Drip tape production equipment and production process thereof

A technology of production equipment and production process, applied in the field of drip irrigation belt production equipment and its production process, can solve the problem of inability to meet the development direction of thin-walled products, high tensile strength, high cleanliness requirements of production raw materials, and very high processing accuracy requirements. problems, to ensure the reliability of welding, improve product quality, and reduce product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

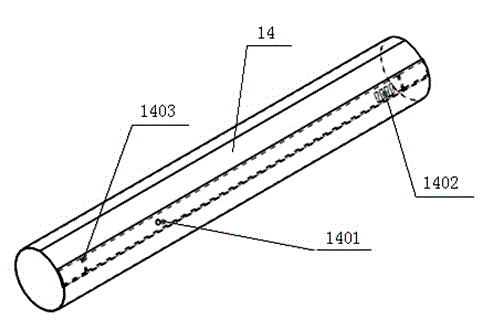

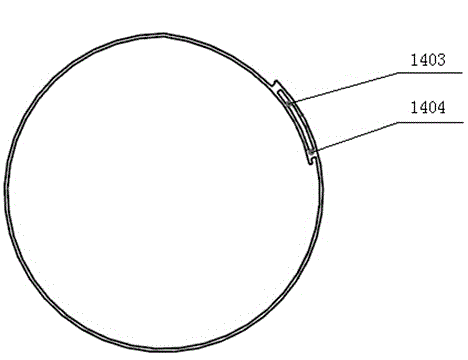

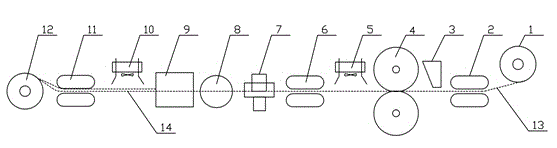

[0041] A kind of drip irrigation belt production equipment, used for preparing such as figure 1 with figure 2 The drip irrigation belt 14 shown, the drip irrigation belt uses the plastic film belt 13 of a specified width as the tube base material, and is formed by opening holes, pressing the flow channel, rolling, and welding. The drip irrigation belt production equipment shown is as follows: image 3 As shown, it includes a film roll placement rack 1, a first pulling device 2, a heater 3, a forming roller group 4, a first cooling device 5, a second pulling device 6, a U roll rack 7, and an O-shaped roll rack 8 arranged in sequence. , Welding equipment 9, second cooling equipment 10, third traction equipment 11, winding frame 12.

[0042] Each traction device described is a common tractor, and each cooling device is an air-cooled cooling device.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com