Blue reactive dye for printing, and preparation methods thereof

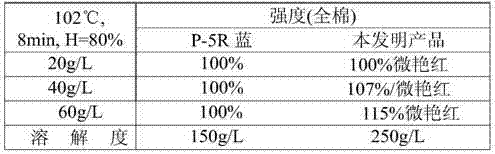

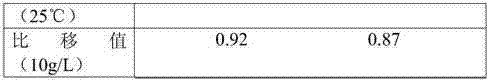

A reactive dye and blue technology, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of poor lifting rate, limited application range, low solubility of printing dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

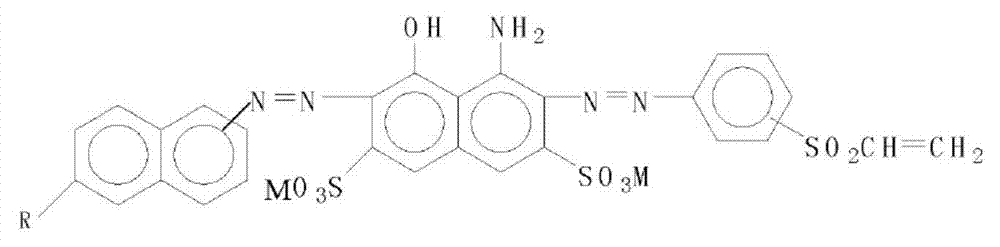

[0109] A blue reactive dye, the blue reactive dye has the structural formula of formula (1):

[0110]

[0111] The preparation method of this blue reactive dyestuff comprises the steps:

[0112] a. One condensation

[0113] Preparation of H-acid solution: take 34.1 parts of H-acid monosodium salt and 100 parts of water for beating, adjust the pH to 6-8 with 5 parts of liquid caustic soda, stir to dissolve completely, and control the temperature below 25°C to obtain H-acid solution, which is to be condensed.

[0114] Primary condensation: 20 parts of water, 100 parts of crushed ice, 0.1 part of beating agent and dispersant NNO in the reaction kettle, after stirring evenly, add 18.45 parts of cyanuric chloride for beating, after beating for 1 hour, slowly add the H acid solution to three In the poly beating suspension, control the pH to 2-2.5, and the temperature is less than 5°C. After the dropwise addition, keep warm for reaction. The process controls the pH to 1.8-2, the ...

Embodiment 2

[0130] A kind of blue reactive dye, this blue reactive dye has the structural formula of formula (1), the preparation method of this blue reactive dye, comprises the steps:

[0131] a. One condensation

[0132] Preparation of sodium sulfanilate solution: take 17.3 parts of sulfanilic acid and add 100 parts of water to make a slurry, adjust pH 6-8 with 5 parts of liquid caustic soda, stir and dissolve completely, and control the temperature below 25°C to obtain sulfanil Sodium acid solution, to be condensed.

[0133] Primary condensation: Add 20 parts of bottom water, 100 parts of crushed ice, 0.1 part of beating agent and dispersant NNO to the reaction kettle, stir well and add 18.45 parts of cyanuric chloride for beating. After beating for 1 hour, mix m-aminobenzenesulfonic acid solution Slowly add it to the tripolymer beating suspension, control the pH to be less than 2, and the temperature to be less than 5°C. After the dropwise addition, keep warm for reaction. During the...

Embodiment 3

[0150] A kind of blue reactive dye, this blue reactive dye has the structural formula of formula (1), the preparation method of this blue reactive dye, comprises the steps:

[0151] The preparation of a.H acid acylate:

[0152] Preparation of H acid solution: Take 34.1 parts of H acid monosodium salt and 100 parts of water for beating, adjust the pH to 6-8 with 5 parts of liquid caustic soda, stir to completely dissolve, control the temperature at 25°C-30°C to obtain H acid solution, and wait for acylation .

[0153] Add 9.8 parts of maleic anhydride to the H acid solution, use 10.6 parts of soda ash to control the pH to 7-9, and the temperature is 25°C-30°C. The end point of the reaction is detected by high performance liquid chromatography. The end point is the disappearance of free H acid, and H is obtained. Acid acylation solution, to be coupled.

[0154] b. Diazotization reaction:

[0155] Add 100 parts of bottom water to the reaction kettle, put in 30.3 parts of amino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com