Copper-nickel-tin alloy and preparation method for wires thereof

A copper-nickel-tin and alloy technology, applied in the field of metallurgical industry, can solve the problems of low yield, long production process, high production cost, etc., and achieve the effect of simple processing equipment, high production efficiency and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

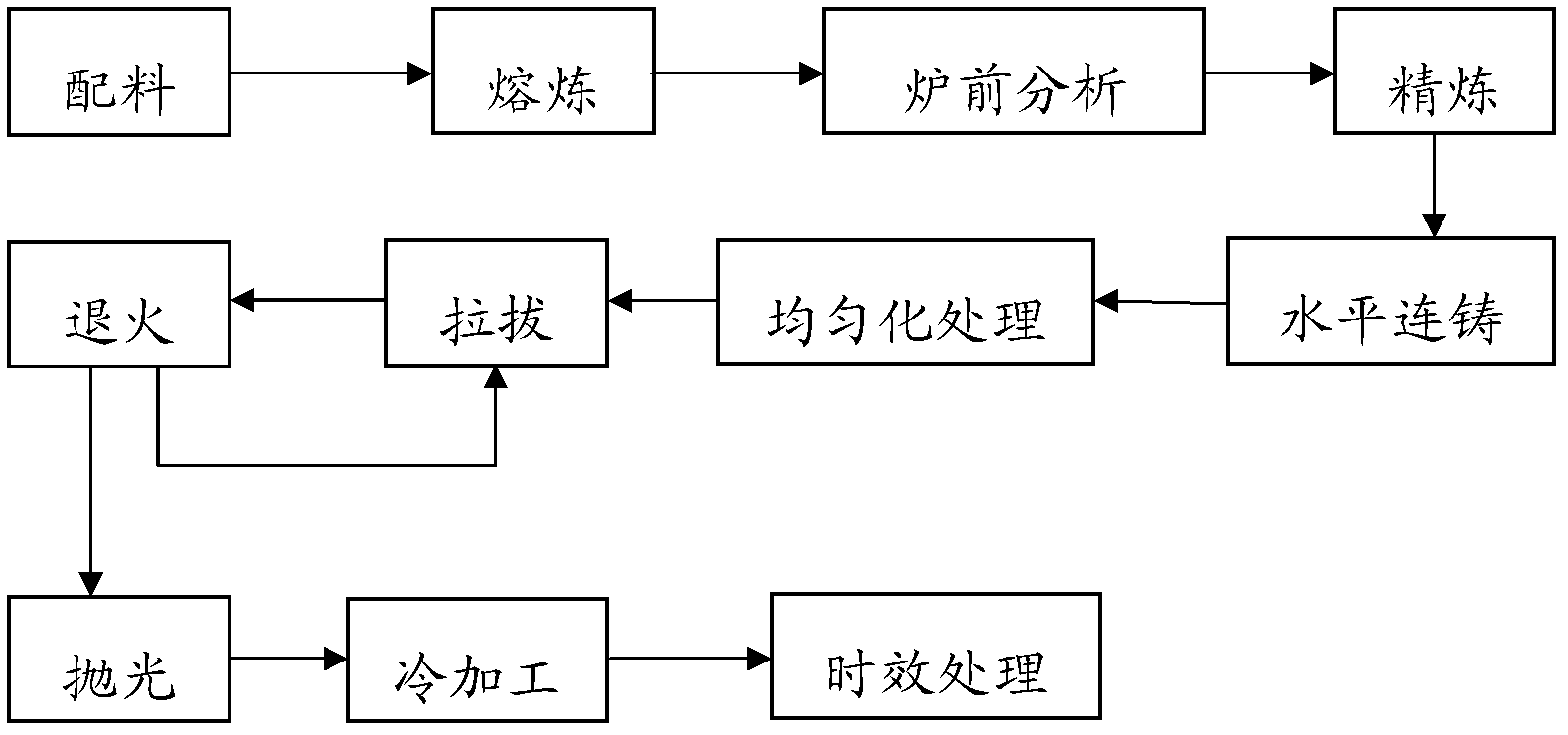

Method used

Image

Examples

Embodiment 1

[0025] 1. Ingredients, smelting, and pre-furnace analysis: 425KG of copper, 47.5KG of nickel, and 27.5KG of tin are used as raw materials to make furnace materials that meet the composition requirements. After approval, they are added to a self-made power frequency holding furnace for melting. After the charge is melted, it is carefully stirred and samples are taken for chemical analysis before the furnace. The weight percentage of the alloy composition obtained after the charge is melted by the above formula is: copper 84.96%, nickel 9.5%, tin 5.46%, and impurities 0.08%.

[0026] 2. Refining: heat the solution to 1200-1250°C, remove slag and add covering agent, and then deoxidize and degas the molten metal. 0.03% rare earth cerium is added by weight percentage as a grain refiner.

[0027] 3. Horizontal continuous casting: Start the tractor for horizontal continuous casting, adopt the pull-stop-retreat-stop traction process, and the continuous casting products are taken up an...

Embodiment 2

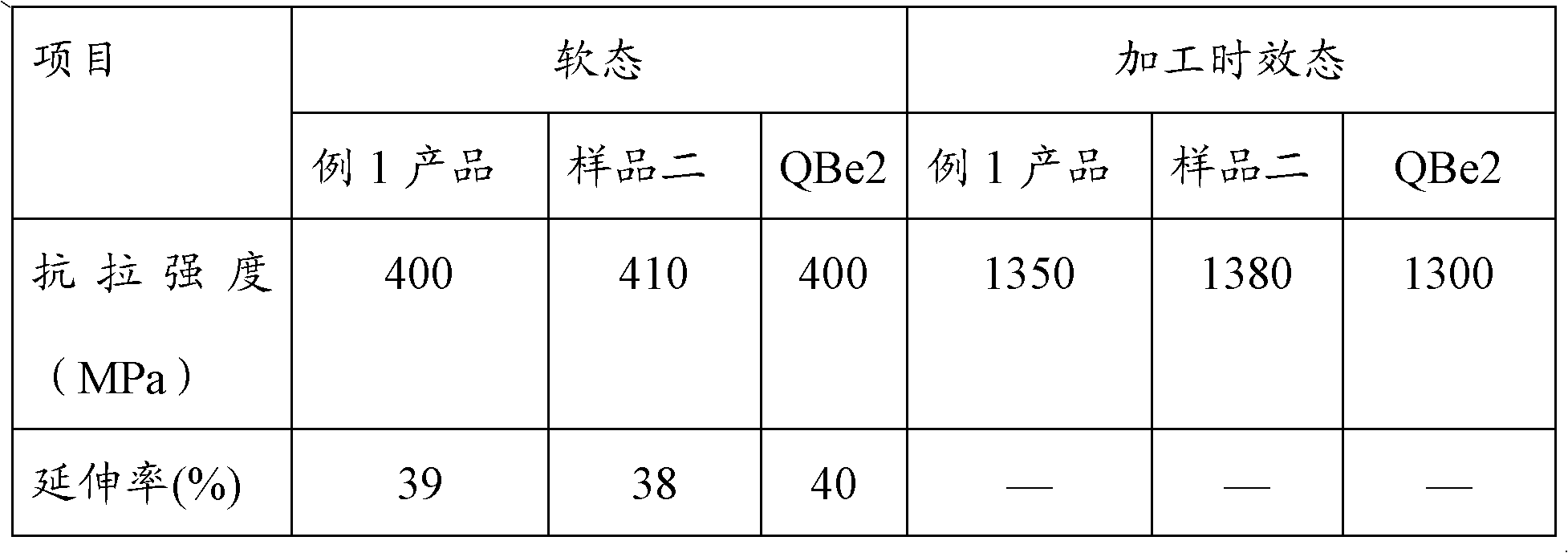

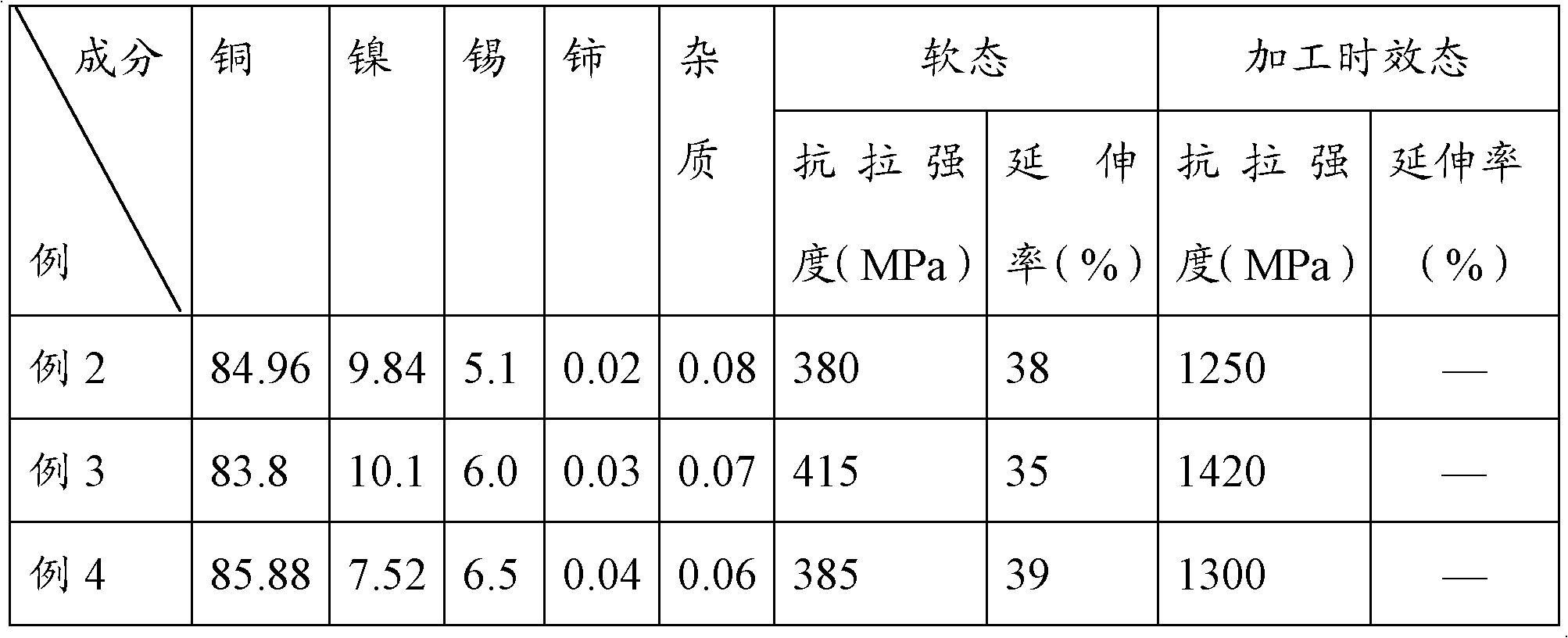

[0037] The basic principles and processes of Examples 2-4 are the same as those of Example 1, the difference lies in the chemical composition of the alloy. Table 2 is the chemical composition of the alloy of each embodiment and the corresponding mechanical property parameters (in the table, example 2 corresponds to the product of embodiment 2, example 3 corresponds to the product of embodiment 3, and example 4 corresponds to the product of embodiment 4) .

[0038] Table 2 Examples 2-4 Mechanical Properties of High Elastic Copper Alloy Wire Products

[0039]

[0040] As can be seen from Table 2, the wire rod product prepared by a kind of high elastic copper alloy production process provided by the present invention is compared with the copper-nickel-tin alloy wire rod prepared by vacuum smelting technology and the high elastic beryllium copper wire rod (shown in table 1) , with comparable mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com