Flow instrument housing

A flow meter and housing technology, applied in the field of the flow meter housing, can solve the problems of high housing cost, easy rusting of the cast iron housing, affecting the service life of the flow meter, measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

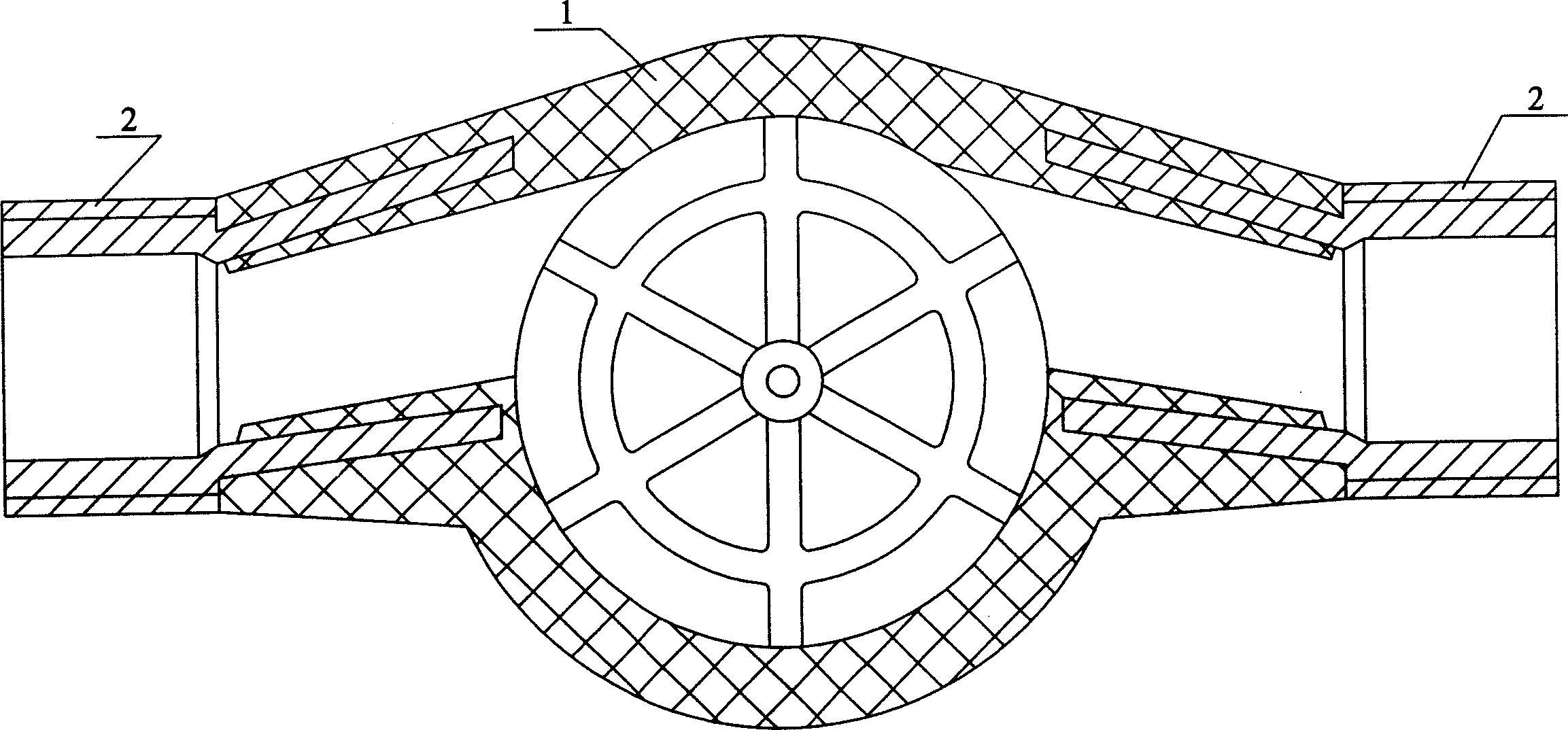

[0005] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment is composed of a plastic casing 1 and connecting pipe fittings 2 arranged on both sides of the casing 1. The casing 1 and the connecting pipe fittings 2 communicate with each other and are integrated by injection molding. One end of the connecting pipe fitting 2 is buried in the solid tissue of the casing 1, and the other end of the connecting pipe fitting 2 is provided with an external thread or an internal thread. With such an arrangement, the connection between the connecting pipe piece 2 and the casing 1 is relatively firm.

specific Embodiment approach 2

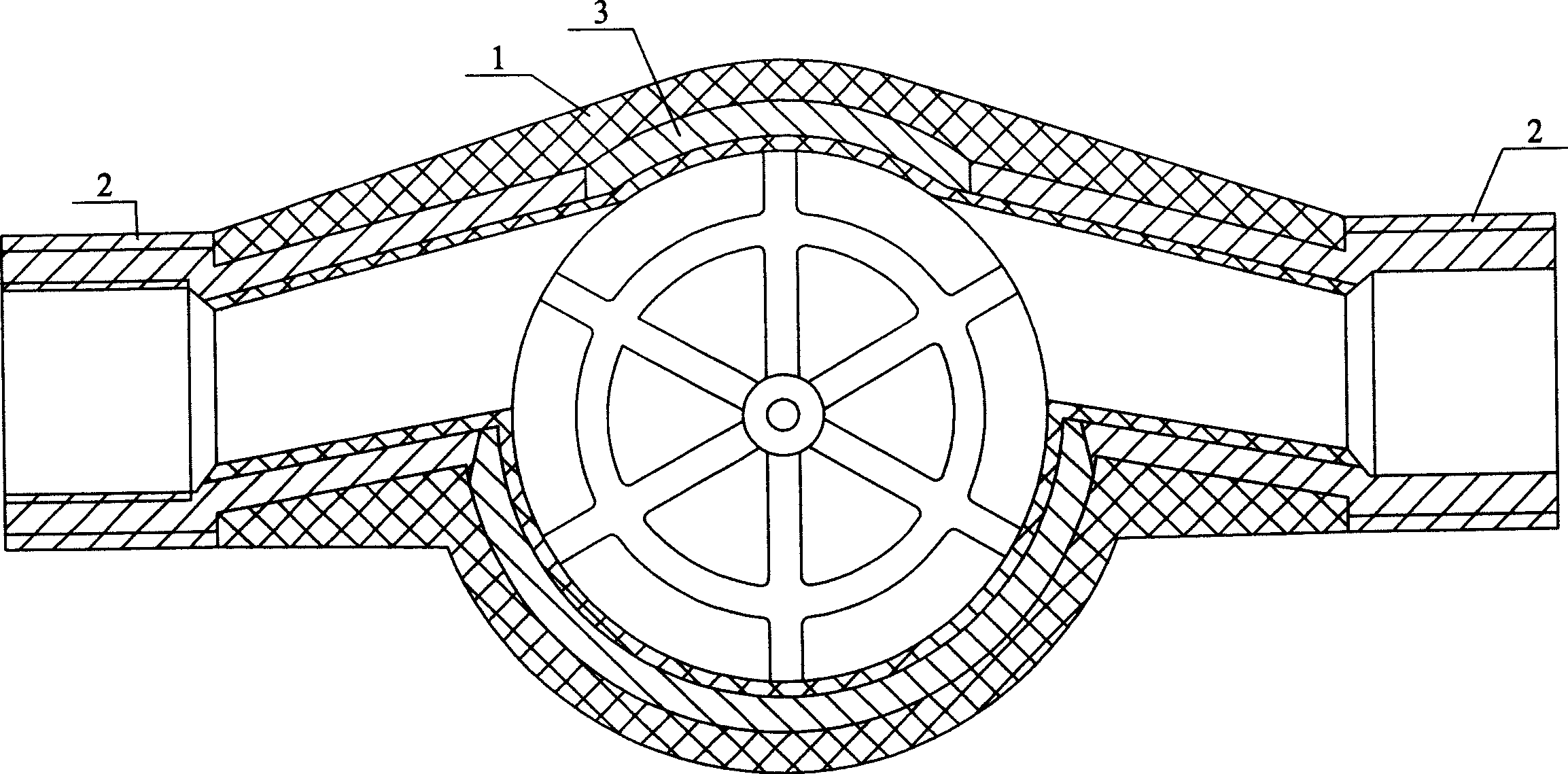

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that it also includes an embedded plate 3 , the embedded plate 3 made of metal is contained in the solid tissue of the shell 1 and is fixedly connected with the connecting pipe 2 . The casing of the flow meter arranged in this way has higher strength, and in addition, the embedded plate 3 does not contact liquid or gas, and the heat deformation is also small.

specific Embodiment approach 3

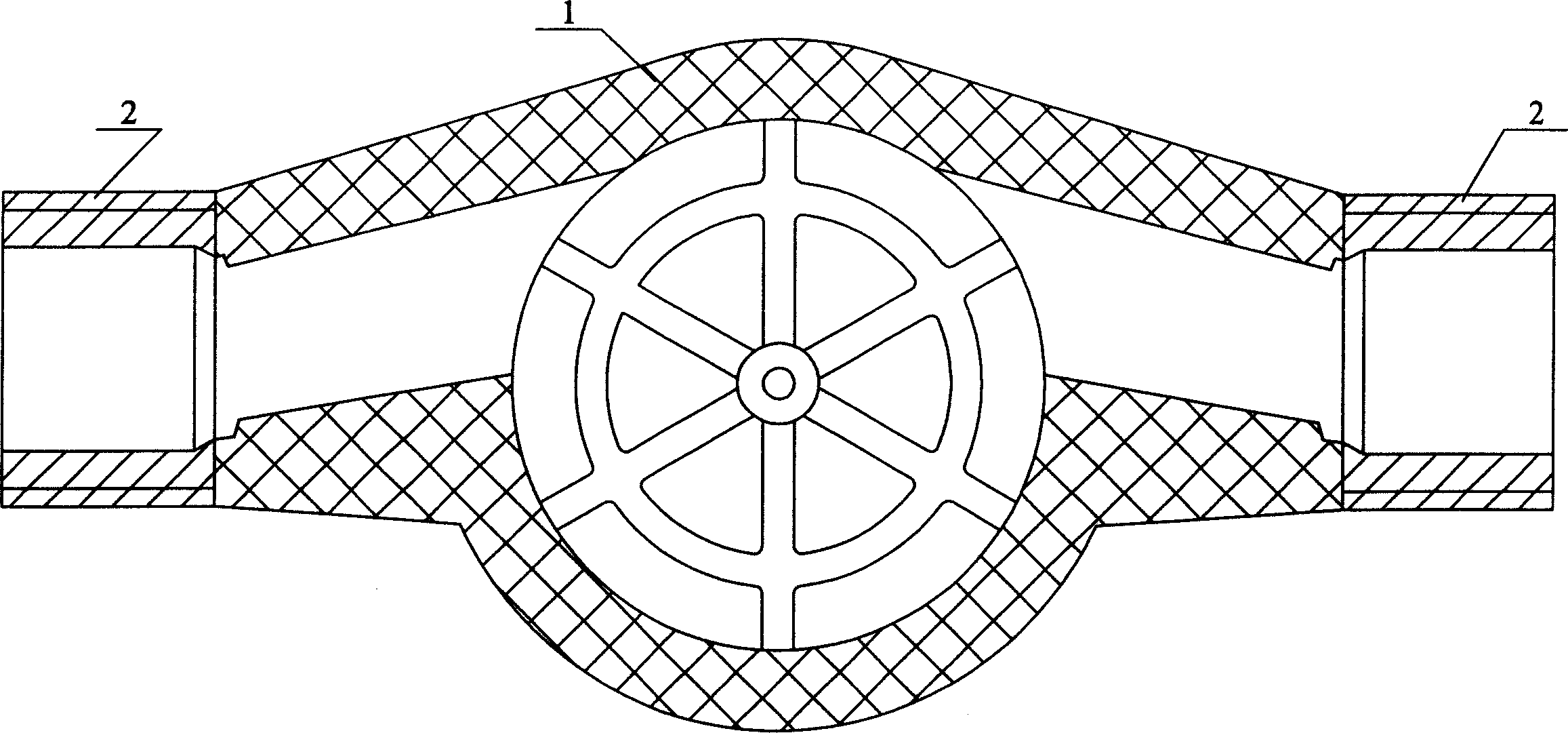

[0007] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the material of the shell 1 is polypropylene random copolymer, English abbreviation (PPR).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com