Waste drip tape recycling machine

A technology of drip irrigation belt and recycling machine, which is applied in the direction of mechanical equipment, pipeline laying and maintenance, winding strips, etc., can solve the problems of labor cost, increase farmers' cost, and find no workers, so as to reduce costs and save labor , The effect of convenient loading and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

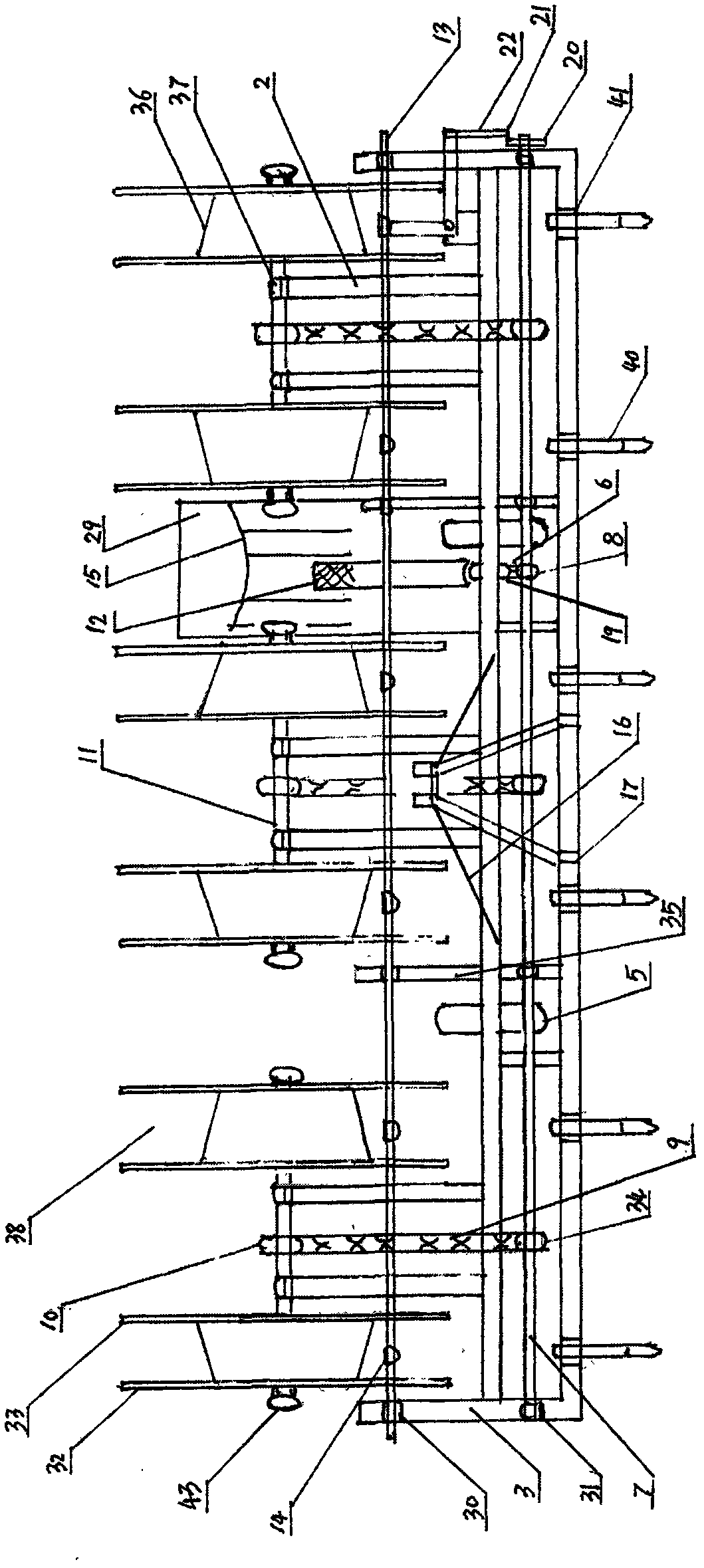

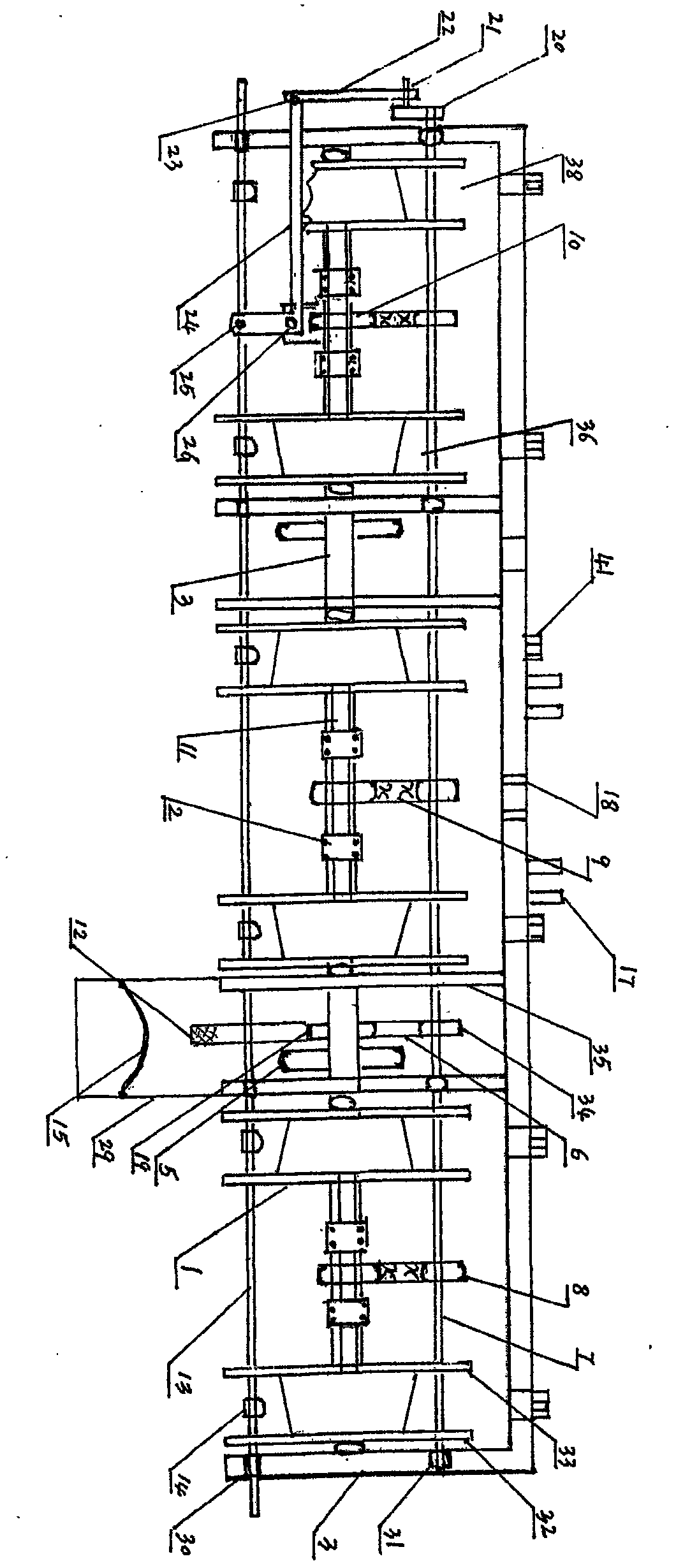

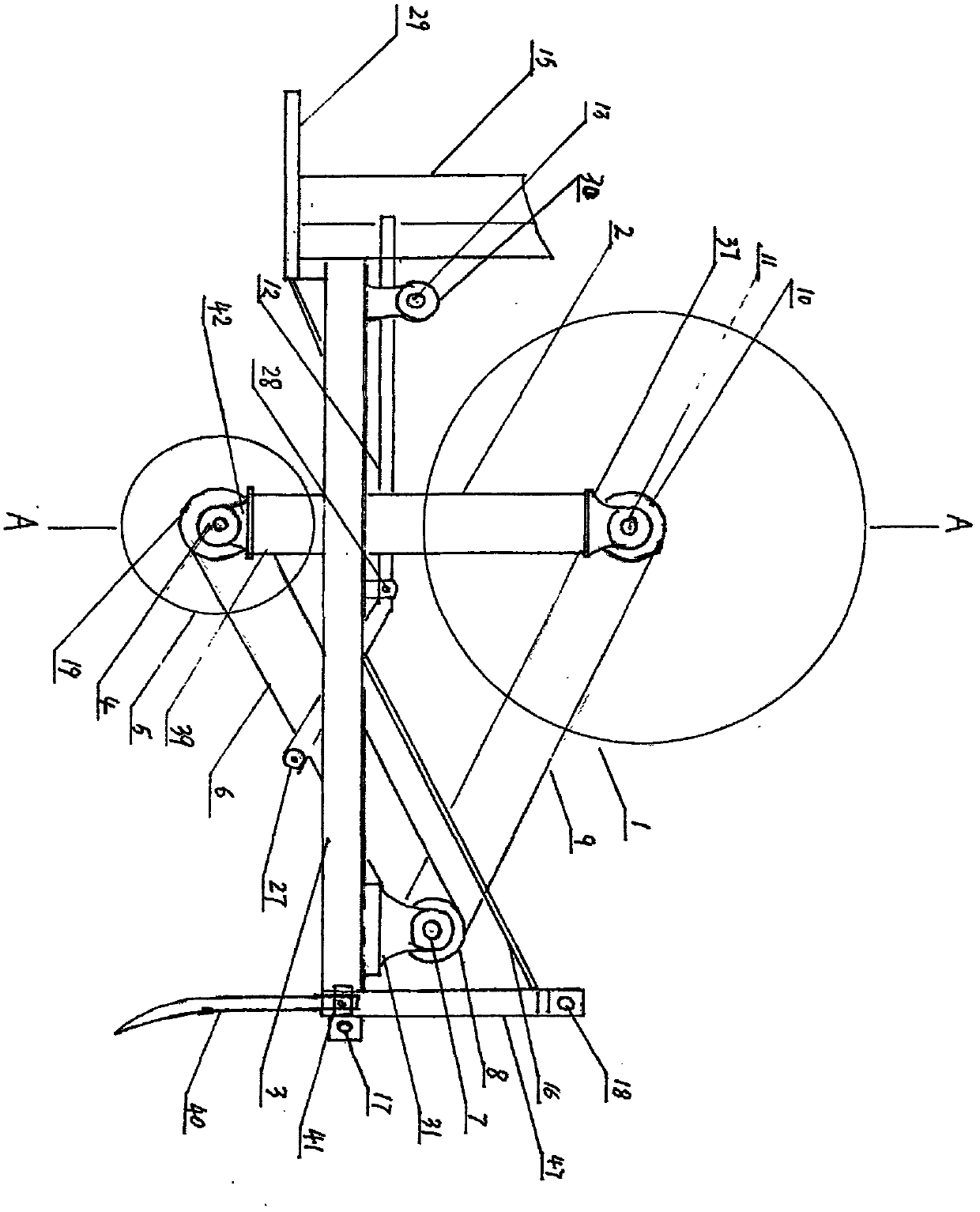

[0025] Such as Figure 1-4 The front, rear, left and right longitudinal beams (35) and diagonal stays (16) of the machine frame (3) of the waste drip irrigation belt recovery machine of the present invention shown in the present invention are mutually welded, and the middle of the front frame (3) of the machine is welded at three points Suspension frame (47), is provided with upper and lower hanging hole (17) (18) on the suspension frame (47). On the frame (3) front cross beam, the bar tooth card (41) is fixed with screws, and the bar tooth card (41) is equipped with the bar tooth (40).

[0026] Long axis (7) is adorned horizontally in front of frame (3), and four sets of long bearing blocks (31) are adorned respectively in the middle of two ends of long axis (7), and long bearing block (31) is fixed on the frame (3) with screws. Three long shaft gears (8) and a long shaft belt pulley (34) are also mounted on the long shaft (7).

[0027] Six seatposts (2) are respectively we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com