Method for preparing carbon nanotube by use of biodegradable plastic

A technology for degrading plastics and carbon nanotubes, applied in the removal of solid waste, etc., can solve the problems of non-renewable raw materials and complicated processes, and achieve the effects of avoiding greenhouse gas emissions, simple processing equipment, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

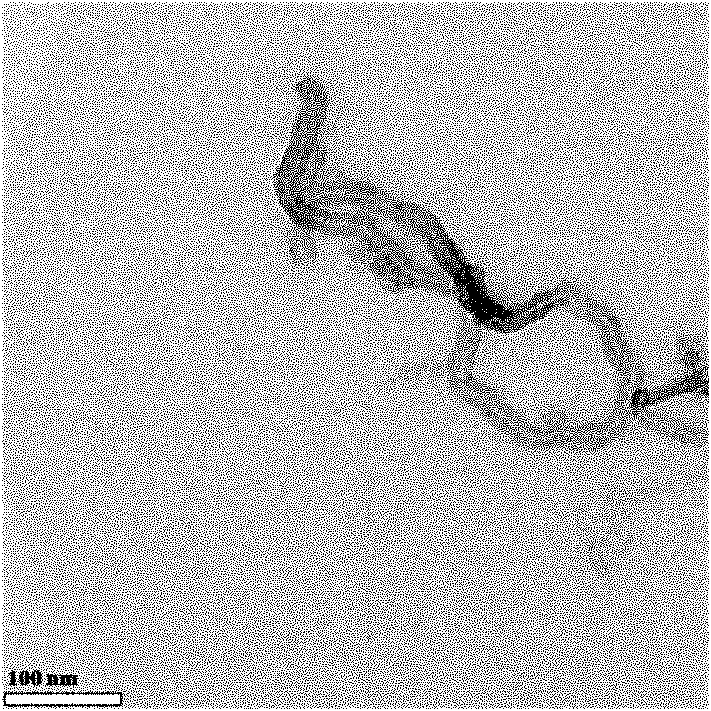

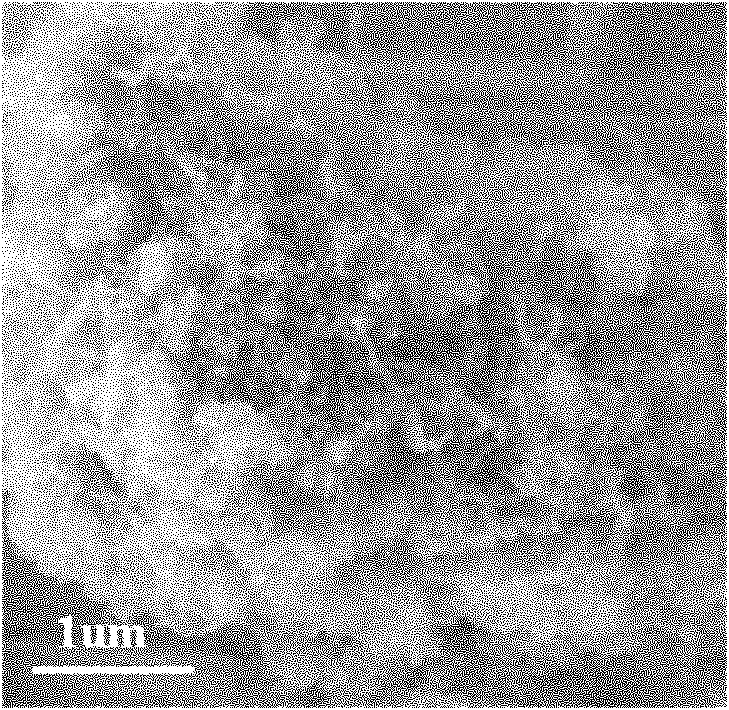

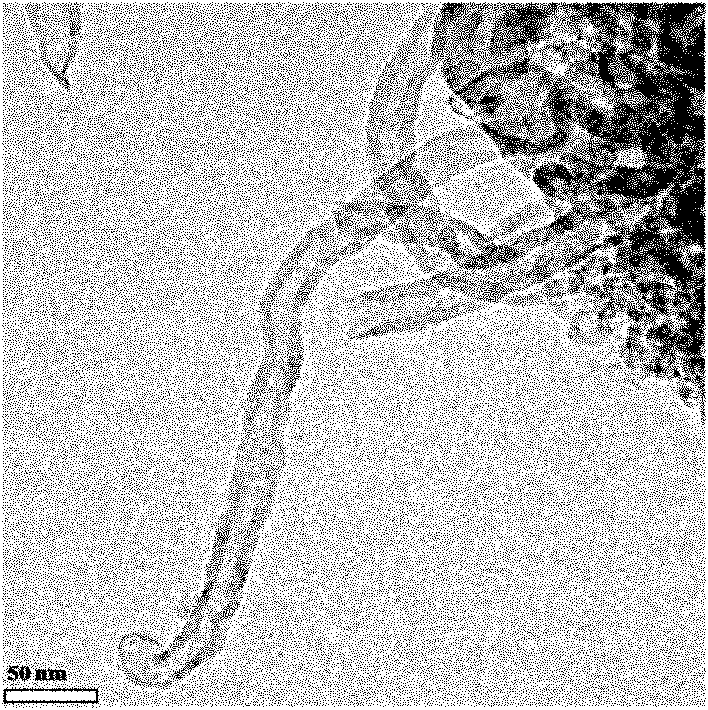

Image

Examples

Embodiment 1

[0030] Zinc nitrate and aluminum nitrate are prepared in a molar ratio of 3:1 to prepare an aqueous solution with a total metal ion concentration of 0.5 mol / l; at room temperature, under stirring, add dropwise an alkali solution with a molar concentration of 1.5 mol / l to adjust the pH to 10, Then heat up to 80°C, add sodium dodecyl sulfate 1.5 times the molar weight of trivalent ions to modify the product, react for 15 hours, centrifuge the precipitate, wash with water until neutral, and obtain organically modified zinc after drying Aluminum double hydroxide.

[0031] Add 85% biodegradable plastic polybutylene succinate into the internal mixer according to the mass ratio, start stirring after heating to a molten state, and then add 10% of the zinc organically modified with sodium lauryl sulfate prepared above After aluminum double hydroxide and 5% nickel oxide are melted and blended uniformly, a polybutylene succinate compound is obtained.

[0032] The polybutylene succinate ...

Embodiment 2

[0036] Magnesium nitrate and ferric nitrate are formulated into an aqueous solution with a total concentration of metal ions of 1 mol / l at a molar ratio of 4:1; at room temperature, under stirring, add dropwise an alkali solution with a molar concentration of 1.0 mol / l to adjust the pH to 9.5, Then heat up to 120°C, add sodium dodecylbenzenesulfonate twice the molar weight of trivalent ions to modify the product, react for 12 hours, centrifuge the precipitate, wash with water until neutral, and obtain organically modified Magnesium iron double hydroxide.

[0037] 87% biodegradable plastic polylactic acid, 8% organically modified magnesium-iron double hydroxide prepared above and 5% iron oxide were premixed at room temperature according to the mass ratio, then added to the twin-screw extruder, and melted After granulation, the material is cut to obtain a polylactic acid compound.

[0038] The polylactic acid compound was placed in a quartz tube, fed with nitrogen, and the quar...

Embodiment 3

[0042] Nickel nitrate and aluminum nitrate are formulated into an aqueous solution with a total metal ion concentration of 1 mol / l at a molar ratio of 3:1; an alkali solution with a molar concentration of 2.0 mol / l is added dropwise under stirring at room temperature to adjust the pH to 9.0, Then heat up to 98°C, add sodium dodecyl sulfate 1.0 times the molar weight of trivalent ions to modify the product, react for 48 hours, centrifuge the precipitate, wash it with water until neutral, and obtain organically modified nickel after drying Aluminum double hydroxide.

[0043] Dissolve 92% biodegradable plastic polyvinyl alcohol, 6% organically modified nickel-aluminum double hydroxide and 2% nickel oxide in dimethyl sulfoxide according to the mass ratio, stir and reflux, and dry to remove solvent to obtain polylactic acid composites.

[0044] The polylactic acid compound was placed in a quartz tube, fed with nitrogen gas, and the quartz tube was placed in a tube furnace at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com