Method for preparing nano zirconium oxide by using spray granulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

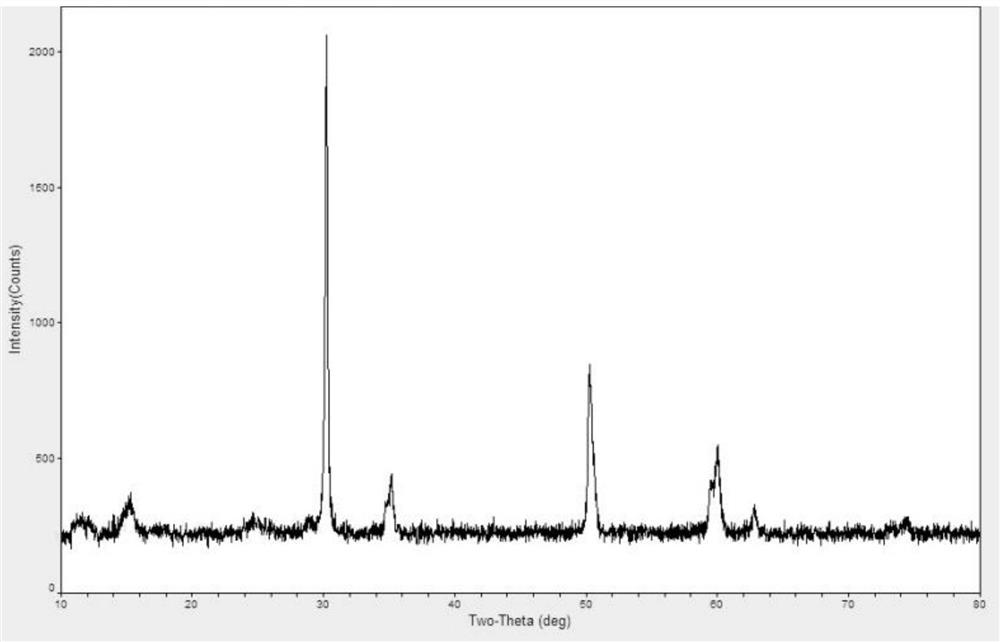

Image

Examples

Embodiment 1

[0037] At room temperature, weigh 17kg of zirconium oxychloride (containing crystal water) and 1.1kg of yttrium nitrate hexahydrate according to the ratio of 3Y, dissolve them in 25L of deionized water, and record it as solution A; mix 5kg of acrylamide (AM), 200g of N,N'-methylenebisacrylamide (MBAM) was dissolved in solution A, and 2ml of tetramethylethylenediamine (TEMED) was added dropwise, which was recorded as solution B; 5g of ammonium persulfate was weighed and added to the solution Stir in B, then immediately introduce the solution into the granulator for thermal reaction; obtain zirconium source gel particles; soak it in excess ammonia water (25% concentration, 60L) for 2 hours; at this time, the particles have changed from transparent to White, wash and filter the particles several times until the chloride ion is less than 20ppm, then dry them in an oven (90-110°C) to obtain micron-sized zirconia precursor gel particles with a certain strength; put the particles at 8...

Embodiment 2

[0039] At room temperature, weigh 17kg of zirconium oxychloride (containing crystal water) and 0.56kg of yttrium chloride according to the ratio of 3Y, dissolve them in 25L of deionized water, and record it as solution A; mix 5kg of acrylamide (AM), 200g of N , N'-methylenebisacrylamide (MBAM) was dissolved in solution A, and 2ml of tetramethylethylenediamine (TEMED) was added dropwise, which was recorded as solution B; 5g of ammonium persulfate was weighed and added to solution B Stir in medium, then immediately introduce the solution into the granulator for thermal reaction; obtain zirconium source gel particles; soak it in excess ammonia water (25% concentration, 60L) for 2 hours; at this time, the particles have changed from transparent to white , wash and filter the particles several times until the Cl- ions are less than 20ppm, and then dry them in an oven (90-110°C) to obtain micron-sized zirconia precursor gel particles with a certain strength; the particles are heated ...

Embodiment 3

[0041] A kind of method utilizing spray granulator to prepare nano zirconia, comprises the following steps:

[0042] Step 1: Mix soluble zirconium source and soluble yttrium source, mix with deionized water, prepare solution A of 0.5mol / L, the total weight of zirconium source and yttrium source is M1; zirconium element and yttrium element in the reaction solution A The molar ratio is 97:6; the soluble zirconium source is any one of zirconium oxychloride and zirconium acetate or a combination of both; the soluble yttrium source is yttrium chloride, yttrium oxalate, yttrium nitrate, and yttrium acetate Any one or two combinations of them;

[0043]Step 2: Cool solution A to 0°C, weigh acrylamide with a weight of M2 and N,N'-methylenebisacrylamide with a weight of M3, put them into solution A to dissolve, and drop into tetramethyldiethyl Amine, to obtain solution B, and keep cooling at a temperature of 0°C, wherein M2:M1 is 1:3, M3:M2 is 1:15;

[0044] Step 3: Add ammonium persu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com