Fiber conduction device for carbon fiber winding machine

A winding machine and carbon fiber technology, which is applied in the field of composite material processing, can solve the problems of carbon fiber products, such as the decline in mechanical properties, uneven unfolding width, and uneven glue content, and achieve the effects of small tension fluctuations, easy maintenance, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

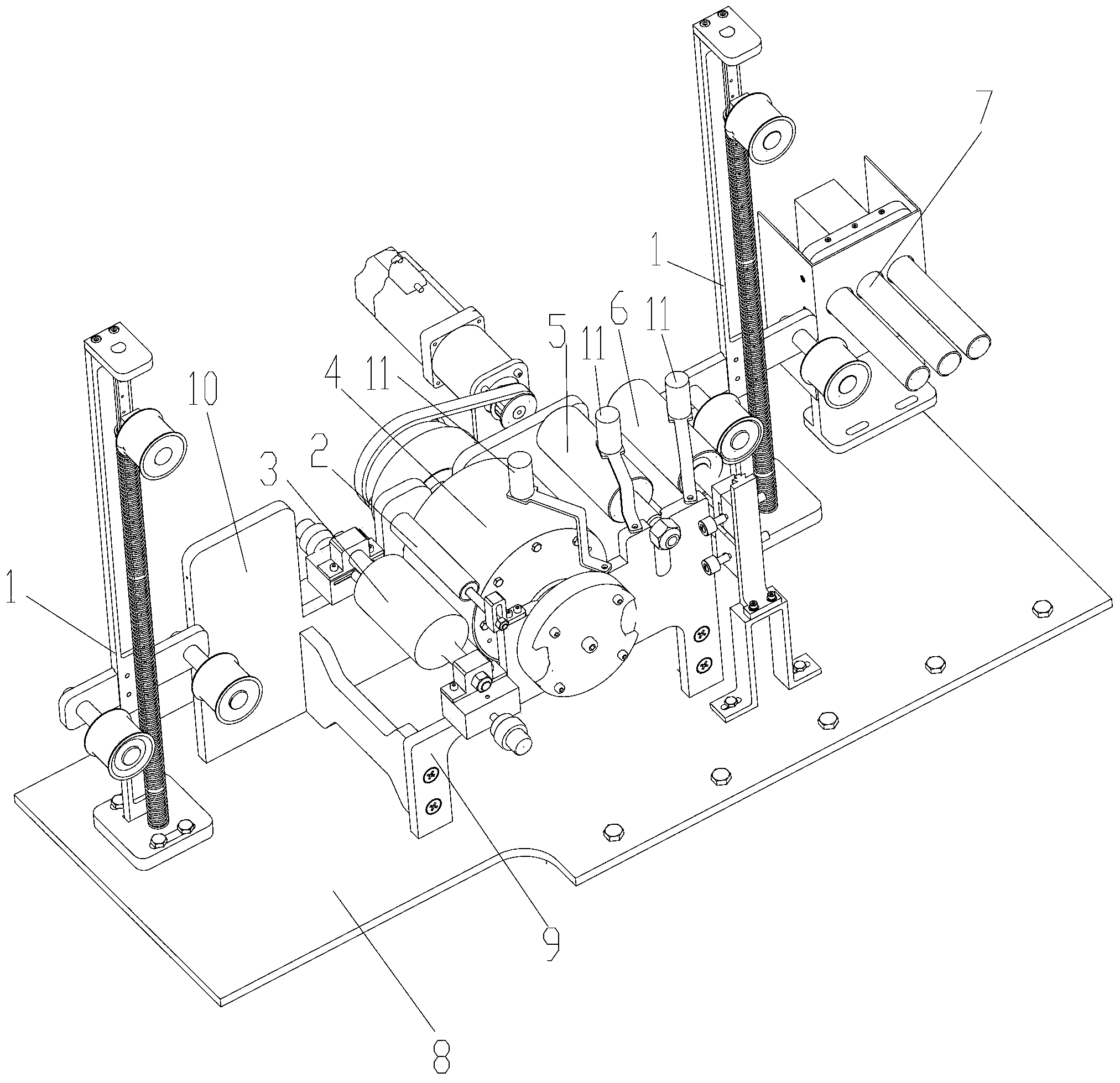

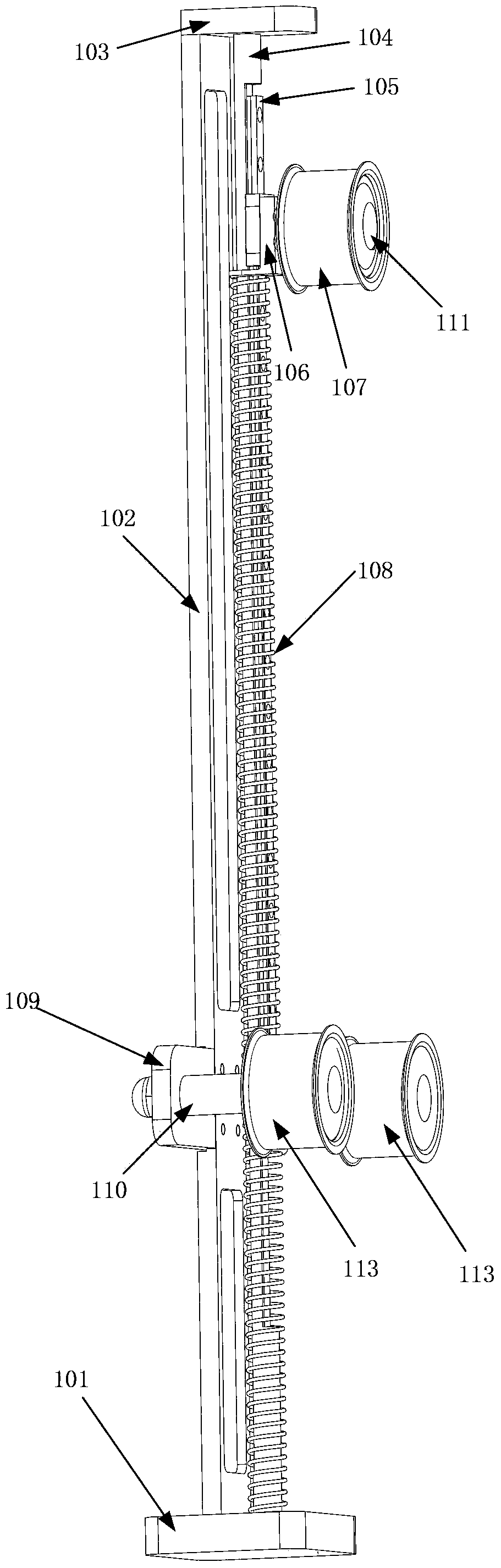

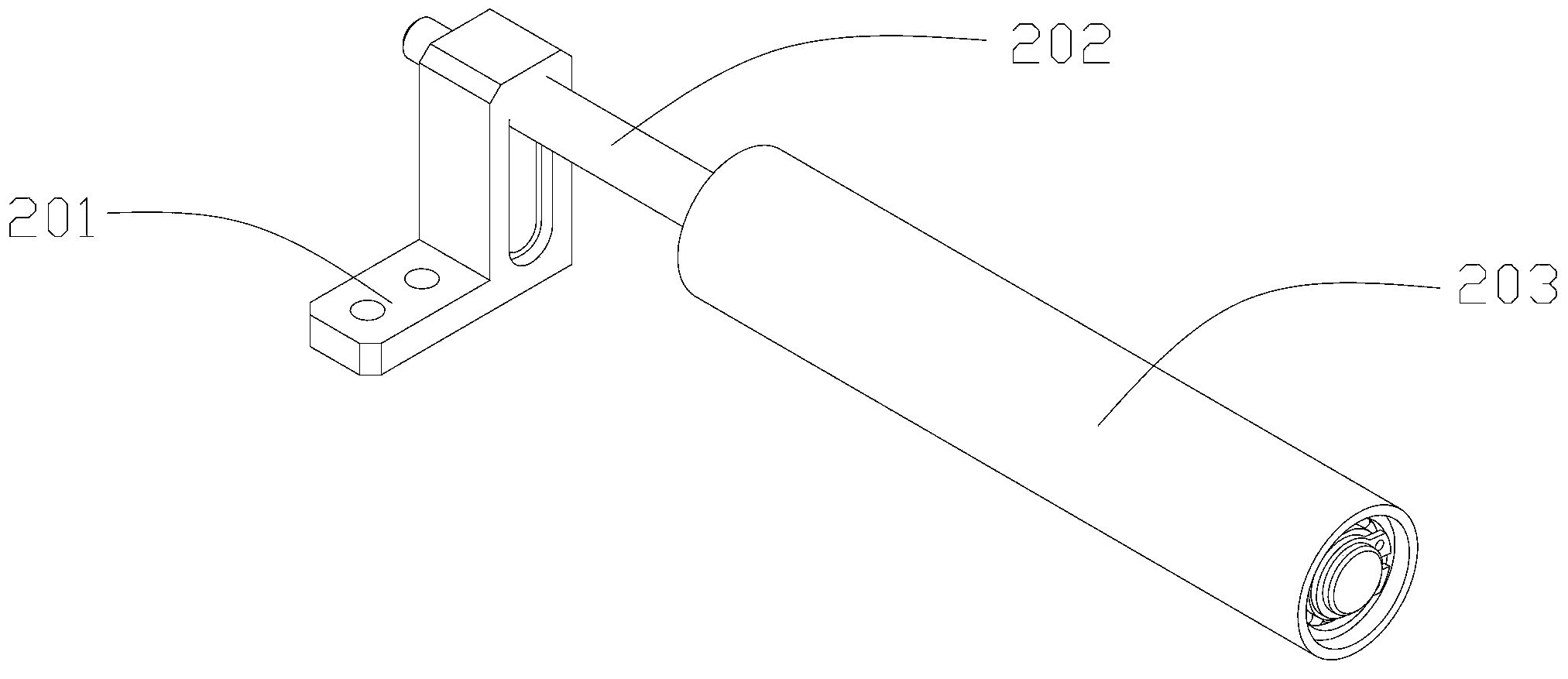

[0030] The present invention is a carbon fiber winding machine fiber conduction device, such as figure 1 As shown, it includes tension adjustment device 1, front wrapping angle adjusting roller 2, rubber scraping device 3, active dipping roller 4, rear wrapping angle adjusting roller 5, rubber squeezing device 6, tension measuring device 7, frame bottom plate 8 , 9 left racks, 10 right racks.

[0031] The left frame 9 and the right frame 10 are respectively fixed on the frame bottom plate 8, the heights of both sides are the same, and they are connected by connecting plates, so that the structure of the left frame 9 and the right frame 10 is stable, and the front wrapping angle adjustment roller 2. Glue scraping device 3 , active dipping roller 4 , rear wrapping angle adjusting roller 5 , and glue squeezing device 6 are respectively fixed on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com