Manufacturing method of elastic non-woven fabric, elastic non-woven fabric and elastic product

A technology of nonwoven fabrics and manufacturing methods, applied in the field of elastic nonwoven fabrics and elastic products, elastic nonwoven fabrics, to achieve the effects of improved aesthetics, uniform tension, and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation before forming a net

[0047] The raw material is a mixture of polyester and viscose. The specification of polyester is 4D×92mm, and the specification of viscose is 3D×76mm. The weight percentage of mixing is 20% of polyester and 80% of viscose. After the raw material passes through the cotton feeding weighing machine, it is sent to the cotton blending curtain opener for opening, and the opened cotton flow enters the multi-compartment blending machine for mixing, and the mixed cotton flow is sent to the cotton opener for further processing. open loose. In the preparation stage before web formation, the fiber raw materials are loosened, and the fiber blocks are changed from large pieces to small pieces. At the same time, the fibers are evenly mixed to prepare for the fiber web formation.

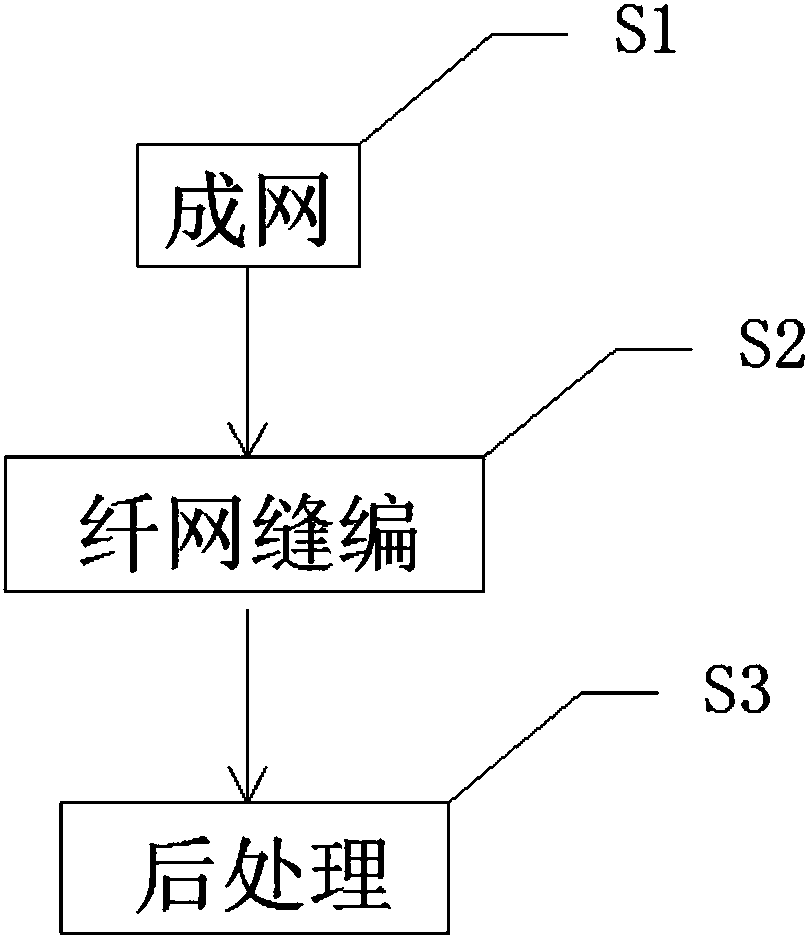

[0048] (2) into a network

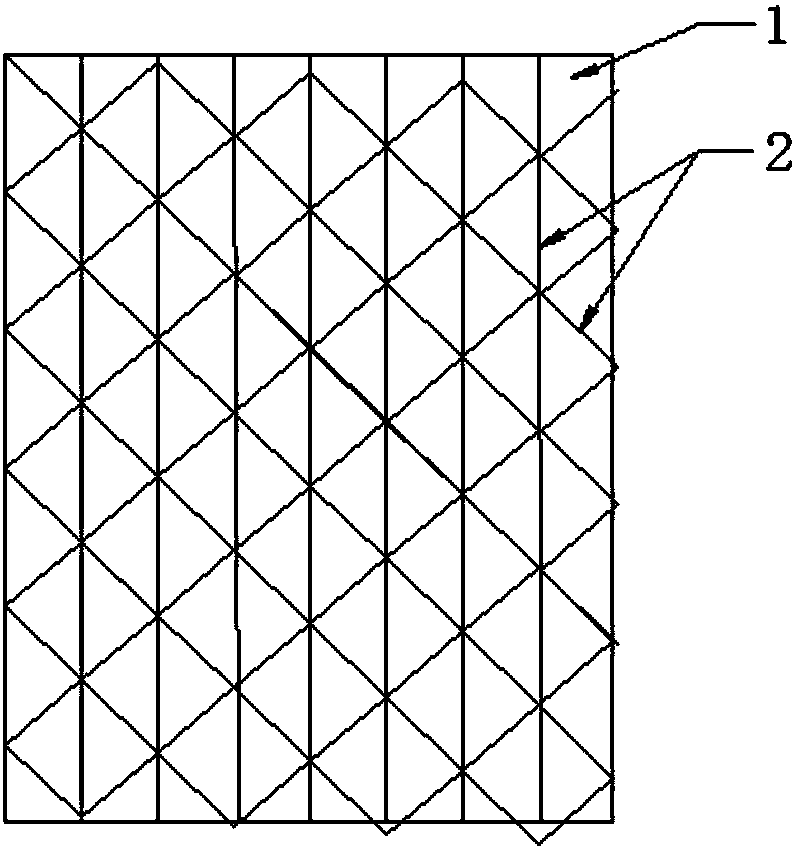

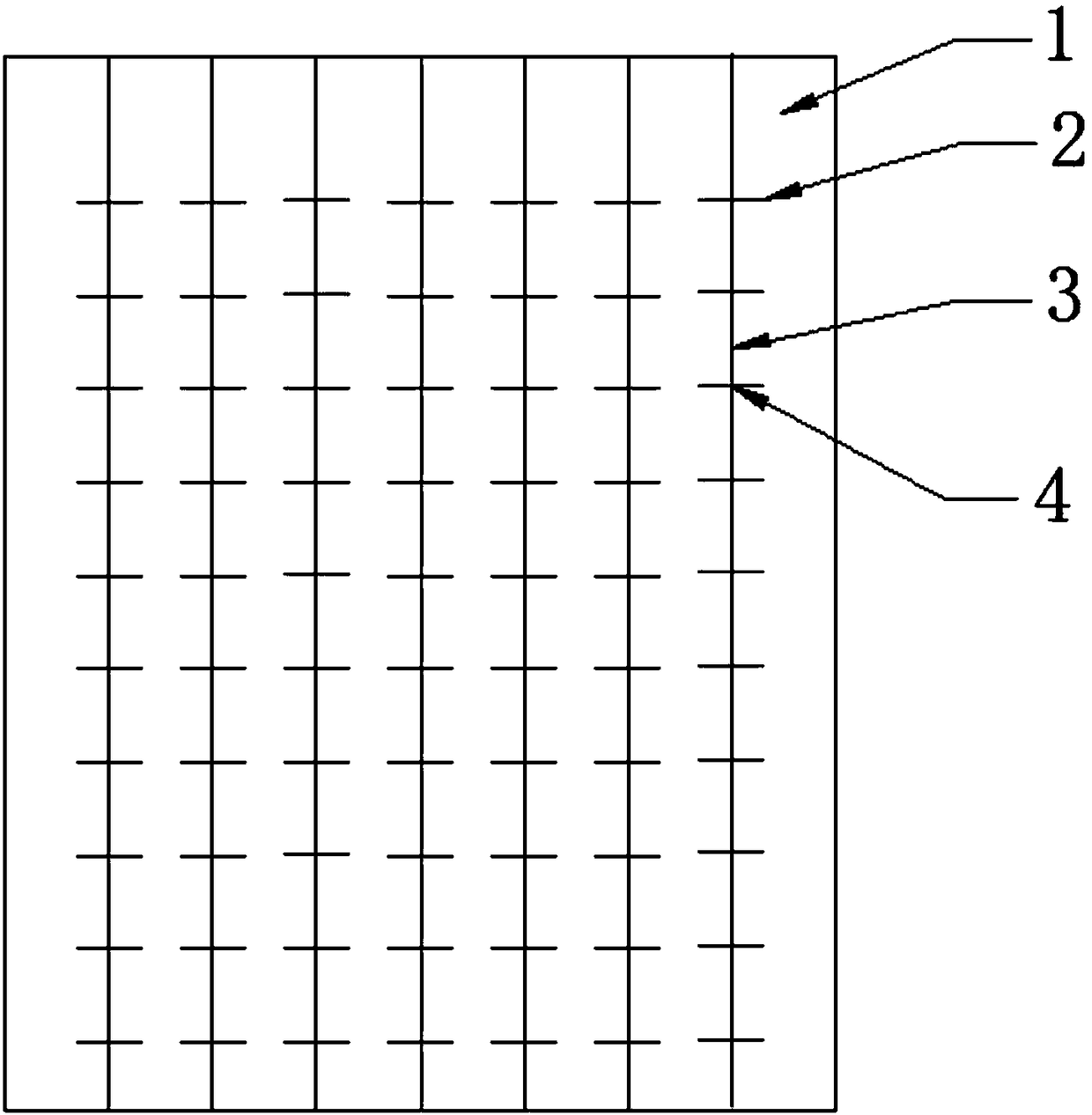

[0049] The cotton after opening and mixing flows through the conveying fan and the carding machine to produce a fiber web 1 with a certain...

Embodiment 2

[0055] Elastic nonwovens prepared by air-laid method:

[0056] The difference from Example 1 is that the short fiber forming is not card forming, but air forming.

Embodiment 3

[0058] Spunbonded composite elastic nonwovens:

[0059] The difference from Example 1 is that the surface of the fiber web 1 after carding and laying is compounded with a layer of spun-bonded nonwoven fabric, and then the fiber web 1 is stitch-bonded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com