Plastic pipe port flanging process

A technology for plastic pipes and nozzles, which is applied in the field of pipeline processing, which can solve the problems of non-softening of the outer wall, scrapping of plastic pipes, broken nozzles, etc., achieve uniform heating, prevent nozzles from breaking, and increase the clamping area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

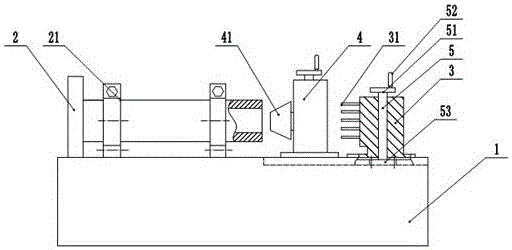

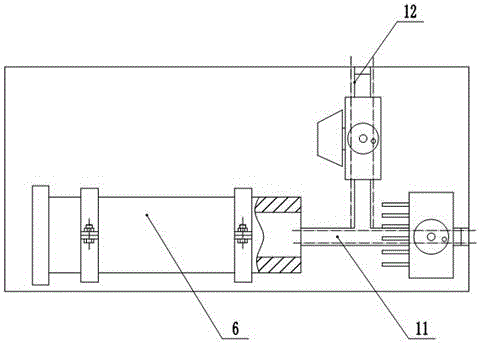

[0020] The reference signs in the drawings of the specification include: mounting seat 1, axial slideway 11, radial slideway 12, stopper 2, clamping hoop 21, heating slide 3, heating probe 31, flanging slide 4 , mold 41, rotating shaft 5, turntable 51, handle 52, gear 53, plastic tube 6.

[0021] The concrete technological process of the present embodiment is:

[0022] 1. Clamp the plastic pipe: Take two arc-shaped clamping hoops and hinge relative to each other, form a round through hole between the clamping hoops, and use screws to connect the two clamping hoops; loosen the screws, and put The plastic tube is placed between the two clamping hoops, and the two clamping hoops are fastened and fixed and locked with screws. Both ends of the plastic tube are locked by clamping hoops; a slidable The stopper is fixed with locking screws to limit the axial displacement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com