Shape memory alloy thermal circulation stability and function fatigue property testing system

A fatigue performance test, memory alloy technology, applied in the investigation phase/state change and other directions, can solve the problems of high local temperature, potential safety hazards, inability to realize heating-cooling cycle action, etc., to achieve synchronous acquisition and storage, and ensure safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

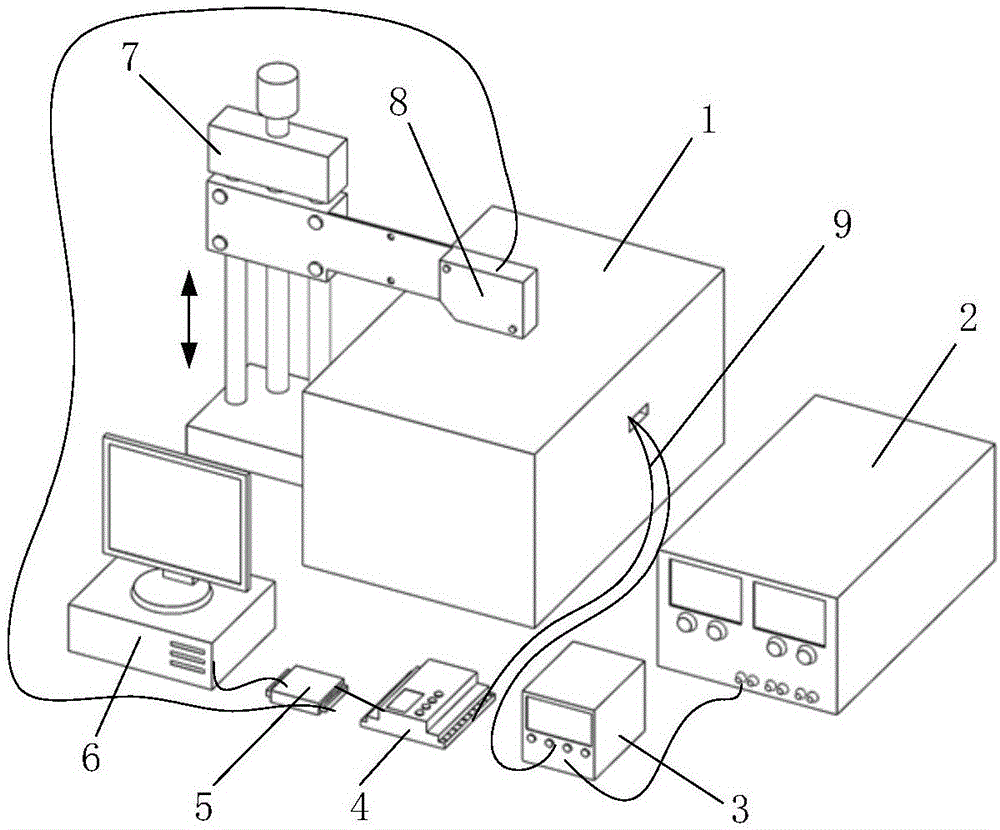

[0031] like figure 1 As shown, the shape memory alloy thermal cycle stability and functional fatigue performance test system includes a temperature control box 1, a sample holder, a thermal cycle temperature control system and a data acquisition system.

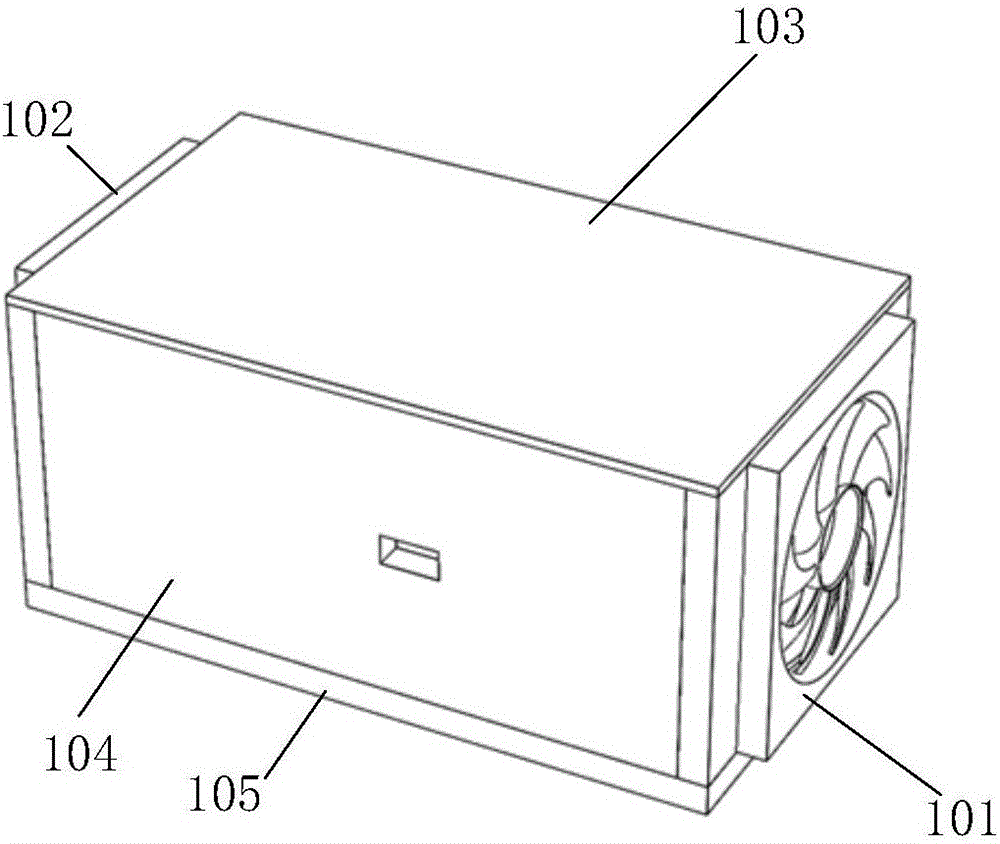

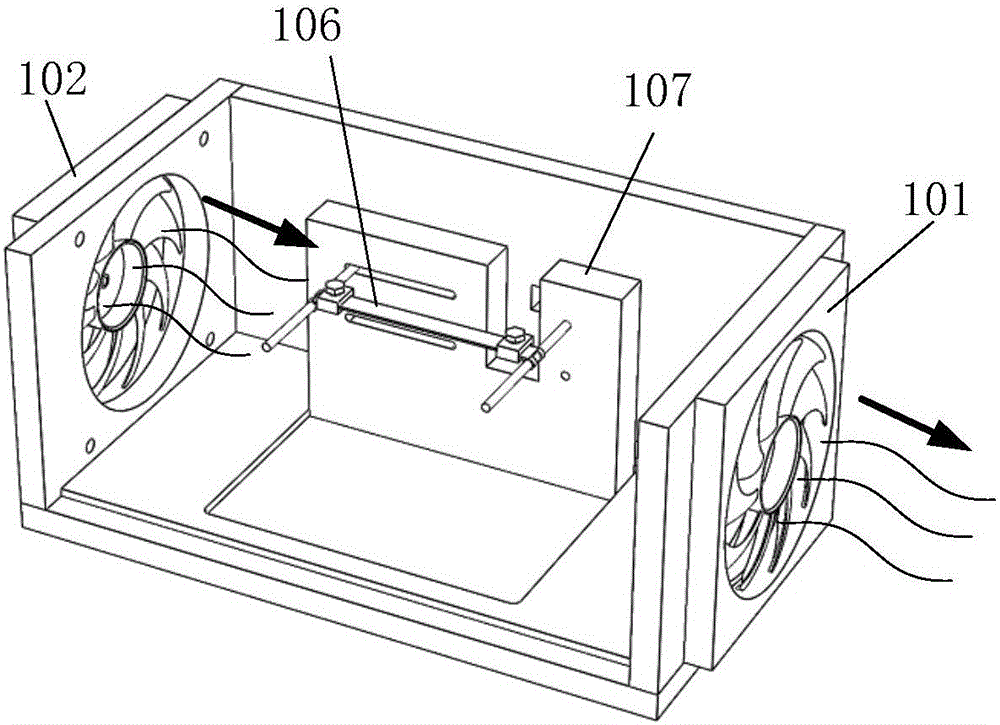

[0032] like Figure 2A As shown, the temperature control box 1 comprises a temperature control box upper cover plate 103, a temperature control box side plate 104 and a temperature control box bottom plate 105; Bottom plate 105 and four temperature control box side plates 104 are connected; temperature control box upper cover plate 103 and four temperature control box side plates 104 are preferably transparent acrylic plates; temperature control box bottom plate 105 is preferably high-strength ny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com