Soft extraction paper slitting device

A soft drawer and mounting frame technology, which is applied in the directions of transportation and packaging, thin material handling, and sending objects, can solve the problems of low cutting efficiency, hidden safety hazards, and high cost, so as to ensure transmission accuracy and transmission speed, and prevent transmission accuracy , to ensure the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

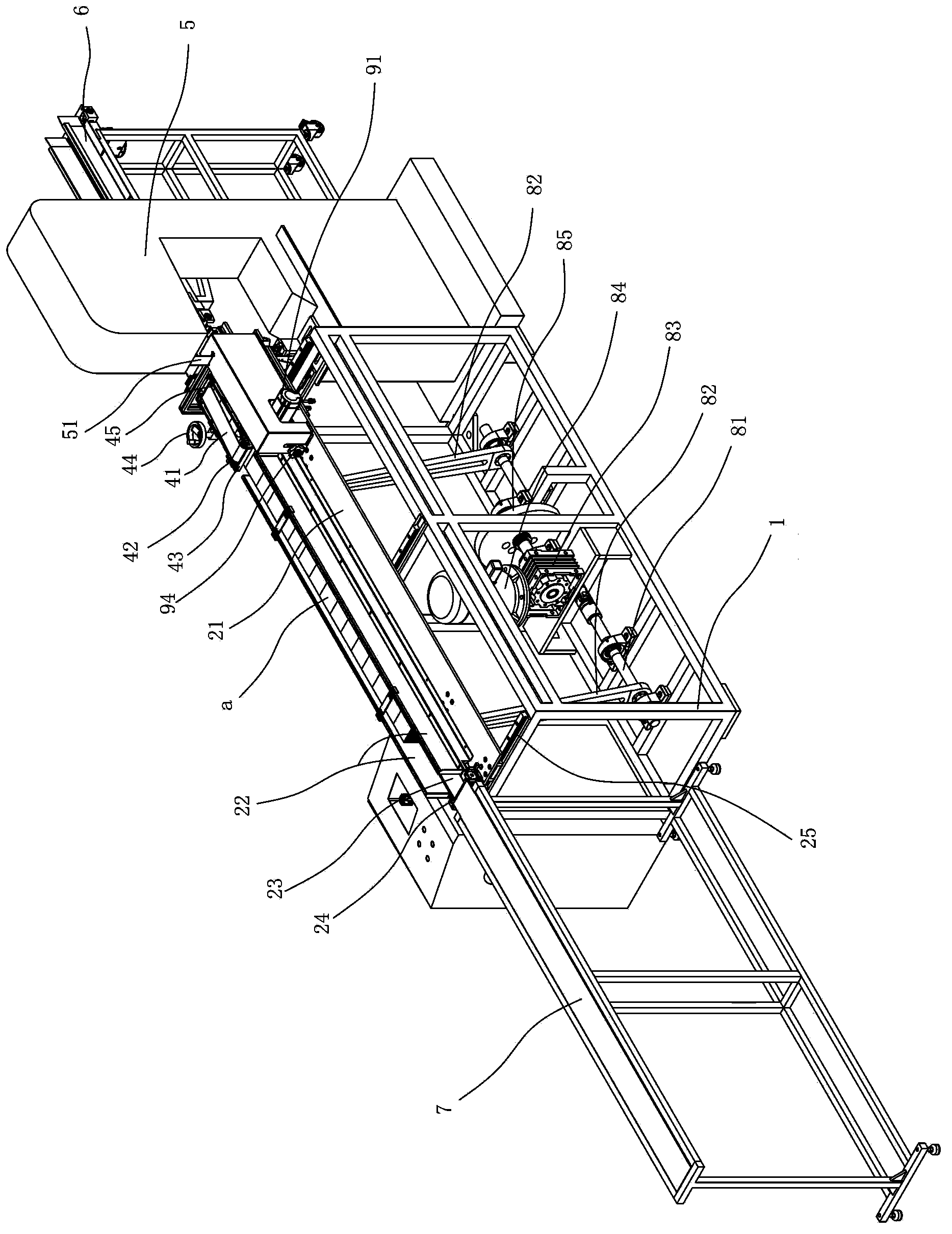

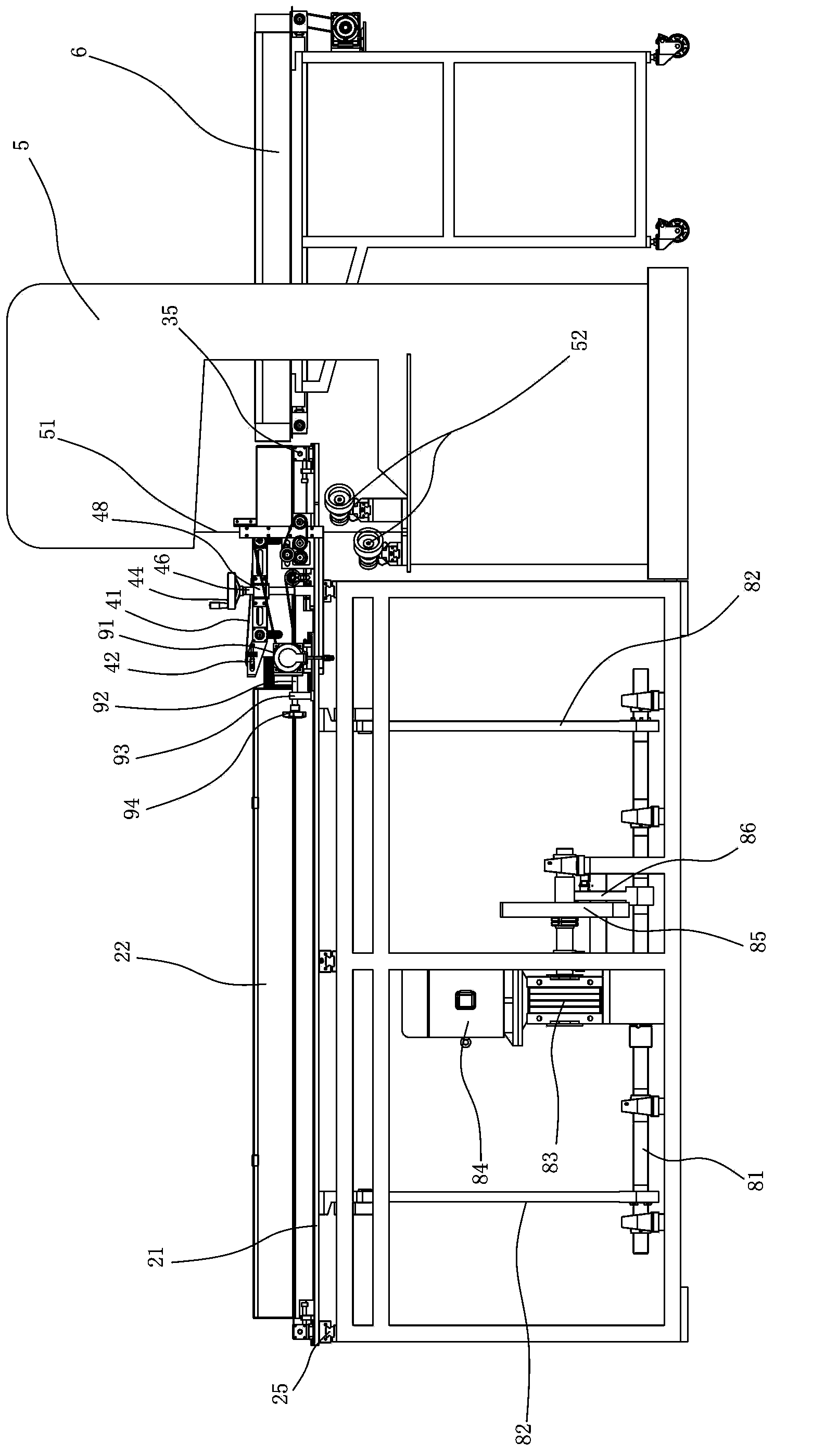

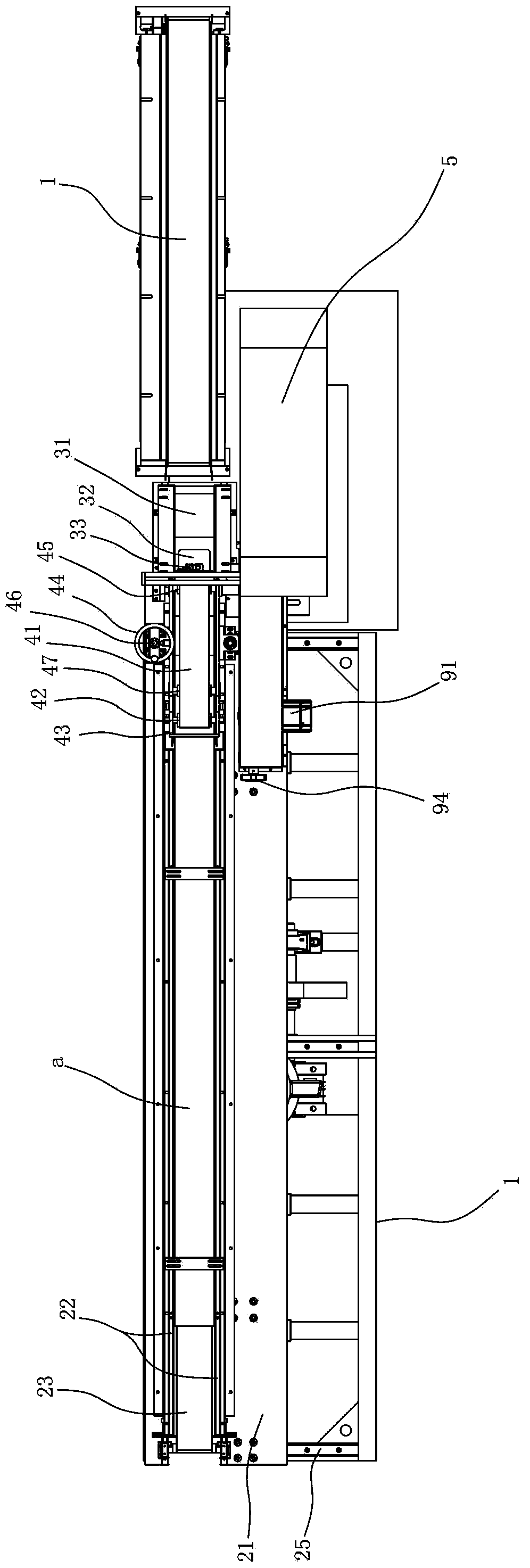

[0030] refer to Figure 1 to Figure 10 As shown, a soft paper cutting device includes a soft paper feeding rack 7, a frame 1, a band saw machine 5, an intermittent paper feeding mechanism that can slide vertically and horizontally on the frame 1, and is arranged on the The frame 1 is connected with the main driving mechanism for driving the intermittent paper feeding mechanism to reciprocate longitudinally and horizontally, the discharge conveying device 6 and the control device connected with the intermittent paper feeding mechanism, the band saw machine 5 and the main driving mechanism respectively.

[0031] The intermittent paper feeding mechanism includes three guide rails 25 arranged longitudinally and horizontally on the frame 1, a sliding seat 21 movably arranged on the guide rails 25, and horizontally arranged on the sliding seat 21 to transport the soft paper a to the band saw The first belt conveying mechanism at the position of machine 5, the second belt conveying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com