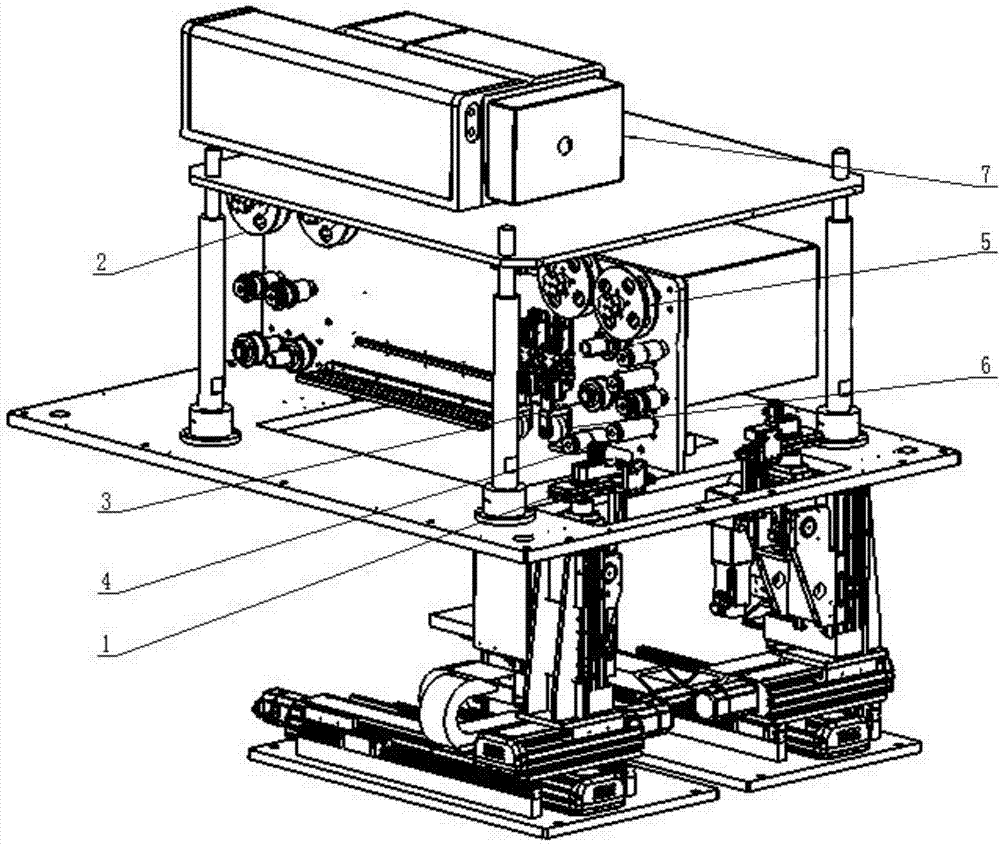

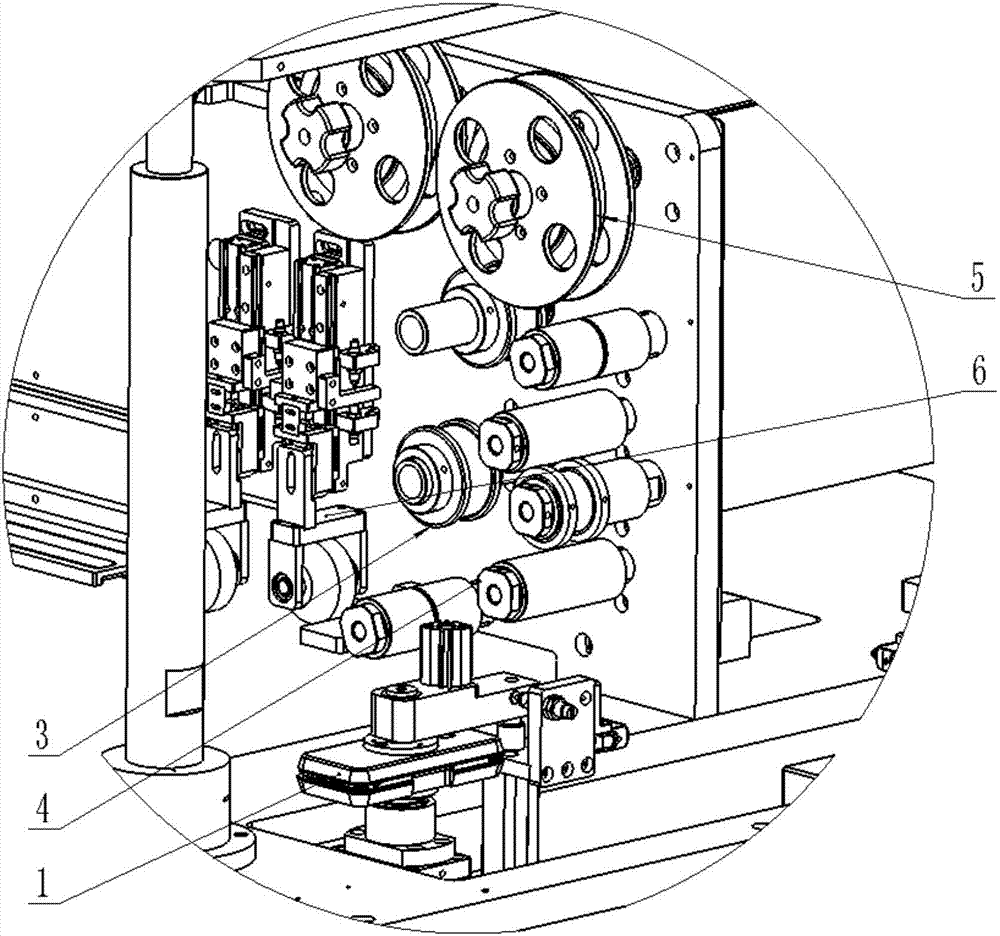

[0033] Such as figure 1 , figure 2 , Figure 11 As shown, the mobile phone automatic 3D film sticking device of the present invention includes: 1. Film sticking rotating assembly; 2. Discharging tray assembly; 3. Servo motor traction film assembly; 4. Material belt tension control roller assembly; 5. Receiving tray assembly; 6 , Laminating head assembly; 7, Laser cutting film assembly; 8, CCD detection assembly.

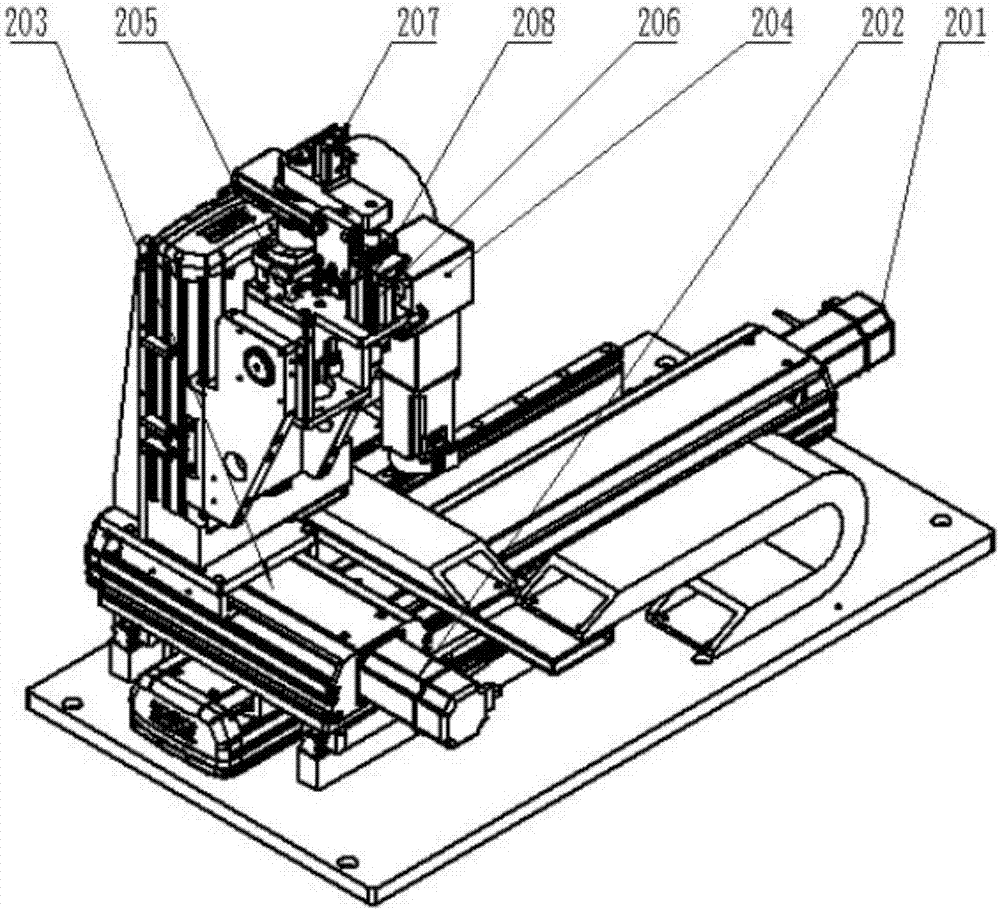

[0034] Such as image 3 As shown, the film rotation assembly includes: 201, X-axis motion servo module; 202, Y-axis motion servo module; 203, Z-axis motion servo module; 204, jig flipping servo module; 205, jig rotation servo Module; 206, rotary cylinder pressing mechanism; 207, upper pressing plate positioning mechanism; 208, reflective photoelectric sensor.

[0035] Such as Figure 4 As shown, the discharge tray assembly includes: 301, a magnetic powder brake; 302, a lock nut; 303, a bearing; 304, a tape chuck; 305, a knob; 306, a film roll.

[0036] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com