Bi-motor yarn tension control device of disposable warping machine

A tension device and control device technology, applied in the field of warping machines, can solve the problems of low tension control accuracy, single yarn tension difference, poor manufacturing accuracy, etc., and achieve the effects of constant tension, smooth surface, and reduced single yarn tension fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

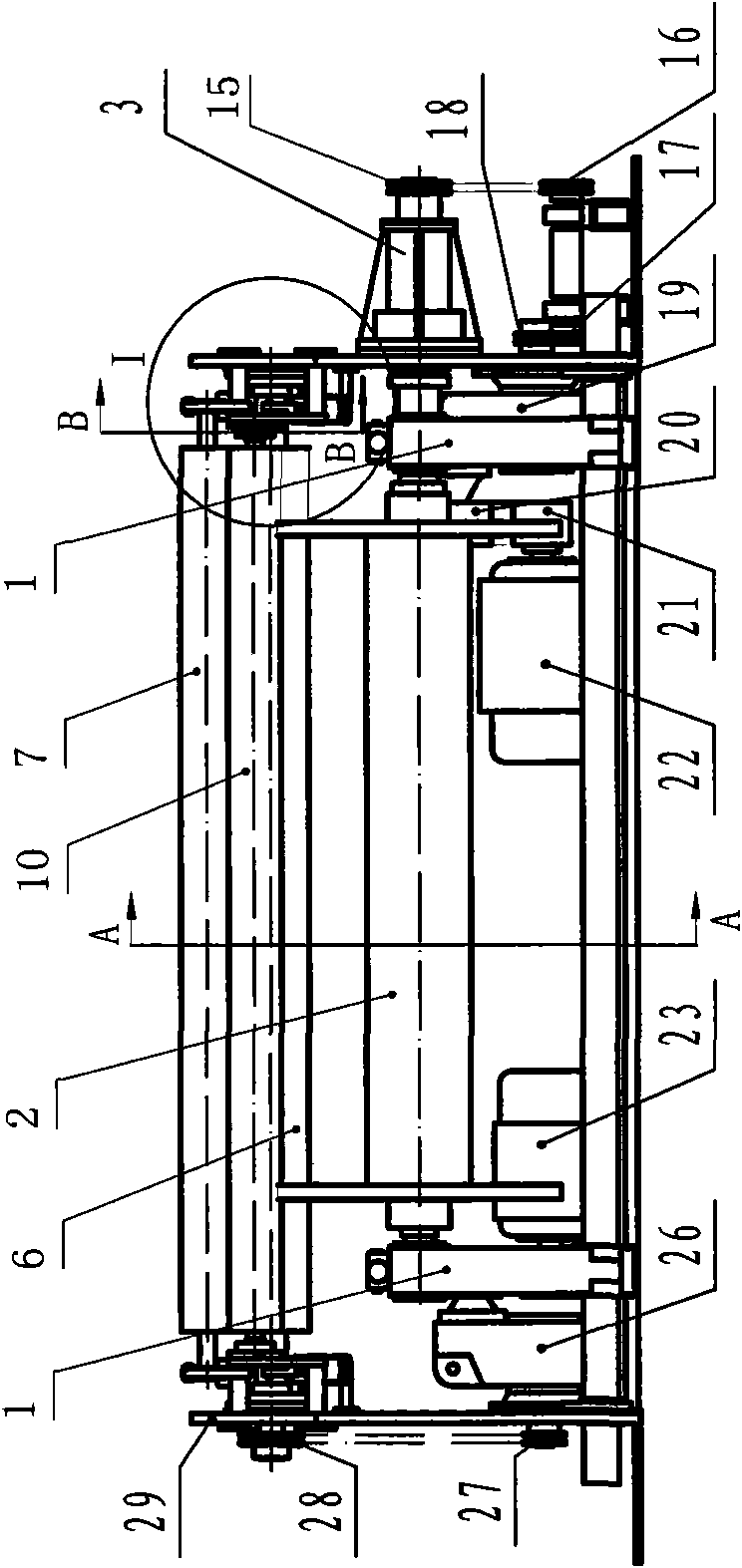

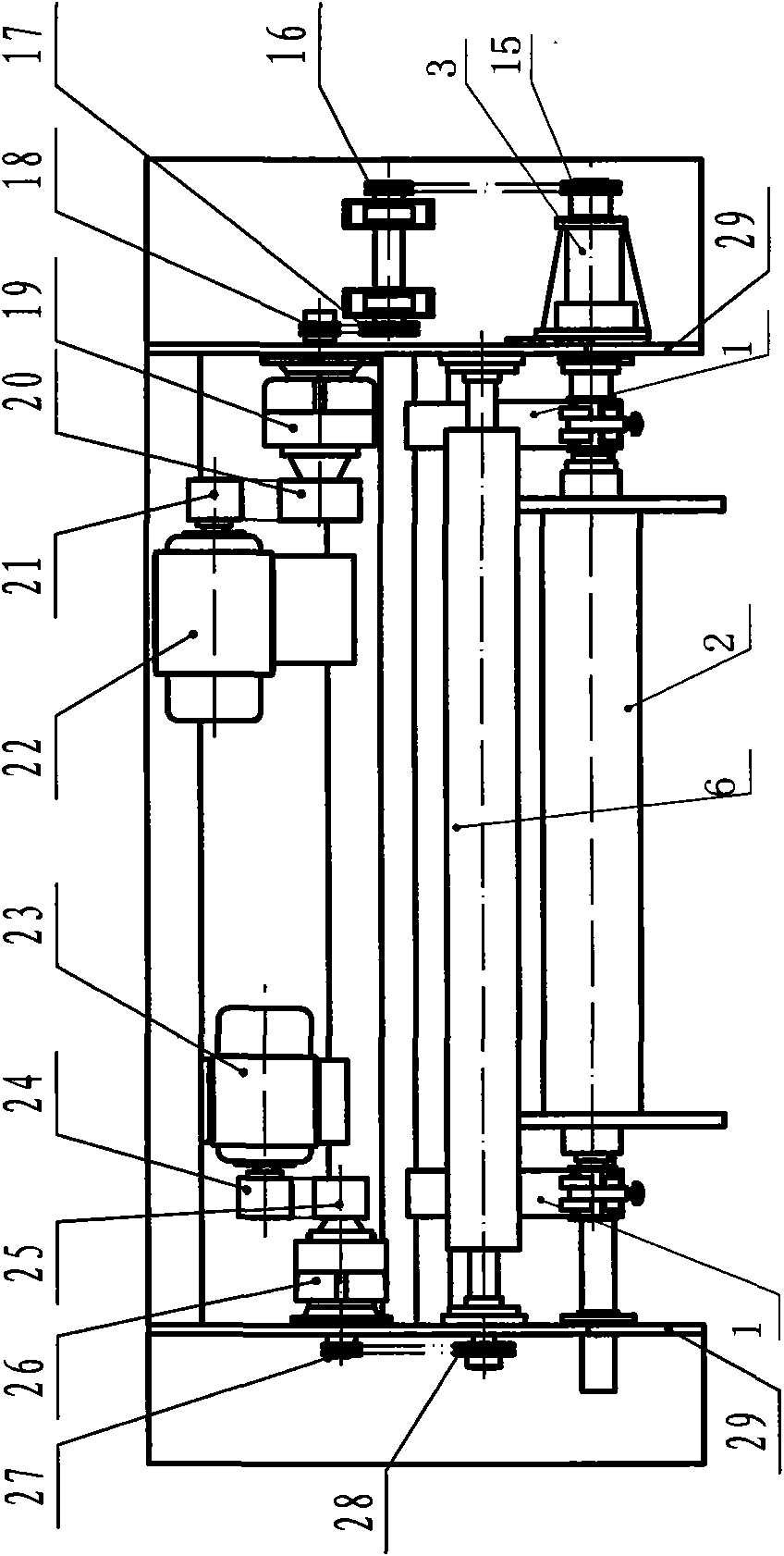

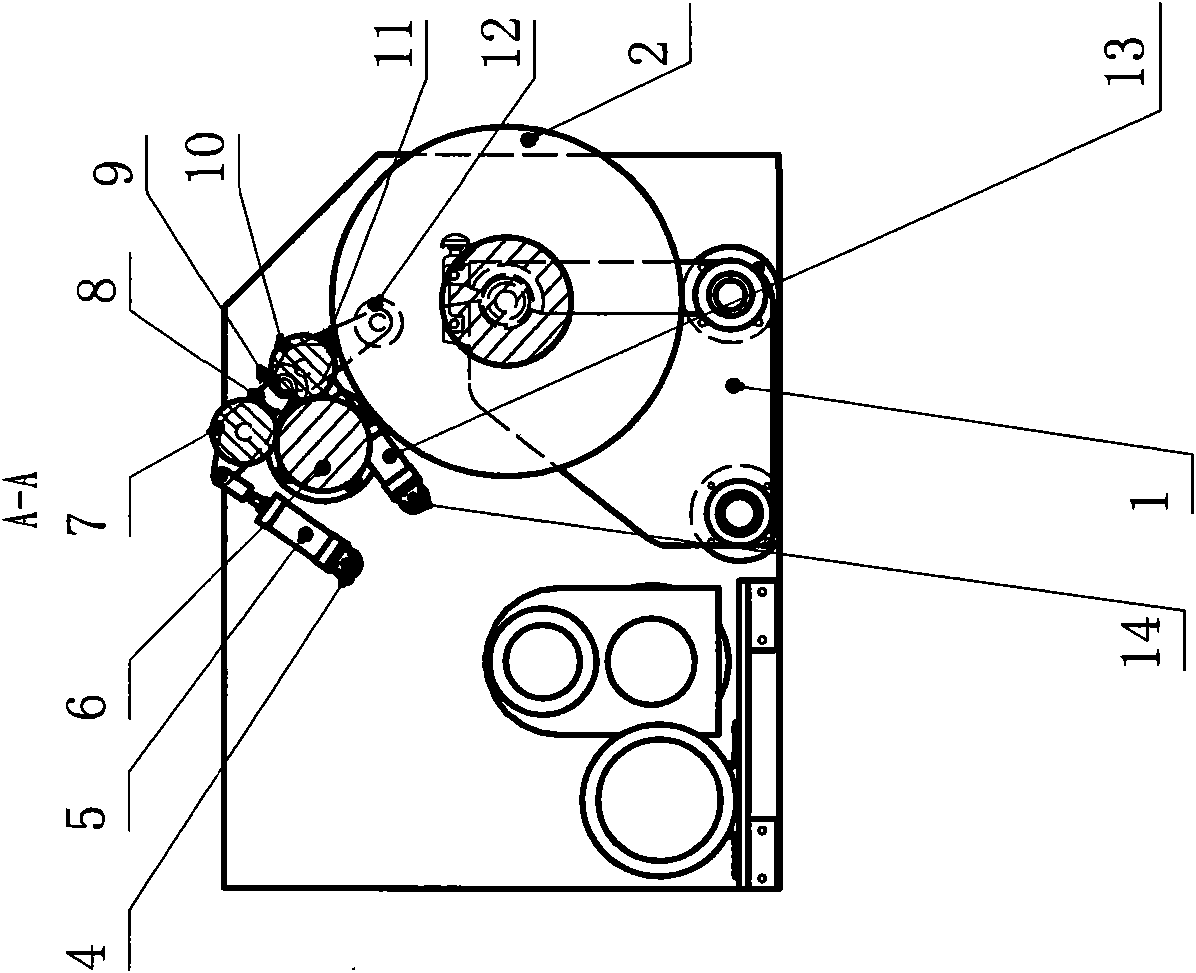

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

[0017] The device includes the creel, screen reed, flat yarn roller, yarn drawing control device of the sub-crew, and the circuit and air circuit control device of the machine in the previous process. The circuit and air circuit control device of this machine described here are the automatic control devices commonly used at present. Yarn tension and warping speed. The creel is the part for storing the yarn bobbin and pulling out the yarn; the screen reed gathers the yarn drawn from the creel to a certain range according to a certain rule; the flat yarn roller uses two rollers to draw the yarn after the screen reed Clamp into pieces of yarn, and increase a certain tension; the split gallows moves up and down through the split reed, so that the yarn is divided into two pieces of yarn one by one at intervals, and put on split ropes for drawing in before weaving. The handpiece is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com