Silicon wafer wire cutting machine

A technology of wire cutting machine and silicon wafer, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc. It can solve the problems of heavy wire wheel weight, low cutting efficiency, and large wire bobbin jump, so as to reduce wire mesh pull Empty, improve cutting efficiency, and increase cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

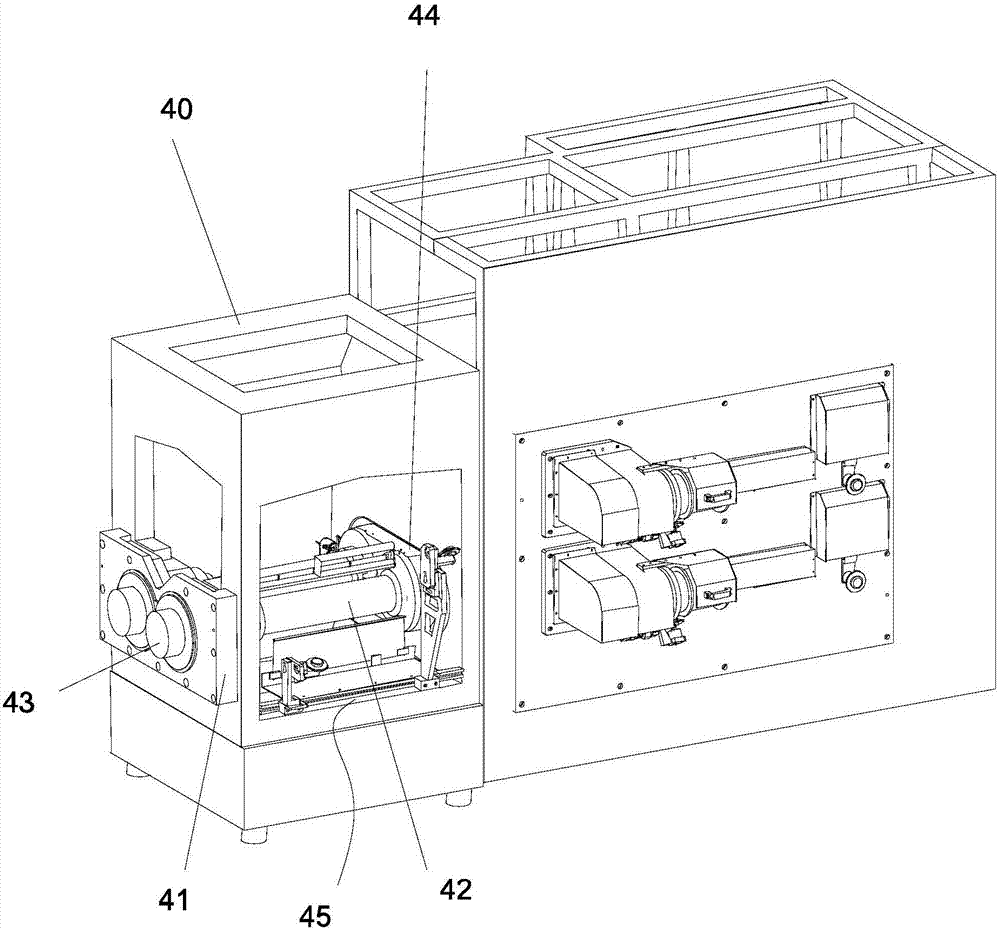

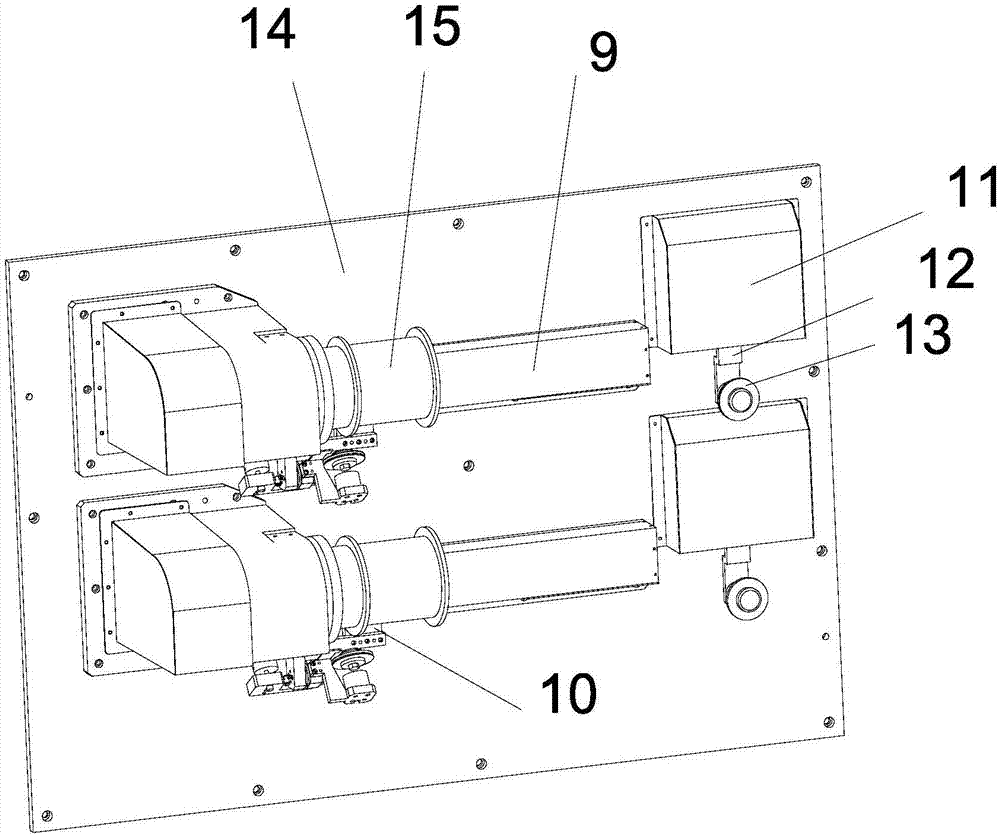

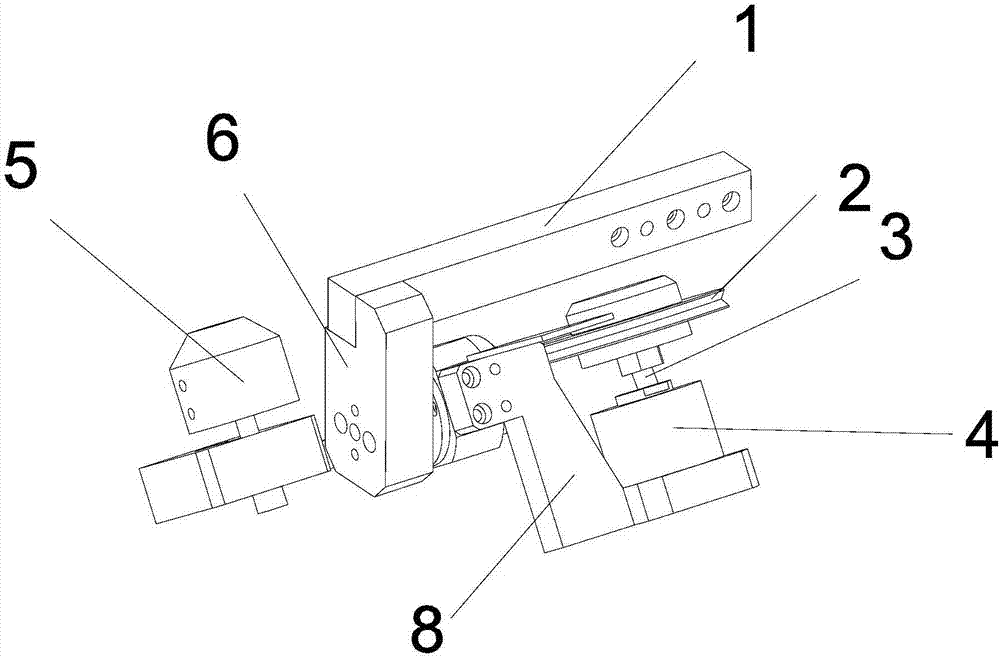

[0016] Such as Figure 1-4 As shown, a wire cutting machine for silicon wafers includes a frame 40, a cutting chamber located at the front of the frame, and a wire barrel chamber positioned behind the cutting chamber. The cutting chamber is provided with a cutting head and a wire reel tooling 45. The wire spool room includes a main board 14, a take-up and pay-off reel unit, two guide wheel frocks respectively located under the take-up and pay-off reels 15, a guide reel frock moving seat 10 connected to the guide pulley frock, and two traversing frames 9 , two tension arm motors, the tension arm 12 that links to each other with the tension arm motor, the tension arm guide wheel 13 that is located at the lower end of the tension arm, the horizontal movement frame 9 is set horizontally, and the horizontal movement frame 9 bottom is provided with a horizontal The guide wheel frock moving seat slide rail, the guide wheel frock moving seat 10 can move laterally along the slide rail;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com