Semi-inclusion direct surface-mounting ground stress relief test device and method

A testing device and geostress technology, applied in measurement devices, force/torque/work measuring instruments, force sensors in holes of stressed structures, etc., can solve the uncertainty of test results, increase test links, and reduce measurement Accuracy and other issues, to achieve the effect of accurate compensation, ensuring accurate installation and installation accuracy, and eliminating measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

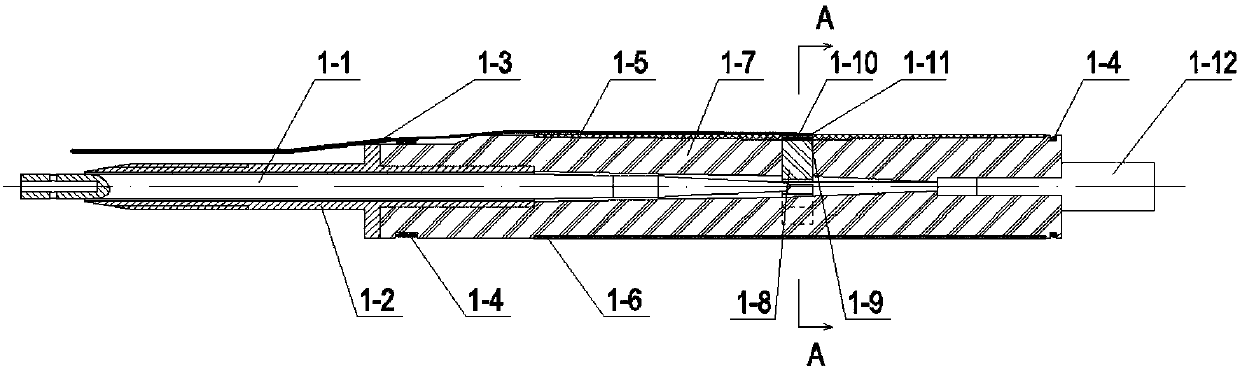

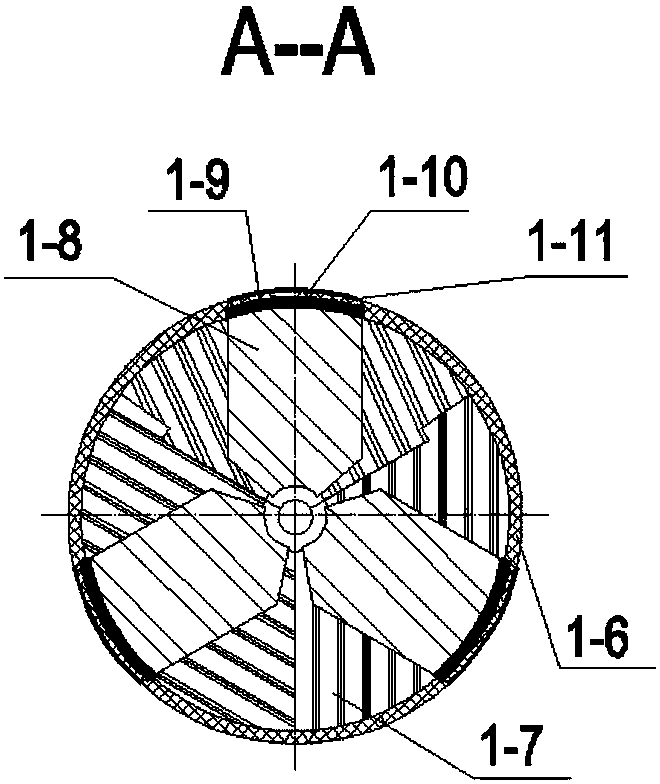

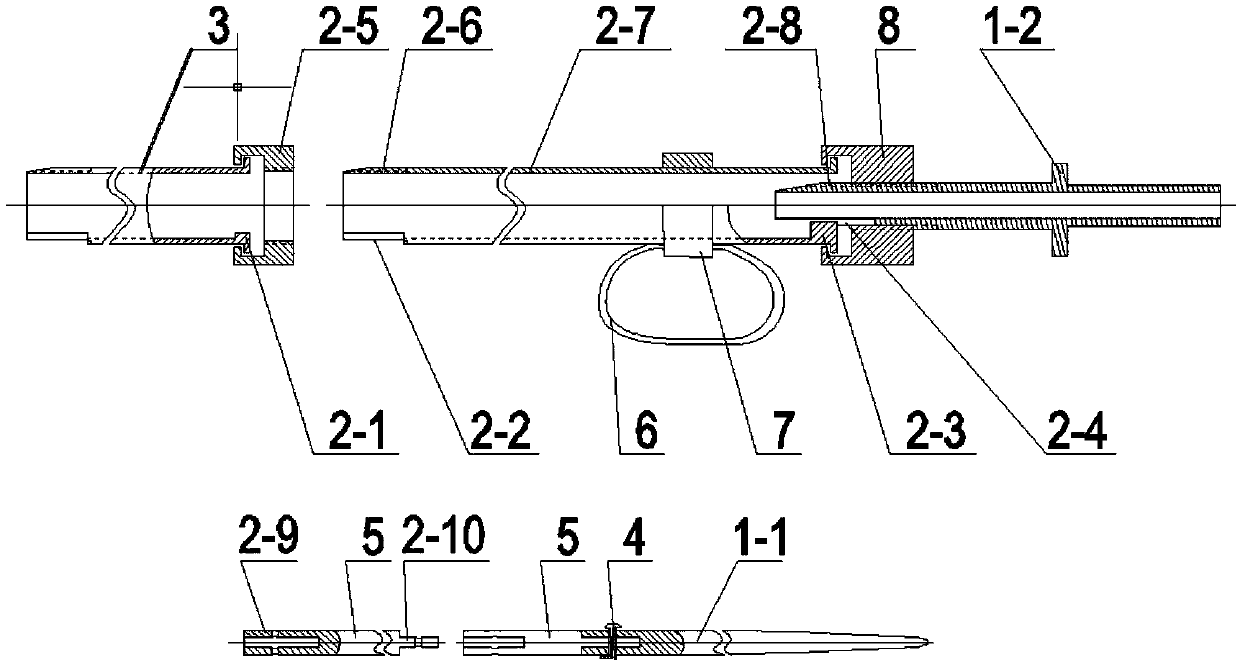

[0035] see figure 1 and figure 2 One embodiment of the semi-enclosed direct patch stress relief test device of the present invention includes a bracket 1-2, a support 1-7 connected to the bracket 1-2, and a rubber tube 1 sleeved on the periphery of the support 1-7 -6, the rubber tube 1-6 is provided with an opening for installing the strain cluster, and is bonded with the non-deformable layer 1-9.

[0036] The support 1-7 is formed by splicing at least 3 arc-shaped blocks, and each arc-shaped block is provided with a quadrilateral slot from the inner hole to the outer surface, for installing the strain cluster push block 1-8, the non-deformable layer 1 -9 etc. The appearance of the strain cluster push block 1-8 is also an arc structure, and a plurality of arc blocks and the strain cluster push block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com