Quick positioning type automatic transmission device

A transmission device and positioning technology, applied in the direction of conveyor, mechanical conveyor, transportation and packaging, etc., can solve the problems of inconsistent speed on both sides of the fixture, large impact force, complex structural design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

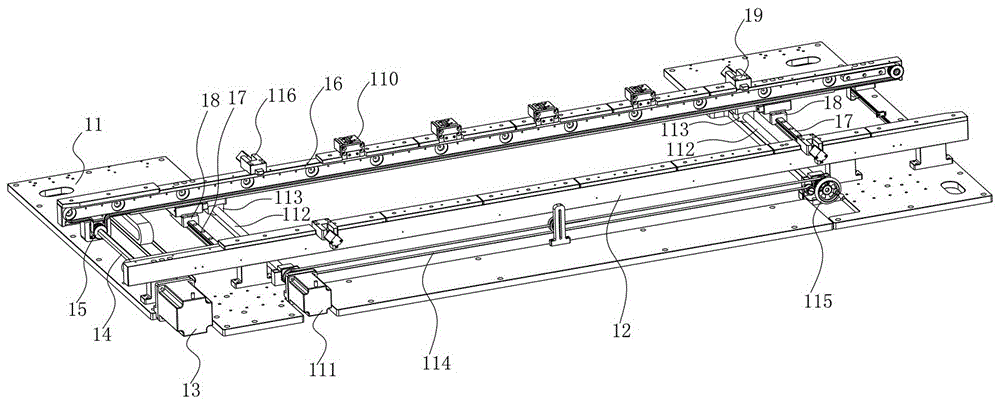

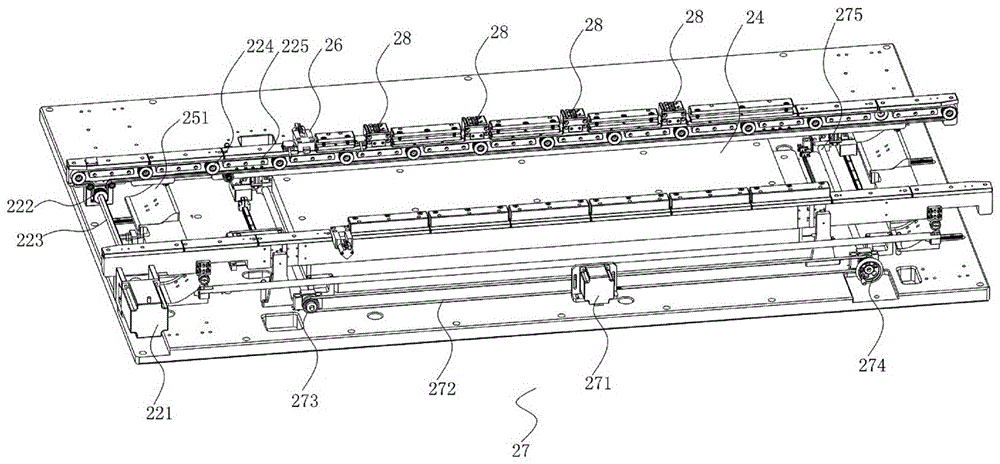

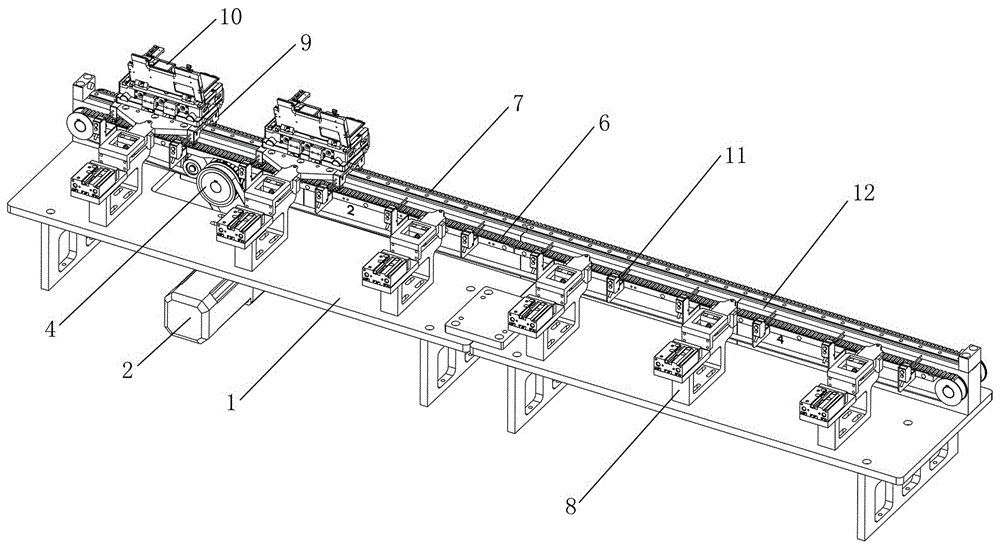

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Such as Figure 3 to Figure 11 As shown, the technical solution adopted by the present invention is as follows: a fast positioning automatic transmission device, including a transmission platform 1, a transmission mechanism, a first synchronous belt 6, a second synchronous belt 7, a transmission seat 9, a jig 10 and a positioning mechanism 8. Wherein, the above-mentioned transmission platform 1 is placed horizontally on the working platform, and a strip-shaped support 12 is provided on the transmission platform 1; the above-mentioned first synchronous belt 6 and the second synchronous belt 7 are respectively arranged on both sides of the support 12, And tensioned by the tensioning pulley fixed on the side wall of the support 12; Seat 12 side synchronous circulation movement; above-mentioned transmission seat 9 comprises at least two, and transmission seat 9 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com