Carbon fiber winding machine process parameter adjusting system and tension adjusting method

A technology of process parameters and adjustment system, which is applied in the field of composite material forming, can solve the problems of high processing cost of composite material components, high price, limiting the application range of winding machines, etc., and achieves convenient design and development, wrap angle optimization, and reduction fluctuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

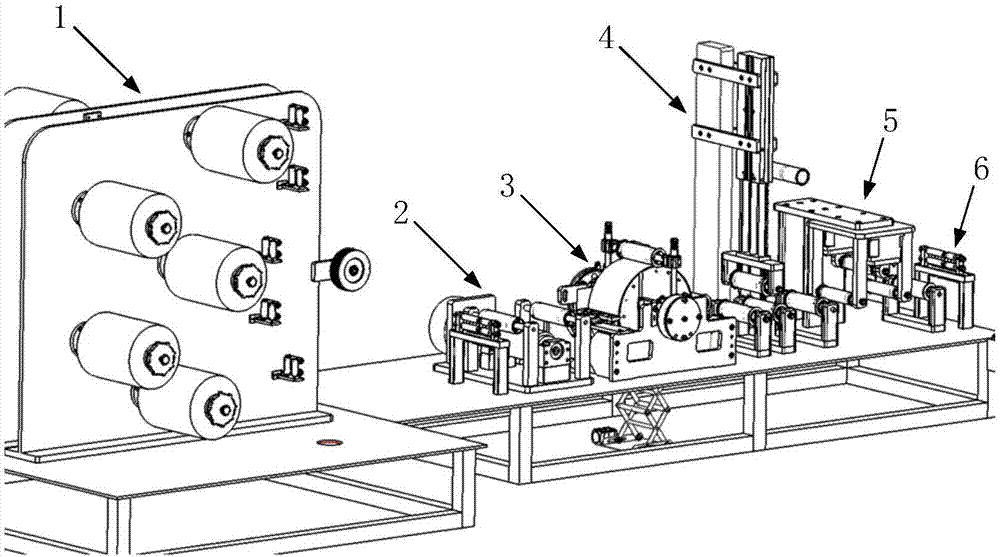

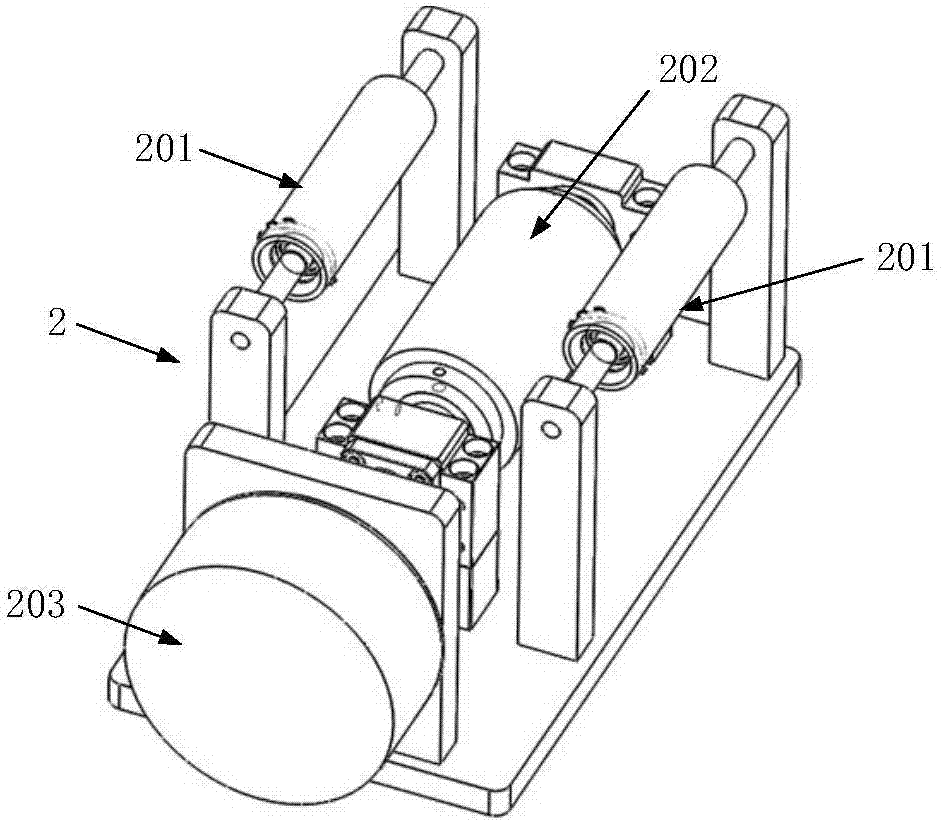

[0040] The carbon fiber winding machine process parameter adjustment system of the present invention includes an unwinding module 1, a tension generation module 2, a dipping amount adjustment module 3, a tension stabilization module 4 and a tension measurement module 5, such as figure 1 shown.

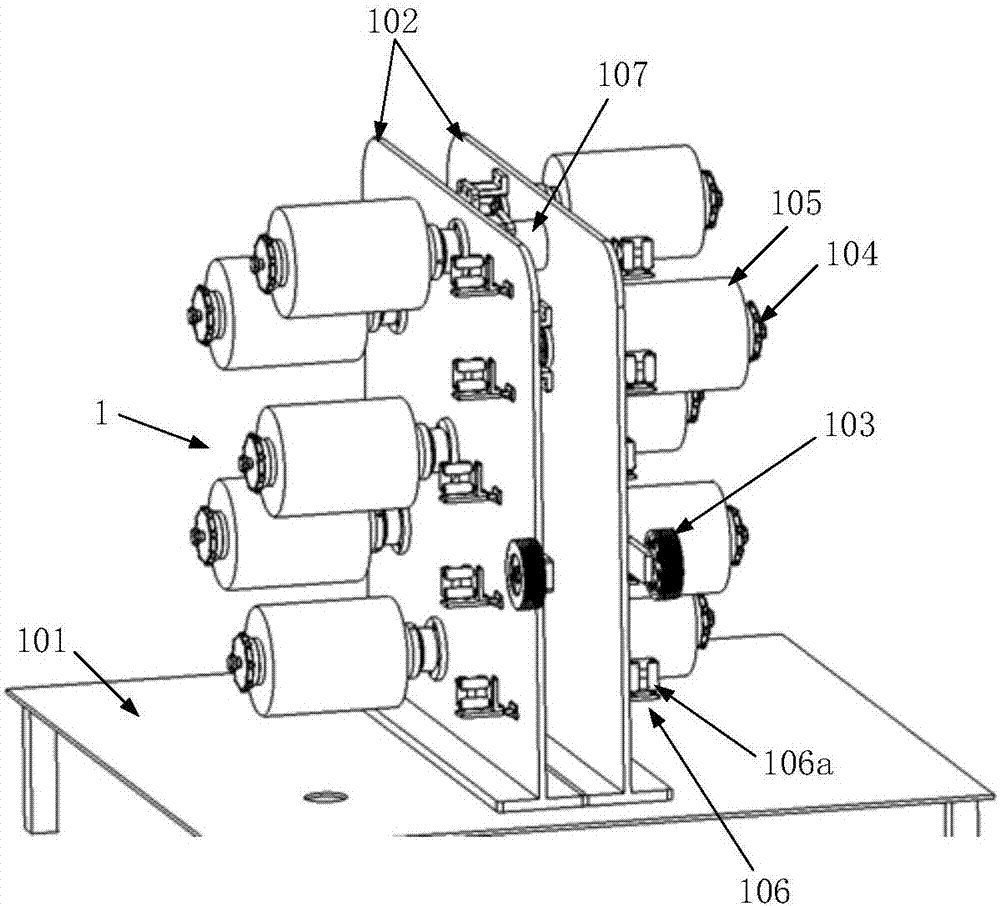

[0041] The unwinding module 1 includes an unwinding module mounting table 101, an unwinding module support 102, a wire feeding cone 103, an unwinding shaft 104, a carbon fiber roll 105, an unwinding module guide roller 106 and an unwinding motor 107, such as figure 2 shown.

[0042] The unwinding module support 102 has two parallel mounting plates, which are perpendicular to the unwinding module mounting table 101 arranged horizontally, and are fixed on the unwinding module mounting table 101. A plurality of unwinding shafts 104 arranged horizontally are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com