Method for machining involute gear

A technology of involute gears and processing methods, applied to elements with teeth, belts/chains/gears, gear teeth, etc., can solve problems that do not conform to the basic meshing laws, achieve the effect of preventing interference and ensuring transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

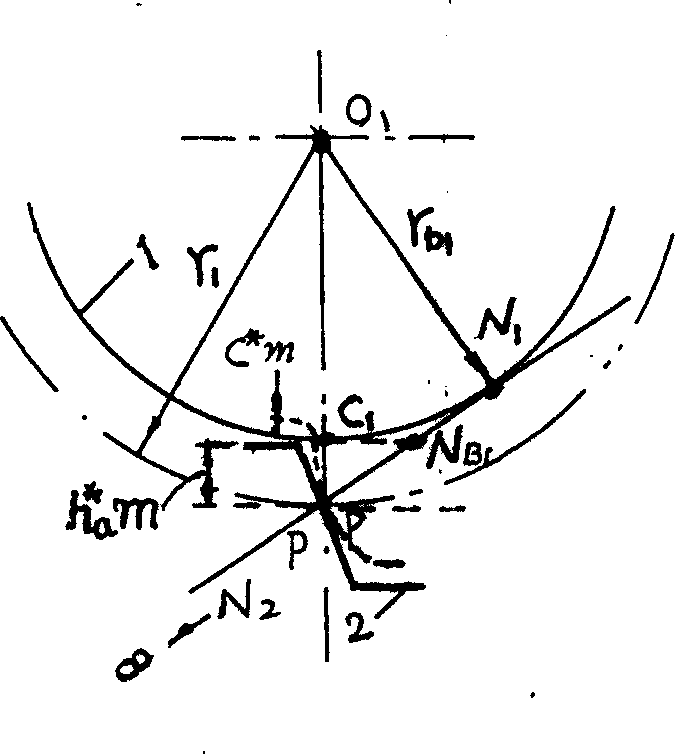

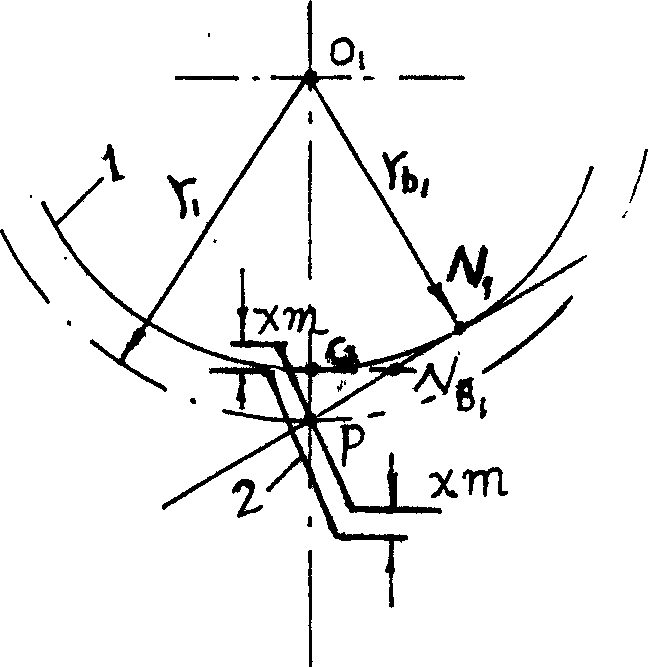

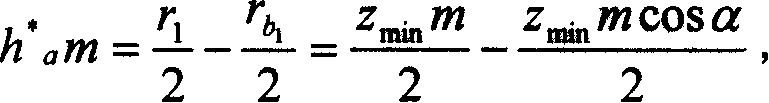

[0014] figure 1 Among them, rack cutter 1 cuts the limit position of gear 2, and the tooth top line of rack cutter is tangent to the base circle of gear C 1 point, and intersects the meshing line at N B1 The point is the limit meshing point of the gear, also known as the theoretical meshing point. In order to prevent the top line of the rack blade from exceeding the limit meshing point, it is also called the theoretical meshing point N B1 , the radius r of the indexing circle of the cut gear 1 and base circle radius r b1 The minimum distance between is the standard addendum height h * a m, national standard addendum height factor h * a =1, the minimum number of teeth can be calculated, h * a m = r 1 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com