Production device and production technology for dacron double-polyester double-splendor Liz silk

A technology of polyester and different colors, which is applied in the field of polyester double-polyester double-colored silk production equipment, which can solve the problems of not having high-temperature heating and setting and oiling, and the inability to achieve double-polyester double-colored silk fabrics, such as easy napping and style feel. , to achieve the effect of stable tension, easy fleece and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

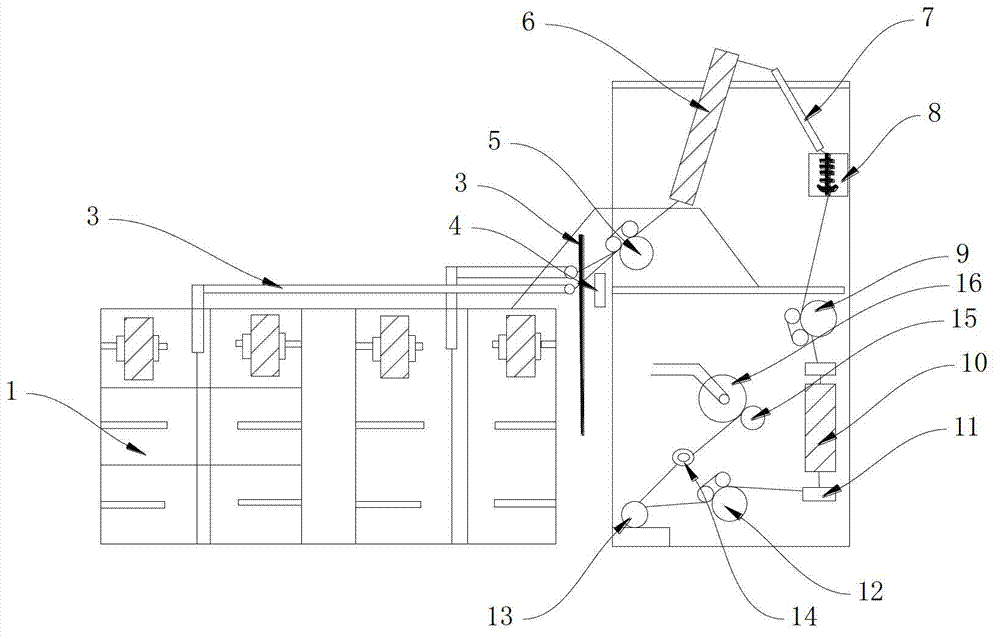

[0014] Such as figure 1 As shown, this embodiment describes a production device for polyester, double-polyester, and double-color Lisi, which includes a raw silk tube 2, a wire pressing rod 3, a first roller 5, an upper heating box 6, a cooling plate 7, and a false twister 8. The second roller 9, the lower heat box 10, the third roller 12, the oil tanker 13, the thread guide 14, the friction roller 15 and the finished bobbin 16. It also includes the double original thread frame 1, the wire pressing rod 3, the first The network nozzle 4 and the second network nozzle 11; the first roller 5 is installed between the exit of the double original yarn rack 1 and the double original yarn tube 2 and the upper heating box 6, and the wire pressing rod 3 and the first roller 5 are installed before the first roller 5. A network nozzle 4, a cooling plate 7, a false twister 8 and a second roller 9 are arranged between the upper heating box 6 and the lower heating box 10. A third roller 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com