Plasma machining production line of dual-trapezoid slotted sieve tube

A plasma and production line technology, applied in the field of mechanical processing, can solve the problems of screen pipes with double trapezoidal seams that have not yet been seen, and achieve the effects of improving sand control effect, strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

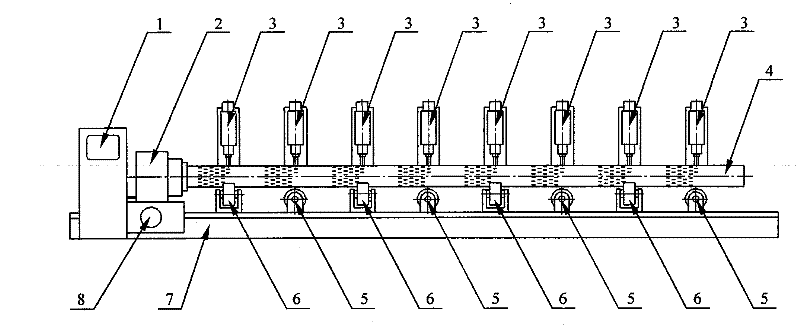

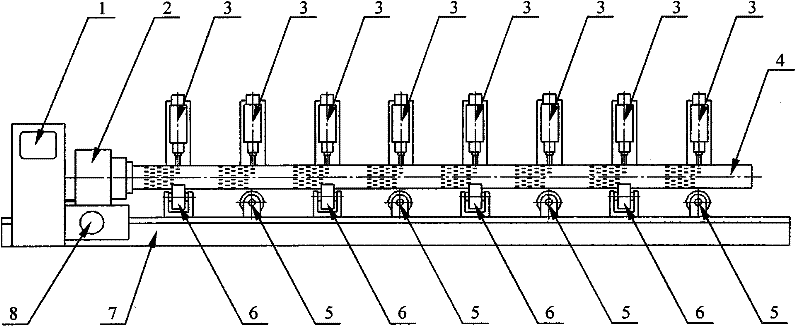

[0010] see figure 1 . In the principle diagram of the composition principle of the double trapezoidal seam screen tube plasma processing production line of the present invention, 1 is the main console, which is used to control the plasma machine tool, numerical control rotary table, axial feed drive device, axial guide and transmission device, radial rotation The processing and motion state of the support device; 2 is the CNC rotary table, which is installed on the axial feed drive device, and is used to clamp the slotted screen and drive the slotted screen to perform rotary indexing motion; 3 is the plasma processing Machine tools, each plasma processing machine tool has its own independent electromagnetic excitation power supply, plasma power supply, ultrasonic power supply, automatic feed servo control system, and 8 plasma processing machine tools are placed side by side behind the bed for processing double The slot of the trapezoidal slotted screen; 4 is the processed slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com