Water-proof structure for civil engineering expansion joint

A civil engineering and waterproof structure technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as expansion joint leakage, bridge deck damage, and corrosion bridge decks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

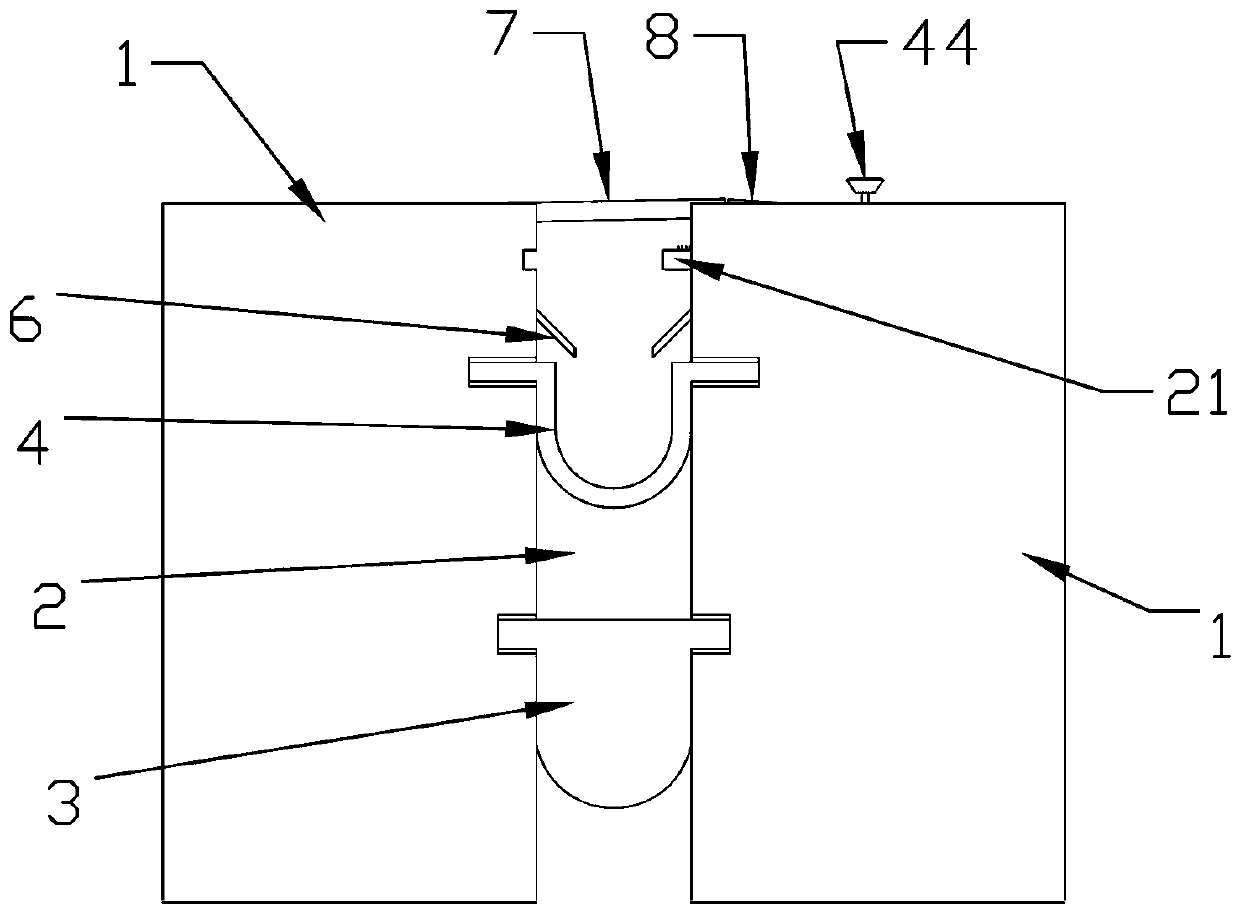

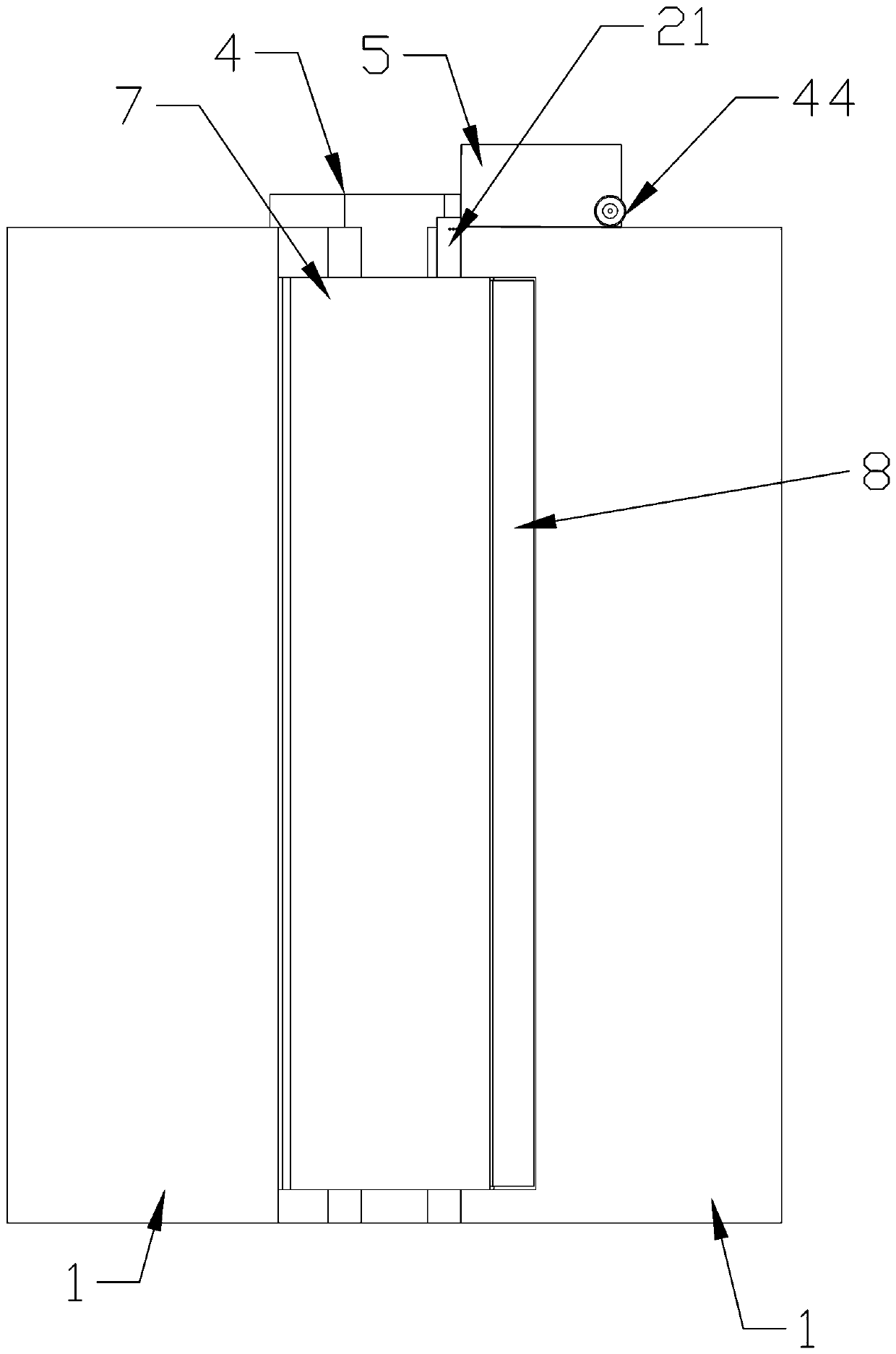

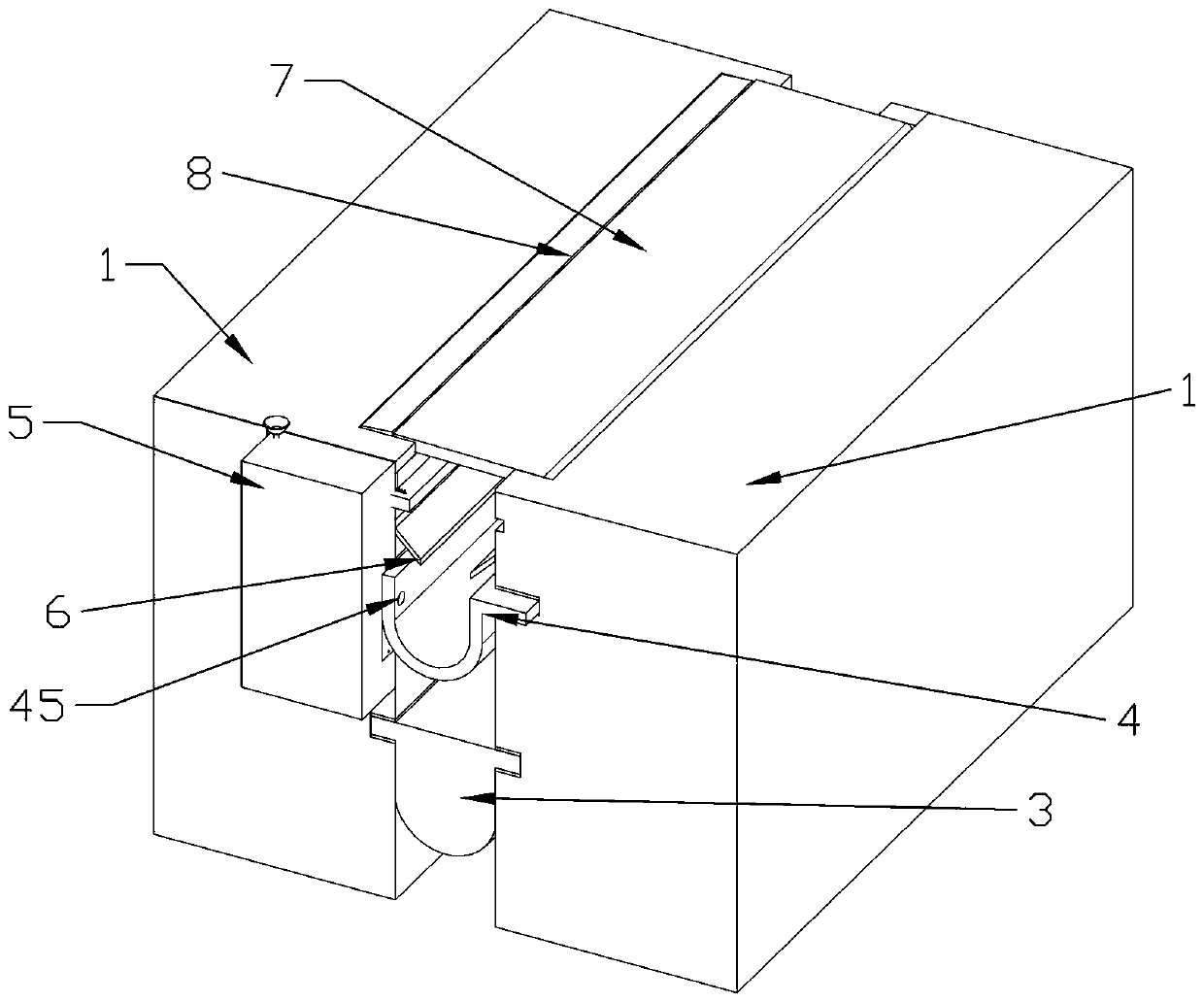

[0039] Embodiment 1, civil engineering expansion joint 2 waterproof structure, the rubber stopper 3 installed in the expansion joint 2 between two bridges 1, the gap between the bridges 1 is the expansion joint 2, and the rubber stopper 3 is fixed and embedded in the cement At the opposite ends of the two sections of the bridge 1, water droplets are prevented from penetrating into the pier below, and the rubber material will not affect the deformation of the bridge 1 after being heated and cooled. A rubber stopper 3 is installed above the two sections of the bridge 1 The drainage board 4, one end of the drainage board 4 protrudes outside the bridge 1, when the water flows out, it will not flow to the top of the bridge 1, the middle of the drainage board 4 is sunken downward, forming an arc shape, and has elasticity, so that the bridge 1 is deformed When the bridge 1 is deformed, it will not prevent the deformation of the bridge 1. When the water drips from the top, it can flow ...

Embodiment 2

[0047] Embodiment 2, on the basis of Embodiment 1, the lower end of the cylindrical surface of the power storage column 31 has a clamping gap 10 facing the left, and the clamping gap 10 is located at the bottom end of the cylindrical surface of the power storage column 31, a row of In the power storage shell 32 on the left side of the power storage column 31, there is a clamping column 11 that can slide longitudinally in the power storage shell 32. The clamping column 11 is in the shape of a cuboid and is slidably connected in the power storage shell 32. The right end of the column 11 is placed with some clamping buttons 12 that cooperate with the clamping notch 10, and the clamping buttons 12 are connected in the clamping groove 14 at the right end of the clamping column 11 through the clamping spring 13, and the clamping buttons 12 can pass through The clamping spring 13 stretches out and retracts in the clamping groove 14. The upper end of the clamping button 12 has rounded ...

Embodiment 3

[0049] Embodiment 3, on the basis of Embodiment 2, two sets of push plates 23 that cooperate with the clamping shell 15 are placed on the rear end of the closing plate 21, and the outer circle of the clamping shell 15 has a circle of rotating plates, and the pushing The plate 23 is rotatably connected in the push groove 24 in the closed plate 21, a set of said push plates 23 is placed on the right side of the closed plate 21, the right end surface of the push plate 23 is against the right side wall of the push groove 24, and the set Described push plate 23 right sides are connected on the closure plate 21 by inclined push spring 25, and one section of push spring 25 connects seal plate 21, and the other end connects push plate 23, and normal state is due to the existence of push spring 25. Pushing plate 23 is in vertical state, and when closing plate 21 moves to the left and contacts rotating plate, pushing plate 23 can not rotate, and when closing plate 21 has moved to and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com