Yellowing-resistant solvent-free quick-drying bright white finish paint and preparation method thereof

A solvent-free, anti-yellowing technology, applied in the field of white topcoat, can solve the problems of hardness and fullness not meeting customer requirements, long production cycle, difficult deep curing and other problems, achieve excellent scratch resistance, reduce environmental pollution and improve the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

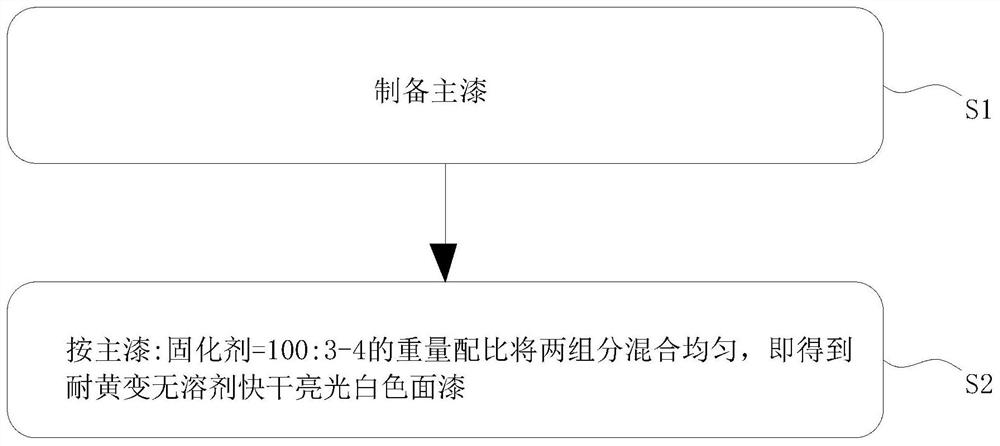

Method used

Image

Examples

Embodiment 1

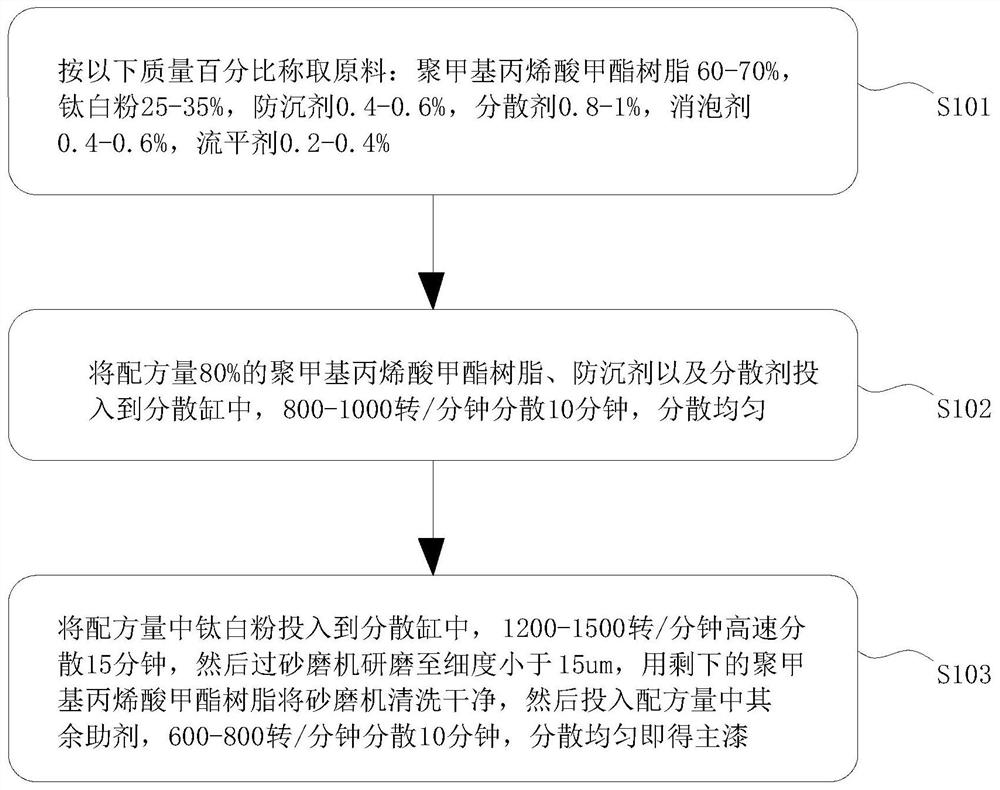

[0030] A kind of anti-yellowing solvent-free fast-drying glossy white topcoat is made of the following components by weight: main paint: curing agent=100:3-4; wherein, the main paint is made of the following components by mass percentage: polyacrylic 62.6% methyl acrylate resin, 35% titanium dioxide, 0.6% anti-sedimentation agent, 1% dispersant, 0.6% defoamer, 0.2% leveling agent, solid content of anti-yellowing non-solvent quick-drying bright white topcoat 100%; polymethyl methacrylate resin is Degaroute465 resin, which is a small molecular substance with extremely low viscosity, can quickly wet the substrate, and has excellent leveling properties. The resin contains a large amount of highly active non-toxic Saturated double bonds, through the initiation of benzoyl peroxide, free radical polymerization occurs, and all of them are quickly cured to form a macromolecular network structure, ensuring excellent performance of the coating film after film formation, forming a high har...

Embodiment 2

[0038] A kind of anti-yellowing solvent-free fast-drying glossy white topcoat is made of the following components by weight: main paint: curing agent=100:3-4; wherein, the main paint is made of the following components by mass percentage: polyacrylic 65% methyl acrylate resin, 32.5% titanium dioxide, 0.6% anti-sedimentation agent, 1% dispersant, 0.5% defoamer, 0.4% leveling agent, solid content of anti-yellowing non-solvent quick-drying bright white topcoat is 100%; the polymethyl methacrylate resin is Degaroute465 resin, the titanium dioxide is nano-scale rutile titanium dioxide, the defoamer is a modified siloxane defoamer suitable for solvent-free coating systems, and the dispersant is modified A copolymer dispersant with a permanent block structure. The leveling agent is made by mixing polyether modified silicone leveling agent and fluorine modified polyacrylic acid leveling agent at a mass ratio of 1:2.

[0039] refer to Figure 1-2 , in order to better demonstrate the p...

Embodiment 3

[0046] A kind of anti-yellowing solvent-free fast-drying glossy white topcoat is made of the following components by weight: main paint: curing agent=100:3-4; wherein, the main paint is made of the following components by mass percentage: polyacrylic 70% methyl acrylate resin, 27.8% titanium dioxide, 0.4% anti-sedimentation agent, 0.8% dispersant, 0.6% defoamer, 0.4% leveling agent, solid content of anti-yellowing non-solvent quick-drying bright white finish is 100%; the polymethyl methacrylate resin is Degaroute465 resin, the titanium dioxide is nano-scale rutile titanium dioxide, the defoamer is a modified siloxane defoamer suitable for solvent-free coating systems, and the dispersant is modified A copolymer dispersant with a permanent block structure. The leveling agent is made by mixing polyether modified silicone leveling agent and fluorine modified polyacrylic acid leveling agent at a mass ratio of 1:2.

[0047] refer to Figure 1-2 , in order to better demonstrate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com