traction sheave elevator

A traction trough and elevator technology, which is applied to elevators, belts/chains/gears, portable lifting devices, etc. in buildings, can solve the problems of rope wear and shorten the service life of ropes, and achieve increased frictional traction, extended service life, Effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

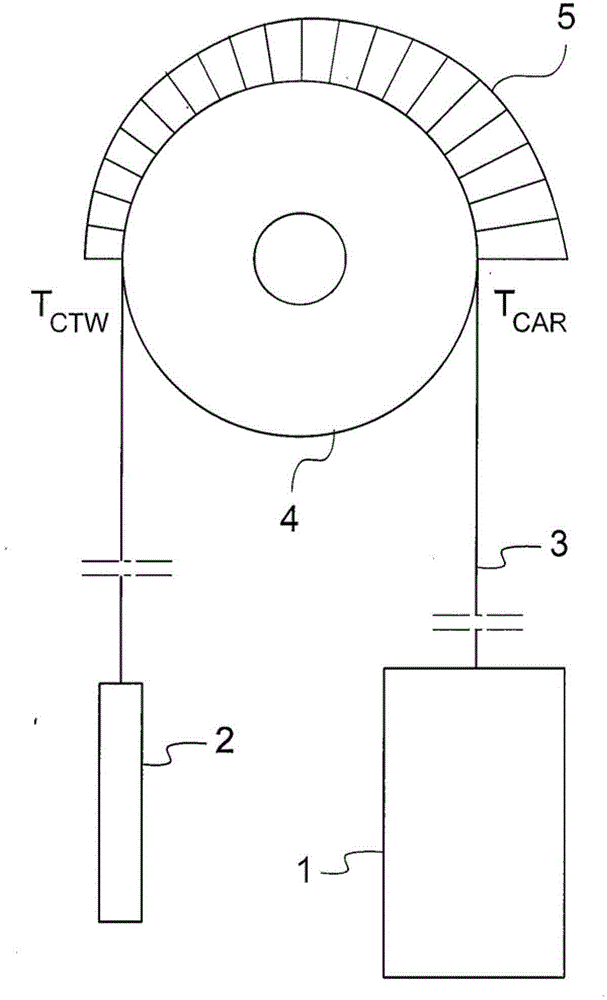

[0031] figure 1 A schematic simplified view of a typical traction sheave elevator is shown, the traction sheave elevator includes an elevator car 1, a counterweight 2 and an elevator roping formed by elevator ropes 3 parallel to each other installed between them . The elevator rope 3 is guided in a rope groove of a size suitable for the elevator rope 3 around the traction sheave 4 that is rotated by the hoist of the elevator. When the traction sheave 4 rotates, the traction sheave 4 simultaneously causes the elevator car 1 and the counterweight 2 to move in the upward and downward directions due to friction.

[0032] Due to the difference between the counterweight 2 and the elevator car 1 plus the load in the elevator car at any given time, the rope force T applied to the elevator rope 3 CTW And T CAR There are different magnitudes on different sides of the traction sheave 4. When the elevator car 1 contains a load less than one-half of the rated load, the counterweight is gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com