Forming tractor for producing casting type drip tape

A drip irrigation belt and production flow technology, applied in the field of drip irrigation belt manufacturing equipment, can solve problems such as restricting the development of drip irrigation, and achieve the effect of improving automation performance and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

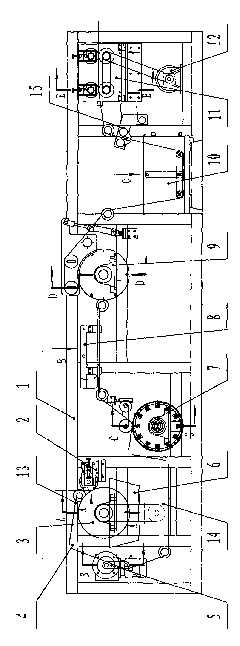

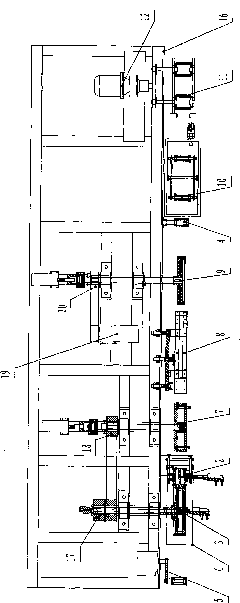

[0022] see figure 1 , figure 2 , the frame 1 of the forming tractor for producing cast-type drip irrigation belts described in this embodiment is a rectangular frame structure, on which a front swing arm mechanism 5 and a forming wheel mechanism 3 are sequentially installed according to the forming process from left to right, and the pressing Wheel mechanism 2, cutter wheel mechanism 7, edge folding mechanism 8, heat sealing wheel mechanism 9, cooling device 10 and traction device 11, the plastic sheet 13 extruded from the extruder enters the forming wheel mechanism 3, until the cast after forming The type drip irrigation belt is sent into the winding machine by the traction device 11, and the plastic sheet 13 running between the various mechanisms is guided by the guide transition roller 4 installed on the frame 1.

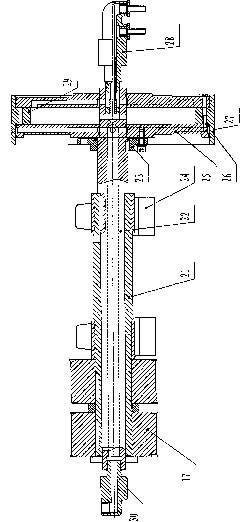

[0023] see image 3 , the forming wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com