Tension stabilizing control method and device for leveling machine

A stable control method and technology of stable control device, which are applied in tension/pressure control, length measuring device, metal rolling, etc., can solve the problems of tension loss, large drop in tension value, and limited adjustment ability of tension controller. Accurate control and reduced amplitude effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

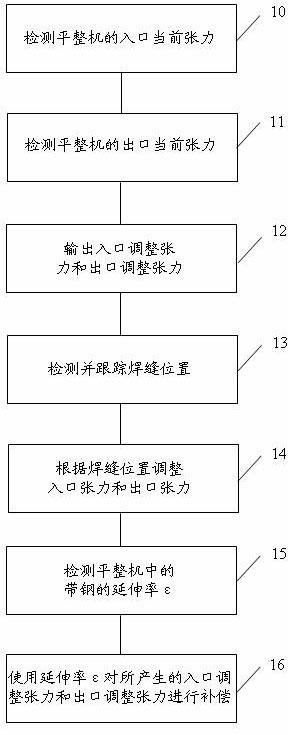

[0032] refer to figure 1 As shown, the present invention proposes a method for stabilizing the tension of a temper mill, comprising the following steps:

[0033] 10. Detect the current tension at the entrance of the tempering machine.

[0034] 11. Detect the current tension at the exit of the tempering machine.

[0035] 12. The tension controller outputs the inlet adjustment tension and the outlet adjustment tension according to the detected inlet tension and outlet tension changes.

[0036] 13. Detect and track weld seam position.

[0037] 14. Adjust the inlet tension and outlet tension according to the weld position. When the welding seam position enters the entrance of the tempering machine, adjust the entrance tension and exit tension of the tempering machine to the average value of the current tension at the entrance and the current tension at the exit. When the welding seam position is out of the exit of the tempering machine, adjust the entrance tension of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com