Patents

Literature

34results about How to "Comply with environmental emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

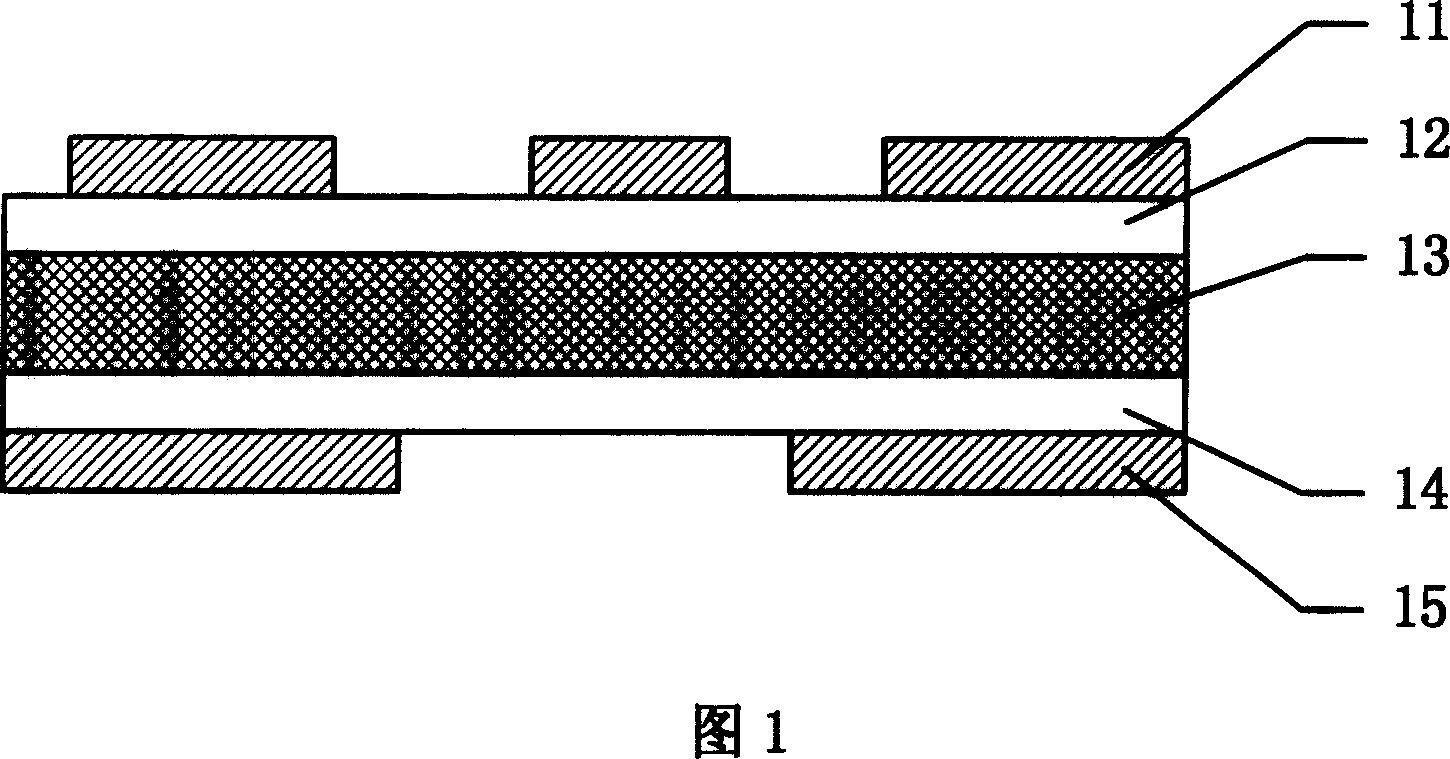

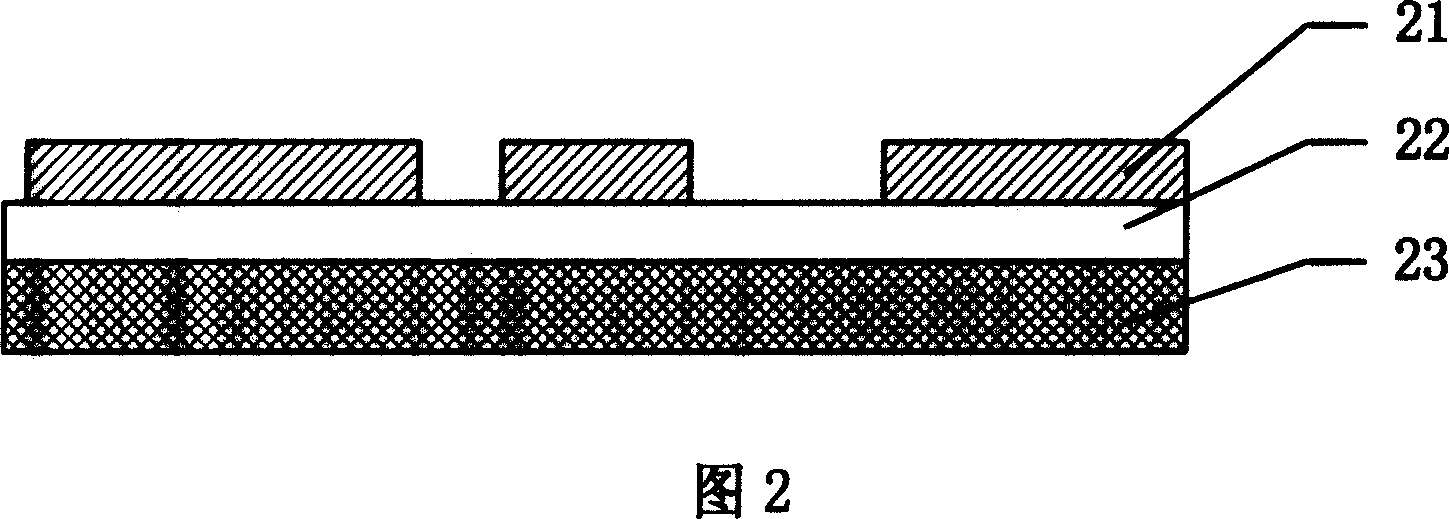

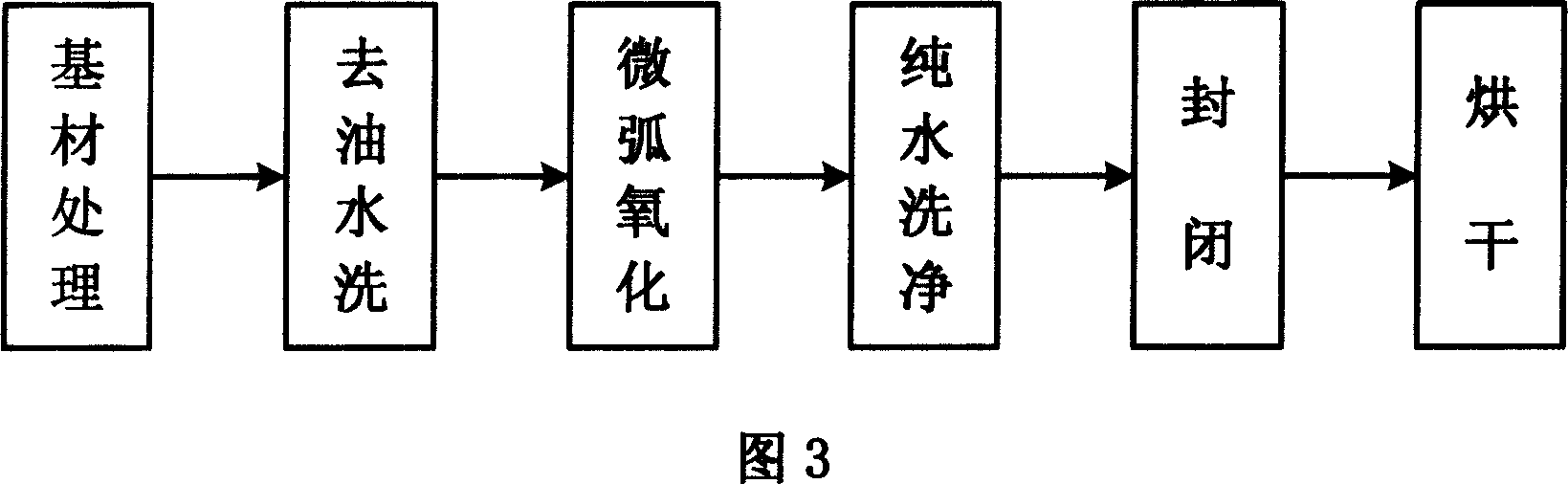

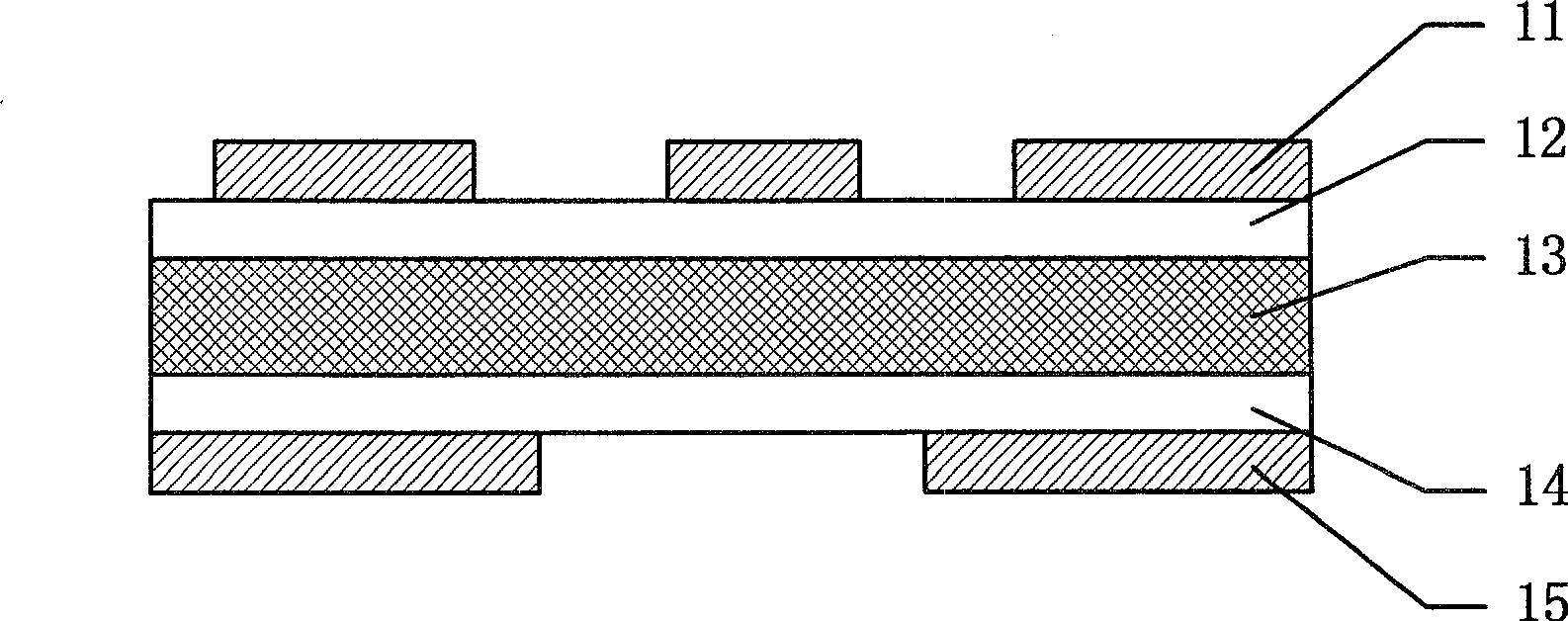

Aluminum-base printing circuit board and its production

InactiveCN101076224AReliable workmanshipSimple processing equipmentPrinted circuit manufactureCircuit susbtrate materialsInsulation resistanceMicro arc oxidation

The bottom layer of invention uses aluminium baseboard; the intermediate layer is a heat conduction insulation layer; the surface layer is an electric conduction layer. It features the following: the heat insulation layer is a ceramic-like thin film layer with 10-400 micron thick and >=100Momega insulation resistance, which chemical composition is aluminium oxide. The preparation method comprises: making pretreatment, de-oiling and washing for the surface of the aluminium baseboard using mechanical method or chemical method to form a clean workpiece plane; using the microarc oxide treatment and the microplasma surface ceramic method to make a heat conduction insulation layer on the workpiece surface; finally, overlapping an electric conduction layer on the heat conduction insulation layer; etching circuit pattern.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

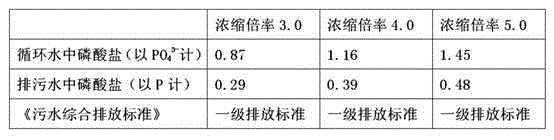

Efficient low-phosphorus compound water treatment agent

InactiveCN102718333AReduce manufacturing costPrevent scalingScale removal and water softeningPolyaspartic acidTricarboxylic acid

The invention provides an efficient low-phosphorus compound water treatment agent and belongs to the technical field of industrial circulating cooling water treatment. The water treatment agent consists of the following raw materials: polyaspartic acid (PESA), 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), zinc salt, azoles, maleic acid-acrylic copolymer (MA / AA) and deionized water, wherein PESA is taken as a main scale inhibitor, PBTCA and MA / AA are taken as auxiliary scale inhibitors, a corrosion inhibitor is formed by the zinc salt, the azoles, PBTCA and PESA, and MA / AA is taken as a dispersing agent. By fully utilizing the synergistic effect of various components, a multifunctional low-phosphorus compound water treatment agent with scale and corrosion inhibition functions is formed.

Owner:SHANDONG TIANQING TECH DEV

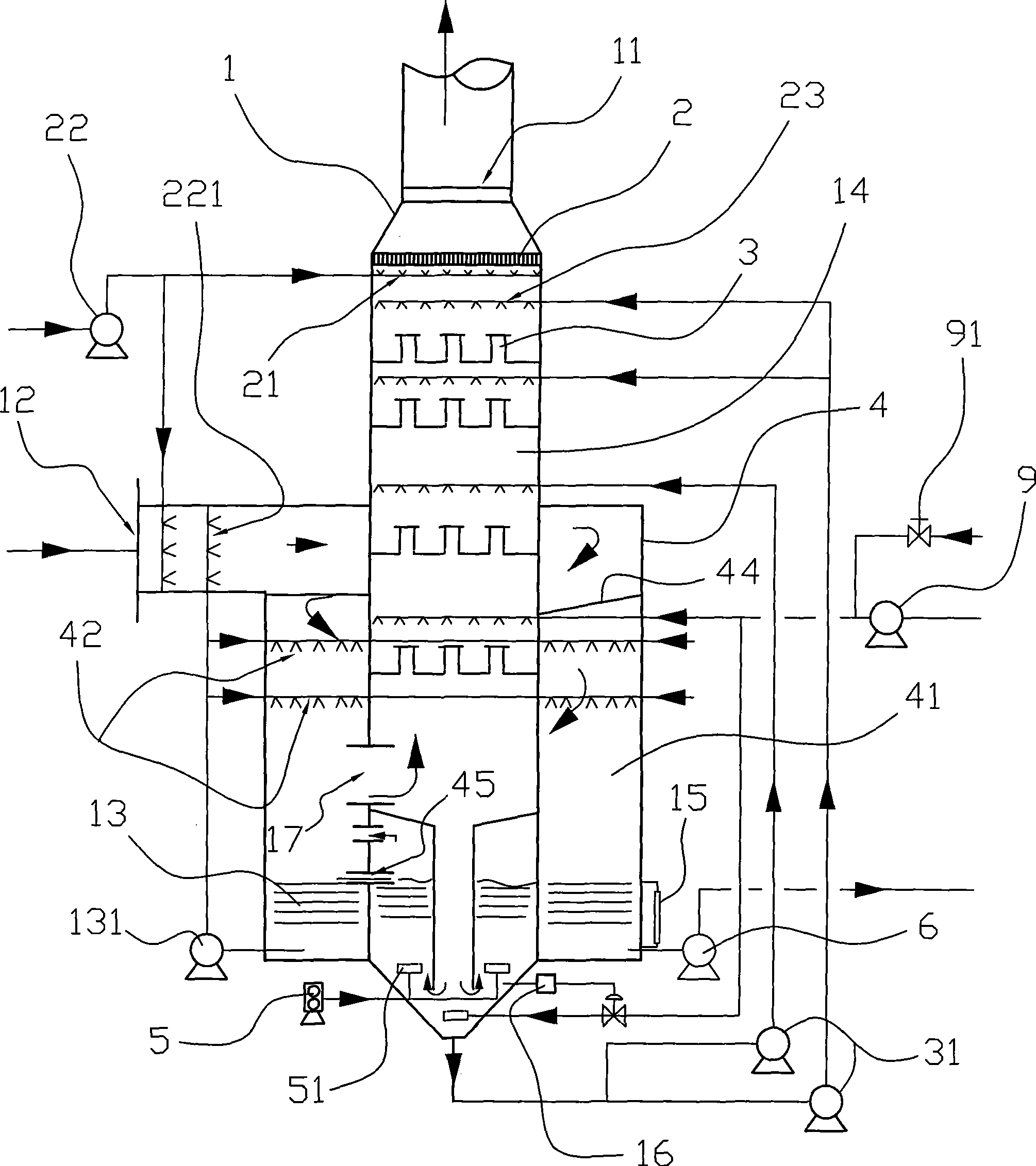

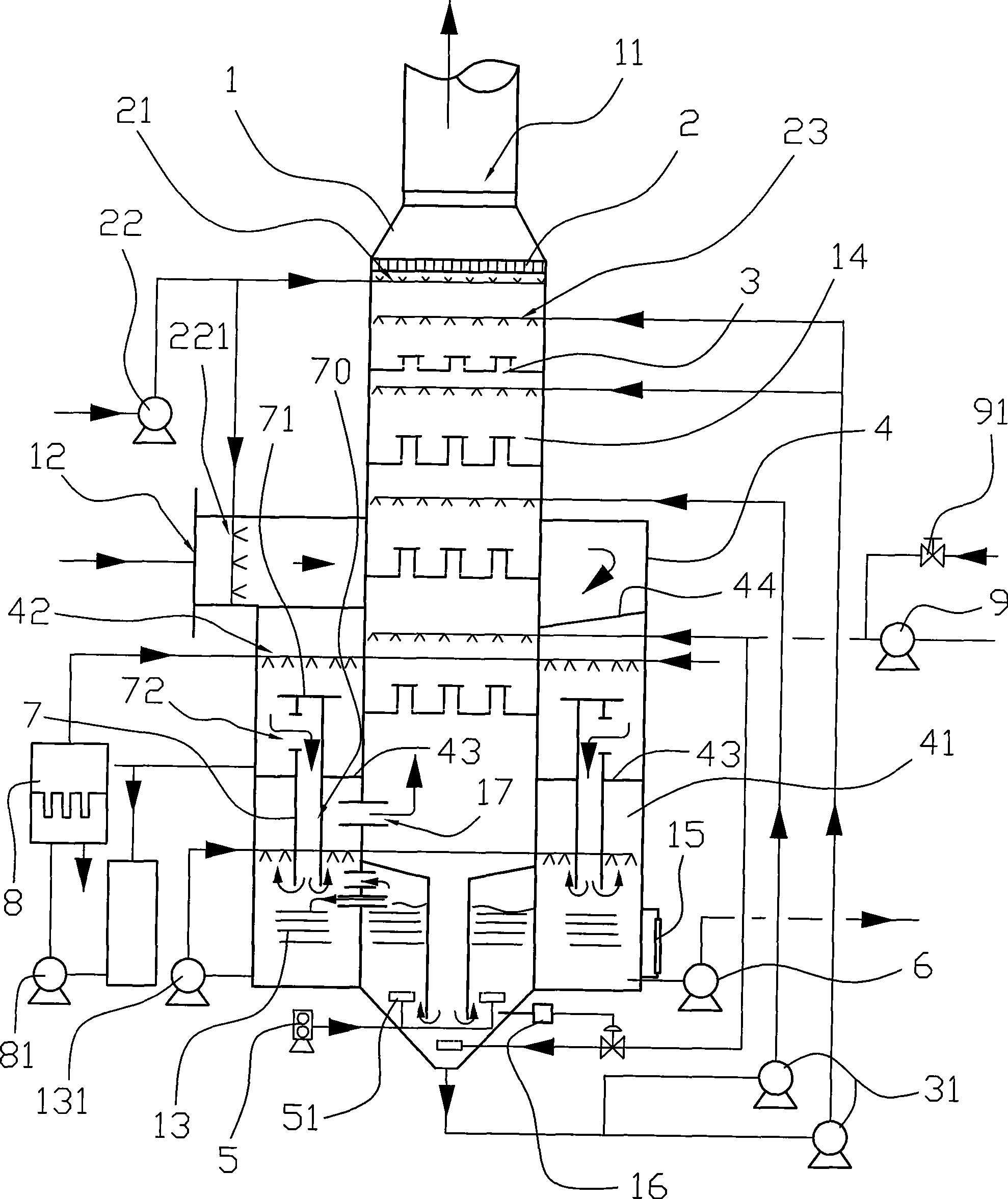

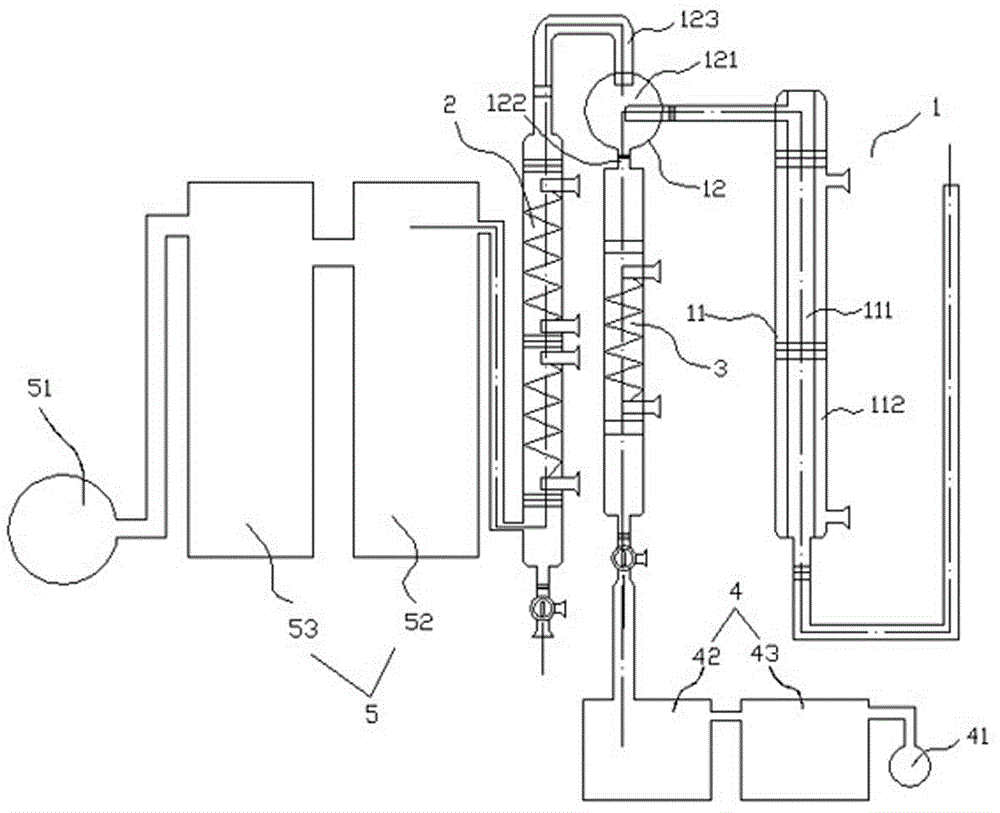

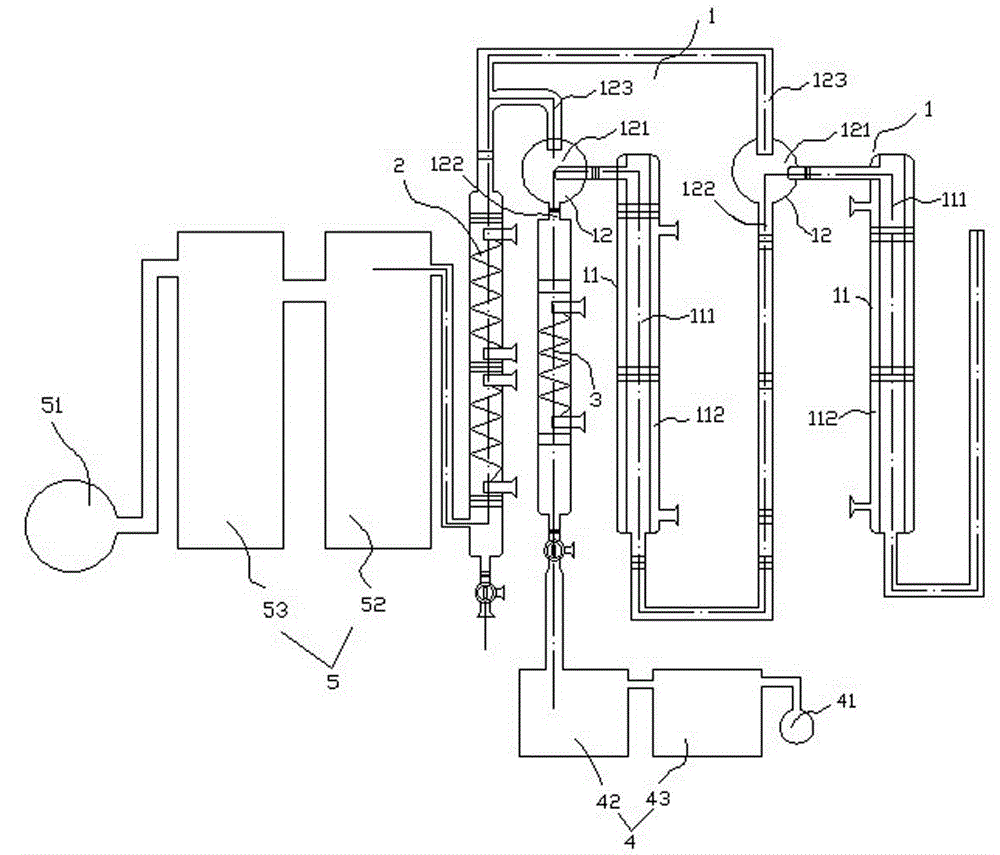

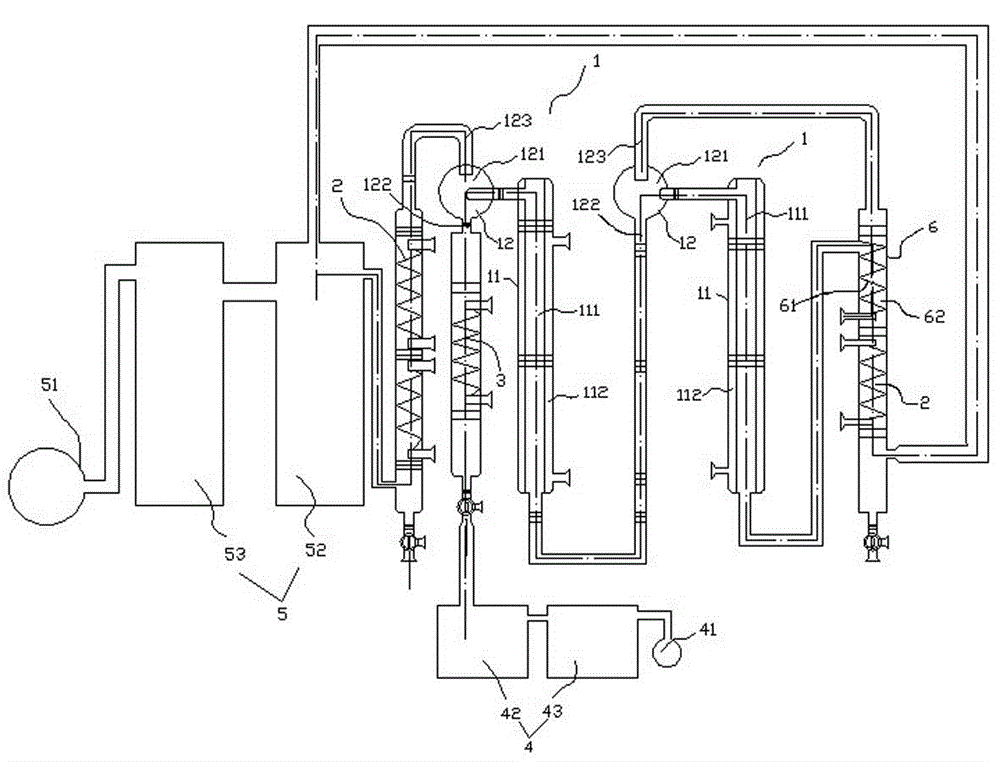

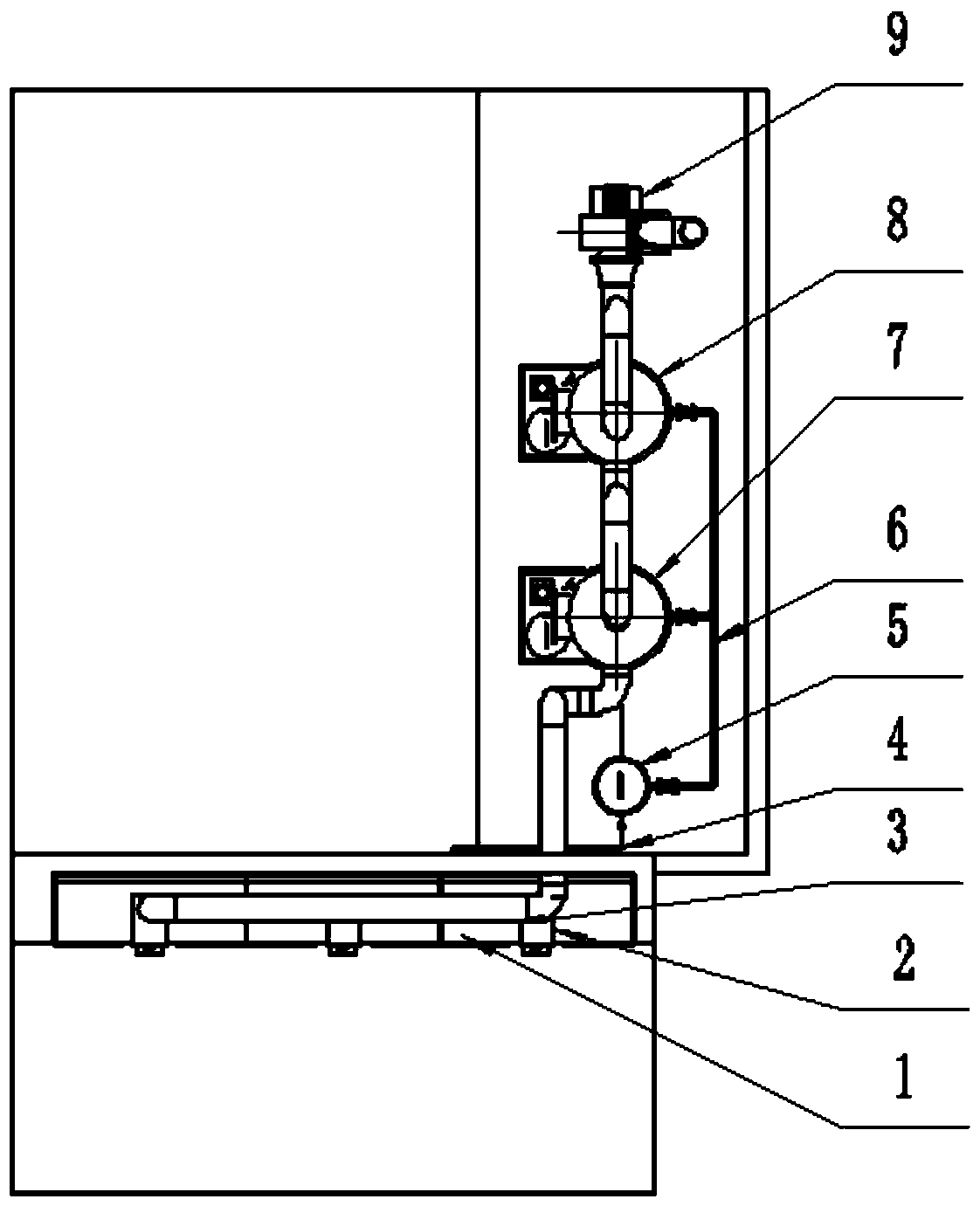

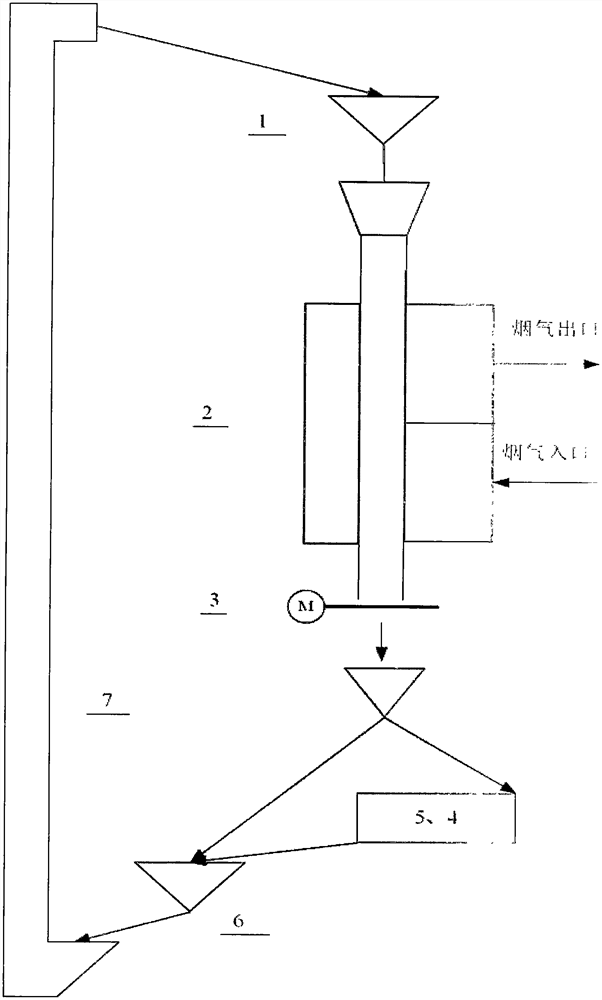

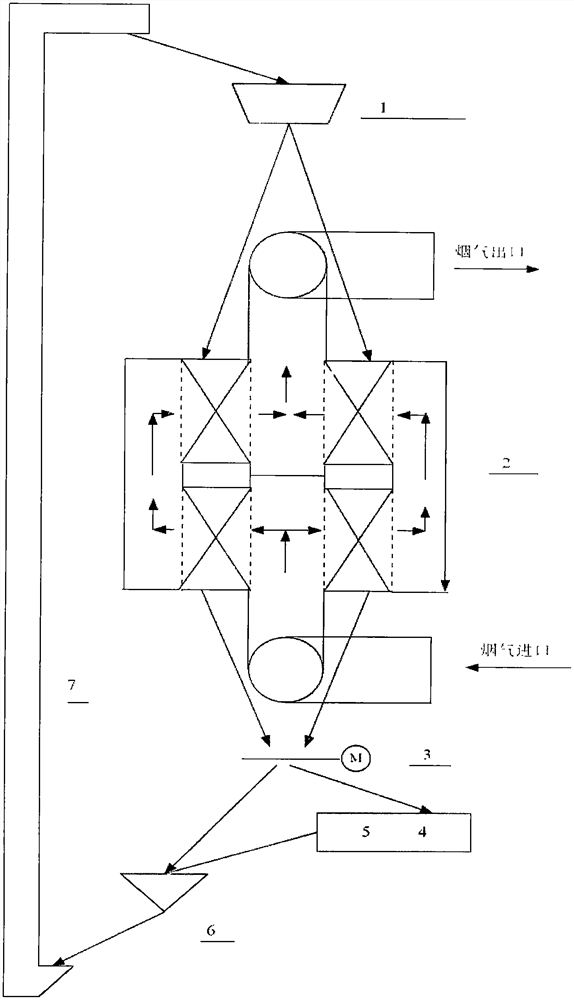

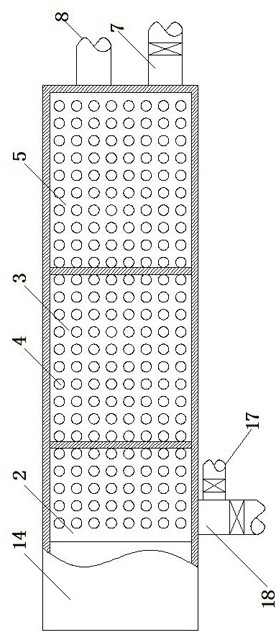

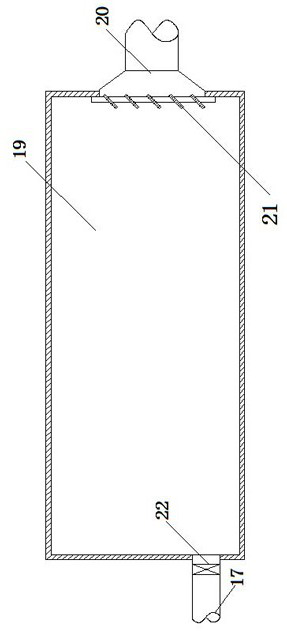

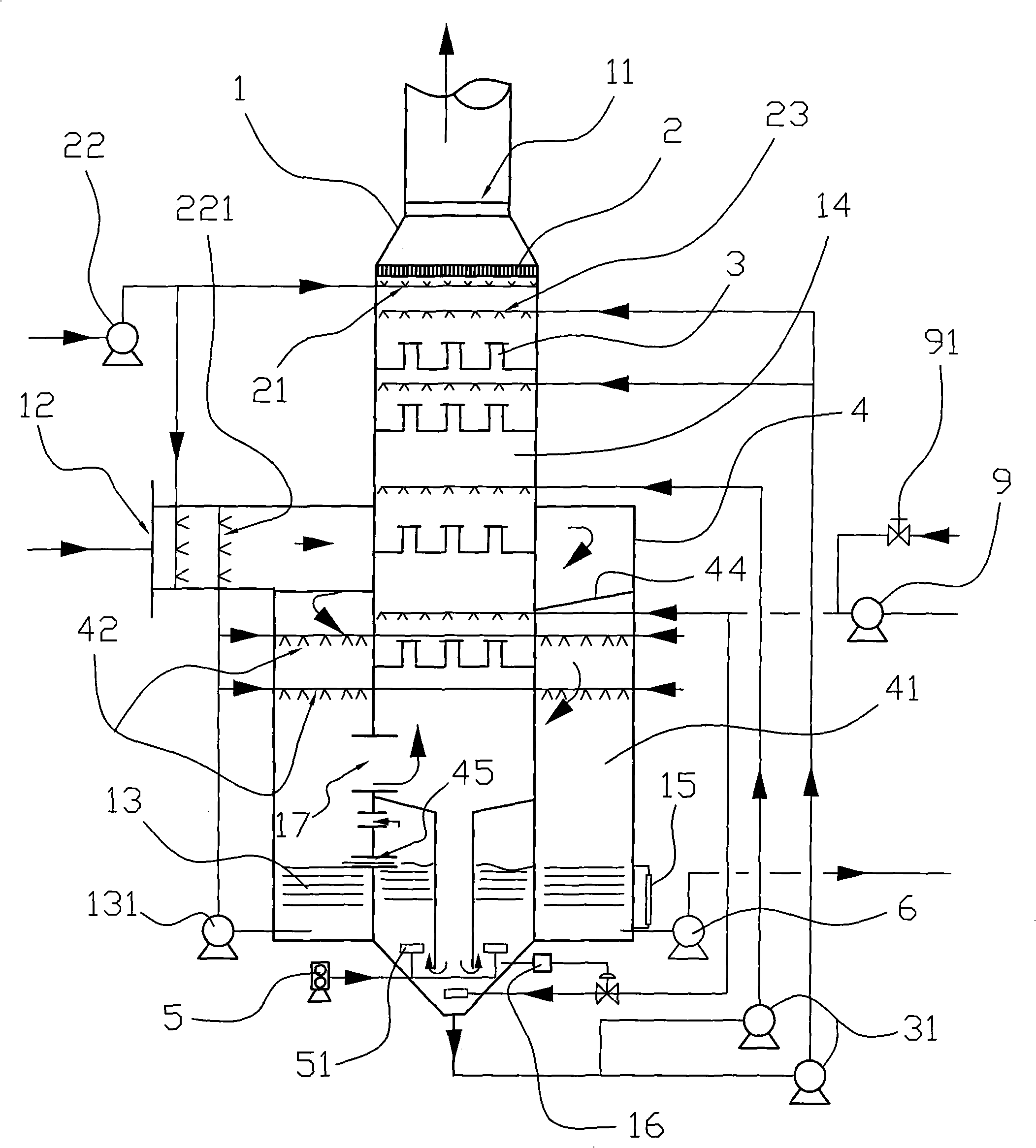

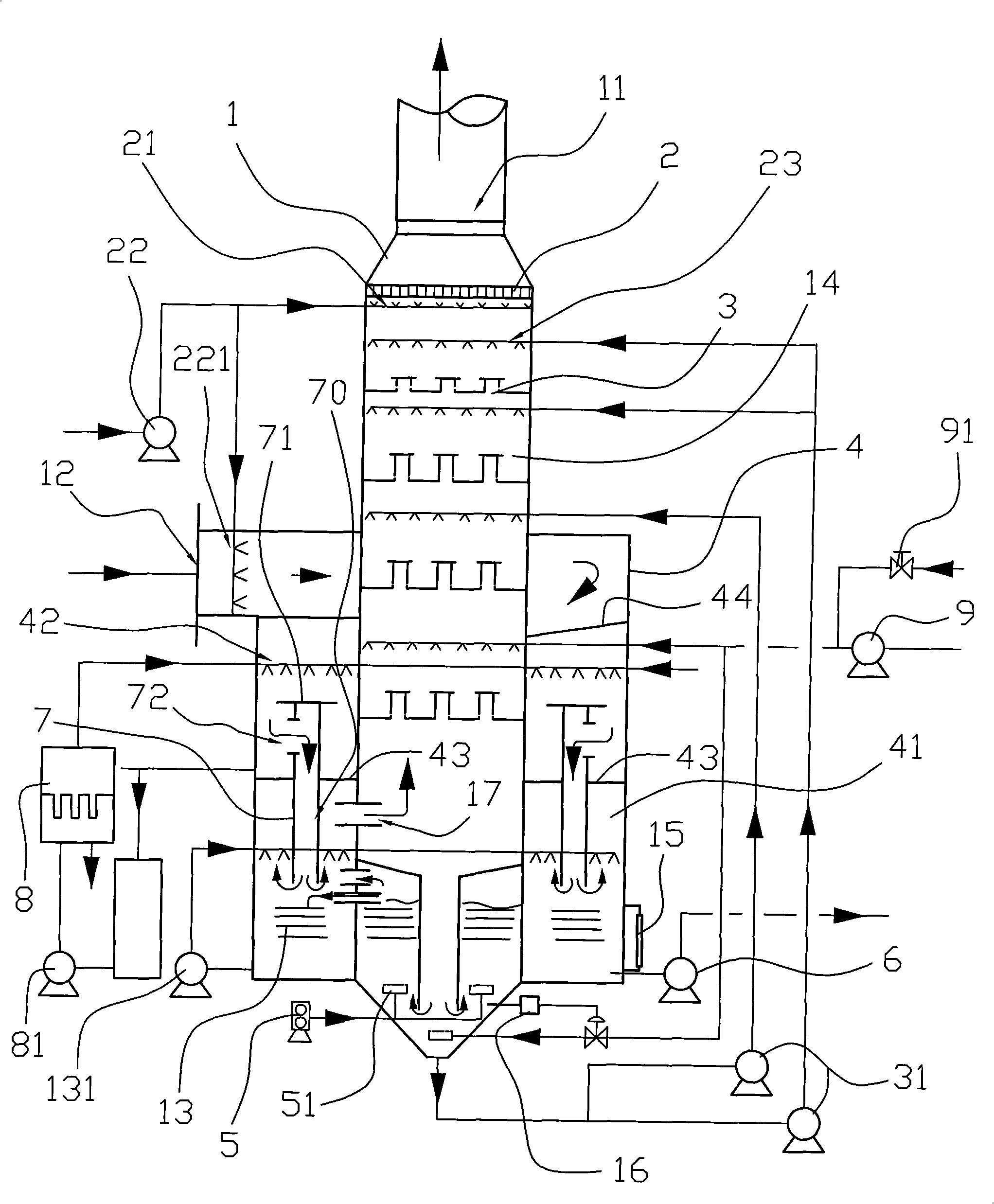

Device for removing sulfuric dioxide in exhaust gas

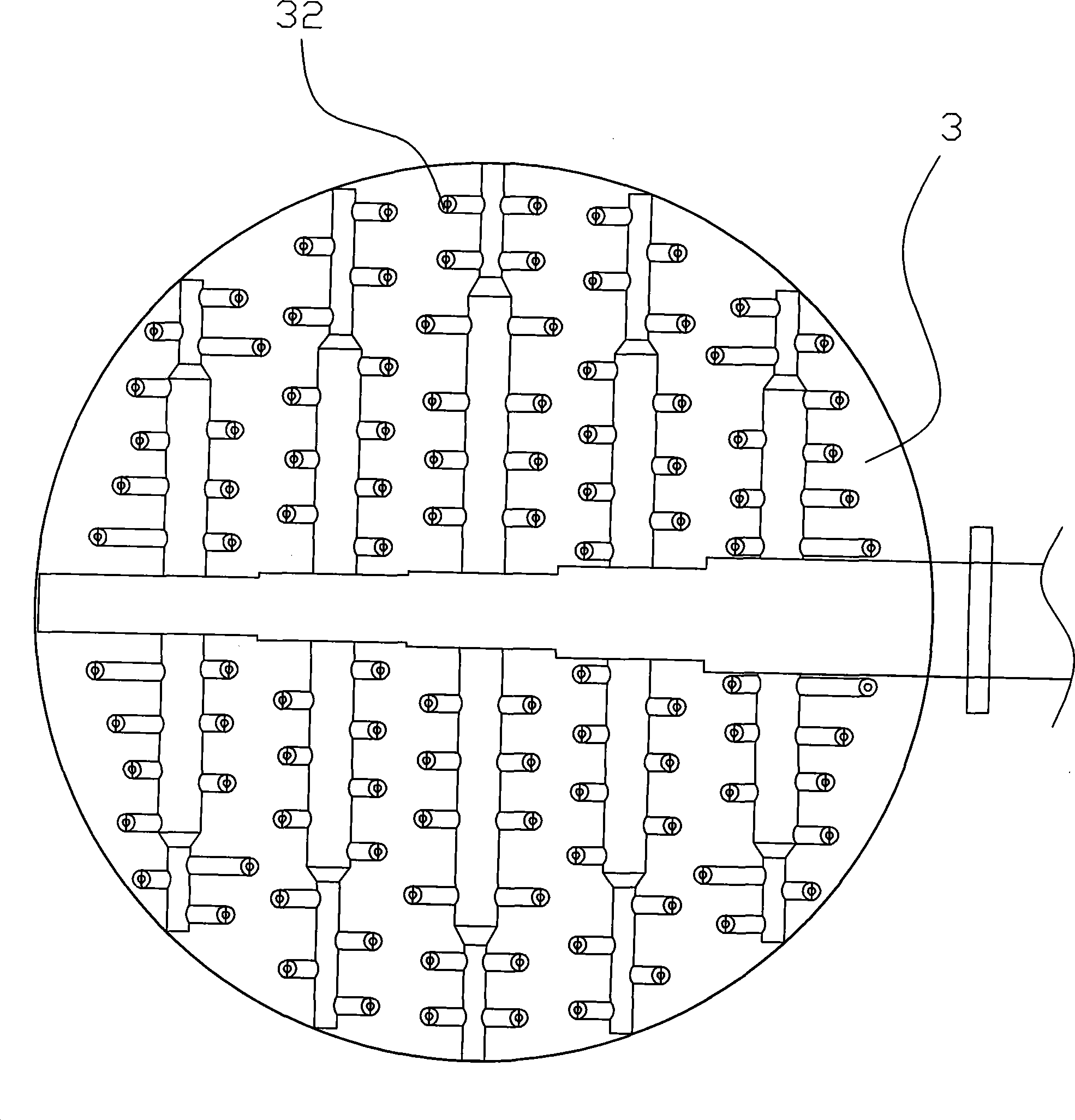

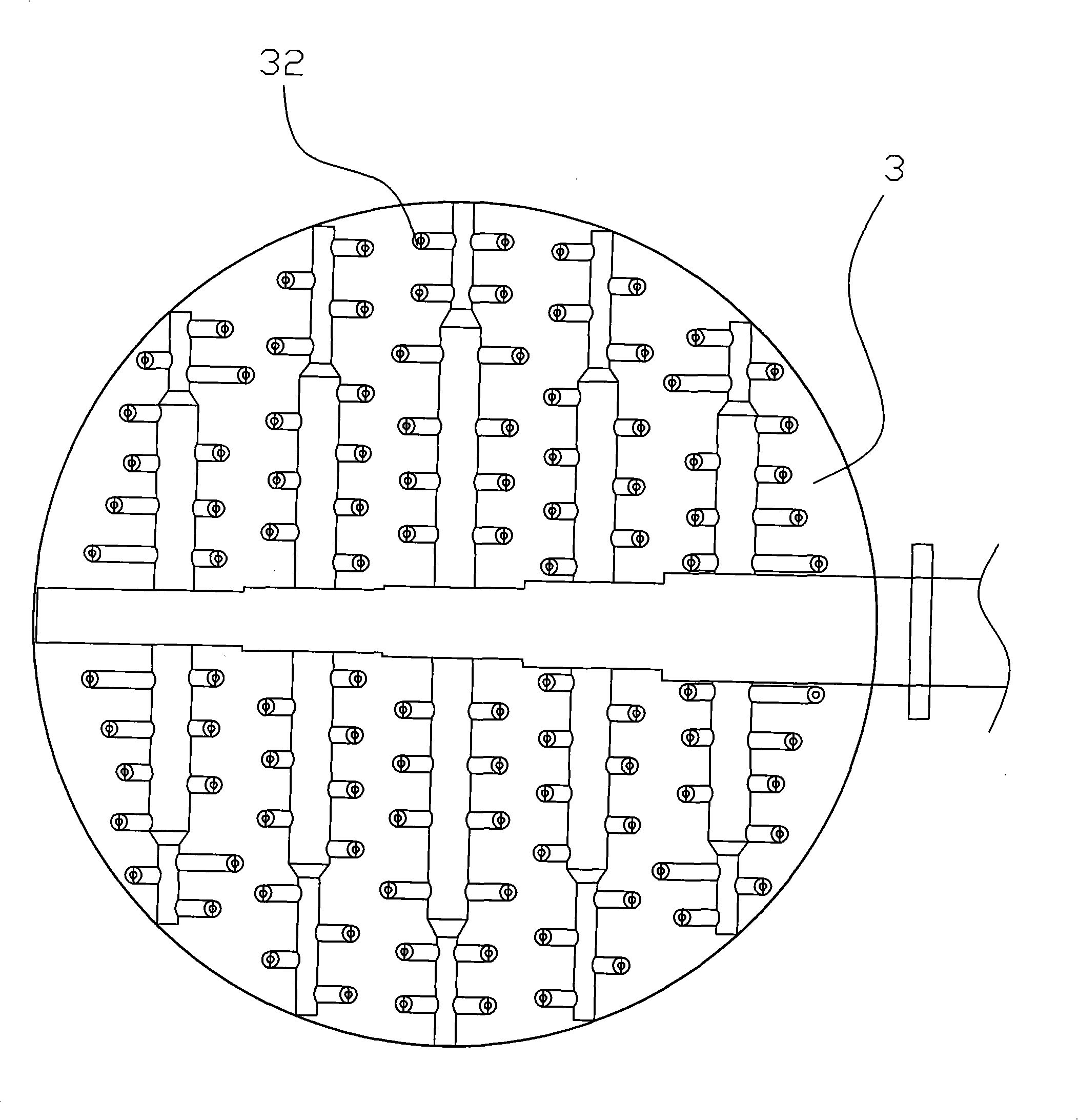

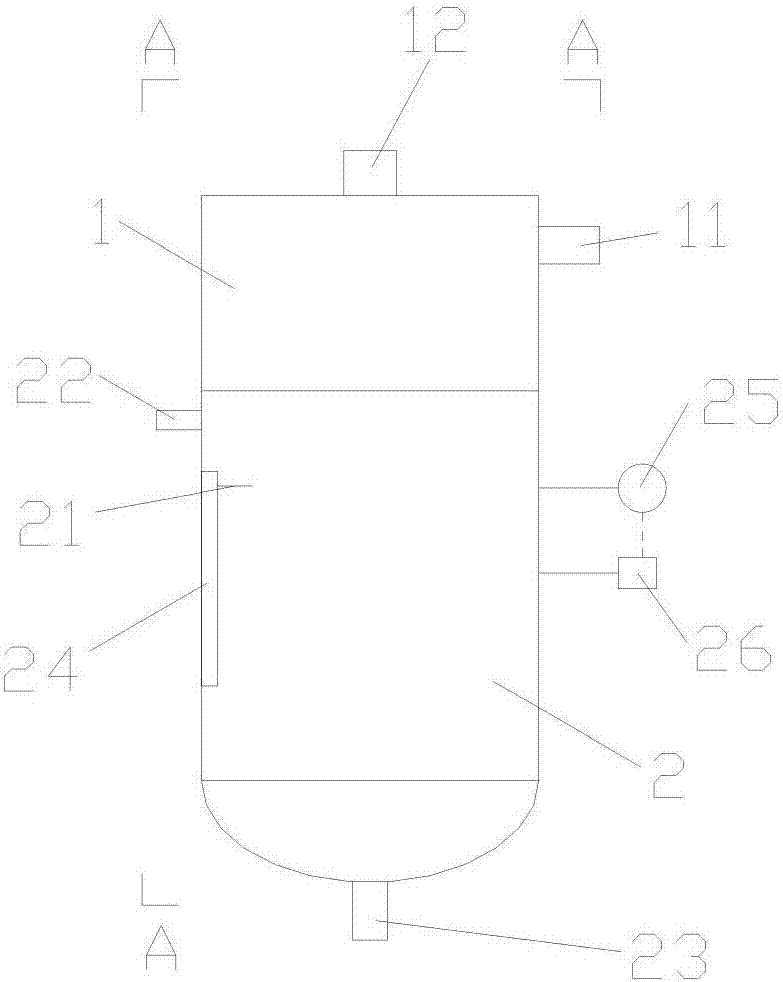

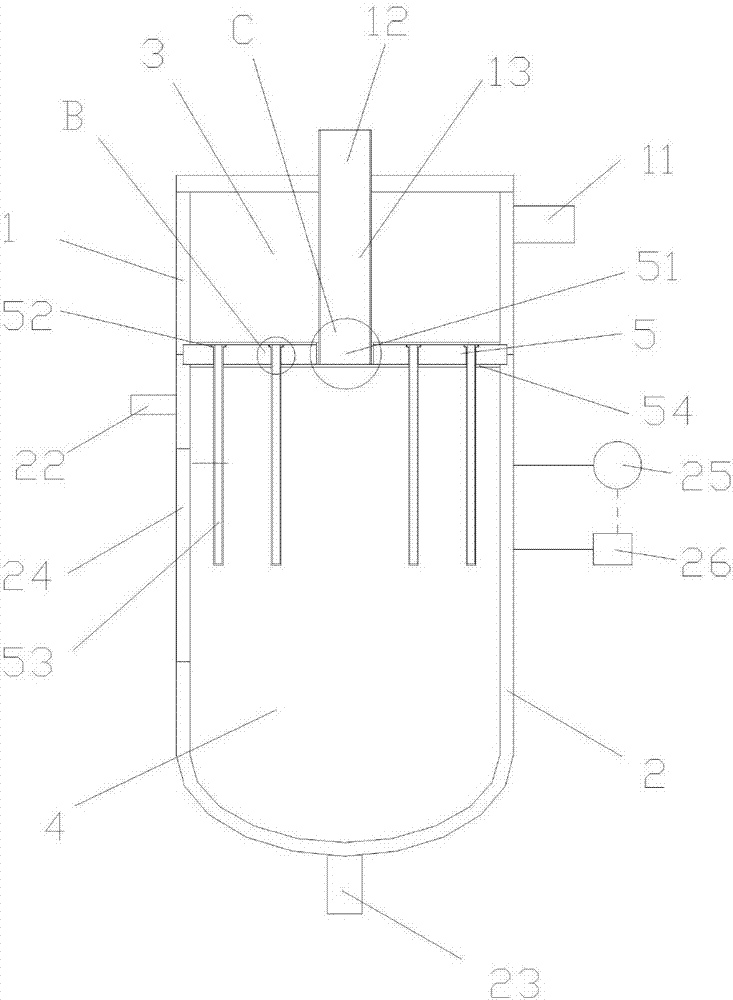

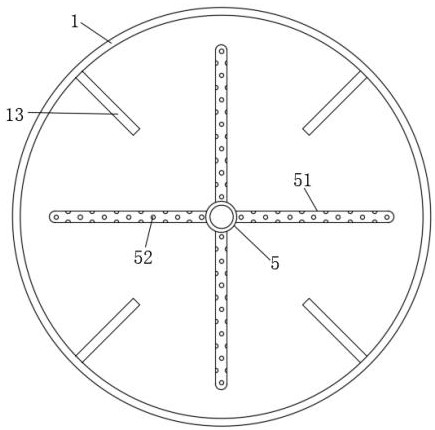

ActiveCN101474528AEliminate biasIncrease contact areaDispersed particle separationProcess engineeringOxidation zone

The invention relates to a device for removing sulfur dioxide in waste gases, which comprises an absorption tower (1). The side surface of the middle of the adsorption tower (1) is provided with a waste gas inlet port (12). The adsorption tower (1) is internally provided with a liquid-gas distributor (3). The top of the adsorption tower (1) is provided with a clean gas discharge outlet (11) while the lower part of the adsorption tower (1) is provided with an absorption liquid concentration oxidation zone (13). The device is characterized in that the waste gas inlet port (12) is communicated with a cooling device in the adsorption tower (1); the gas outlet of the cooling device is arranged below the liquid level of the absorption liquid of the concentration oxidation zone (13); the concentration oxidation zone (13) is communicated with the inner chamber of the adsorption tower (1). The device has the advantages that the waste gas cooling is carried out in the cooling device in the adsorption tower (1); the temperature of the gas in the inner chamber of the absorption tower is reduced into 45 DEG C to 60 DEG C; as the temperature is lower, the absorption effect is better after the gas and the liquid contact; therefore, when the gas with low temperature enters into the adsorption tower, the absorption rate is drastically increased; the device causes that processes such as waster gas, temperature reduction, concentration absorption liquid, desulphurization, oxidation and the like are concentrated in a desulfurizing tower to be completed, thus simplifying the low, reducing the equipment investment, fully making the best of device space and optimal land utilization.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

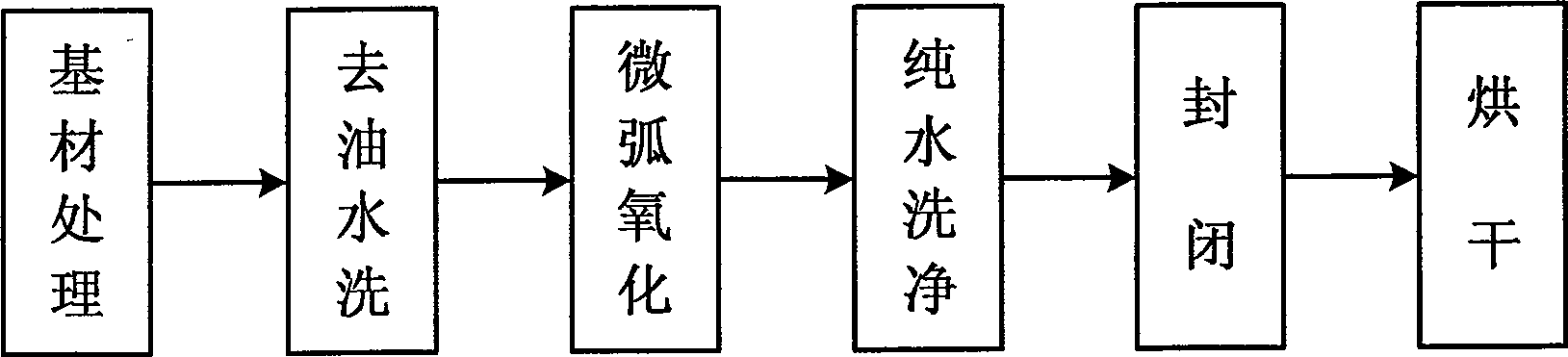

Differential arc oxidization abrasive polishing method for stainless steel surface

InactiveCN1737211AImprove the protective effectBroaden the field of applicationAnodisationMicro arc oxidationMetallurgy

The invention discloses a polishing method of non-corrosive steel surface by differential arc. The invention comprises the following steps: exerting mechanically polishing and degreasing on surface of stainless steel products; cleaning it; placing said stainless steel products in electrolyte solution and intensifying reaction near anode to form intensified oxidation film on it by using sine-wave differential arc that is generated by sine-wave current; cleaning and drying it. The invention resolves the previous problem that differential arc oxidization can not be processed on surface of stainless steel watch.

Owner:江门市福斯特金属表面处理技术发展有限公司

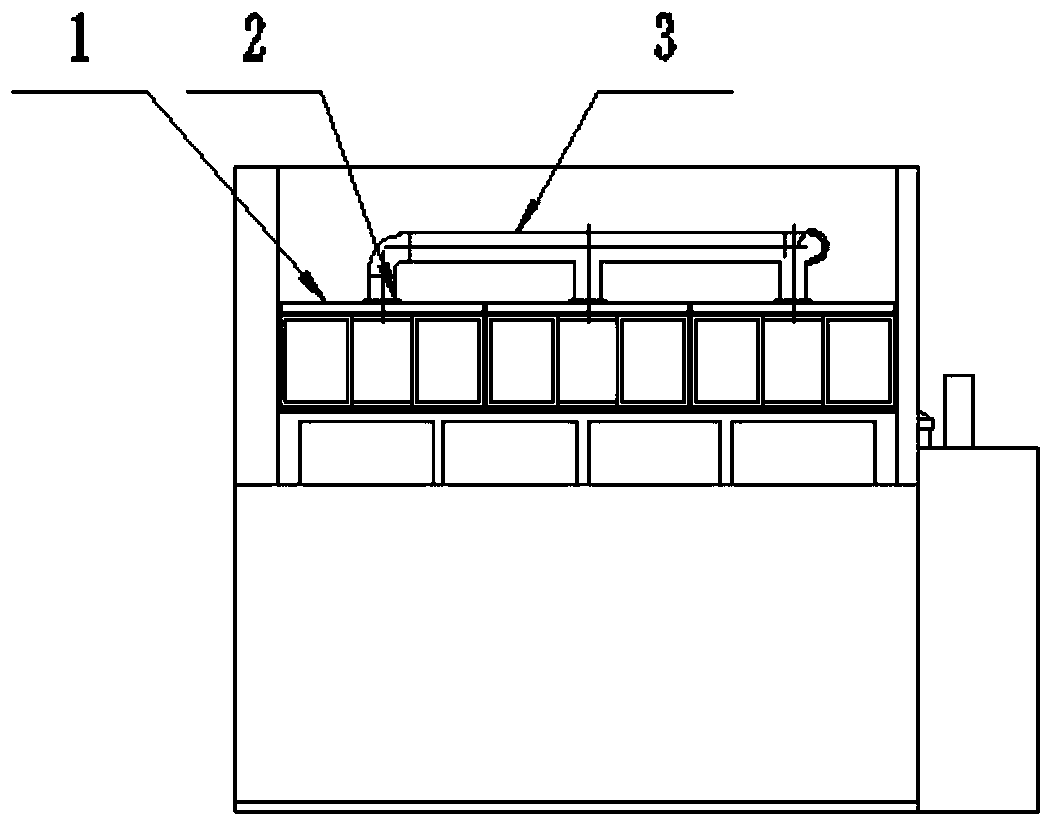

Waste gas purifying method for textile printing and dyeing setting machine and complete equipment thereof

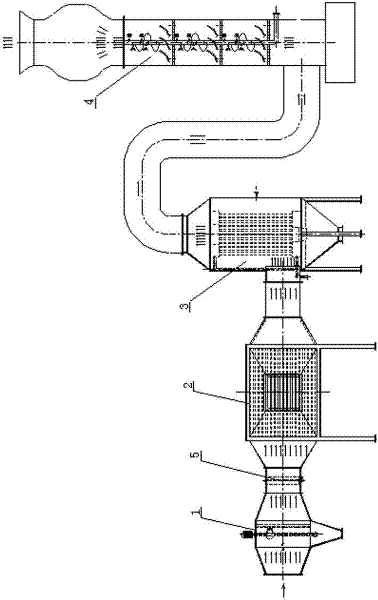

InactiveCN102330311AImprove cleanlinessAvoid secondary and tertiary pollutionCombination devicesVapor condensationTemperature resistanceGas separation

The invention discloses a waste gas purifying method for a textile printing and dyeing setting machine and complete equipment thereof, relates to the technical field of textile and also relates to the technical field of waste gas purification. After cotton velvet in waste gas is separated by a cotton velvet separation device, waste gas is subjected to heat energy recovery by a heat energy recovery device, is subjected to oil removal by an oil-gas separation device, is purified by a gas purification device and finally is discharged. The waste gas purifying method for the textile printing and dyeing setting machine and the complete equipment thereof has the excellent characteristics that the waste gas purifying method and the complete equipment thereof are simple and convenient to operate, have no hazard and are safe and reliable; the complete equipment has corrosion resistance and temperature resistance; the cost is saved; the occupied area is small; the service life is long; wastewater is recycled; the investment and the operation cost of the equipment are low; the efficiency of degreasing, removing dust and collecting oil is high; and the like. Therefore, the finally discharged gas meets the requirements of environmental-friendly discharge.

Owner:扬州荣康空气净化设备厂

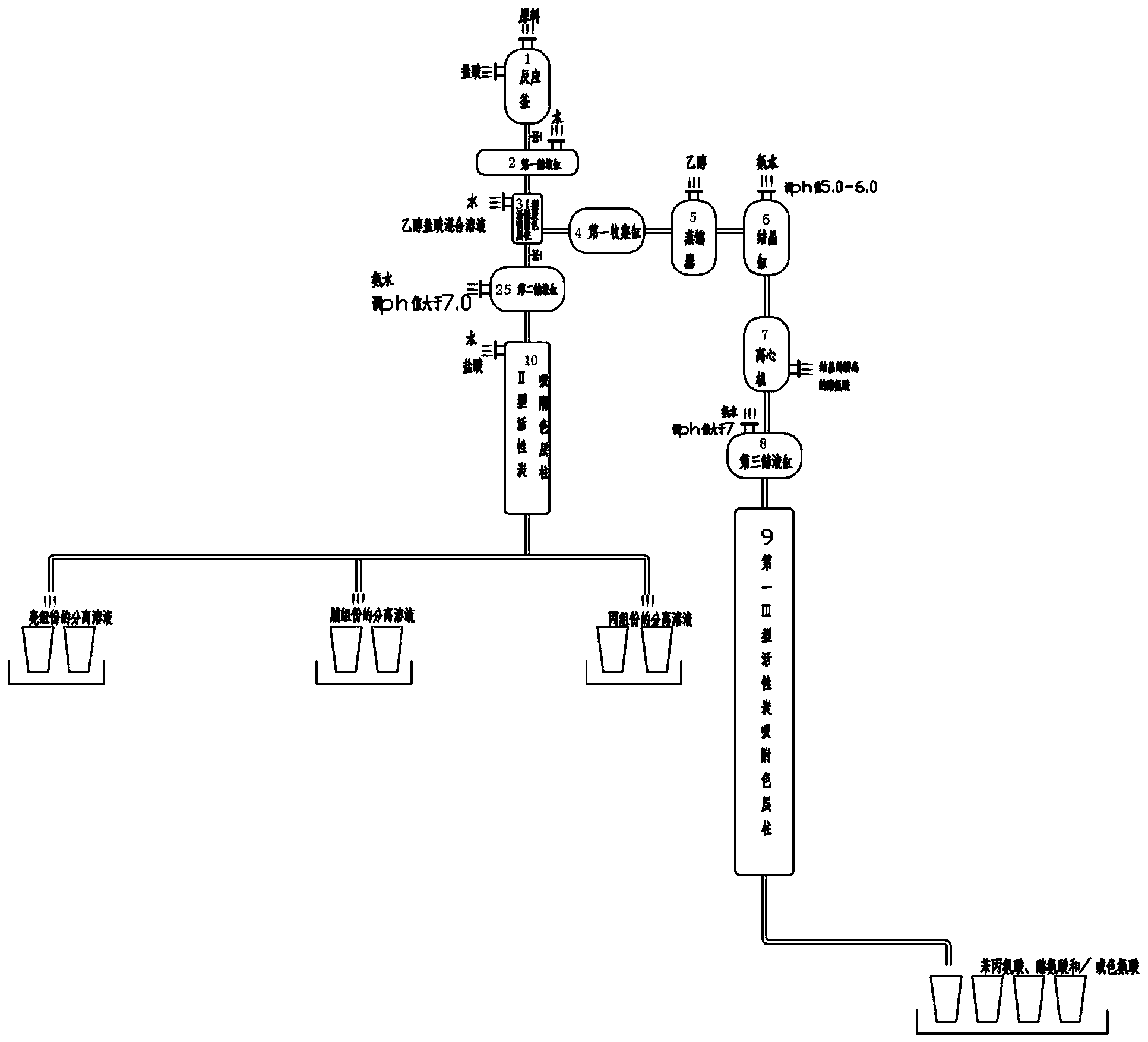

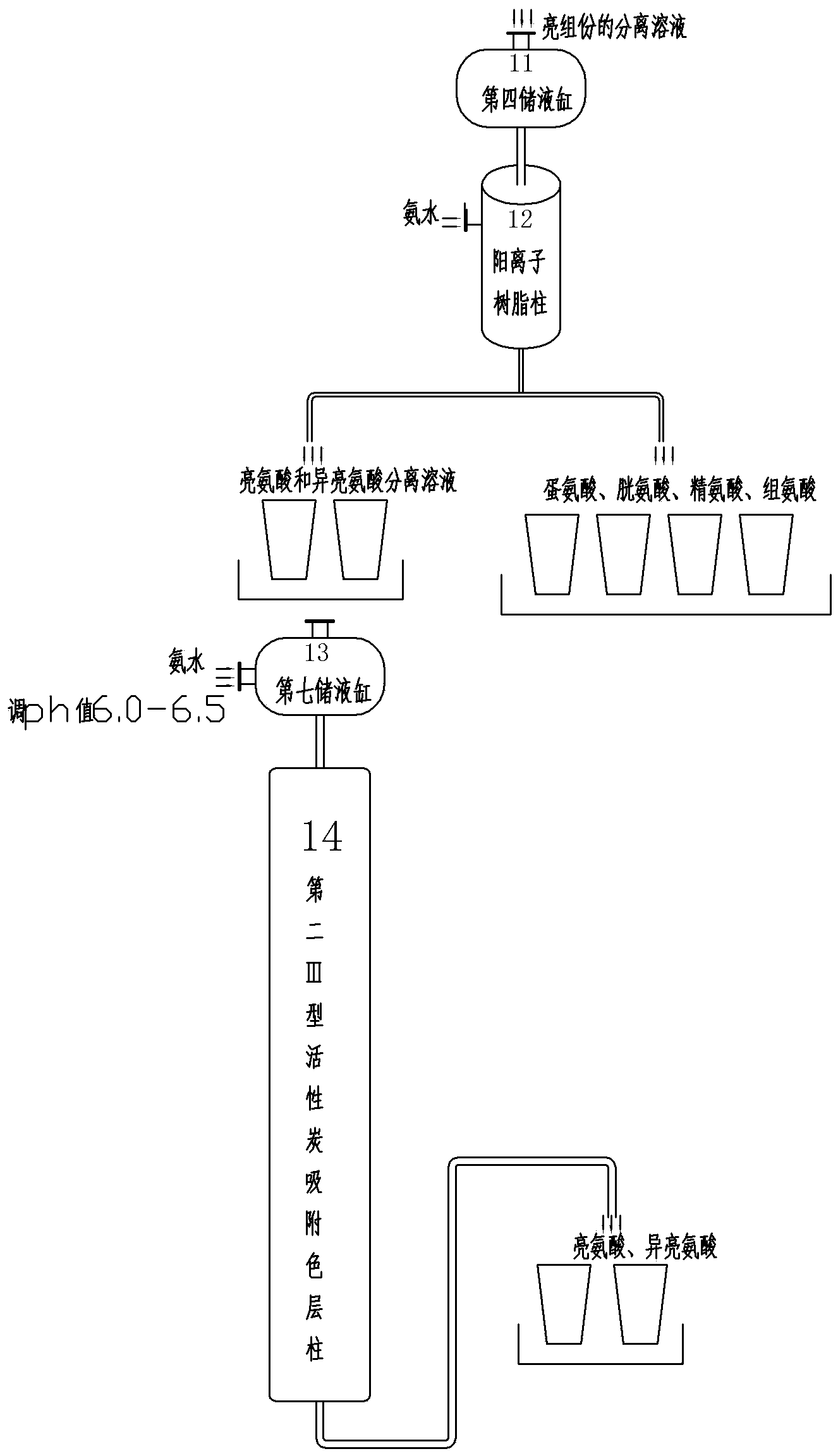

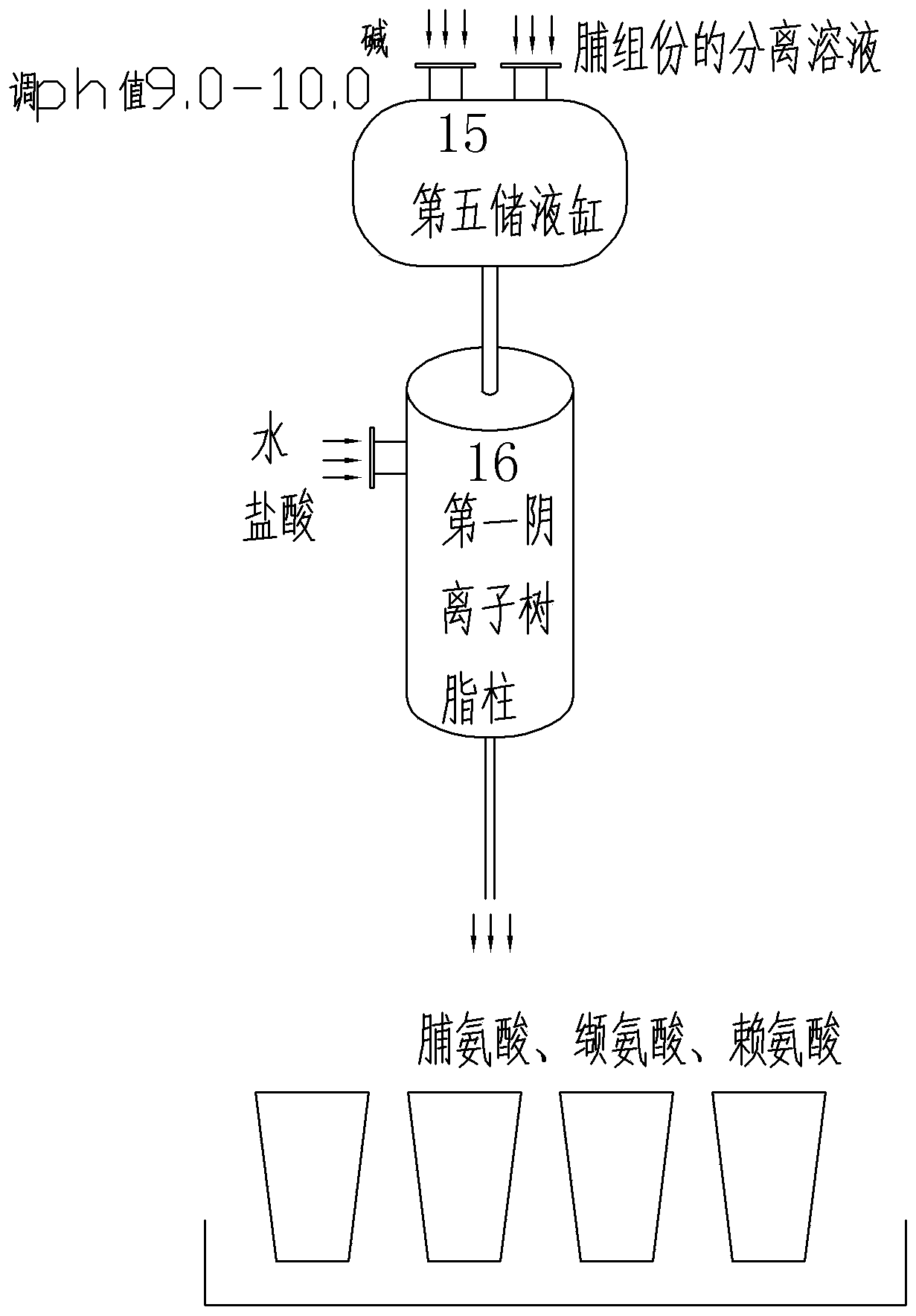

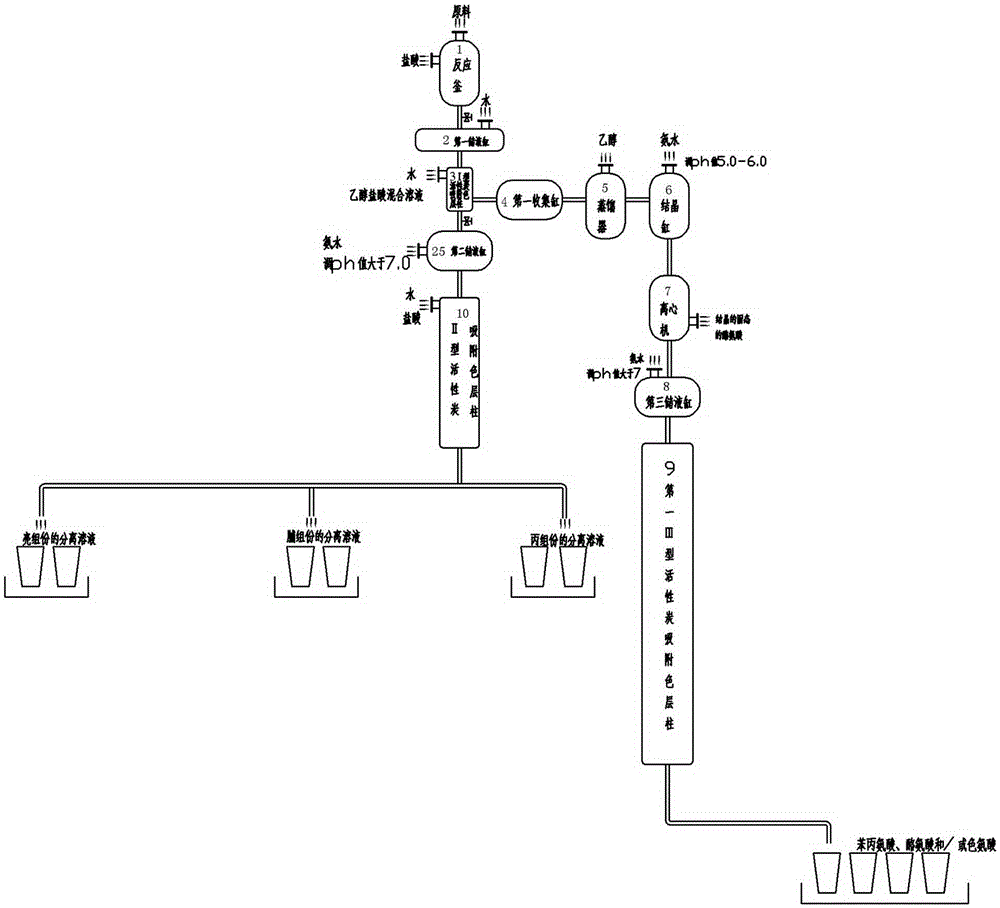

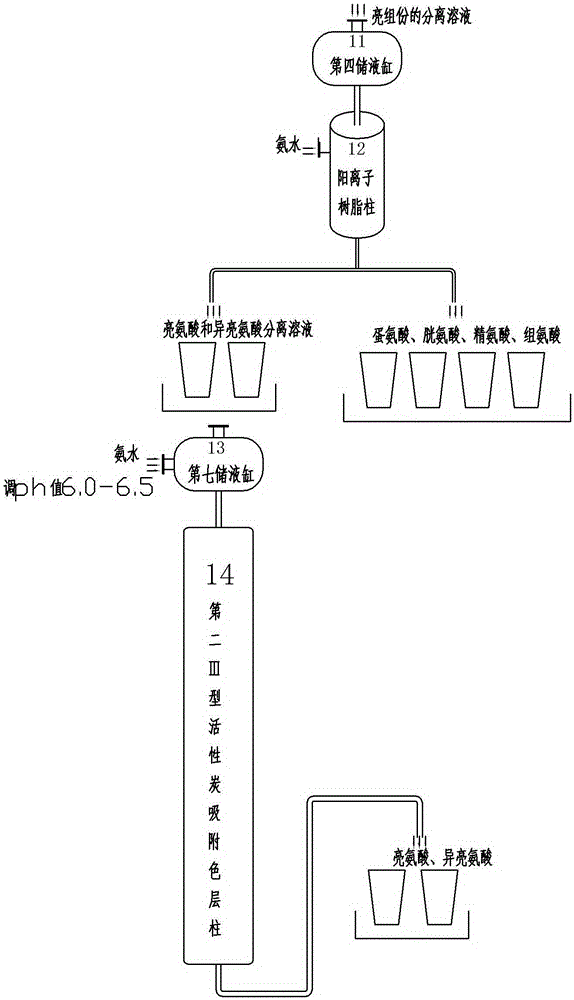

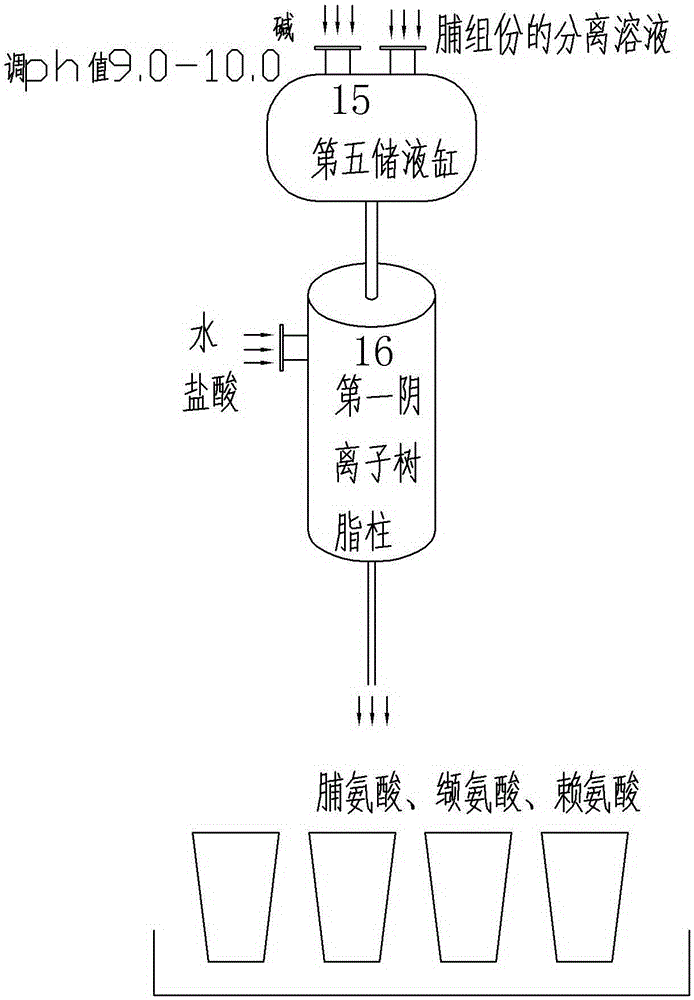

Method and device of separating and extracting amino acid products from protein hydrolysates

ActiveCN103787939AHigh yieldComply with environmental emission requirementsOrganic compound preparationAmino-carboxyl compound preparationPhenylalanine+TyrosineTyrosine

The invention discloses a method and device of separating and extracting amino acid products from protein hydrolysates. The method comprises the following steps that amino acid mixed solutions are attenuated by water, flow through an I-shaped column, and are washed, ethanol hydrochloric acid mixed solutions flow through the chromatographic column, collecting fluids are obtained by the combination of washing liquor and the ethanol hydrochloric acid mixed solutions, the collecting fluid is adjusted at the PH of about 5.0 to about 6.0, tyrosine can be acquired through filtration, a filter liquor is neutralized by alkali at the PH of more than 7.0, the filter liquor flows through a III-shaped column, and phenylalanine, tyrosine and / or tryptophan are acquired through separation; the ethanol hydrochloric acid mixed solutions flowed through the I-shaped column is adjusted at the PH of more than 7.0, the ethanol hydrochloric acid mixed solutions flow through a II-shaped column, and light components separation solutions, pulp components separation solutions and propanal components separation solutions can be acquired by the sequential adoption of washing, hydrochloric acid extrication and collecting the scrubbing solution in segments; A subsequent separation is conducted for the separation solutions and all the amino acid products are acquired. The method can increase variety of species and yield rate of a single amino acid, the water body for separation and extraction can be recycled, and waste water meets the requirements of environmental emissions.

Owner:广州博采生物科技有限公司

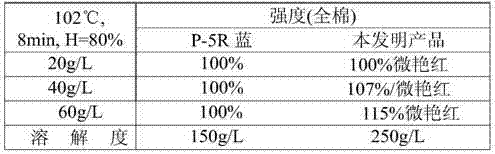

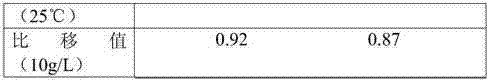

Blue reactive dye for printing, and preparation methods thereof

InactiveCN103709784ABright colorExcellent fastness performanceReactive dyesDyeing processColour fastnessStructural formula

The invention discloses a blue reactive dye for printing, and preparation methods thereof. The blue reactive dye has a structural formula shown as formula (1). The invention also discloses three different preparation methods of the blue reactive dye. The reactive dyes prepared by the three methods all blue printing reactive dyes with excellent color fastness such as washing durability, rub resistance and sunlight fastness, and meet the requirements of various indexes.

Owner:ZHEJIANG JINGGUANG IND

Concentration and recovery device for industrial electroplating wastewater

InactiveCN102794025AComply with environmental emission requirementsTurn waste into treasureCellsWaste water treatment from metallurgical processLiquid wasteCyclone

The invention discloses a concentration and recovery device for industrial electroplating wastewater. The whole device comprises a heating separation system, a water condenser, a liquid material condenser, a liquid material collection tank and a distilled water collection tank; at least one stage of separation device is included in the heating separation system, and each stage of the separation device is composed of a straight-tube type evaporator and a cyclone-type separator; a straight-tube inner passage and a straight-tube outer passage used as waste liquid pipelines are included in the straight-tube type evaporator; and the outlets of the waste liquid pipelines in the same stage of the separation device directly extend into a separation cavity in the same stage of the inner cyclone-type separator, a liquid collection tube is arranged at the bottom of the separation cavity, and a gas collection tube is arranged at the top of the separation cavity. The concentration and recovery device for industrial electroplating wastewater can be used for effectively recovering precious metal ingredients in the electroplating wastewater and is large in unit heating area, short in solution flow-stopping time, high in heat evaporation efficiency, and economical in concentration cost.

Owner:ENSOO TAIZHOU CHEM

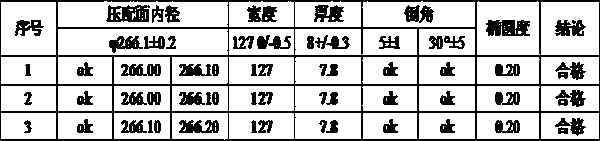

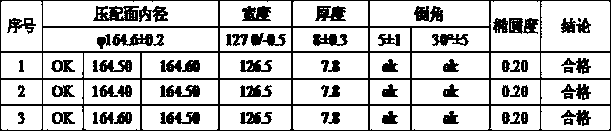

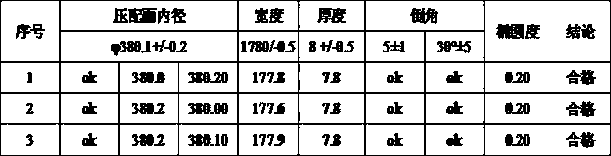

Press-fit type steel ring production process

The invention discloses a press-fit type steel ring production process. The press-fit type steel ring production process comprises the following steps that raw material steel rolls are sheared into blanking steel rolls required by press-fit type steel ring standard specification utilizing longitudinal shearing strip dividing equipment, the blanking steel rolls are fabricated into pipe-shaped blankparts through a molding process after roll opening and flattening, the pipe-shaped blank parts are conveyed into electric resistance welding equipment, continuous welding is performed, welding seamsare processed and scraped synchronously, and press-fit type steel ring siamesed blank parts are fabricated; fabricated press-fit type steel ring siamesed blank part finished products are cut into single-piece press-fit type single-body blank parts utilizing cutting equipment; finishing is performed on the fabricated press-fit ring single-body blank parts to eliminate stress, and stable machining single-body blank parts are obtained; and the obtained stable machining single-body blank parts are ground to the specified width, and press-fit type steel ring finished products are obtained. By meansof the press-fit type steel ring production process, the cost is lowered, the whole production process has less process nodes, less labour is used, the consistency and stability of the welding seamsare high, and the single-piece good product rate of the machined steel rings is greatly increased.

Owner:唐银成

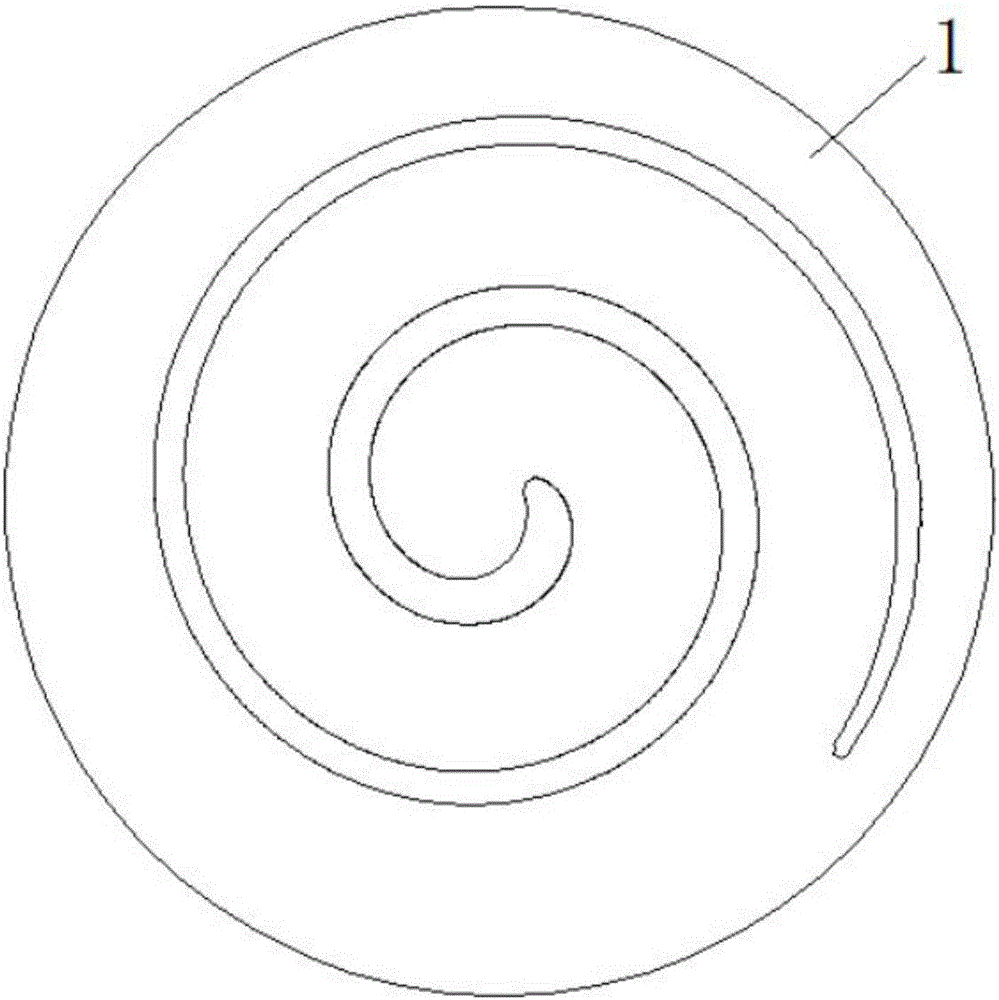

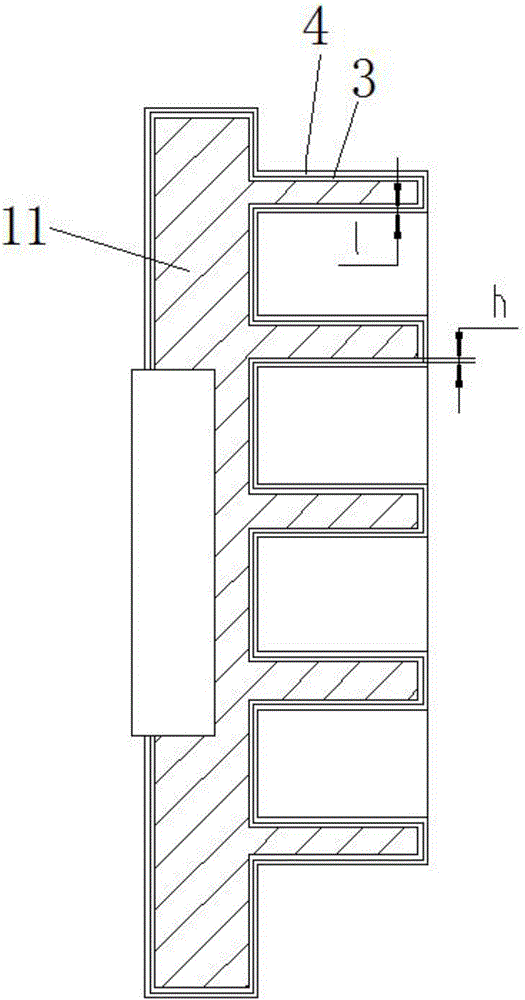

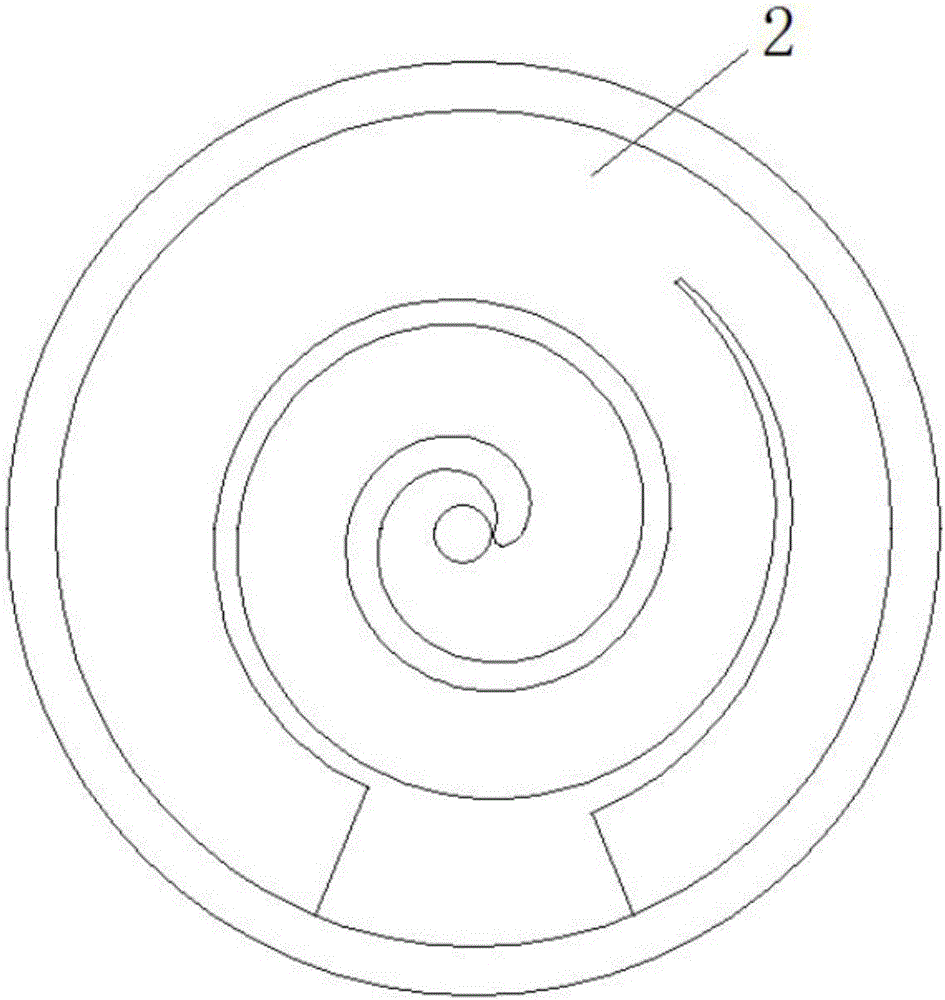

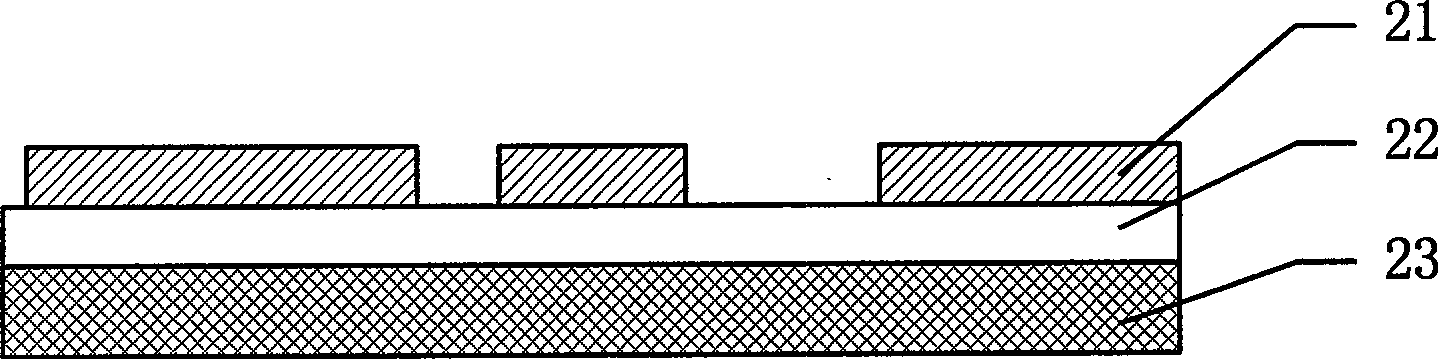

Scroll compressor assembly, manufacturing method thereof and scroll compressor

ActiveCN106762631ACompact structureHigh hardnessAnodisationRotary piston pumpsMicro arc oxidationSurface roughness

The invention relates to a scroll compressor assembly. The scroll compressor assembly comprises a movable scroll part and a static scroll part, wherein the movable scroll part comprises a first main body; the static scroll part comprises a second main body; the surface, opposite to the second main body, on the first main body is defined as a first surface; the surface, opposite to the first main body, on the second main body is defined as a second surface; ceramic layers are formed on the first surface and / or the second surface through micro-arc oxidation treatment, so that service wear of the movable scroll part and the static scroll part is reduced; and the ceramic layers are good in abrasion resistance, high in hardness and low in surface roughness, so that the scroll compressor assembly can maintain high matching precision and stable working performances during the long-term utilization process. The invention further relates to a scroll compressor with the scroll compressor assembly and a manufacturing method of the scroll compressor assembly. The scroll compressor is high in reliability and long in service life. The manufacturing method is simple, efficient and energy-saving, and pollution is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

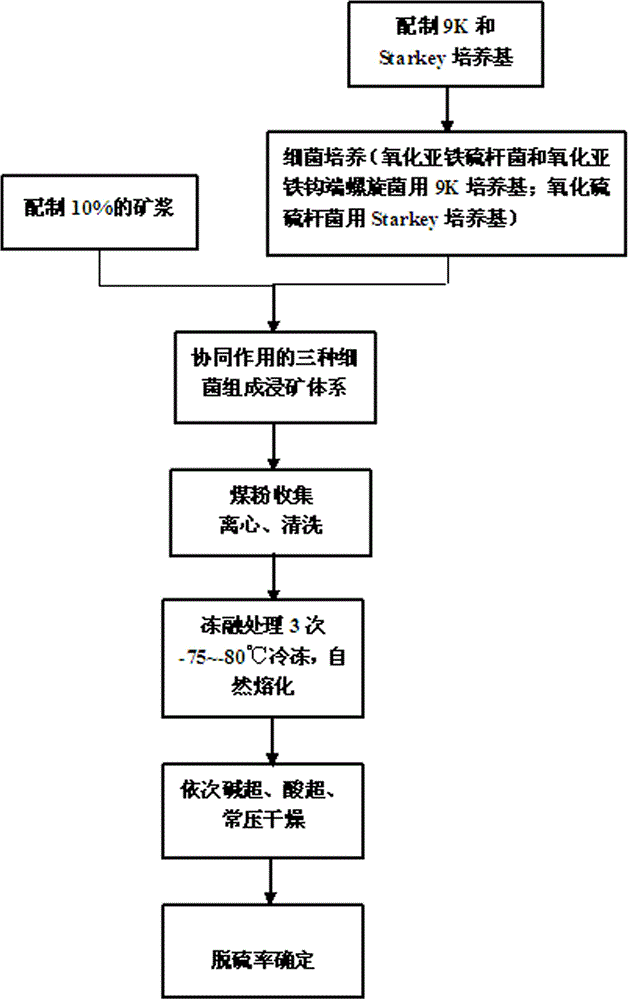

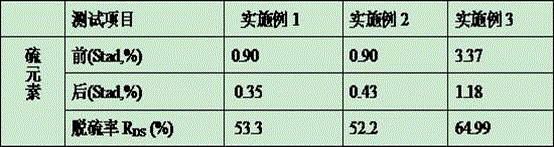

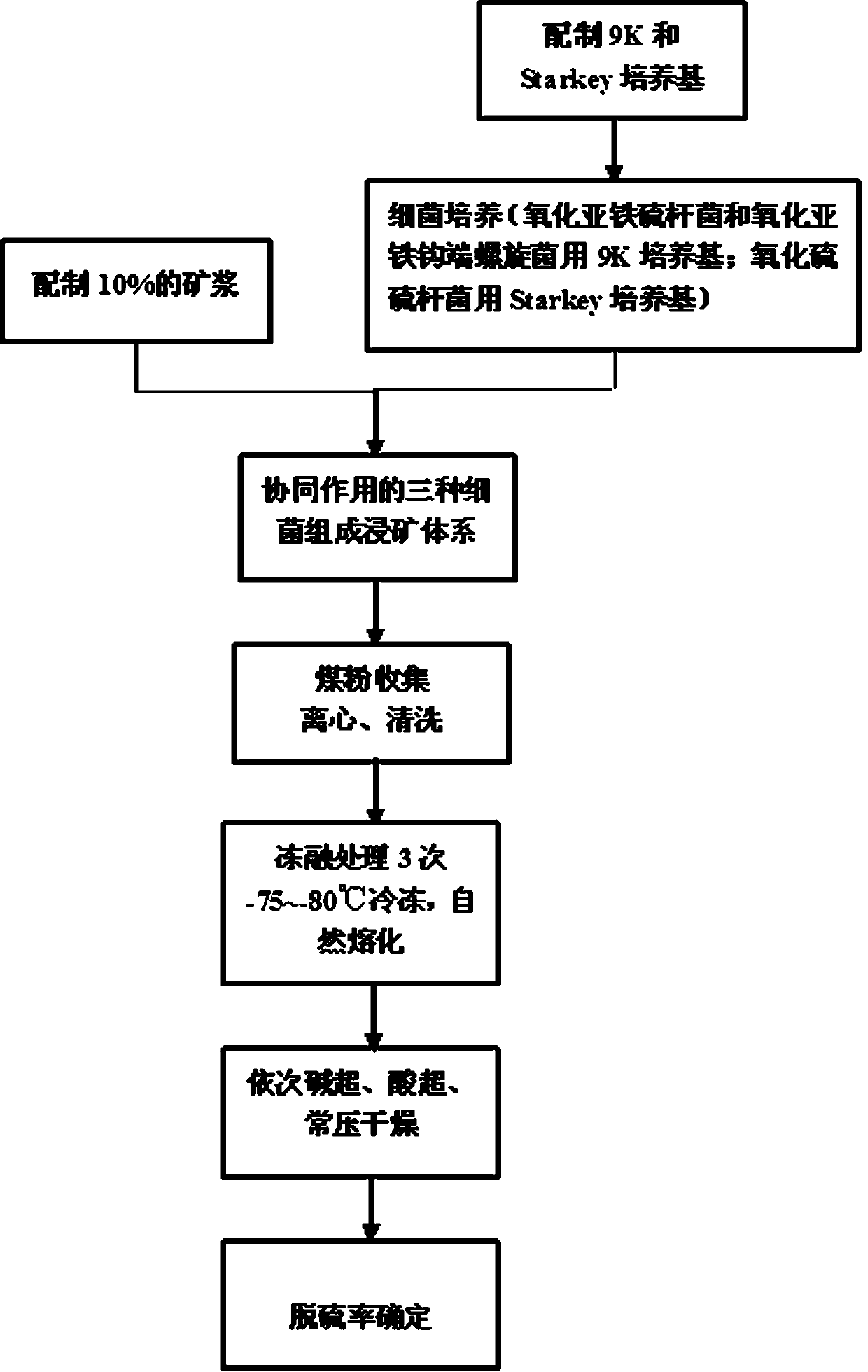

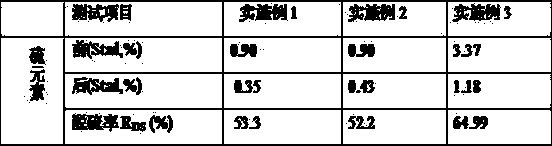

Desulphurization method of coal dust via biological oxidation

ActiveCN105542898AEmission reductionReduce pollutionBacteriaMicroorganism based processesAfter treatmentSulfur content

The invention provides a desulphurization method of coal dust via biological oxidation. The process comprises the following steps: (1) preparation of a medium; (2) culture of bioleaching bacteria; (3) preparation of pulp; (4) inoculation of bacteria in a leaching system; (5) ore leaching; (6) collection of coal dust; (7) freezing-thawing treatment; (8) ultrasonic treatment with alkali for the coal dust; (9) ultrasonic treatment with acid for the coal dust; (10) drying of the coal dust; (11) determination of desulfurization rate of the coal dust. The ore leaching is carried out with synergistic effects of three species of bacteria at normal temperature and normal pressure, freezing-thawing, ultrasonic treatment with alkali, and ultrasonic treatment with acid are combined, so that sulfur in the coal dust is oxidized into sulfate and dissolved in water for separating from the coal dust; the desulfurization rate of the coal dust after treatment reaches above 50%, the sulfur content of the coal dust after treatment is below 1.2%, the lowest sulfur content is 0.35%, and the discharge meets the environmental protection requirements.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for microwave treatment of oily sludge

InactiveCN111170614AHigh calorific valuePromote generationSludge treatmentLiquid hydrocarbon mixture productionMicrowave pyrolysisSludge

The invention discloses a method for microwave treatment of oily sludge. The method comprises the following steps: introducing oily sludge into microwave treatment equipment, carrying out microwave pyrolysis reaction under the protection of nitrogen, carrying out condensation separation on the generated pyrolysis gas to obtain purified oil, and discharging the residual sludge from the microwave treatment equipment. Compared with traditional pyrolysis, microwave pyrolysis has a unique heat and mass transfer rule and better heating uniformity, temperature regulation and control, the pyrolysis process and expected final products are easy to control, a large amount of time and energy can be saved, and the thermal inertia of the equipment is small; according to the method for microwave treatment of oily sludge, oil and water in the oily sludge can be fully recycled, meanwhile, the recycling cost of the oily sludge is reduced, the treated sludge meets the environment-friendly emission requirement (the oil content reaches 0.3% or below), and secondary pollution is prevented.

Owner:大庆中科清溪水处理技术服务有限公司

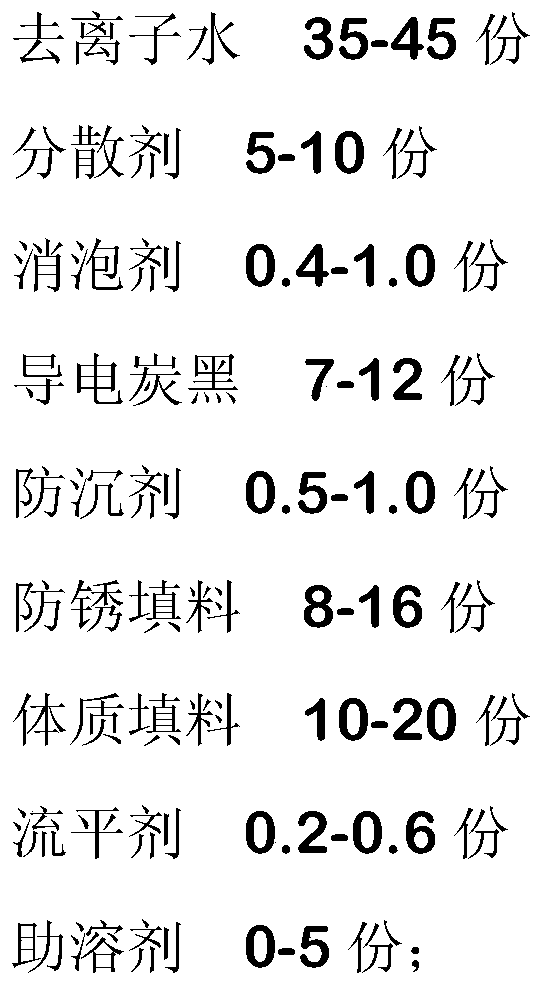

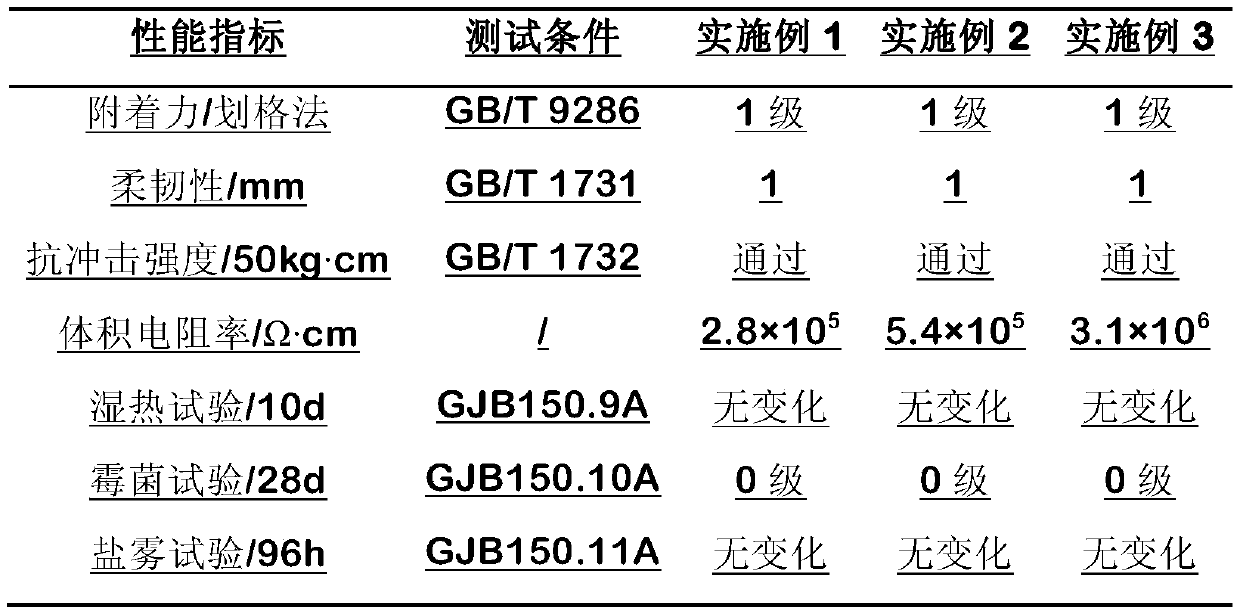

Waterborne epoxy four-proofing paint as well as preparation method and application thereof

InactiveCN111234651AStrong adhesionGood toughness strengthAntifouling/underwater paintsPaints with biocidesEpoxySocial benefits

The invention relates to waterborne epoxy four-proofing paint and a preparation method and application thereof. The waterborne epoxy four-proofing paint is capable of preventing static electricity, salt mist, damp-heat and mould, and belongs to the technical field of preparation of special functional coatings. The preparation process is simple, water is used as a medium for dispersion and spraying, no hazardous waste is generated in the production process, high practicability is achieved, and the prepared waterborne epoxy four-proofing paint can meet related industry standards, can be popularized and applied to the military field, meets the national environmental protection emission requirement and has good economic benefits and social benefits.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

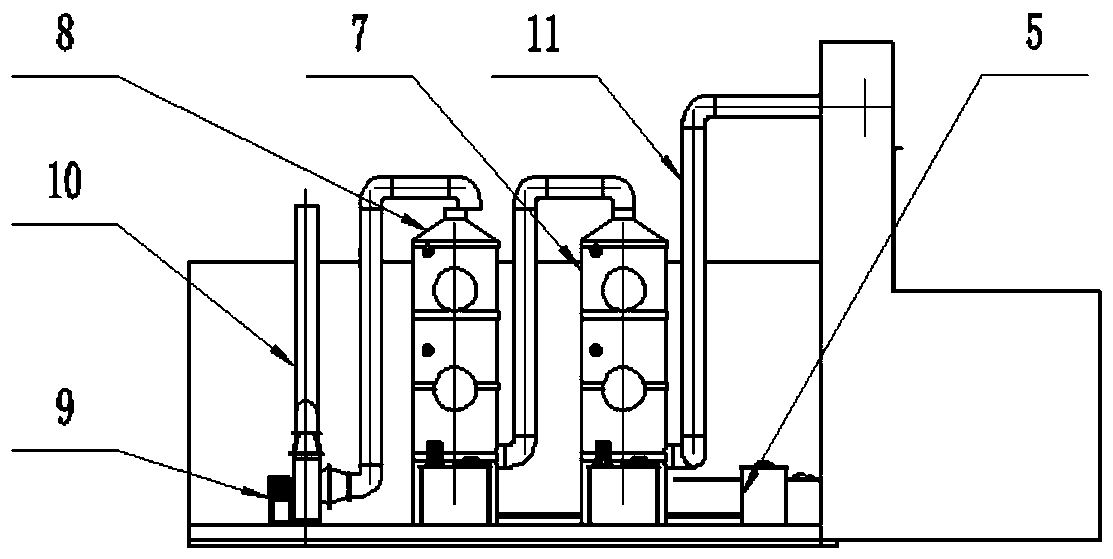

Device for environment-friendly treatment of acid gases in laboratory

PendingCN108211707ASimple structureLow costGas treatmentDispersed particle separationVentilation tubeEngineering

The invention relates to a device for environment-friendly treatment of acid gases in a laboratory in the field of the laboratory. The device comprises a ventilating cupboard, an inner ventilating pipe, a first-stage purifying tower, a second-stage purifying tower, an exhausting chimney and an outer ventilating pipe, wherein the ventilating cupboard is arranged at the position corresponding to theposition above an indoor testing platform of the laboratory; an air valve is arranged at a flue-gas outlet at the top part of the ventilating cupboard; one end of the inner ventilating pipe is connected with an exhausting port of the air valve, and the other end of the inner ventilating pipe is connected with the outdoor ventilating pipe; the outer ventilating pipe is correspondingly communicatedwith the bottom part of the first-stage purifying tower for carrying out oxidizing purification; the top part of the first-stage purifying tower is correspondingly communicated with the bottom part of the second-stage purifying tower for absorbing purification; the top part of the second-stage purifying tower is correspondingly communicated with the exhausting chimney by an exhausting fan. The device has the beneficial effect that the hazard of the acid gases generated in the laboratory to the environment can be effectively managed.

Owner:洛阳三轩金研环保科技有限公司

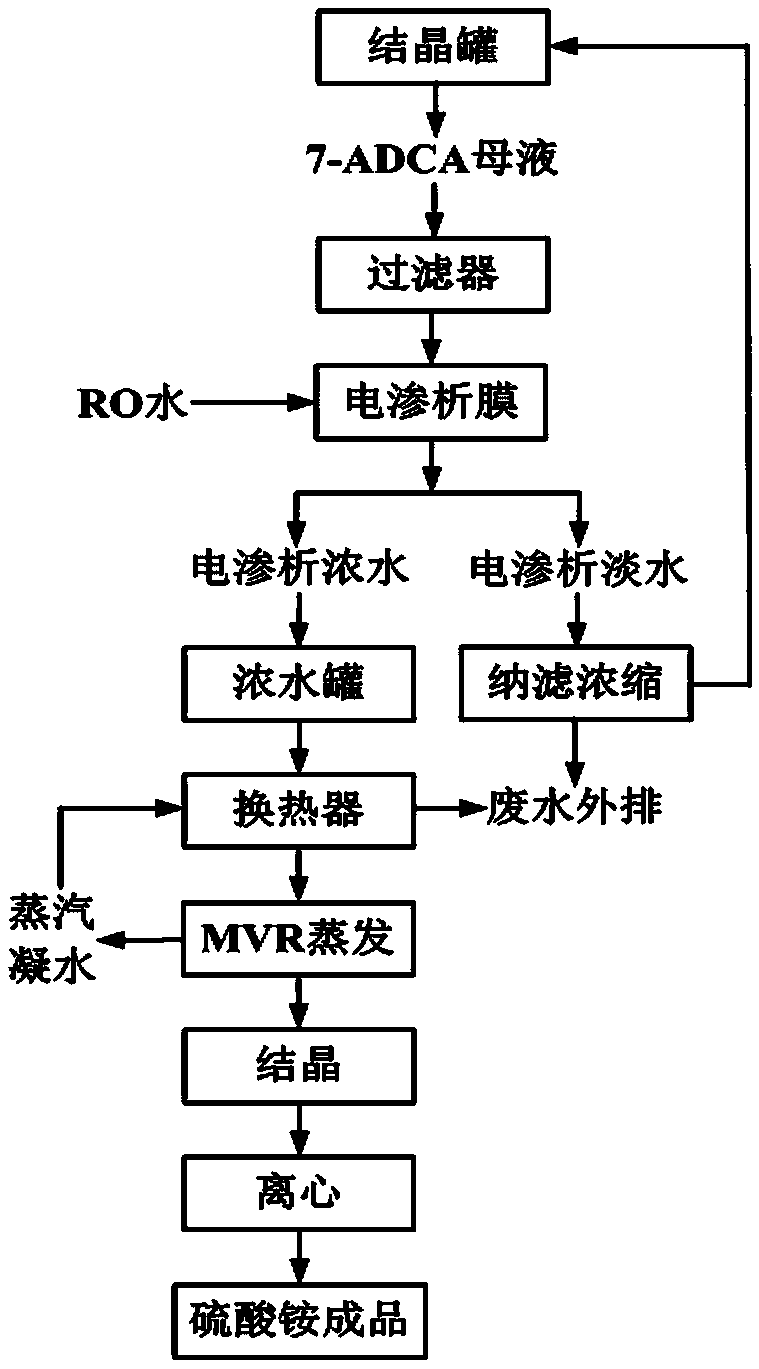

7-ADCA mother liquor recovery treatment method

PendingCN111484182AEfficient recyclingAmmonia nitrogenWater/sewage treatment by centrifugal separationWater contaminantsAmmoniacal nitrogenSulfate radicals

The invention provides a recovery treatment method of 7-ADCA mother liquor. The method comprises the following steps: (a) filtering the mother liquor, feeding the mother liquor into an electrodialysistreatment device, enabling ammonium ions and sulfate ions in the mother liquor to penetrate through an ion exchange membrane of the electrodialysis treatment device to obtain an ammonium sulfate concentrated solution, retaining 7-ADCA and organic impurities in the mother liquor in the mother liquor, and discharging the 7-ADCA and the organic impurities as electrodialysis fresh water; (b) concentrating the electrodialysis fresh water through a nanofiltration membrane, and crystallizing to recover 7-ADCA; (c) feeding the ammonium sulfate concentrated solution into an MVR evaporation system, andtreating to obtain ammonium sulfate crystal mush; and (d) cooling, crystallizing and centrifuging the ammonium sulfate crystal mush to obtain an ammonium sulfate finished product. According to the method, 7-ADCA and ammonium sulfate with economic value in the mother liquor can be effectively recovered, and the purity of the ammonium sulfate finished product can reach 98% or above; the method is simple in process and easy to operate, the effect of reducing ammonia nitrogen and salinity in the wastewater is obvious, and the current-stage environment-friendly emission requirement is met.

Owner:NORTH CHINA PHARMA COMPANY

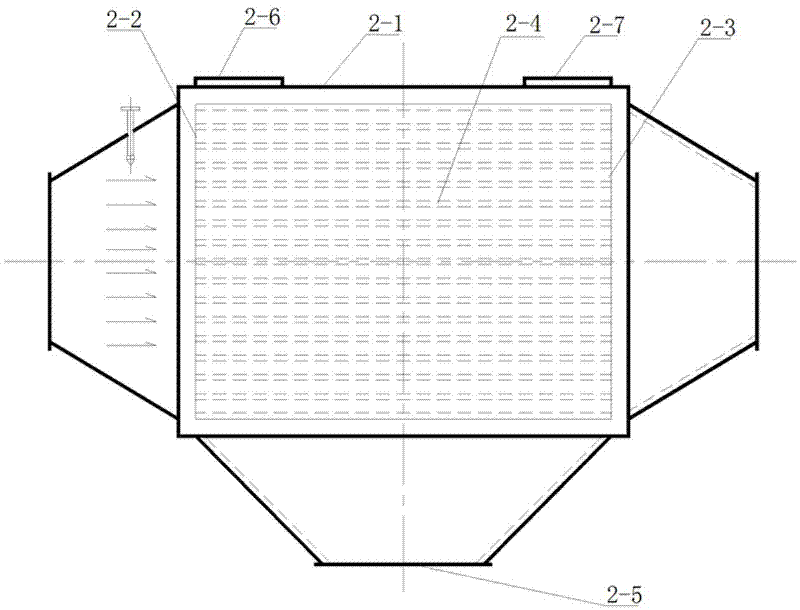

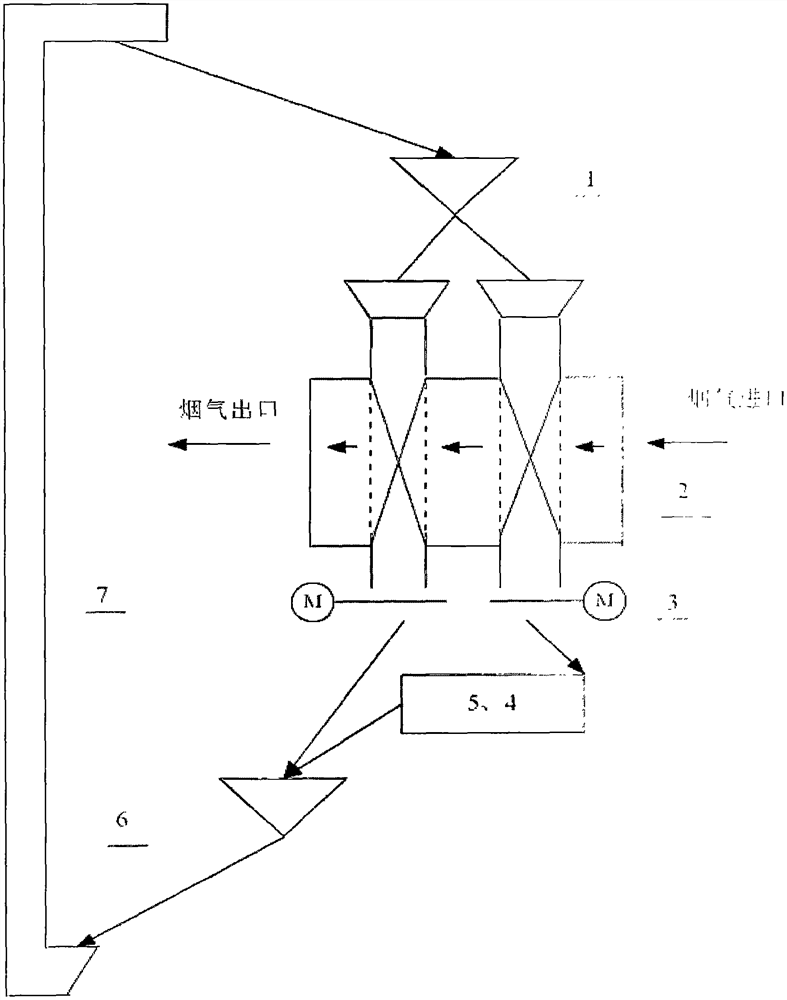

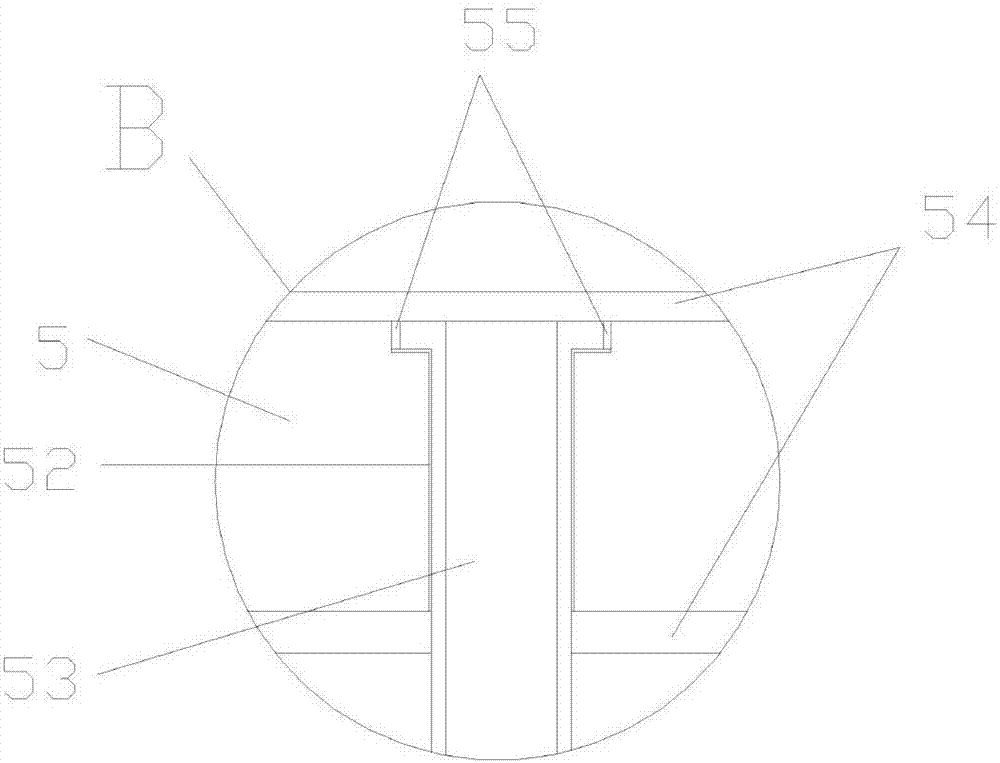

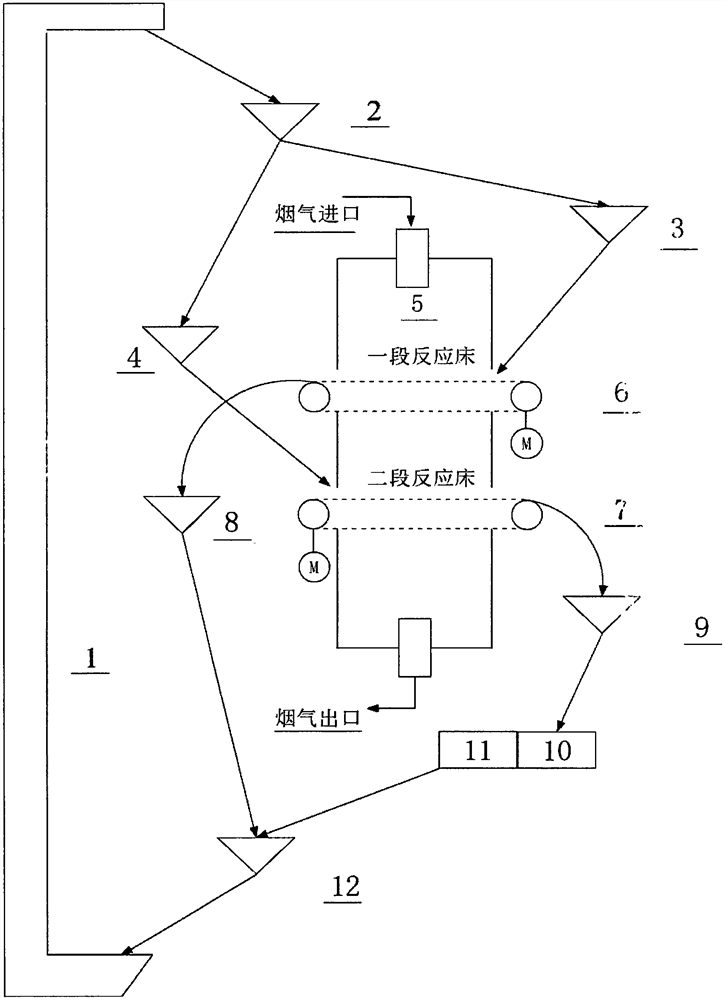

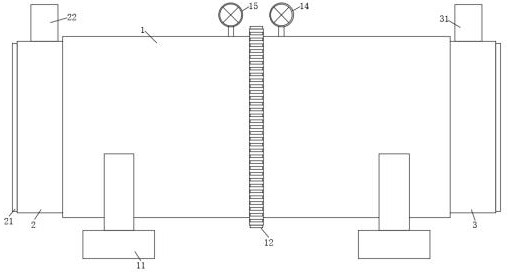

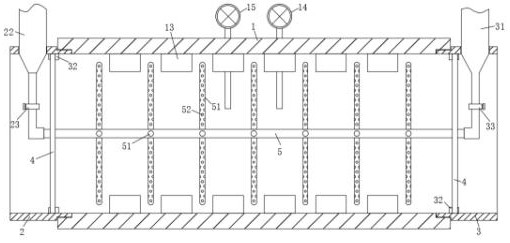

Moving bed dry flue gas desulfurization method

ActiveCN113332851AIncrease profitEasy to moveGas treatmentDispersed particle separationCalcium hydroxideCombustion

The invention discloses a process method for removing sulfur dioxide from boiler flue gas, coke oven flue gas, oil refining FCC regeneration flue gas and the like in hydrocarbon oxidative combustion, and a system for implementing the method. Therefore, the desulfurization process method disclosed by the invention has the advantages that the desulfurization efficiency and the emission suspended matter index can reach the special emission limit standard of atmospheric pollution of the Ministry of Environmental Protection; and in addition, the method also has the characteristics of low water content of the discharged flue gas and high flue gas emission temperature, and effective support is provided for reducing the generation of atmospheric haze and high-altitude heat emission of the flue gas. The typical implementation scheme is as follows: a carrier ball loaded with calcium hydroxide particles is in full contact with flue gas flowing transversely, radially and vertically through a moving bed reactor and is subjected to desulfurization reaction. The carrier ball can vertically move from top to bottom and also can obliquely move and flow according to a certain angle, so that a concentration difference is formed between a desulfurizing agent and sulfur dioxide in flue gas, and the desulfurizing effect is ensured to meet the environment-friendly emission requirement.

Owner:薛援

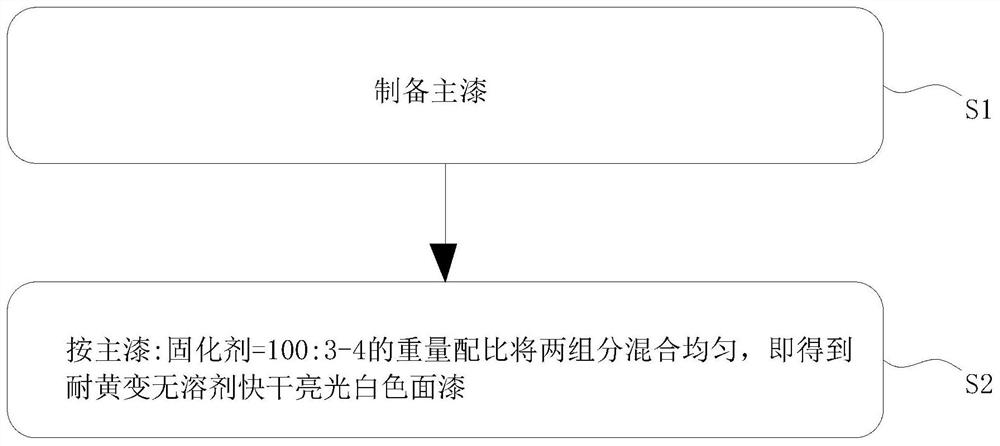

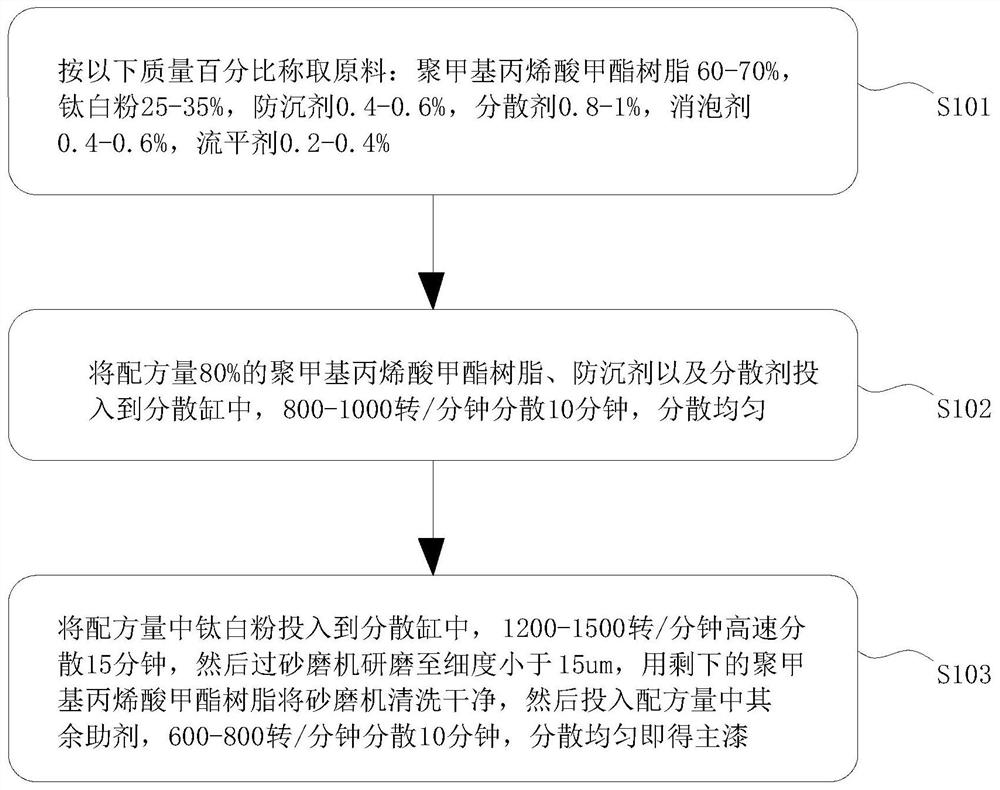

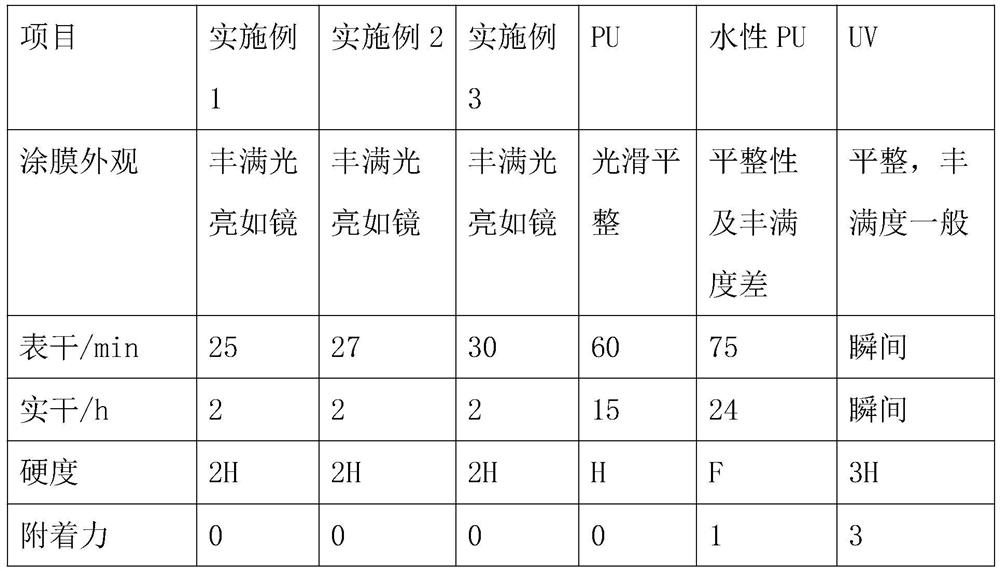

Yellowing-resistant solvent-free quick-drying bright white finish paint and preparation method thereof

InactiveCN111635687ALittle influence on curing reactionMeet construction requirementsCoatingsBenzoyl peroxideColored white

The invention discloses yellowing-resistant solvent-free quick-drying bright white finish paint and a preparation method thereof. The yellowing-resistant solvent-free quick-drying bright white finishpaint is prepared from the following components in parts by weight: 100 parts of main paint and 3 to 4 parts of curing agent, wherein the main paint is prepared from components in percentage by mass as follows: 60%-70% of polymethyl methacrylate resin, 25%-35% of titanium dioxide, 0.4%-0.6% of an anti-settling agent, 0.8%-1% of a dispersing agent, 0.4%-0.6% of an antifoaming agent and 0.2%-0.4% ofa leveling agent, and the curing agent is benzoyl peroxide. The paint has the advantages of ultralow temperature curing performance, quick curing, higher production efficiency, excellent weather resistance, no solvent addition, no VOC emission and excellent scratch resistance, reduces the environmental pollution, and achieves the coating effect of high hardness, flatness, fullness, smoothness andbrightness like a mirror.

Owner:安徽名士达新材料有限公司

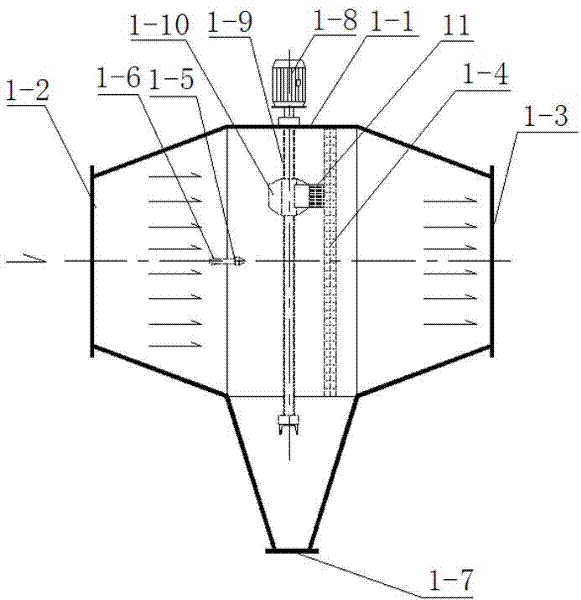

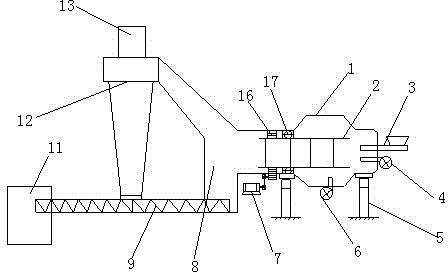

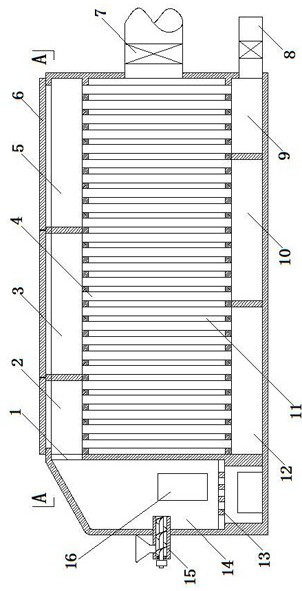

Sludge incineration device

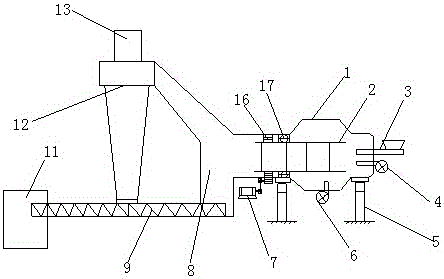

ActiveCN104944733AReduce dust contentComply with environmental emission requirementsCombination devicesSludge treatment by de-watering/drying/thickeningCombustorMuffler

The invention discloses a sludge incineration device which is characterized by comprising a combustion furnace (1); a feeding component (3) is arranged at one end of the combustion furnace (1); a first combustor (4) is arranged below the feeding component (3); a second combustor (6) is arranged on the lower surface of the combustion furnace (1); the other end of the combustion furnace (1) is connected with a cooling furnace (8); the upper outlet of the cooling furnace (8) is communicated with the air inlet of a cyclone separator (12); the air outlet of the cyclone separator (12) is communicated with a muffler (13); the discharging opening in the bottom of the cyclone separator (12) is communicated to the feeding opening of a packing auger (9); another feeding opening in the bottom of the cooling furnace (8) is also formed in the packing auger (9); a discharging opening of the packing auger (9) is connected to an ash collecting tank (11). The sludge incineration device has the advantages that the combustion efficiency of sludge can be improved, and the purposes of being more energy-saving and environmental-friendly are achieved.

Owner:京津冀钢铁联盟(迁安)协同创新研究院有限公司

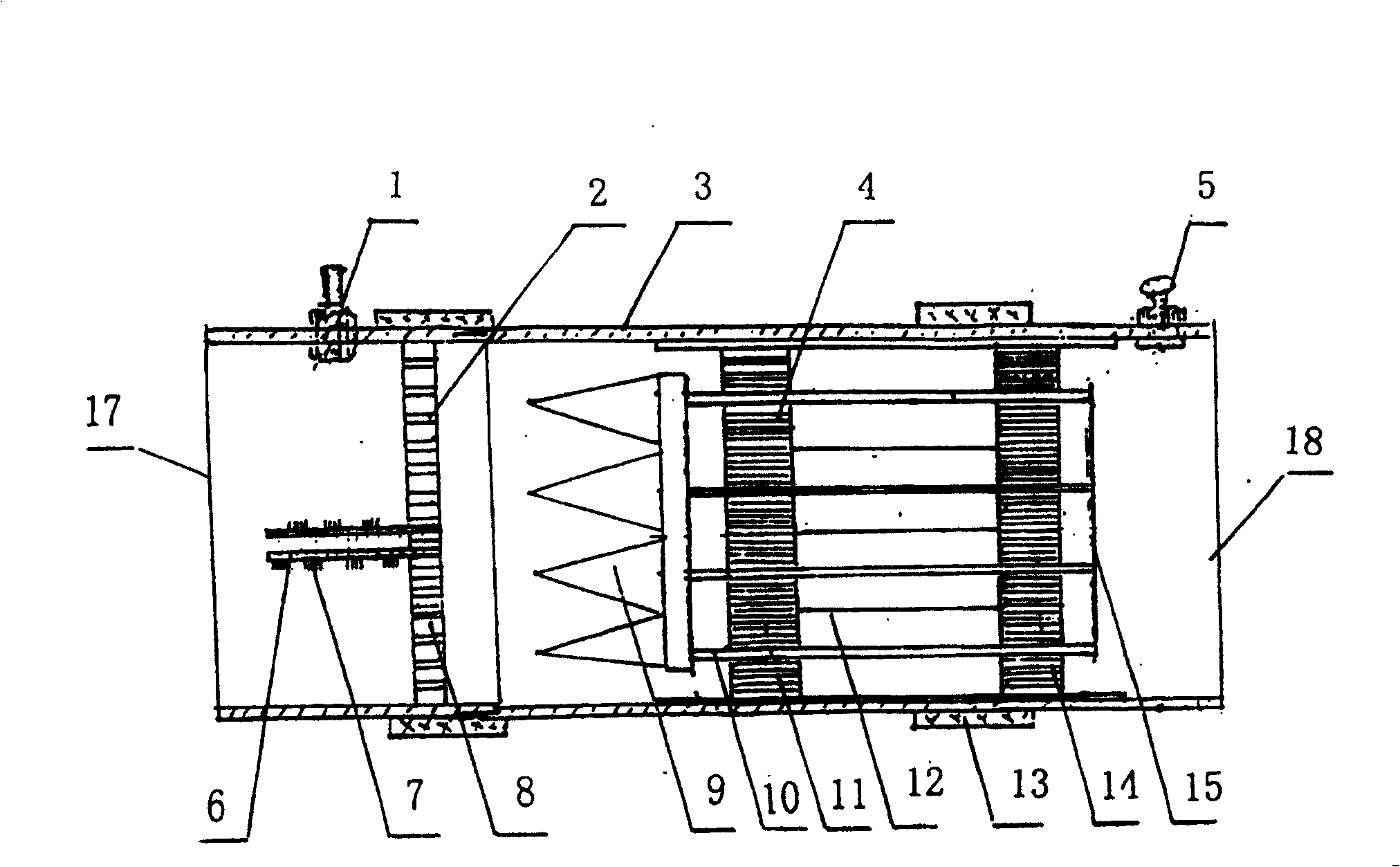

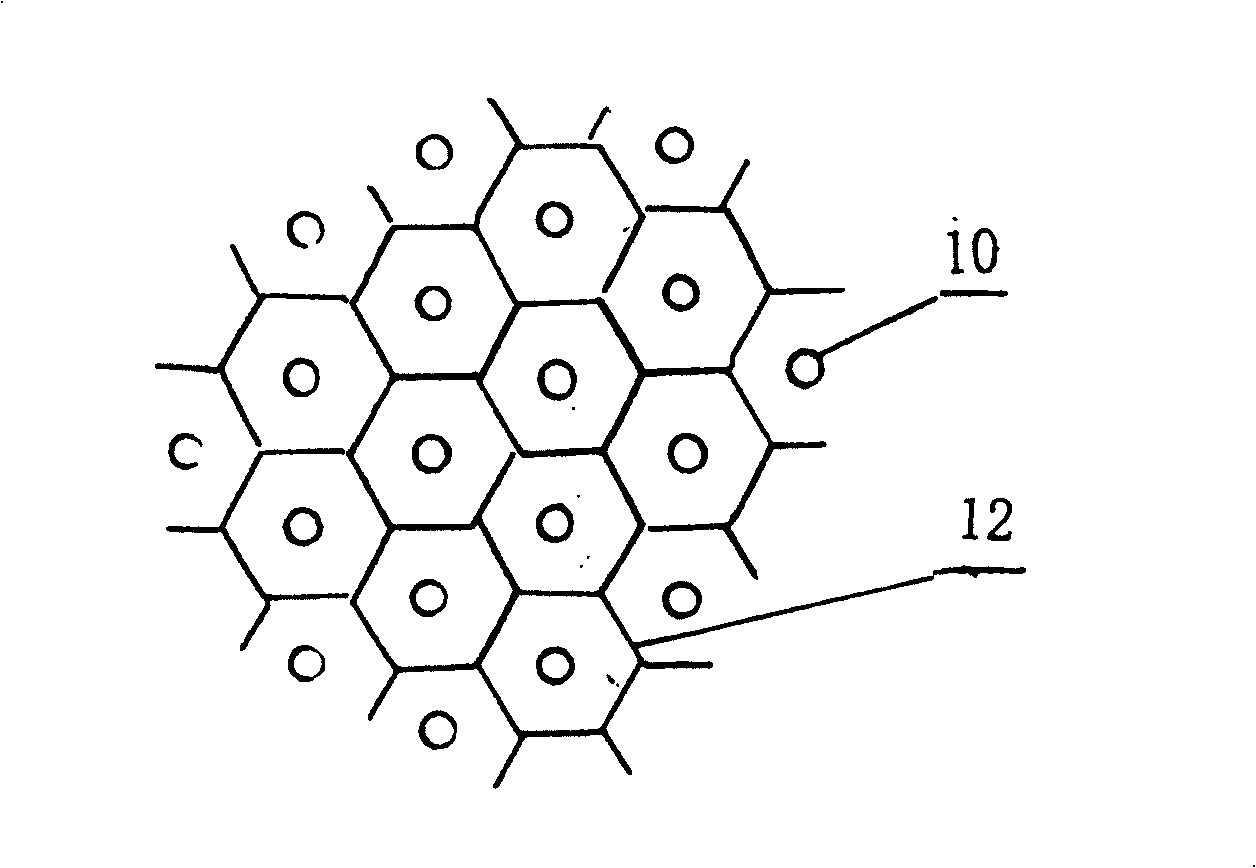

Tail-gas purifier of vehicle

InactiveCN100476166CComply with environmental emission requirementsSimple structureExhaust apparatusSilencing apparatusElectricityEngineering

The present invention relates to an automobile tail gas cleaning device. It includes shell body, two ends of said shell body are respectively gas inlet and gas outlet, and on the described shell body an electric connecting component and a ring-shaped insulator are mounted. It is characterized by that the interior of said shell body is equipped with ion electrode, corona electrode, rod-shaped electrode, absorption electrode and molecular sieve plates, on two ends of the described absorption electrode the molecular sieve plate is respectively mounted, on the described molecular sieve plate the gas guide hole is set, the described rod -shaped electrode can be plug-connected on the molecular sieve plate, and the partial rod-shaped electrode is positioned in the space enclosed by absorption electrode, the inner end of the rod-shaped electrode is connected with corona electrode. Said invention is characterized by simple structure, convenient application, low cost and good cleaning effect, etc.

Owner:赵胤铨 +1

Differential arc oxidization abrasive polishing method for stainless steel surface

InactiveCN100422390CImprove the protective effectReliable workmanshipAnodisationMicro arc oxidationMetallurgy

The invention discloses a polishing method of non-corrosive steel surface by differential arc. The invention comprises the following steps: exerting mechanically polishing and degreasing on surface of stainless steel products; cleaning it; placing said stainless steel products in electrolyte solution and intensifying reaction near anode to form intensified oxidation film on it by using sine-wave differential arc that is generated by sine-wave current; cleaning and drying it. The invention resolves the previous problem that differential arc oxidization can not be processed on surface of stainless steel watch.

Owner:江门市福斯特金属表面处理技术发展有限公司

A kind of pulverized coal biological oxidation desulfurization method

ActiveCN105542898BEmission reductionReduce pollutionBacteriaMicroorganism based processesFreeze thawingAfter treatment

The invention provides a desulphurization method of coal dust via biological oxidation. The process comprises the following steps: (1) preparation of a medium; (2) culture of bioleaching bacteria; (3) preparation of pulp; (4) inoculation of bacteria in a leaching system; (5) ore leaching; (6) collection of coal dust; (7) freezing-thawing treatment; (8) ultrasonic treatment with alkali for the coal dust; (9) ultrasonic treatment with acid for the coal dust; (10) drying of the coal dust; (11) determination of desulfurization rate of the coal dust. The ore leaching is carried out with synergistic effects of three species of bacteria at normal temperature and normal pressure, freezing-thawing, ultrasonic treatment with alkali, and ultrasonic treatment with acid are combined, so that sulfur in the coal dust is oxidized into sulfate and dissolved in water for separating from the coal dust; the desulfurization rate of the coal dust after treatment reaches above 50%, the sulfur content of the coal dust after treatment is below 1.2%, the lowest sulfur content is 0.35%, and the discharge meets the environmental protection requirements.

Owner:LIAONING TECHNICAL UNIVERSITY

A method and equipment for separating and extracting amino acid products from protein hydrolyzate

ActiveCN103787939BHigh yieldComply with environmental emission requirementsOrganic compound preparationAmino-carboxyl compound preparationPhenylalanine+TyrosineTyrosine

The invention discloses a method and equipment for separating and extracting amino acid products from protein hydrolyzate, comprising the following steps: diluting the amino acid mixed solution with water, making it flow through a type I column, washing with water, and then flowing the amino acid mixed solution with ethanol hydrochloric acid After passing through the chromatographic column, combine the washing liquid and the mixed solution of ethanol hydrochloric acid and adjust the collected liquid to a pH value of 5.0~6.0, filter to obtain tyrosine, then neutralize the filtrate with alkali until the pH value is greater than 7.0, and pass it through Type III column to separate phenylalanine, tyrosine and / or tryptophan; adjust the pH value of the mixed solution of amino acids flowing through the type I column to be greater than 7.0, make it flow through the type II column, and then adopt Washing with water, freeing with hydrochloric acid, collecting the washing liquid in sections to obtain the separation solution of bright component, preserved component and C component; and then performing subsequent separation on these separation solutions to obtain all amino acid products. This method can increase the number of single amino acid varieties and yield The water body in the separation and extraction can be recycled, and the waste water meets the environmental protection discharge requirements.

Owner:广州博采生物科技有限公司

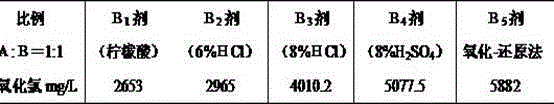

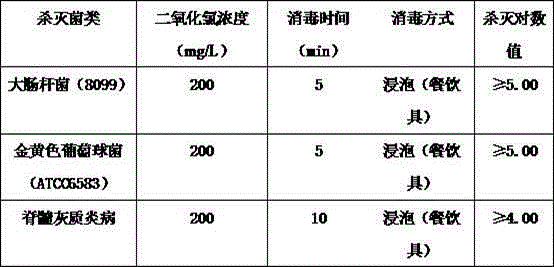

Preparation method for chlorine dioxide disinfectant

InactiveCN104145989AAccurate dosageAvoid wasting medicineBiocideDisinfectantsDisinfectantEnvironmental chemistry

The invention discloses a preparation method for a chlorine dioxide disinfectant. The preparation method comprises the steps of dissolving 130-140 grams of A-agent chlorite into 1,000ml of water with the temperature of 23-32 DEG C, and stirring to dissolve the A-agent chlorite; dissolving 130-150 grams of B-agent sulfite into 1,000ml of water with the temperature of 23-32 DEG C, and finally adding clean water with the temperature of 23-32 DEG C for dilution until the required concentration of the chlorine dioxide disinfectant is achieved, wherein the chlorine dioxide disinfectant can be used for disinfection and sterilization. The preparation method has the technical effects that according to an oxidization-reduction reaction principle and balancing and calculation according to a chemical reaction equation, the using amount of reactants (an oxidant and a reducing agent) is accurate, and the waste of medicines is avoided; meanwhile, the PH value of the prepared chlorine dioxide disinfectant is 6 to 7 during use, so that influence on a human body and the environment is avoided.

Owner:李明川

Baking oven

The invention discloses a baking oven. The baking oven comprises a combustion furnace, a baking room and a smoke dust treatment device, wherein the combustion furnace comprises a combustion cavity, ahot air cavity and a smoke discharge flue; a smoke outlet is formed in the upper portion of the combustion cavity; the front end of the hot air cavity is connected with and isolated from the combustion cavity; an air supplementing opening and an air outlet are respectively formed in the front end and the rear end of the hot air cavity; the smoke discharge flue comprises a first steering cavity, asecond steering cavity, a third steering cavity, a fourth steering cavity and a smoke pipe group; an air inlet is formed in the head end of the baking room, and an air outlet is formed in the tail endof the baking room; the smoke dust treatment device comprises a storage tank, a spraying system and a filter; the spraying system comprises a spraying pipe, a water pump and a water pipe, and water spraying openings which are uniformly arranged are formed in the spraying pipe; the spraying pipe communicates with a water source through the water pump and the water pipe; and the filter comprises arotating shaft, a driven roller, a filter screen and a motor.

Owner:郴州宏基铭锐科技有限公司

Device for removing sulfuric dioxide in exhaust gas

ActiveCN101474528BEliminate biasIncrease contact areaDispersed particle separationProcess engineeringOxidation zone

The invention relates to a device for removing sulfur dioxide in waste gases, which comprises an absorption tower (1). The side surface of the middle of the adsorption tower (1) is provided with a waste gas inlet port (12). The adsorption tower (1) is internally provided with a liquid-gas distributor (3). The top of the adsorption tower (1) is provided with a clean gas discharge outlet (11) whilethe lower part of the adsorption tower (1) is provided with an absorption liquid concentration oxidation zone (13). The device is characterized in that the waste gas inlet port (12) is communicated with a cooling device in the adsorption tower (1); the gas outlet of the cooling device is arranged below the liquid level of the absorption liquid of the concentration oxidation zone (13); the concentration oxidation zone (13) is communicated with the inner chamber of the adsorption tower (1). The device has the advantages that the waste gas cooling is carried out in the cooling device in the adsorption tower (1); the temperature of the gas in the inner chamber of the absorption tower is reduced into 45 DEG C to 60 DEG C; as the temperature is lower, the absorption effect is better after the gas and the liquid contact; therefore, when the gas with low temperature enters into the adsorption tower, the absorption rate is drastically increased; the device causes that processes such as waster gas, temperature reduction, concentration absorption liquid, desulphurization, oxidation and the like are concentrated in a desulfurizing tower to be completed, thus simplifying the low, reducing the equipment investment, fully making the best of device space and optimal land utilization.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

Sludge incinerator

ActiveCN104944733BReduce dust contentComply with environmental emission requirementsCombination devicesSludge treatment by de-watering/drying/thickeningCombustorPulp and paper industry

The invention discloses a sludge incineration device which is characterized by comprising a combustion furnace (1); a feeding component (3) is arranged at one end of the combustion furnace (1); a first combustor (4) is arranged below the feeding component (3); a second combustor (6) is arranged on the lower surface of the combustion furnace (1); the other end of the combustion furnace (1) is connected with a cooling furnace (8); the upper outlet of the cooling furnace (8) is communicated with the air inlet of a cyclone separator (12); the air outlet of the cyclone separator (12) is communicated with a muffler (13); the discharging opening in the bottom of the cyclone separator (12) is communicated to the feeding opening of a packing auger (9); another feeding opening in the bottom of the cooling furnace (8) is also formed in the packing auger (9); a discharging opening of the packing auger (9) is connected to an ash collecting tank (11). The sludge incineration device has the advantages that the combustion efficiency of sludge can be improved, and the purposes of being more energy-saving and environmental-friendly are achieved.

Owner:京津冀钢铁联盟(迁安)协同创新研究院有限公司

Separating device for kiln flue gas

The invention discloses a separating device for a kiln flue gas. The separating device comprises a drum; the drum comprises an upper drum body and a lower drum body; a closed drum chamber is formed after the upper drum body and the lower drum body are buckled with each other; a separating plate which is used for separating the drum chamber into an upper chamber body and a lower chamber body is arranged at a joint of the upper drum body and the lower drum body; a flue gas inlet is formed on a side wall of the upper drum body; a first purified gas outlet is formed at the top of the upper drum body; a rated liquid level line is arranged on a side wall of the lower drum body; a liquid inlet is formed on the side wall of the lower drum body and above the rated liquid level line; a drain outlet is formed at the bottom of the lower drum body; HEPA filtering screens are arranged at the first purified gas outlet and the inlet ends of all the guide pipes. The separating device is free from secondary pollution in a separating process, has an excellent purifying effect, is low in processing cost, is simple and convenient in use and is wide in application scope.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Dry flue gas desulfurization method of belt conveying horizontal moving bed

PendingCN113713581AIncrease profitEasy to moveGas treatmentDispersed particle separationHydrocotyle bowlesioidesAtmospheric pollution

The invention discloses a process method for removing sulfur dioxide from boiler flue gas, coke oven flue gas, oil refining FCC (fluid catalytic cracking) regeneration flue gas and the like in hydrocarbon oxidative combustion, and a system for implementing the method. Therefore, the desulfurization process method disclosed by the invention has the advantages that the desulfurization efficiency and the emission suspended matter index can reach the special emission limit standard of atmospheric pollution of the Ministry of Environmental Protection, in addition, the method also has the characteristics of low water content of the discharged flue gas and high flue gas emission temperature, and effective support is provided for reducing the generation of atmospheric haze and high-altitude heat emission of the flue gas. The typical implementation scheme is as follows: a carrier ball loaded with calcium hydroxide particles is in full contact with vertically flowing flue gas through a moving bed reactor and desulfurization reaction is conducted. The carrier ball is moved horizontally by a belt conveyor. Concentration difference is formed between the desulfurizer and sulfur dioxide in flue gas, and it is guaranteed that the desulfurization effect meets the environment-friendly emission requirement.

Owner:薛援

Cooling equipment for producing compound fertilizer

PendingCN114857955AReduce power lossAvoid retrofittingDomestic cooling apparatusCorrosion preventionCold airAgricultural engineering

The cooling equipment comprises a main cylinder, a first side cylinder, a second side cylinder, a sealing plate and a main air pipe, the first side cylinder and the second side cylinder are located on the two sides of the main cylinder, and the main cylinder is rotatably installed between the first side cylinder and the second side cylinder; the two sealing plates are detachably installed in the first side cylinder and the second side cylinder respectively to seal the main cylinder, the main air pipe is horizontally located at the central axis position in the main cylinder, and the two ends of the main air pipe penetrate out of the sealing plates on the two sides respectively. A plurality of branch air pipes for contacting compound fertilizer are arranged on the side surface of the main air pipe, and a plurality of lifting plates for lifting the compound fertilizer are arranged on the inner wall of the main cylinder. According to the invention, air intermittently enters the main cylinder, passes through the air-distributing pipe, is in full contact with compound fertilizer moving from top to bottom and performs heat exchange, and is filtered by the air-distributing pipe when intermittently flowing out, so that the cooling efficiency is improved, the power loss of cold air flowing is reduced, the production cost is reduced, and the flowing-out air is dust-free and meets the environment-friendly emission requirement.

Owner:GARSONI FERTILIZER PINGYUAN

Aluminum-base printing circuit board and its production

InactiveCN100496188CReliable workmanshipSimple processing equipmentPrinted circuit manufactureCircuit susbtrate materialsInsulation layerMicro arc oxidation

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com