Multifunctional V-belt fatigue test machine

A fatigue testing machine, multi-functional technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of high failure rate, low test accuracy, low test efficiency, etc., and achieve work stability guarantee and control The effect of improving precision and ensuring test precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

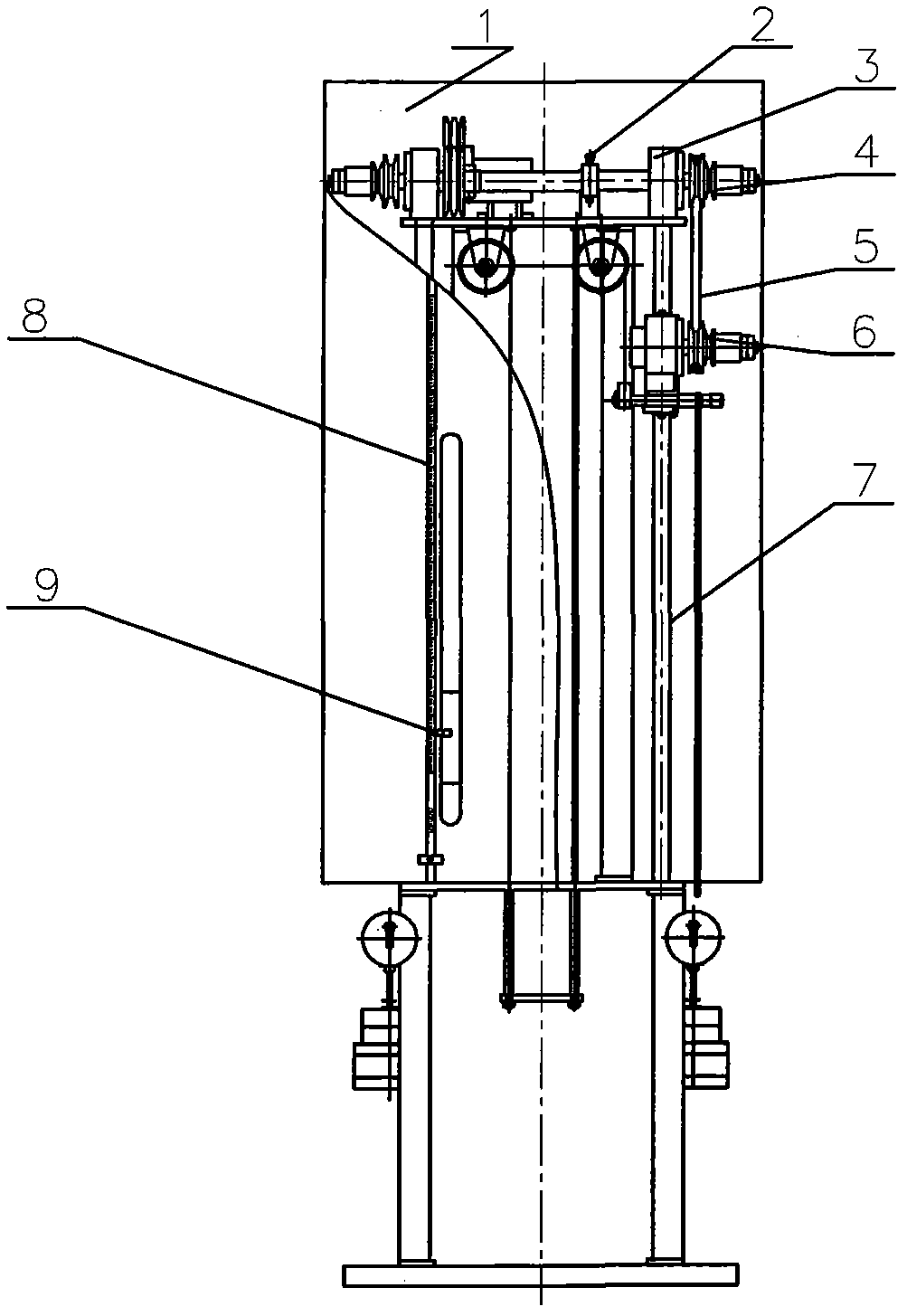

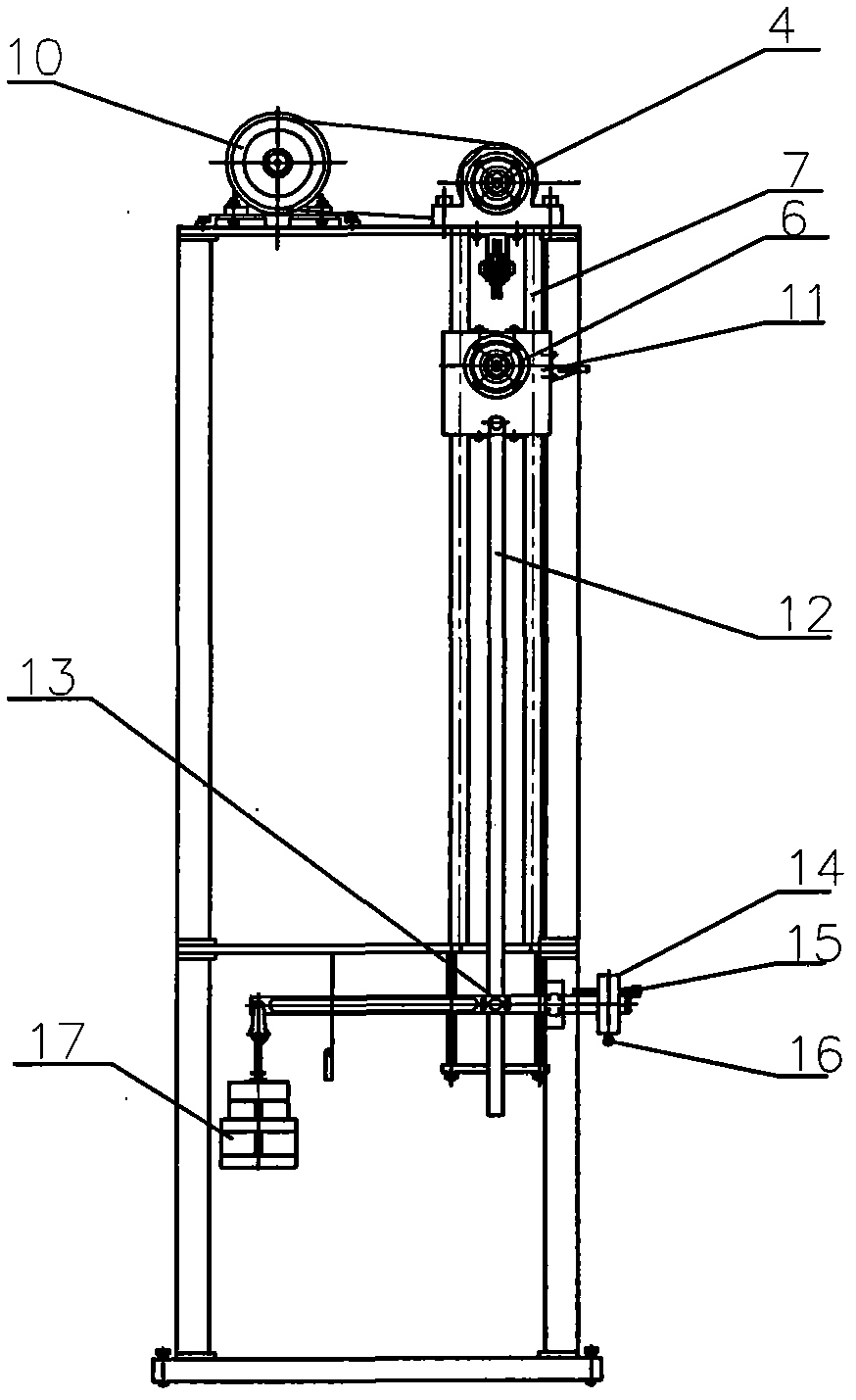

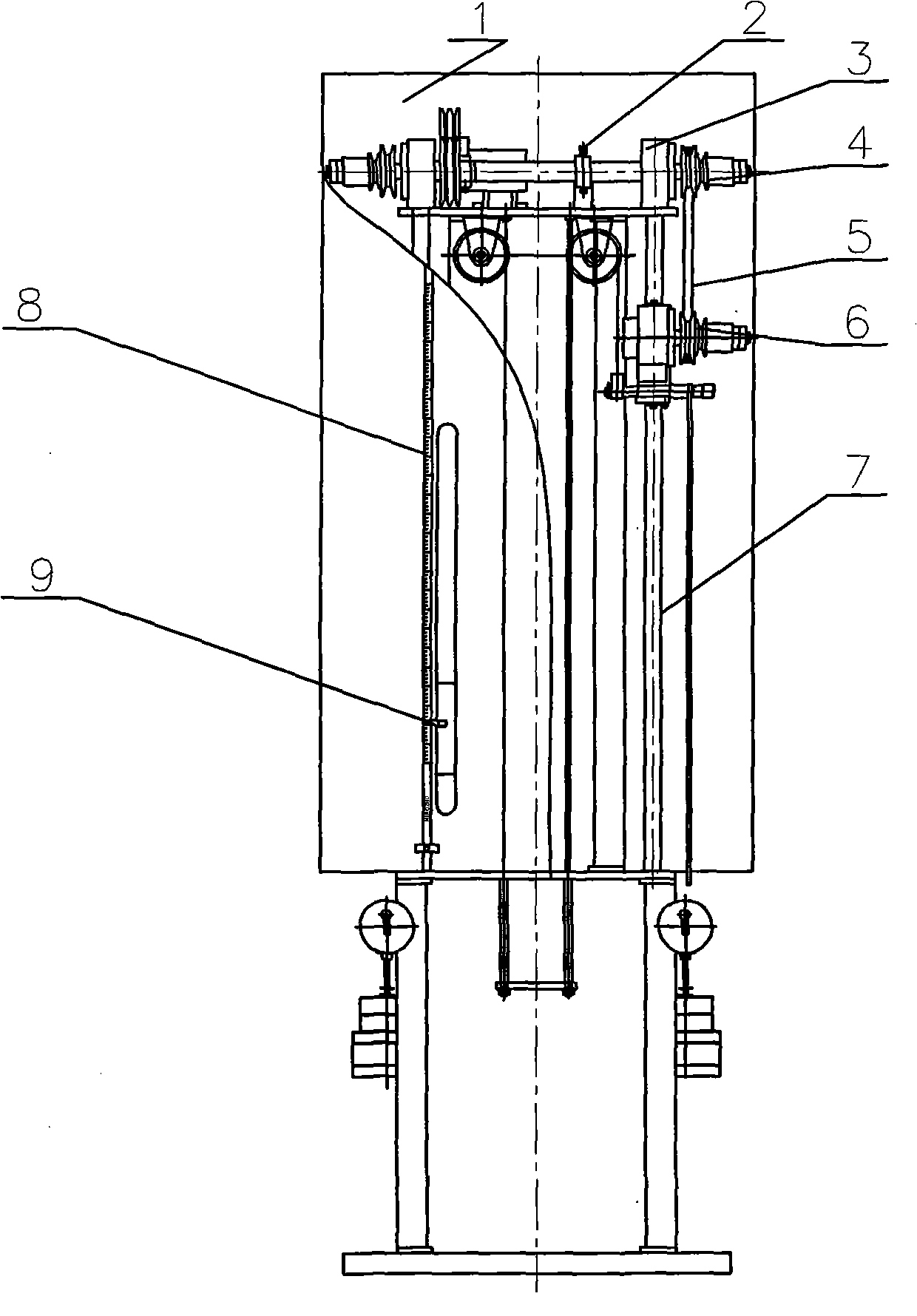

[0010] The invention includes a frame 1, a motor 10 arranged on the frame 1, a testing device and a loading device.

[0011] The test device comprises a driving pulley 4 driven by a motor 10, a driven pulley 6 driven by the driving pulley 4, the driven pulley 4 is arranged on a sliding seat 11, and the sliding seat 11 is arranged along a slide provided on the frame 1. Rail 7 moves up and down, and slide seat 11 lower end connects pull bar 12; The present invention establishes speed control unit 2 on the transmission path of motor 10 and drive pulley 4, and this speed control unit 2 controls drive pulley 4 rotating speeds and can realize no-speed according to the situation. Step speed regulation; a transmission disc 3 is set between the driving pulley 4 and the motor 10 and between the driving pulley 4 and the driven pulley 6. When working, the V-shaped belt 5 is arranged on the driving pulley 4 and the driven pulley 6 On, when the driving pulley 4 and the driven pulley 6 need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com