Cold-field corn cultivation method with 1000kg per mu

A cultivation method and 1000-kilogram technology, applied in the field of super-high-yield corn cultivation, can solve problems such as low yield, achieve large yield potential, improve light and ventilation conditions, and enhance the effects of photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

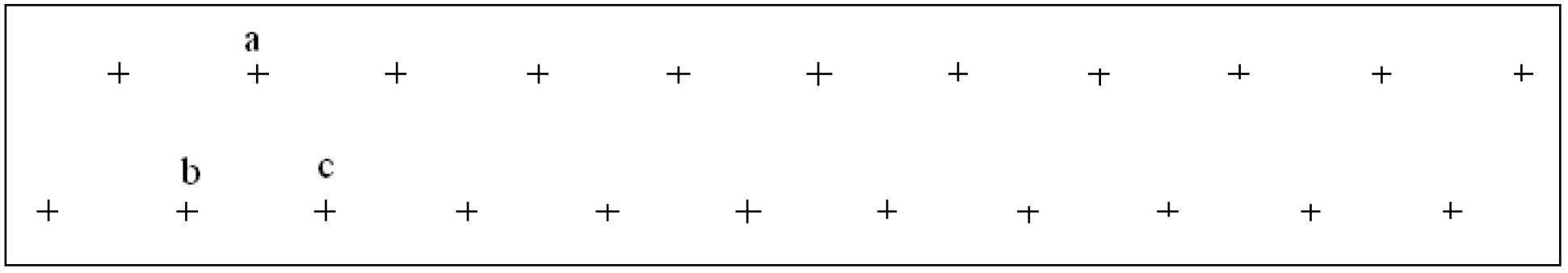

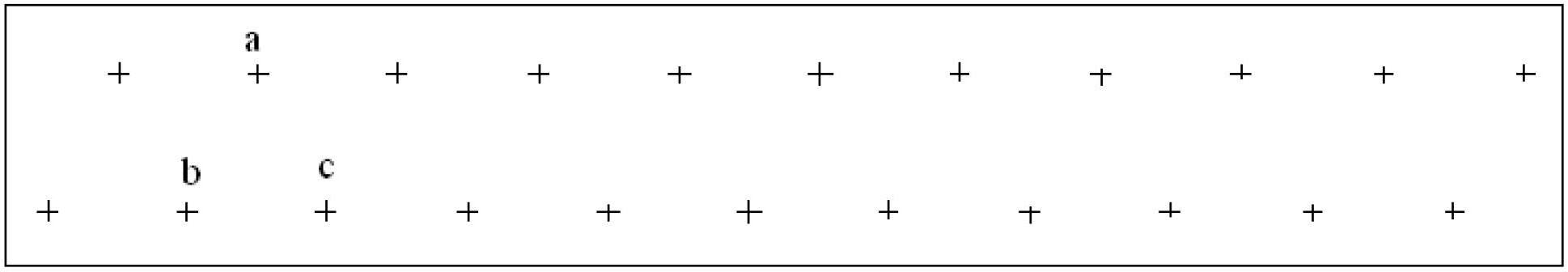

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the cultivation method of a kind of cold area corn yield thousand kilograms per mu of the present embodiment is carried out according to the following steps:

[0019] 1. Before freezing in autumn, spread the decomposed organic fertilizer evenly on the field at a rate of 15 tons per hectare, and then carry out deep loosening and soil preparation. The thickness of the loose soil layer is 25-30cm. is 130 cm, and the width of the ridge table is 90 cm;

[0020] 2. In the spring of the second year, when the average low temperature of 10 centimeters of the cultivated layer has passed 5-6°C, apply 150 kilograms of diammonium phosphate, 90 kilograms of potassium sulfate, 75 kilograms of urea and 30 kilograms of zinc sulfate per hectare. Mix diammonium phosphate, potassium sulfate, urea and zinc sulfate evenly, and apply them as base fertilizer at the same time when corn seeds are sown in double rows. 10-12 cm; corn seeds are sown into the ridge table at...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that the thickness of the loose soil layer in Step 1 is 26-28 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the base fertilizer is applied to 12 to 18 centimeters on both sides of the center line on the ridge table, and the depth of application is 10.5 to 11.5 centimeters. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com