Rod-like article forming apparatus

a technology of forming apparatus and rods, which is applied in the field of forming apparatus, can solve the problems of garniture tape tearing and frequent suspension of making machines, and achieve the effects of reducing friction resistance, excessive resistance, and reducing the running resistance of garniture tap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

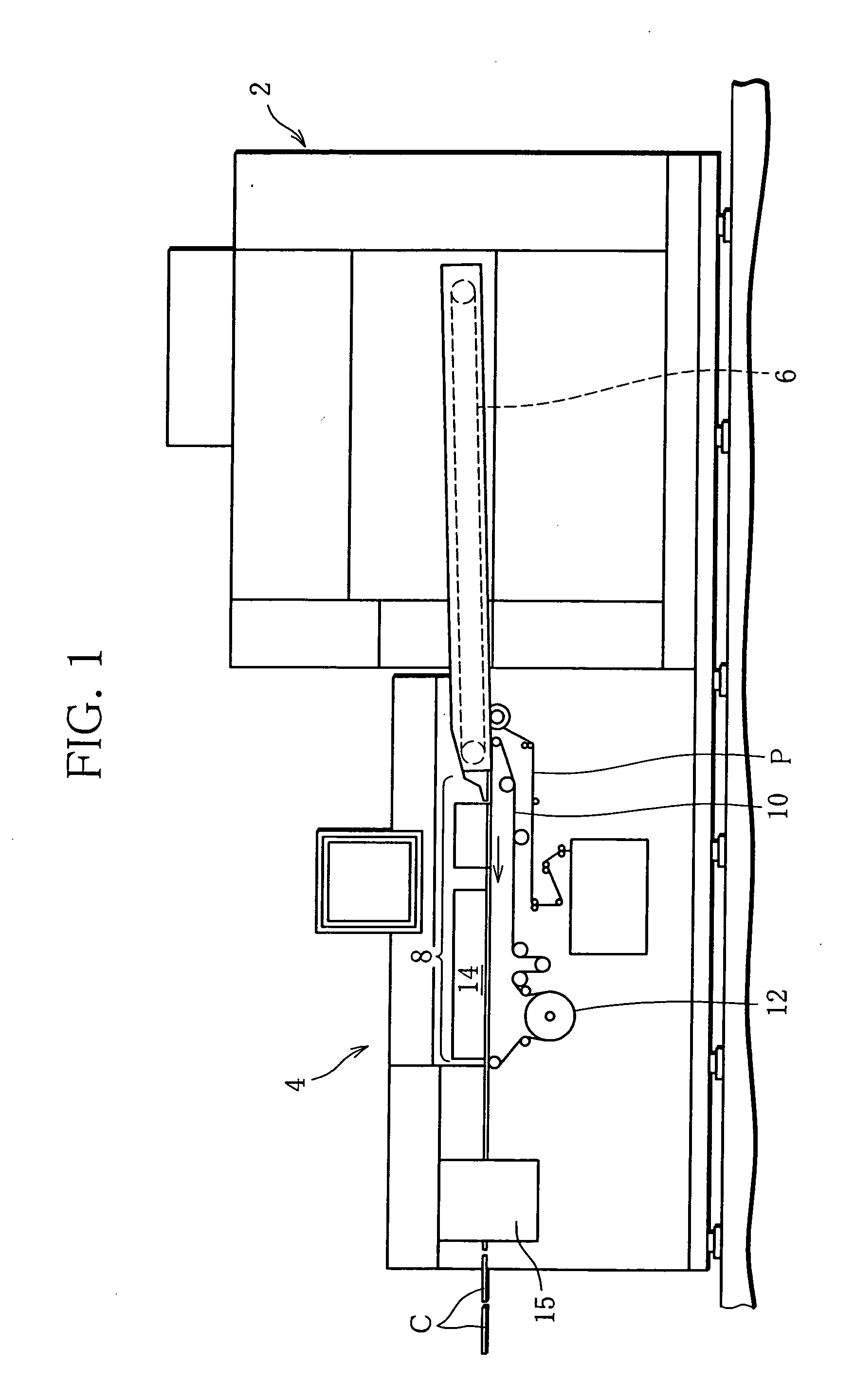

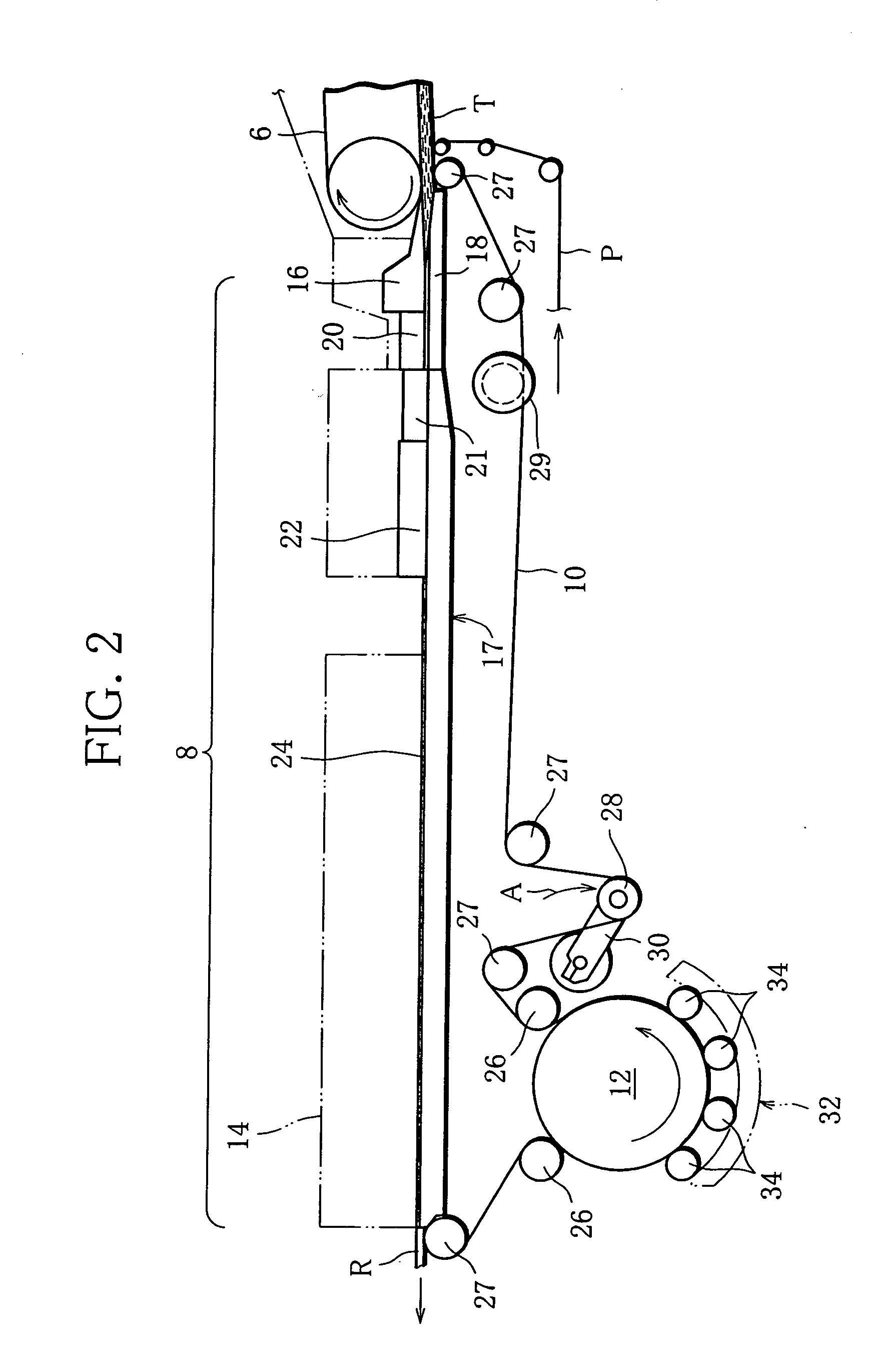

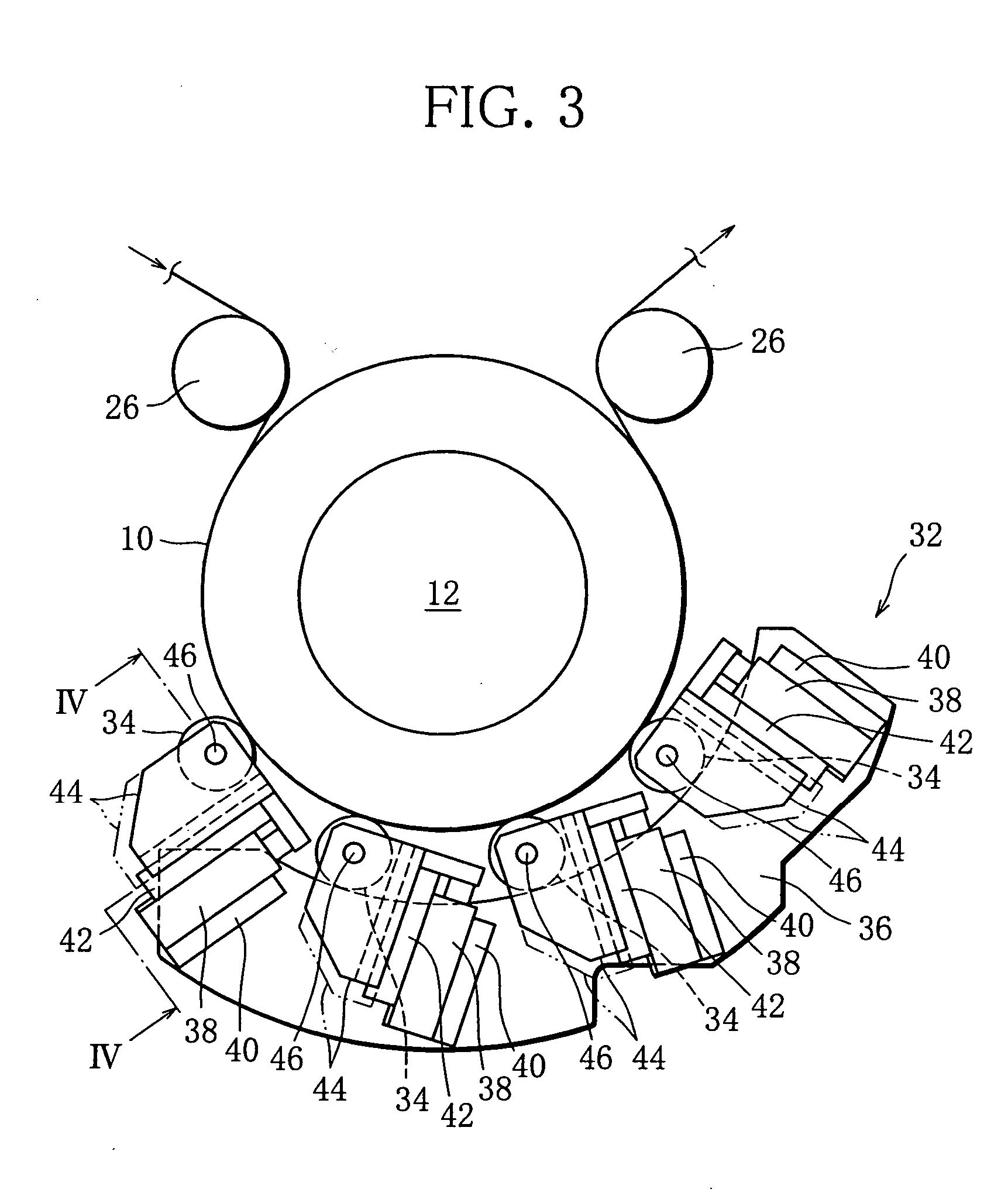

[0029] A rod-like article forming apparatus constitutes a part of a cigarette making machine or a filter making machine. As illustrated in FIG. 1, the cigarette making machine comprises a shredded tobacco-supplying device 2 and a forming apparatus 4. The forming apparatus 4 forms cigarette rods.

[0030] More specifically, the supplying device 2 has an endless suction belt, namely a tobacco band 6, which runs in one direction. While the tobacco band 6 travels, a suction face of the tobacco band 6 sucks shredded tobacco in layers to form a shredded tobacco layer. The shredded tobacco layer is transferred toward the forming apparatus 4 along with the travel of the tobacco band 6.

[0031] The forming apparatus 4 includes a wrapping section 8 continuing to the tobacco band 6. The wrapping section 8 receives the shredded tobacco layer and a paper web P at a start end thereof. The shredded tobacco layer and the paper web P pass through the wrapping section 8, and in this process, the shredde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com