Elongation coefficient control method of rewinding straightening and withdrawal unit

A control method and elongation rate technology, which is applied in the direction of elongation rate control, etc., can solve the problems of closed-loop control of elongation rate, such as easy oscillation, large tension fluctuation, and easy oscillation of tension, so as to avoid the vibration of closed-loop control of elongation rate and large tension fluctuation , The effect of small tension fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] In order to facilitate the understanding of the elongation control method proposed by the present invention, the composition of the tension leveling device is firstly introduced.

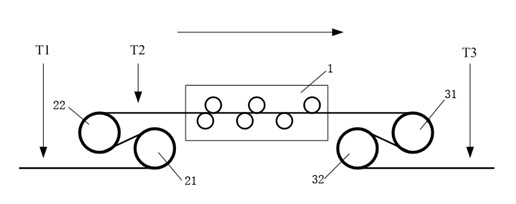

[0026] attached figure 1 A schematic diagram of the tension-leveling device is shown, figure 1 The direction of the middle arrow is the running direction of the strip steel. The tension leveling machine body 1 includes bending rollers, anti-bending rollers, anti-bending rollers, etc.; the entrance tension roller group 1# roller 21 and the entrance tension roller group 2# roller 22 together form the entrance tension roller group, and the entrance tension roller group 2# Roller 22 is the main roller; the outlet tension roller group 1# roller 31 and the outlet tension roller group 2# roller 32 together form the outlet tension roller group, and the outlet tension roller group 1# roller 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com