Patents

Literature

65results about How to "Limit axial displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

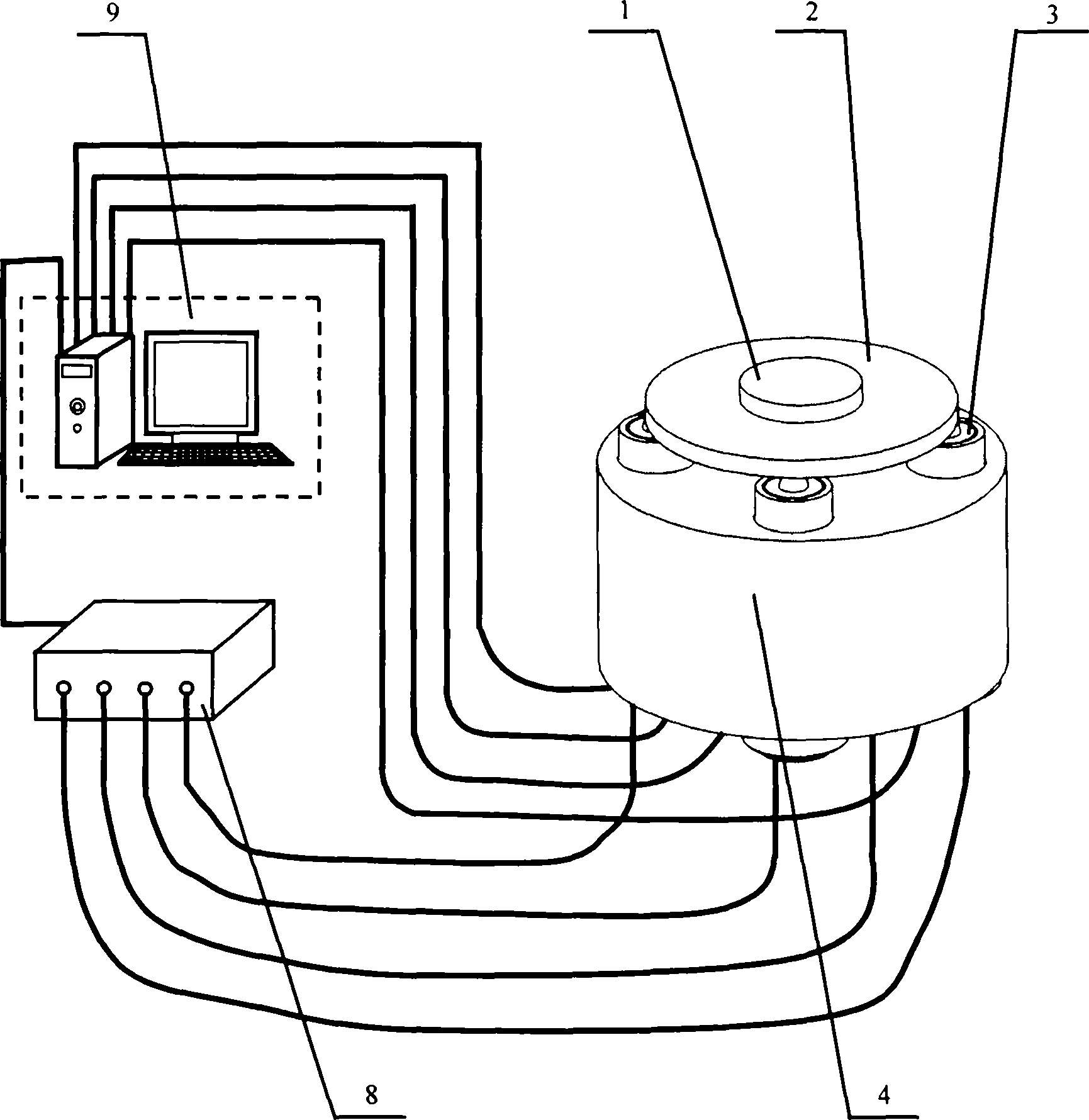

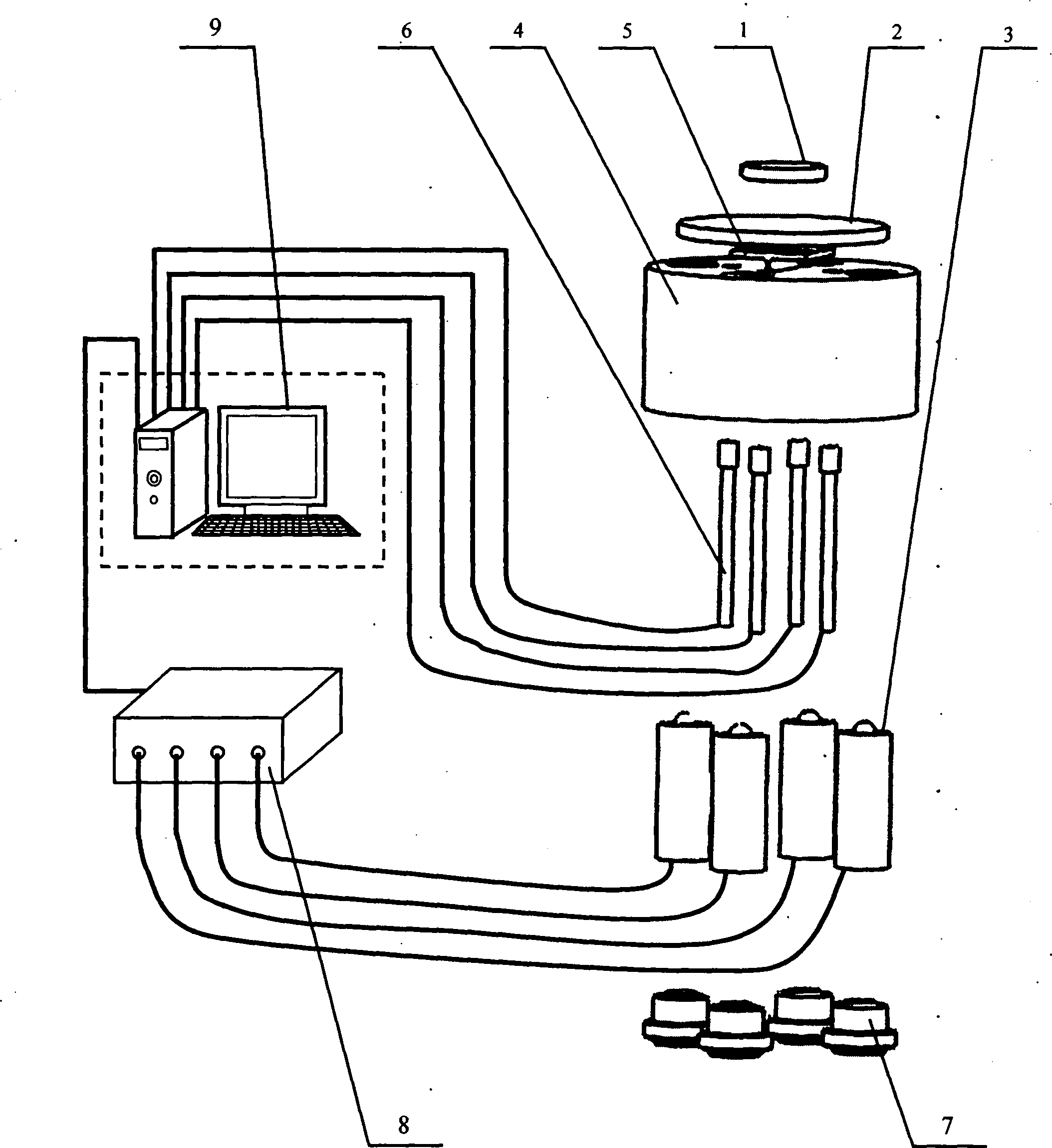

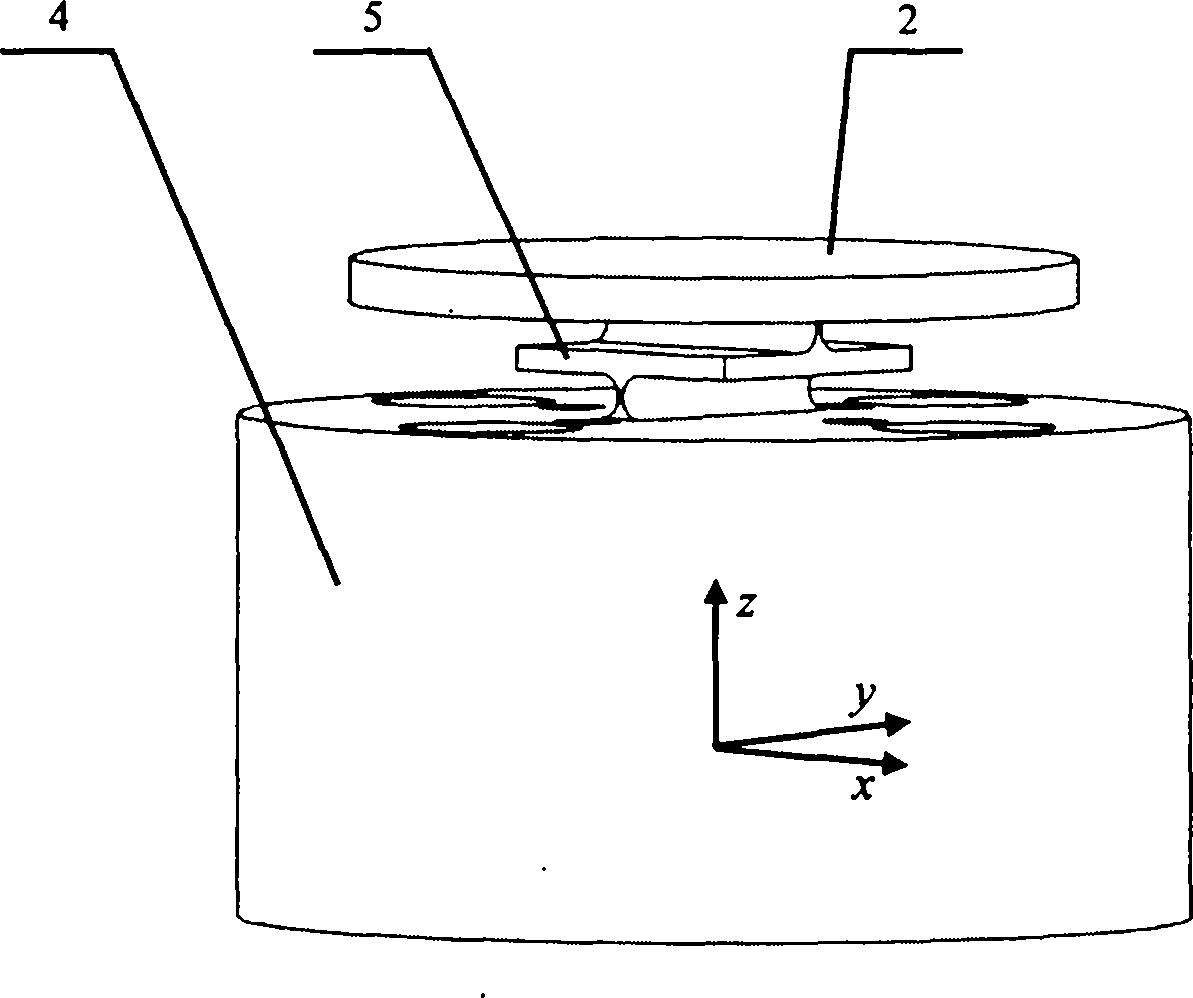

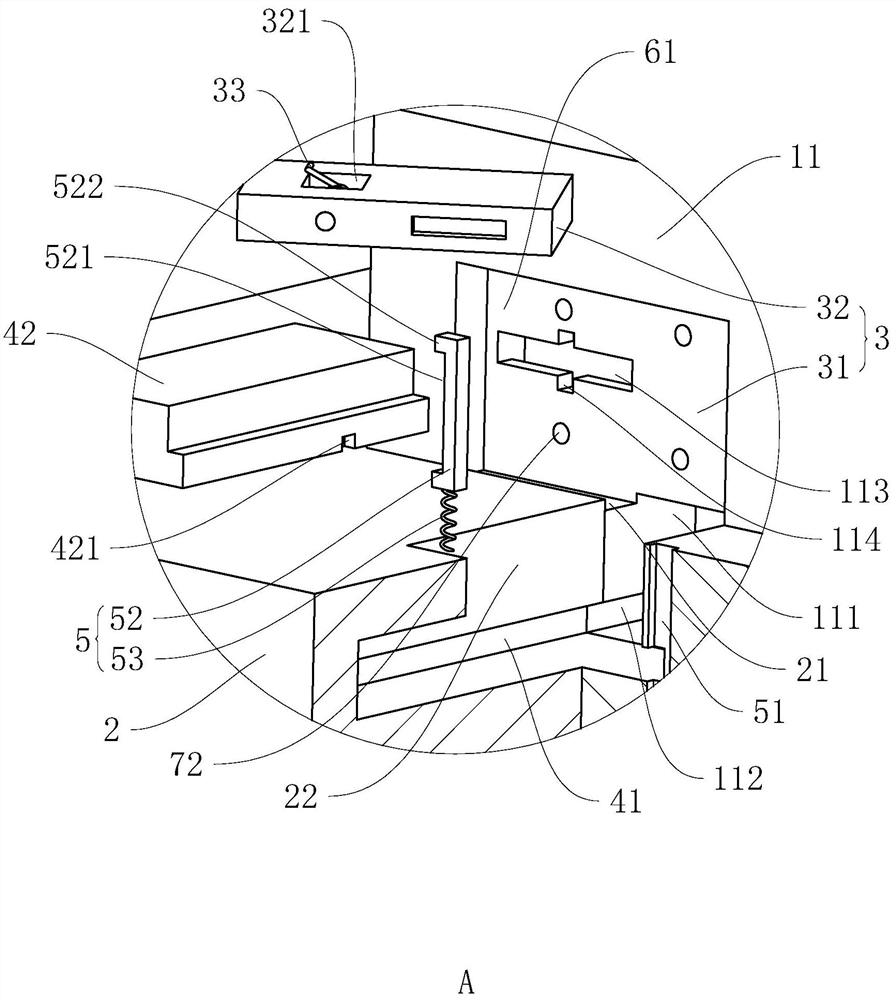

High-frequency response two-dimensional micro angular deflection control reflector based on double-shaft flexible hinge

InactiveCN102323656AAccurate and high sensitivity micro-angular displacementLimit axial displacementMountingsEngineeringFrequency response

The invention discloses a high-frequency response two-dimensional micro angular deflection control reflector based on a double-shaft flexible hinge, and belongs to a light beam control device. The high-frequency response two-dimensional micro angular deflection control reflector based on the double-shaft flexible hinge comprises a reflector, a two-dimensional deflection mechanism based on the double-shaft flexible hinge, a drive mechanism and a control system, wherein the reflector is fixedly assembled on a rigid platform of the two-dimensional deflection mechanism based on the double-shaft flexible hinge; an incident light beam is emitted after being reflected by the reflector; and the control system controls a positive micro drive mechanism and a negative micro drive mechanism to push the rigid platform at a high speed along a negative position and a positive position respectively at symmetric positions, so that the reflector on the rigid platform deflects at a micro angle to realize the direction control of the emitted light beam; and a displacement sensor of the control system feeds the rotation angle information of the reflector back to a computer system to adjust the micro deflection angle of the reflector in real time. The high-frequency response two-dimensional micro angular deflection control reflector based on the double-shaft flexible hinge has the characteristics of no-coupling and no-axial translation in a two-dimensional deflecting direction, and high response speed.

Owner:HARBIN INST OF TECH

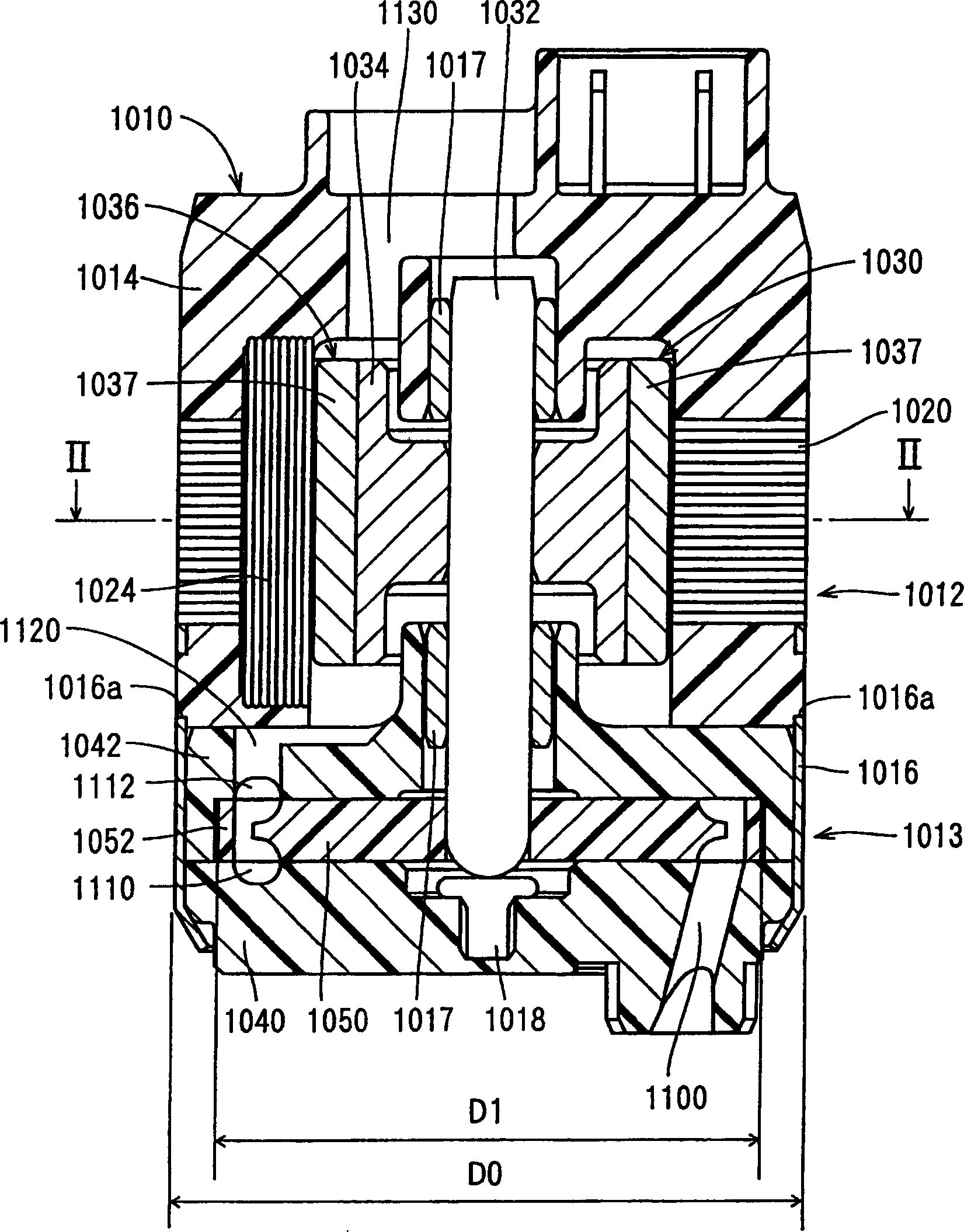

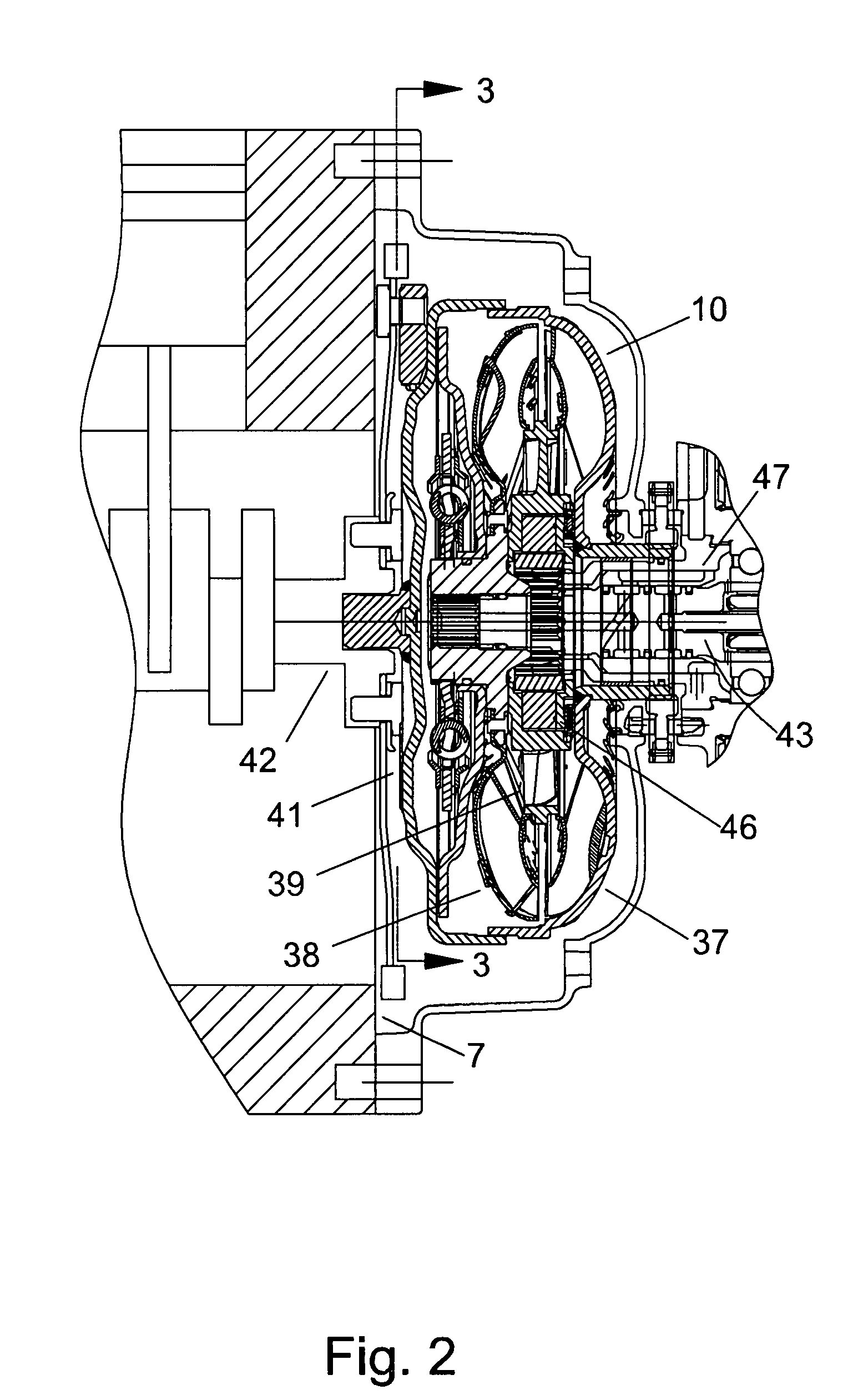

Fuel pump, fuel supply equipment using fuel pump and method for manufacturing fuel pump

ActiveCN1676915AEasy to wrapStop sheddingCircumferential flow pumpsTransverse flow pumpsElectricityBrushless motors

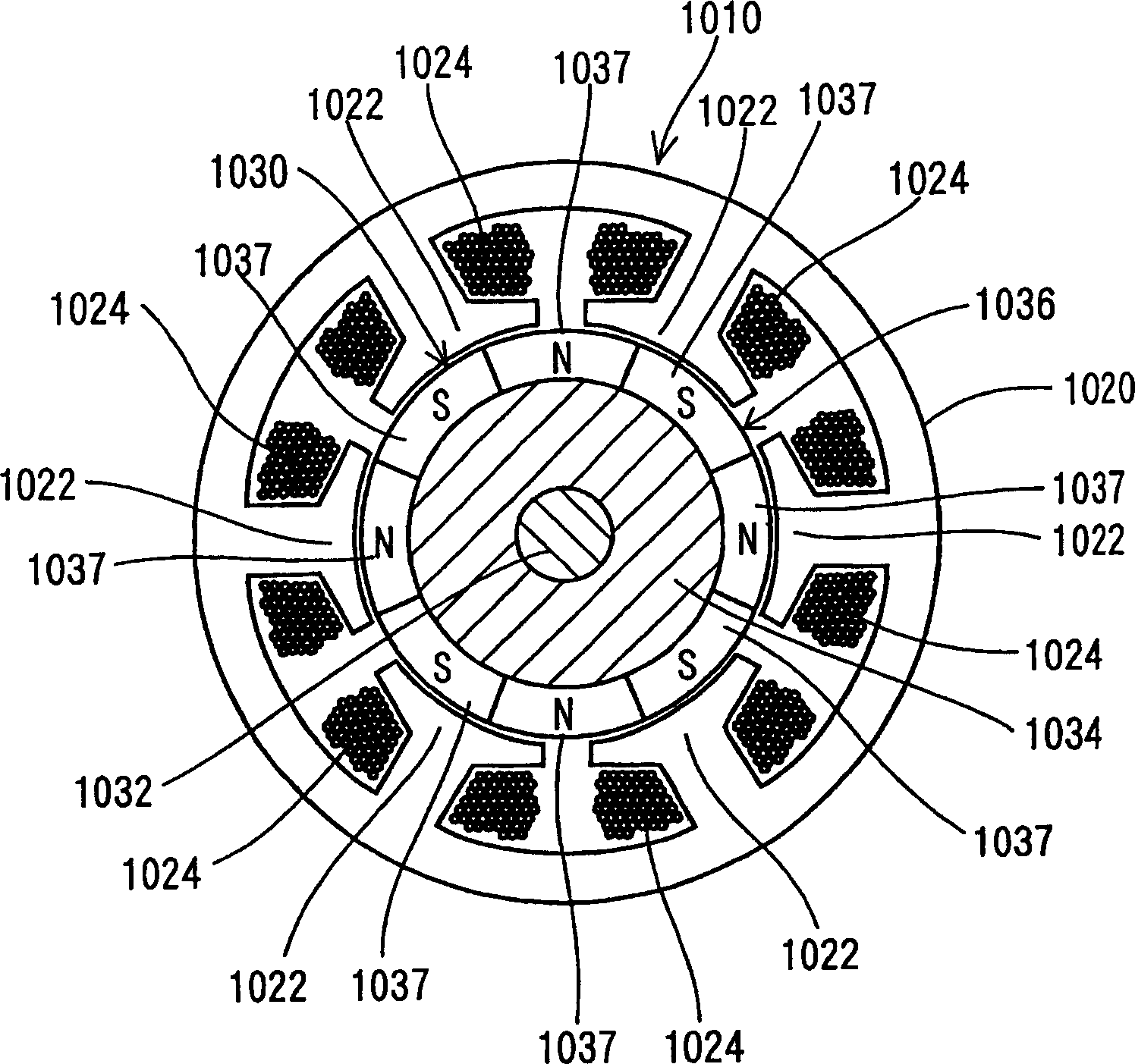

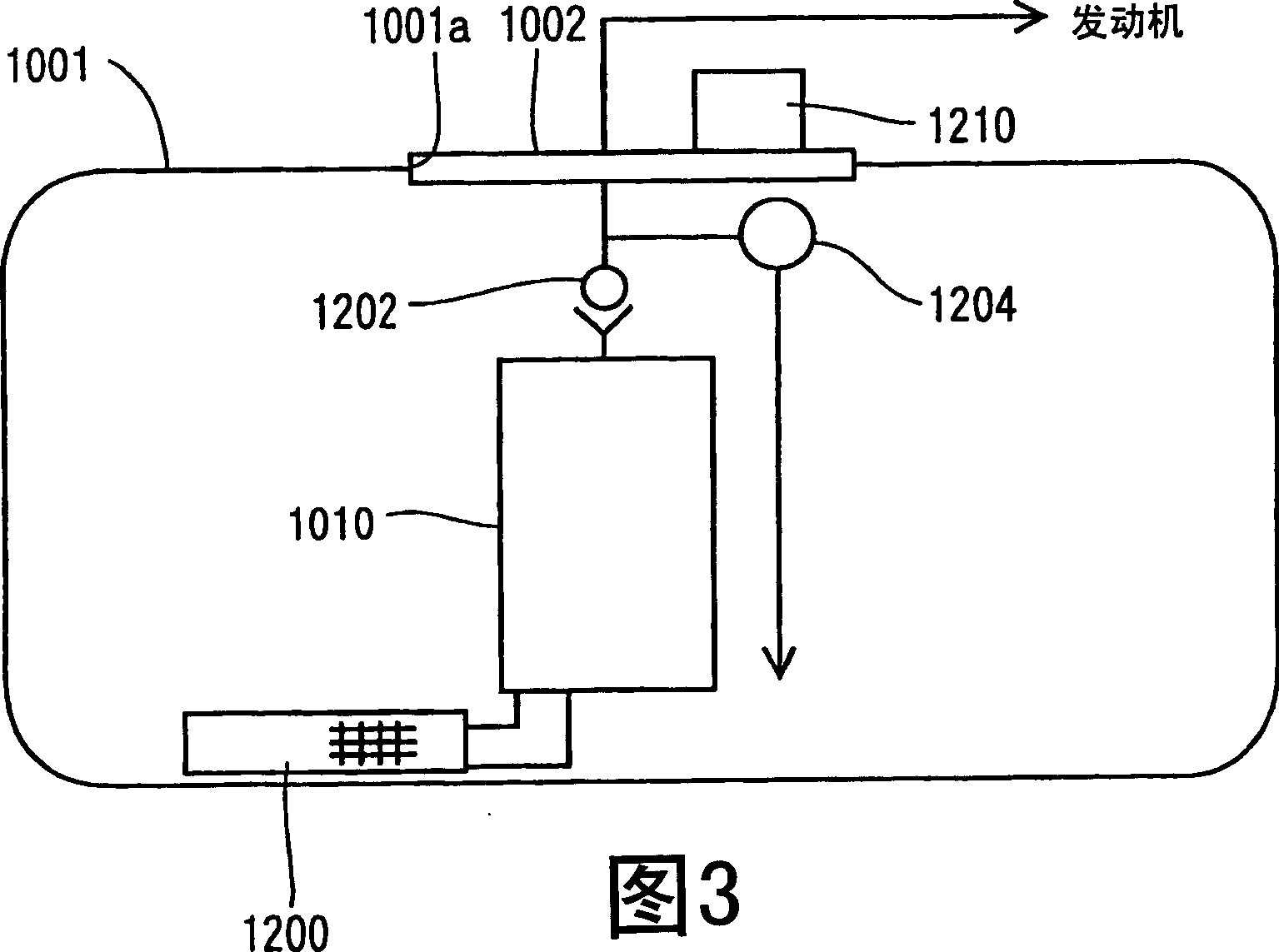

The fuel pump 1010 is installed in a fuel tank for a motorcycle. The fuel pump 1010 comprises a motor 1012 and a pump 1013 driven by the motor 1012 for pressurizing sucked fuel. The motor 1012 is a brushless motor, and has a stator 1020, coils 1024 and a rotor 1030. Current-passage to the coils 1024 wound around the stator core 1020 is controlled on the basis of a rotational position of the rotor, and thereby the rotor 1030 is rotated. The rotor 1030 has a shaft 1032, a rotary core 1034, and a permanent magnet 1036. The rotor 1030 is rotatably mounted on the inner circumstance of the stator core 1020. The permanent magnet 1036 is mounted on the outer circumference of the rotary core 1034, and magnetized so as to form magnetic poles different alternately in the rotation direction on the side of the outer circumferential surface facing to the stator core 1020.

Owner:DENSO CORP

Solid stop leaf spring

ActiveUS20080190723A1Avoid contactControl displacementYielding couplingRotary clutchesAxial displacementEngineering

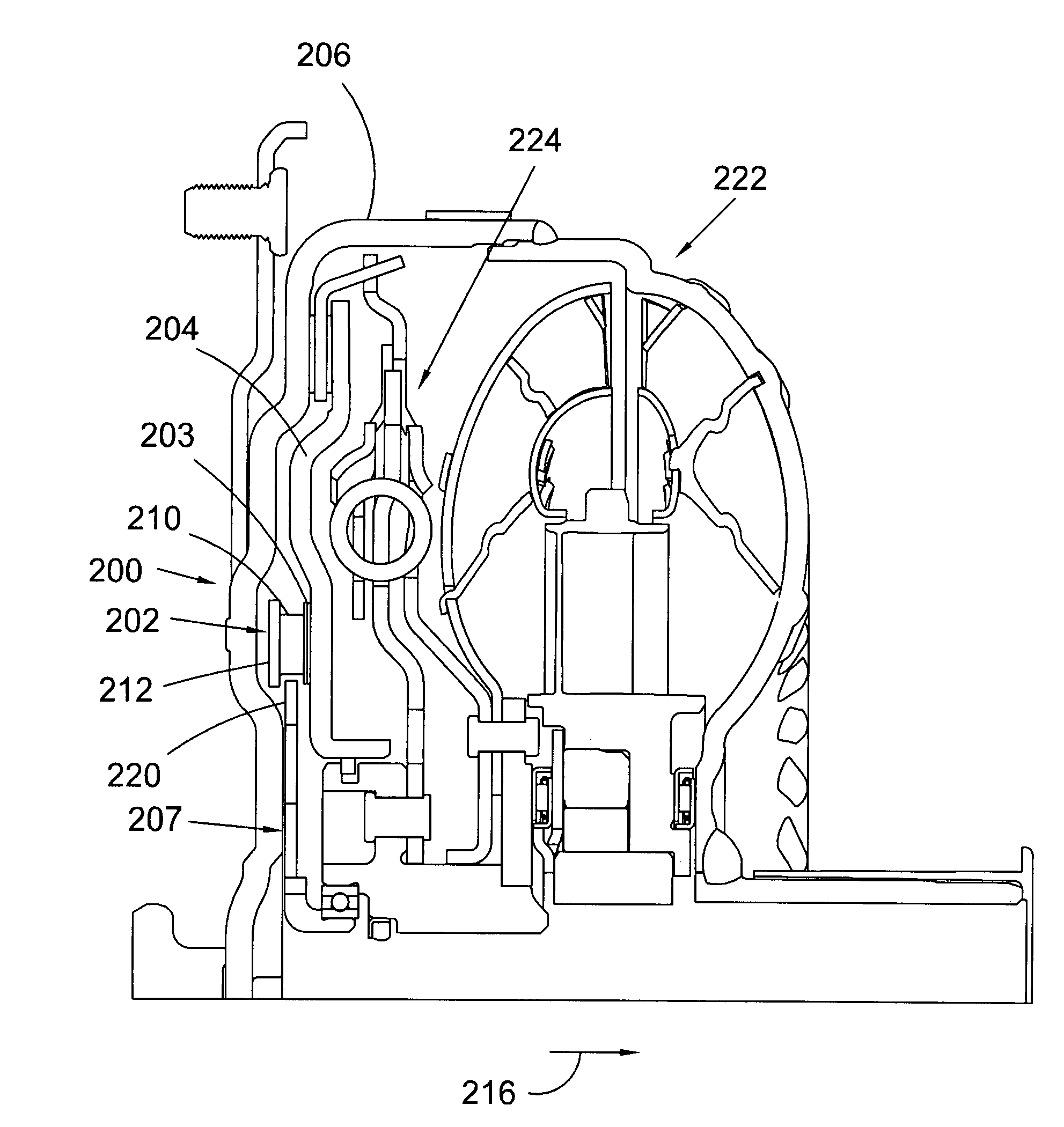

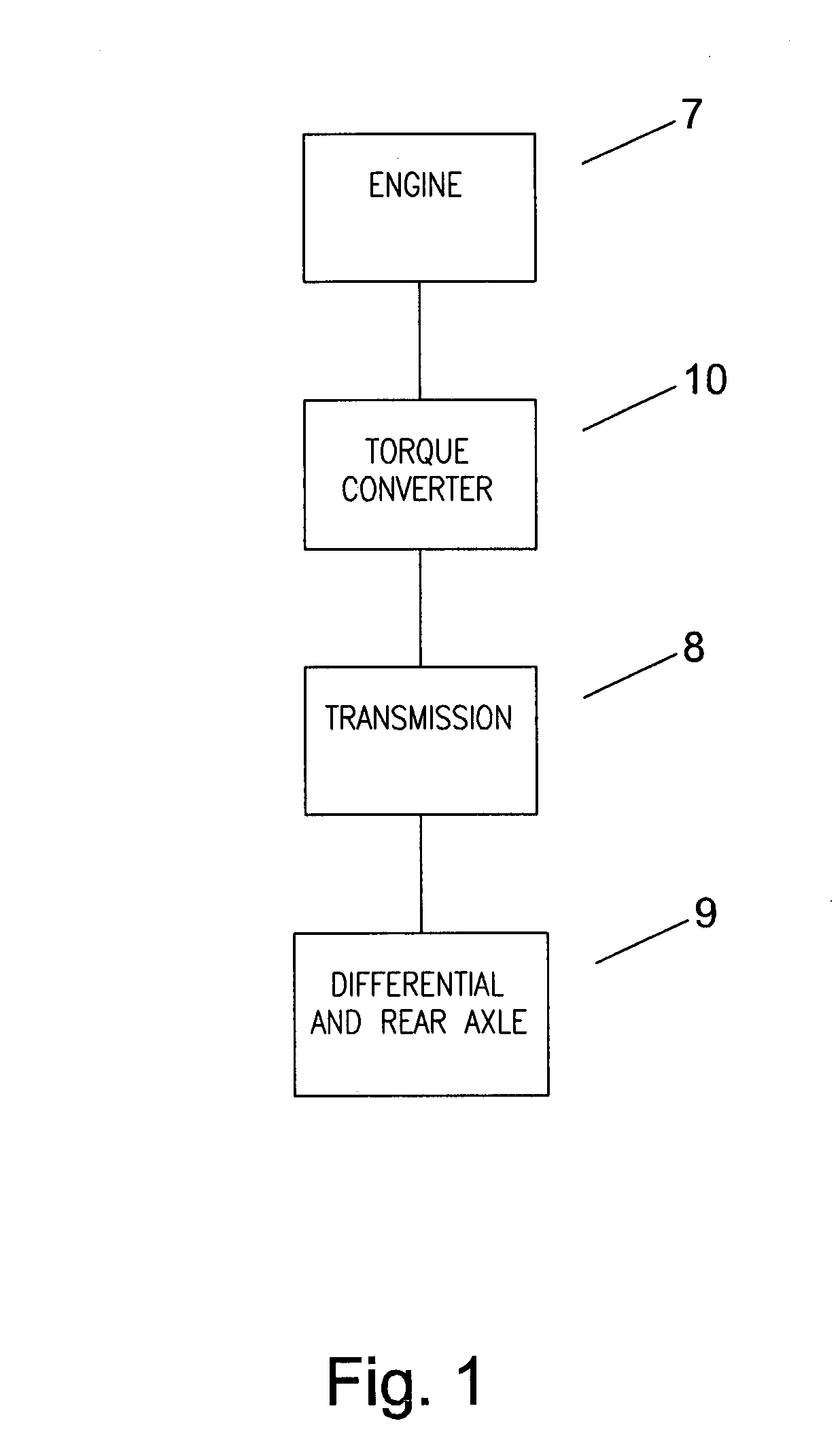

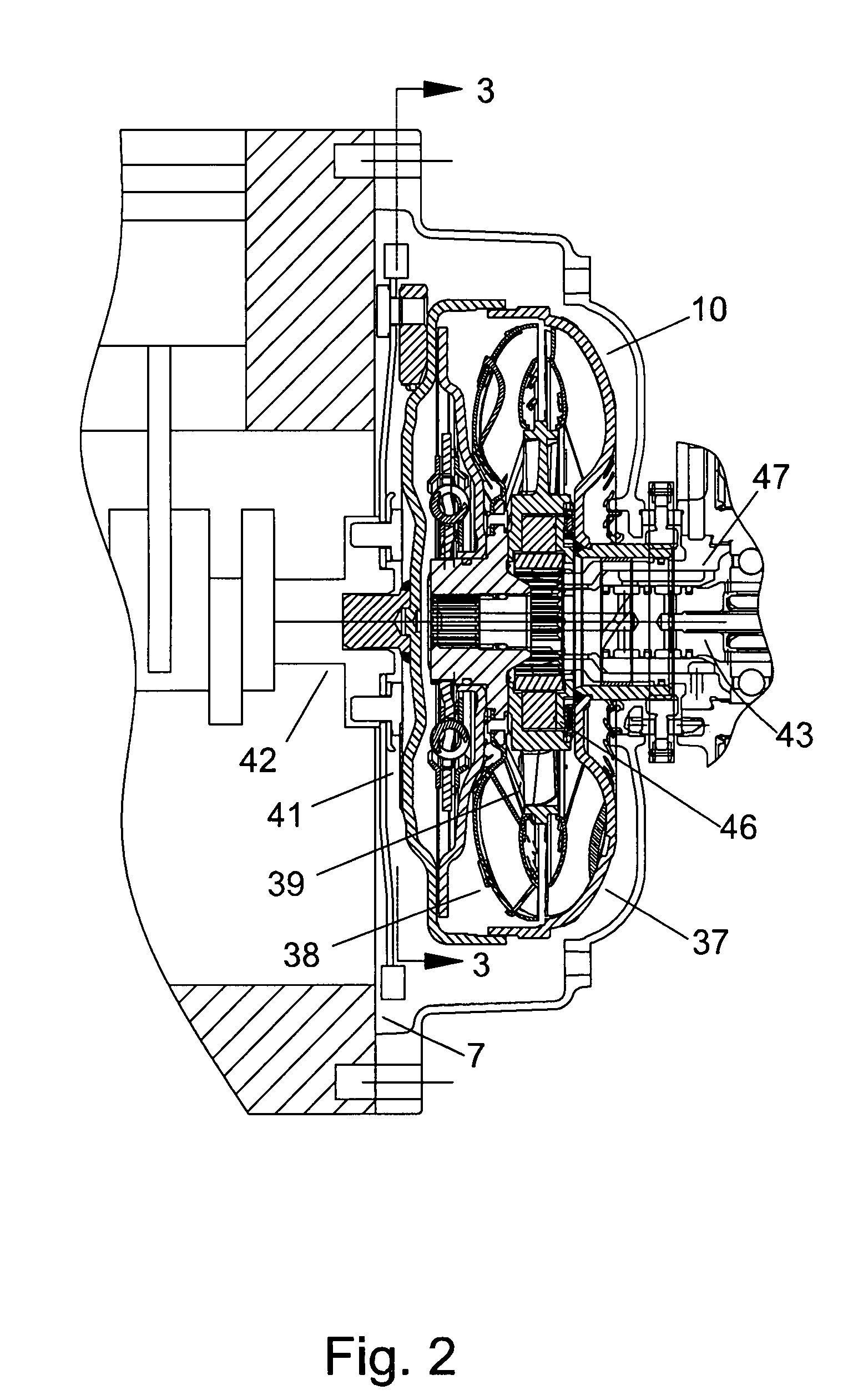

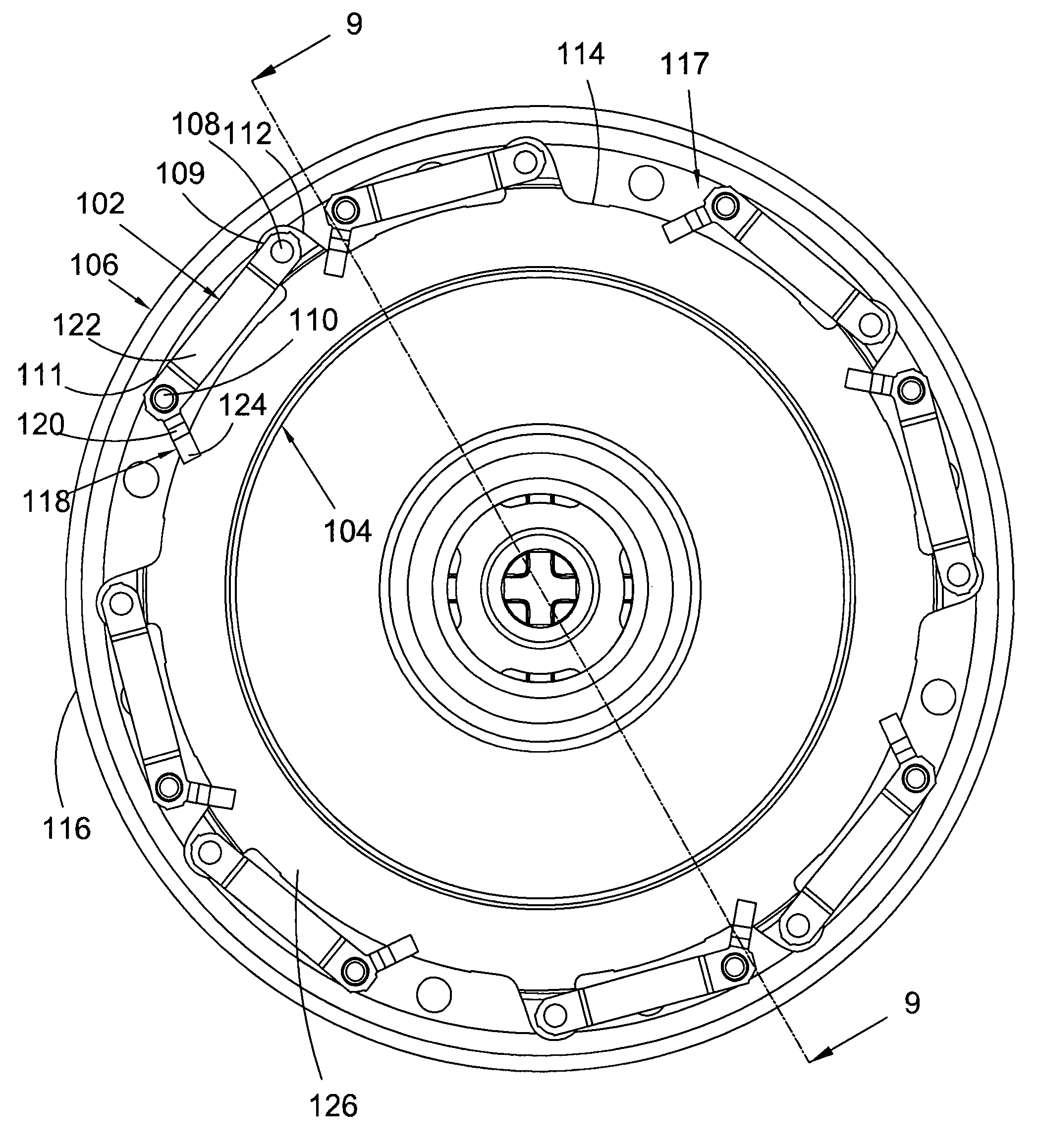

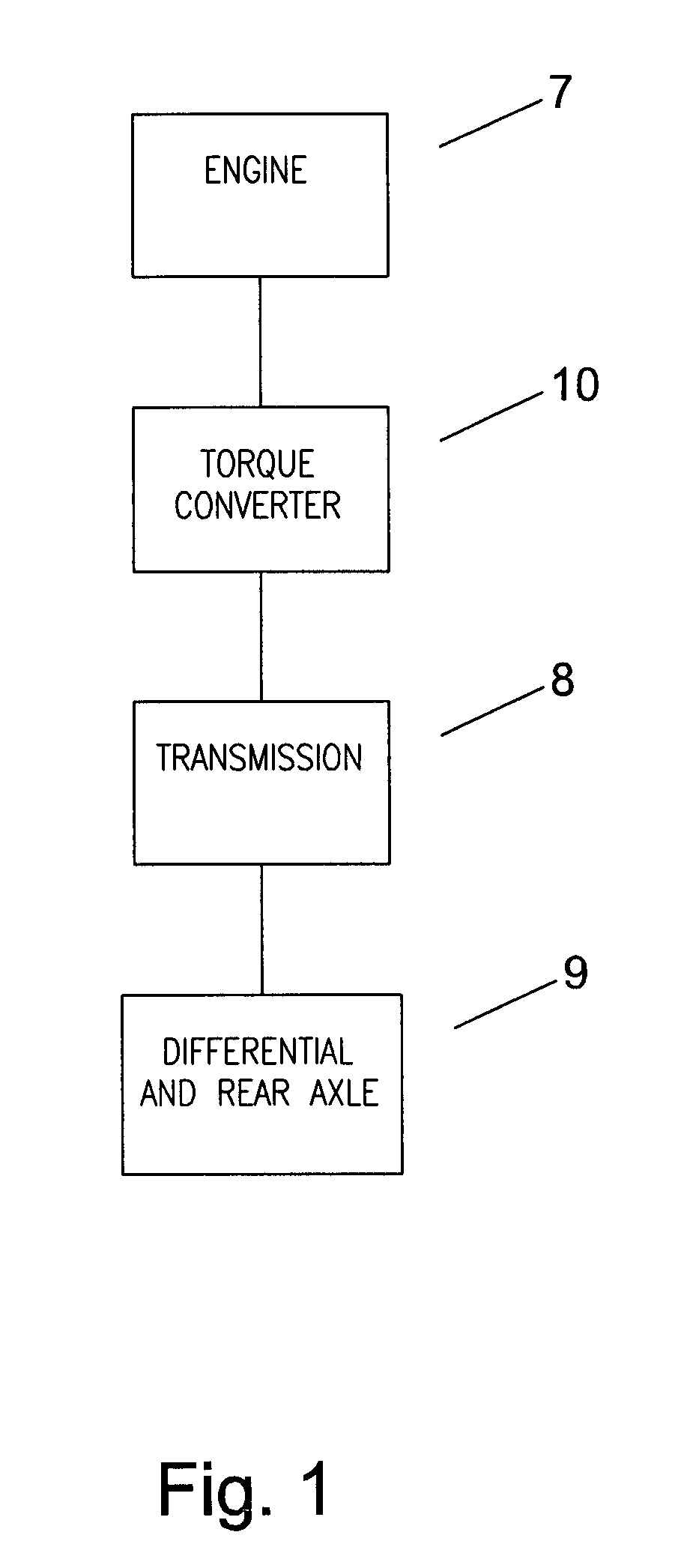

A piston plate stop for a torque converter including: a flexible connection element with a first end and a second end, the first end arranged to connect to a piston plate for the torque converter, the second end arranged to rotationally connect to a cover for the torque converter and a stop disposed on the flexible connection element. The stop is arranged to restrict axial movement of the piston plate. In some aspects, the flexible connection element is arranged to rotationally connect the cover and the piston plate. A torque converter including a piston plate; a cover; and at least one flexible connection element rotationally connecting the piston plate and the cover. The flexible connection element has a tab that is positioned to limit axial displacement of the piston plate away from the cover.

Owner:SCHAEFFLER TECH AG & CO KG

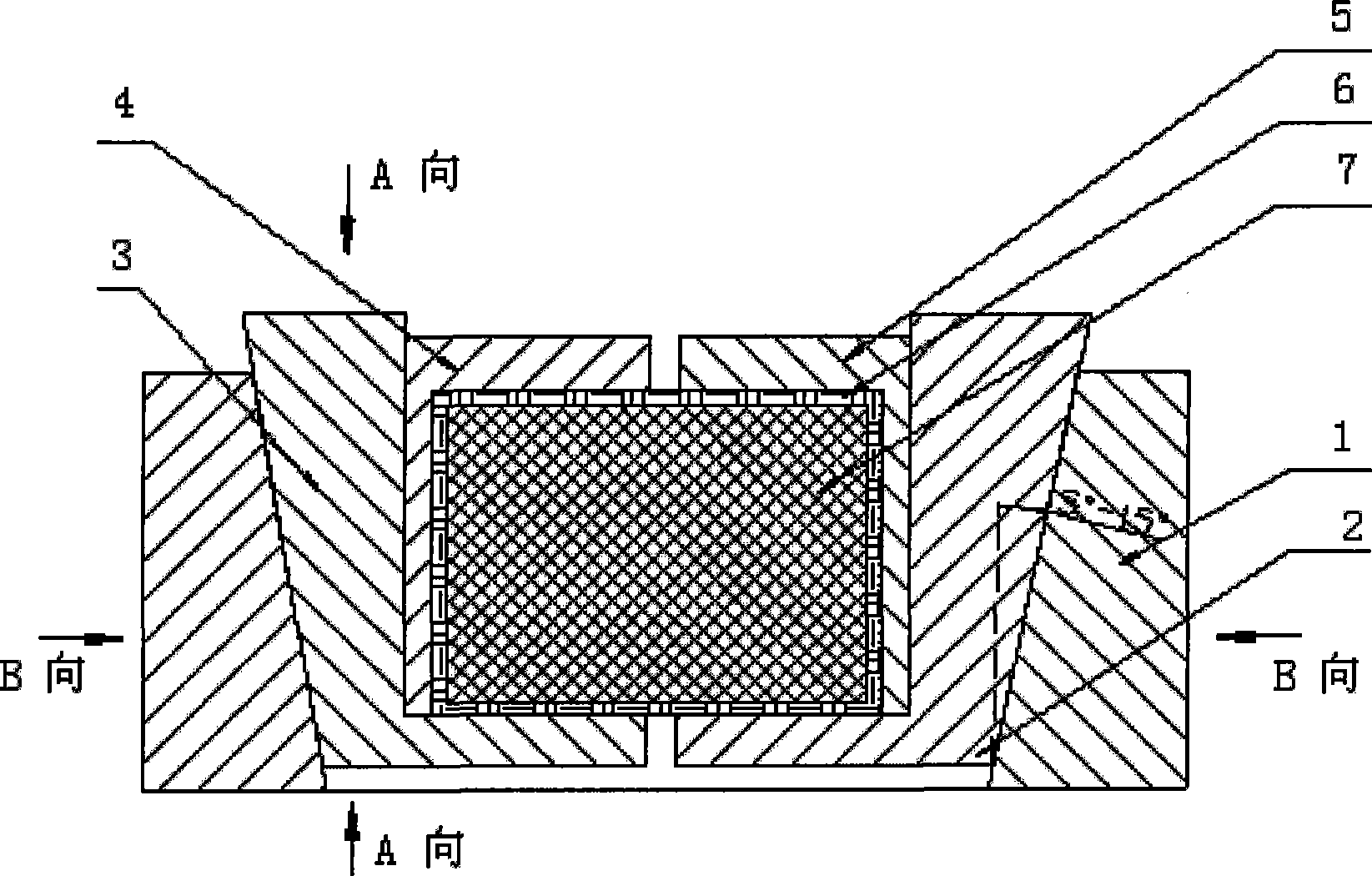

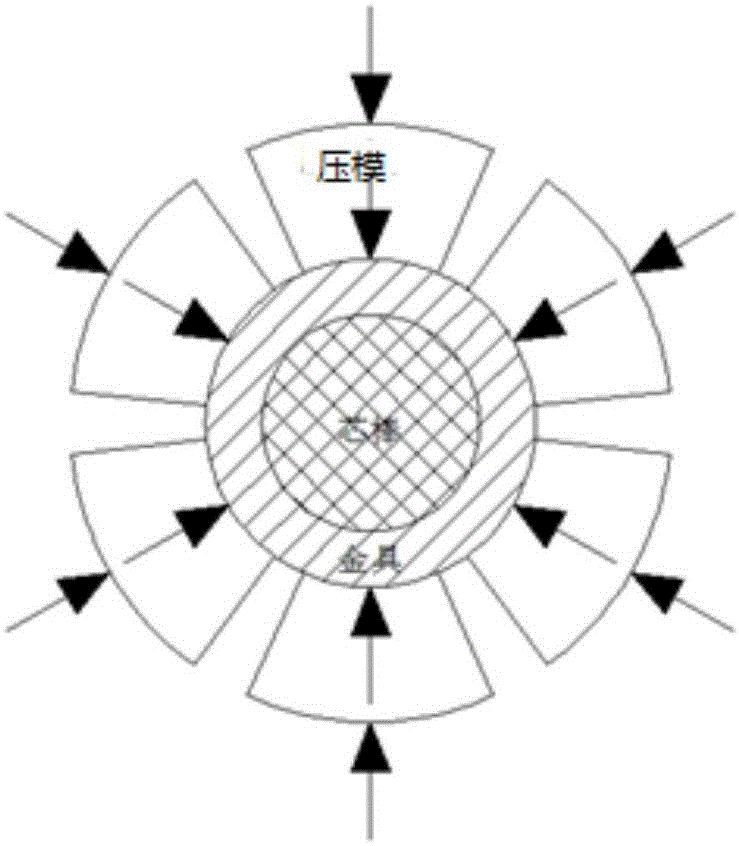

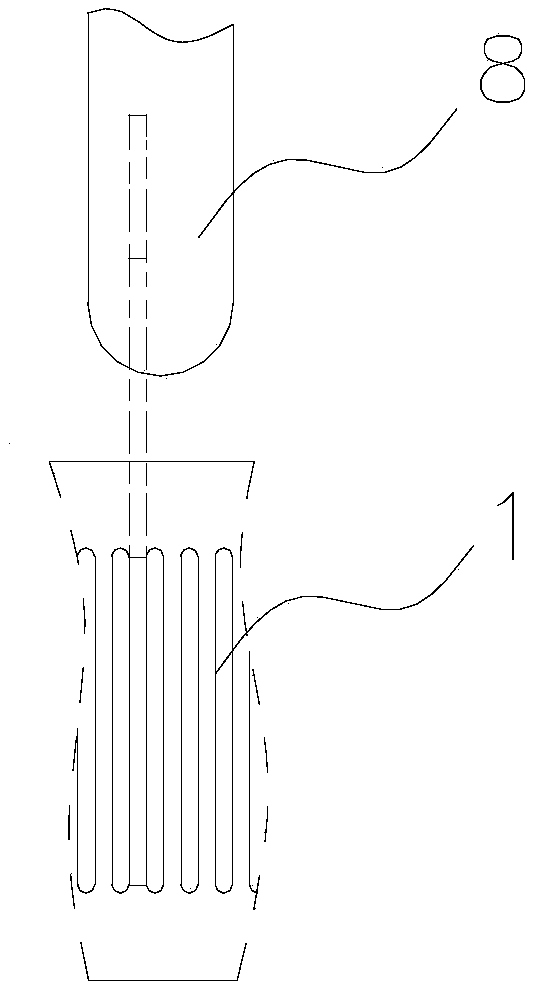

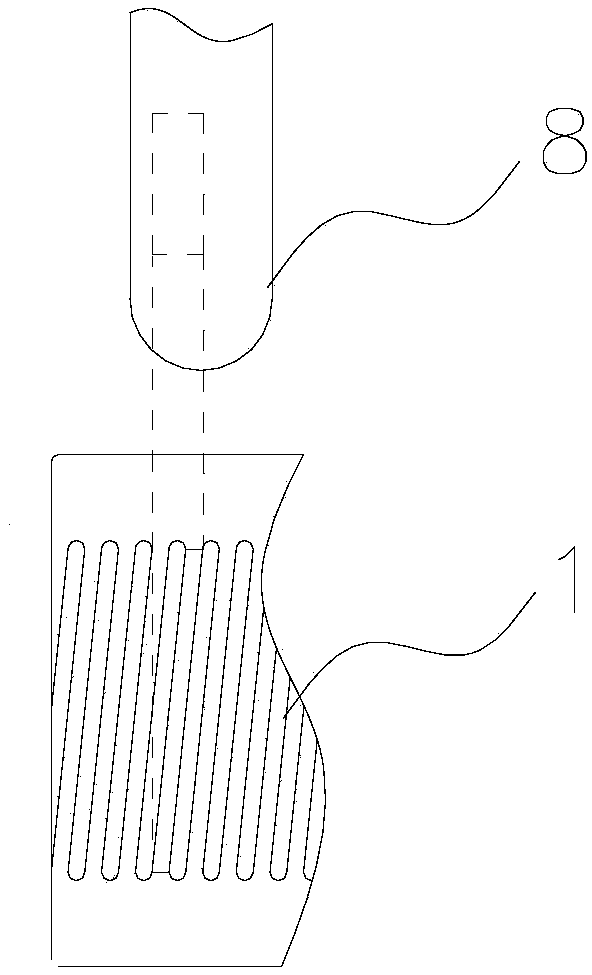

Method for controlling the defect of sintering expansion of powder metallurgy material and products thereof and mold

ActiveCN101530916AControl axial displacementControlling Constrained Axial Displacement of Sintering Expansion Defects in Powder Metallurgy Materials and Their ProductsChemical reactionVolumetric Mass Density

The invention discloses a method for controlling the defect of sintering expansion of powder metallurgy material and products thereof and a mold. In the sintering process of powder body, three-dimensional restraint compressive stress is applied to the body, thus generating restraint action to the body, restraining volume expansion generated by physical or chemical reactions of the body in the sintering process, realizing restraint sintering, controlling sintering densification thereof and eliminating the defects of sintering expansion. A restraint mold (1) is internally provided with an external mold; the matching conicity between the restraint mold (1) and the external mold is Theta which is larger than 5 degrees and smaller than 15 degrees; the external mold is internally provided with an internal mold; and a spacer (6) which is used for preventing the reaction of the body and the mold is arranged between the internal mold and the sintering body. The invention is a restraint sintering method which can effectively prevent the powder metallurgy material and products thereof from generating expansion, deformation, cracking and pore / hole and the like and can improve the sintering density and quality; and the using method of the mold is simple and easy to operate.

Owner:CENT SOUTH UNIV

Solid stop leaf spring

ActiveUS8016091B2Control displacementAvoid displacementYielding couplingRotary clutchesAxial displacementControl theory

Owner:SCHAEFFLER TECH AG & CO KG

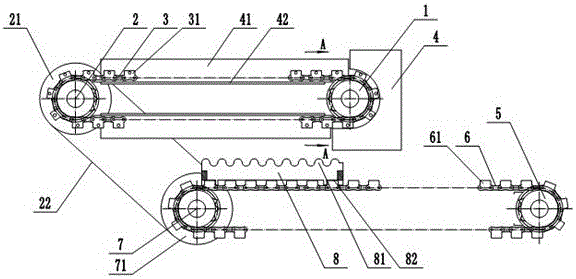

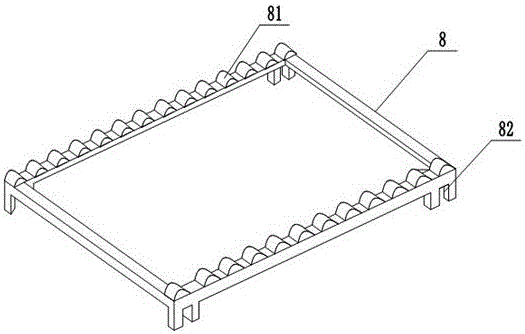

Soybean gluten stick conveying mechanism

The invention relates to the field of food processing and discloses a soybean gluten stick conveying mechanism.The mechanism comprises upper chain wheels, upper chains and upper rotating shafts, the two upper rotating shafts are arranged oppositely, the two ends of each upper rotating shaft are each connected with the corresponding upper chain wheel, the two upper chain wheels located at each same end of the two upper rotating shafts are matched with the corresponding upper chain, upper check blocks are arranged on chain bodies which are located on the upper chains at intervals, and a gap used for allowing for placing a soybean gluten stick therein is reserved between every two adjacent upper check blocks; the mechanism further comprises lower chain wheels, lower chains, lower rotating shafts and a tray, the two lower rotating shafts are arranged oppositely, the two ends of each lower rotating shaft are each connected with the corresponding lower chain wheel, the two lower chain wheels located at each same end of the two lower rotating shafts are matched with the corresponding lower chain, and the tray is detachably connected to the lower chains and provided with limiting teeth which are arranged uniformly.By means of the conveying mechanism, efficiency is improved, and meanwhile errors of manual operation is reduced; the tray is provided with the limiting teeth, so that the soybean gluten sticks are separated uniformly and automatically and arranged in order, it is convenient to air the soybean gluten sticks, and meanwhile time and labor are saved.

Owner:LIANGPING XINGYU BEAN PROD CO LTD

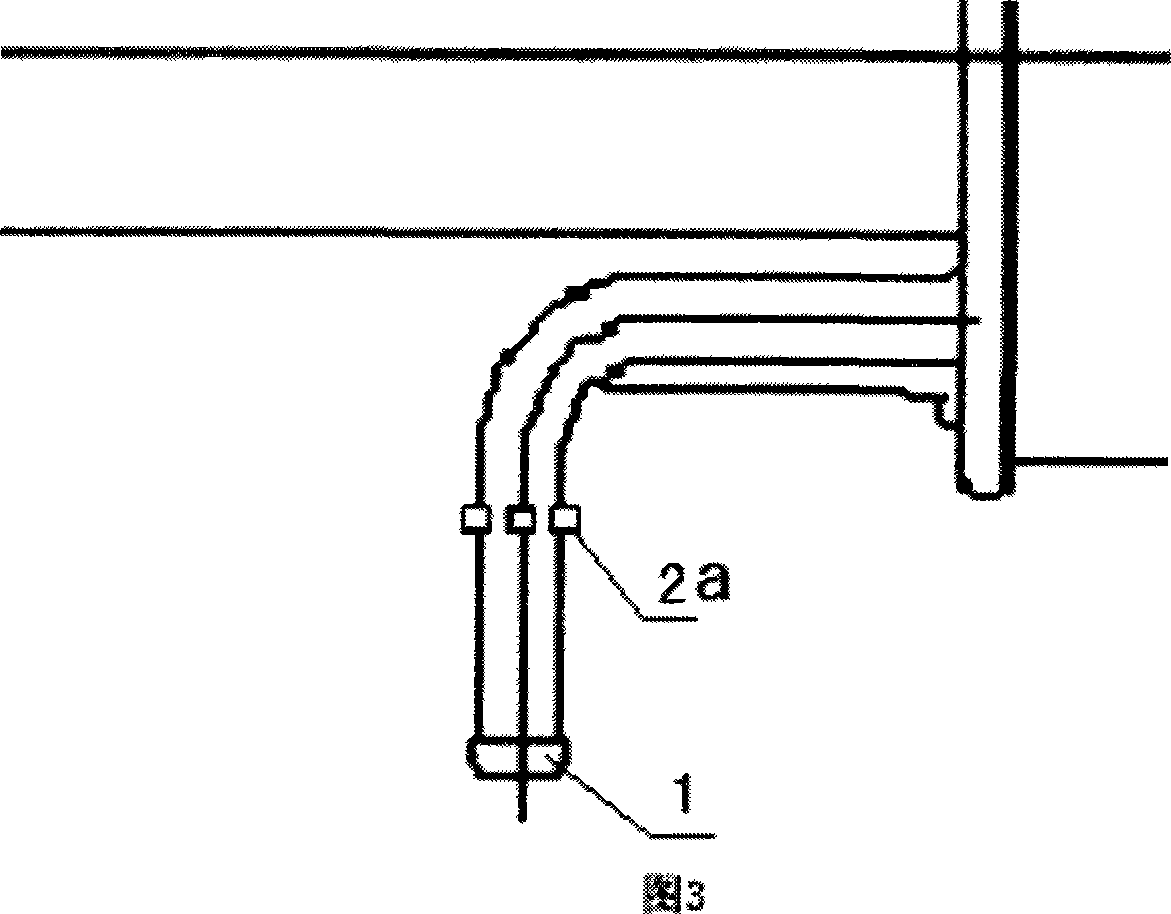

Plastic pipe port flanging process

The invention relates to the technical field of pipe machining, and discloses a plastic pipe port flanging process. The plastic pipe port flanging process comprises the technological flows of: (S1) clamping of a plastic pipe; (S2) arrangement of the heating device; (S3) arrangement of the flanging device; (S4) heating of a pipe port; (S5) flanging molding; and (S6) cooling and surface treatment. Compared with the prior art, the plastic pipe port flanging process changes a heating mode to heating from internal of plastic, so that the heating becomes more uniform, the uniform heating of the inner wall and the outer wall of the pipe port is realized, the softening effect is better, and the breakage of the pipe port in reflanging is prevented.

Owner:ERA PIPELINE (CHONGQING) CO LTD

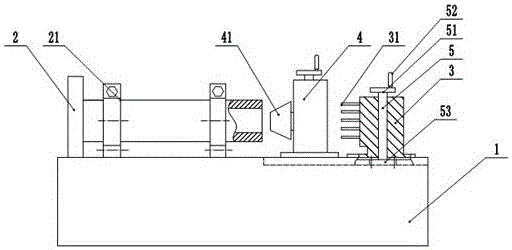

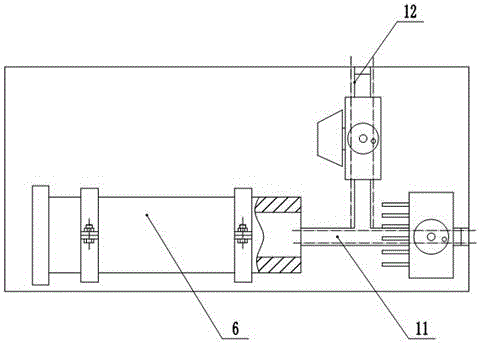

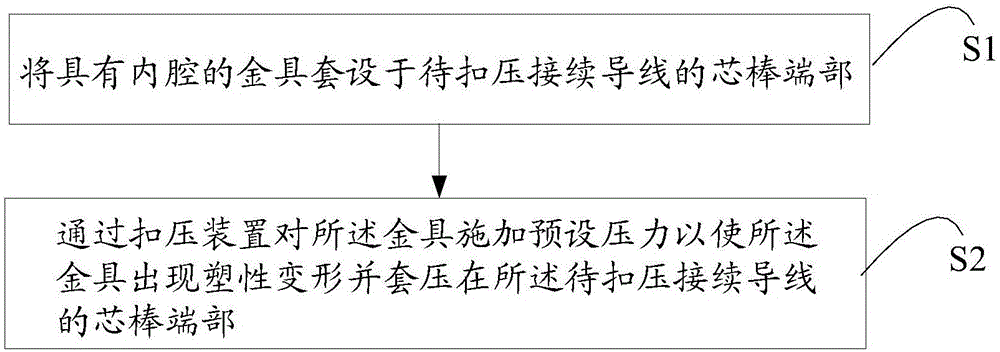

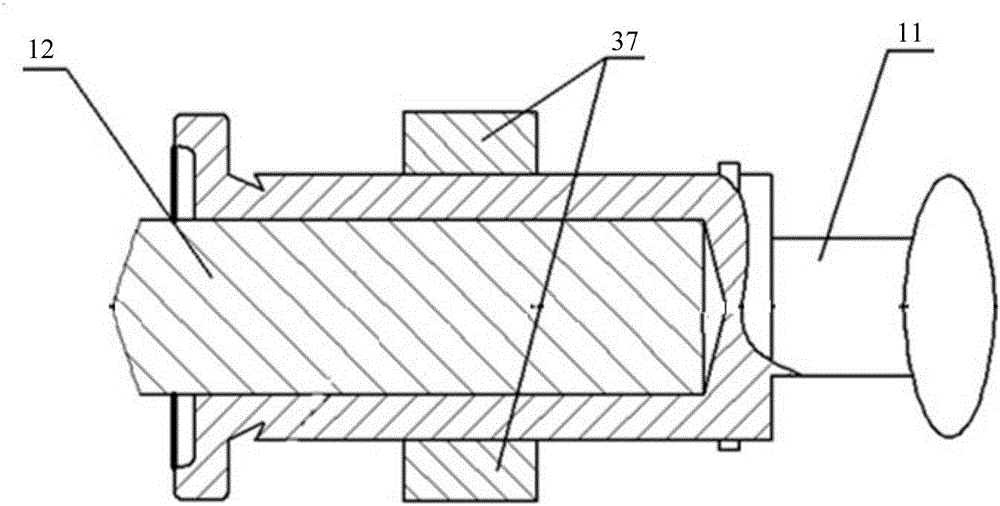

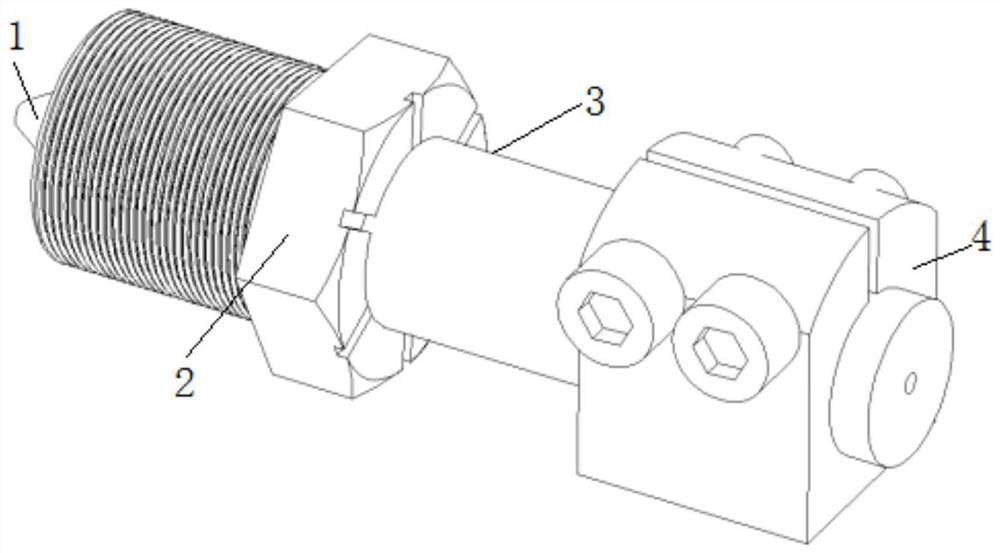

Carbon fiber composite core wire crimping and connection process and crimping device

InactiveCN107437668AAvoid damageShorten the lengthConnections effected by permanent deformationMultiple conductors connectorEngineeringPulley

The invention provides a carbon fiber composite core wire crimping and connection process and a crimping device. The process comprises the following steps: a fitting with a cavity sleeves the core rod end part of a to-be-crimped and connected wire; a preset pressure is applied to the fitting through a crimping device to enable the fitting to be deformed plastically and to sleeve and press the core rod end part of the to-be-crimped and connected wire. The preset pressure is applied to the fitting sleeving the wire through the crimping device to enable the fitting to press the wire tightly, the length of the fitting for wire connection can be shortened effectively, the length of a connection pipe protection device is shortened, the construction cost is reduced, and damages to the carbon fiber composite core wire when the connection pipe passes across a pulley can be avoided.

Owner:CHINA ELECTRIC POWER RES INST +2

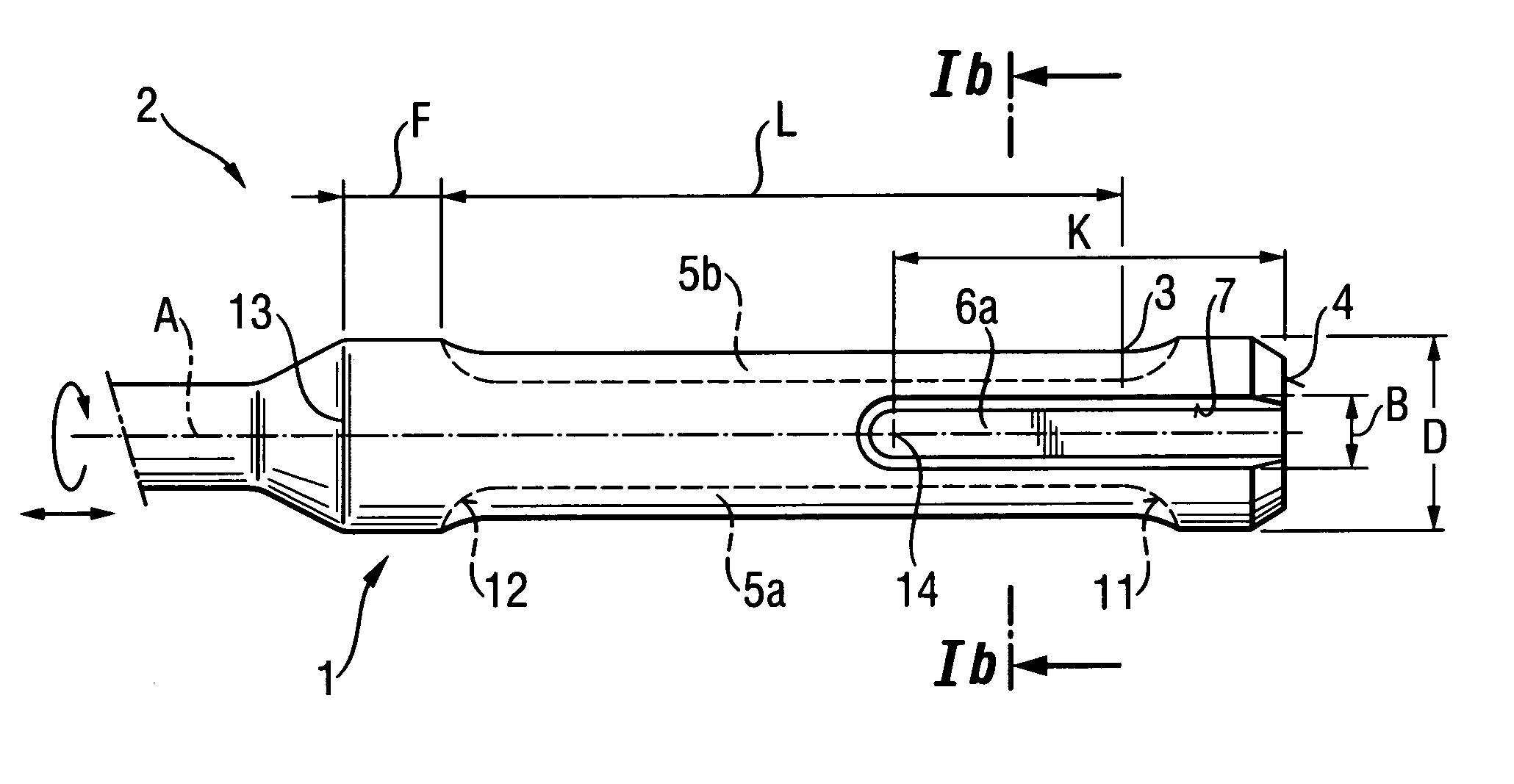

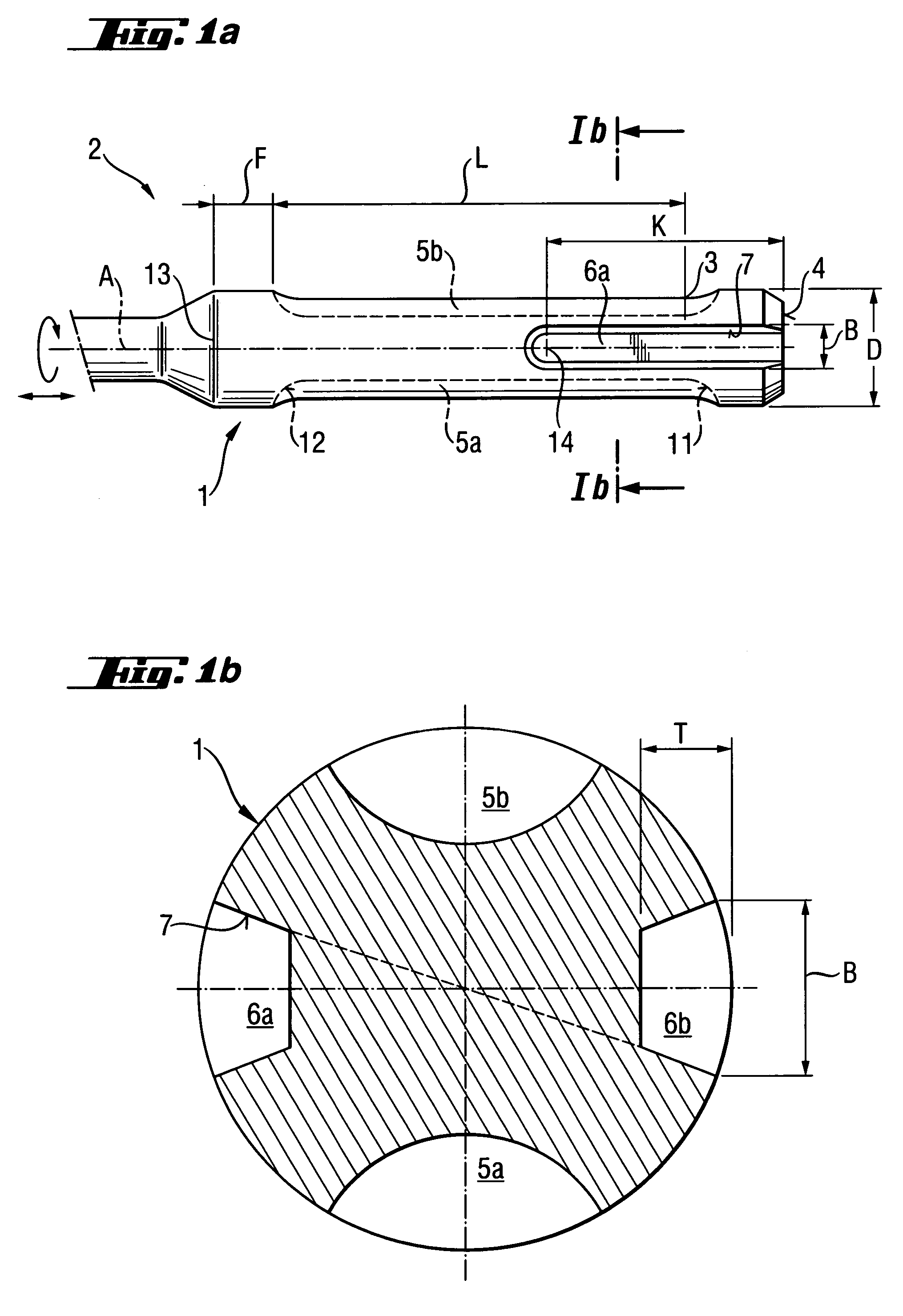

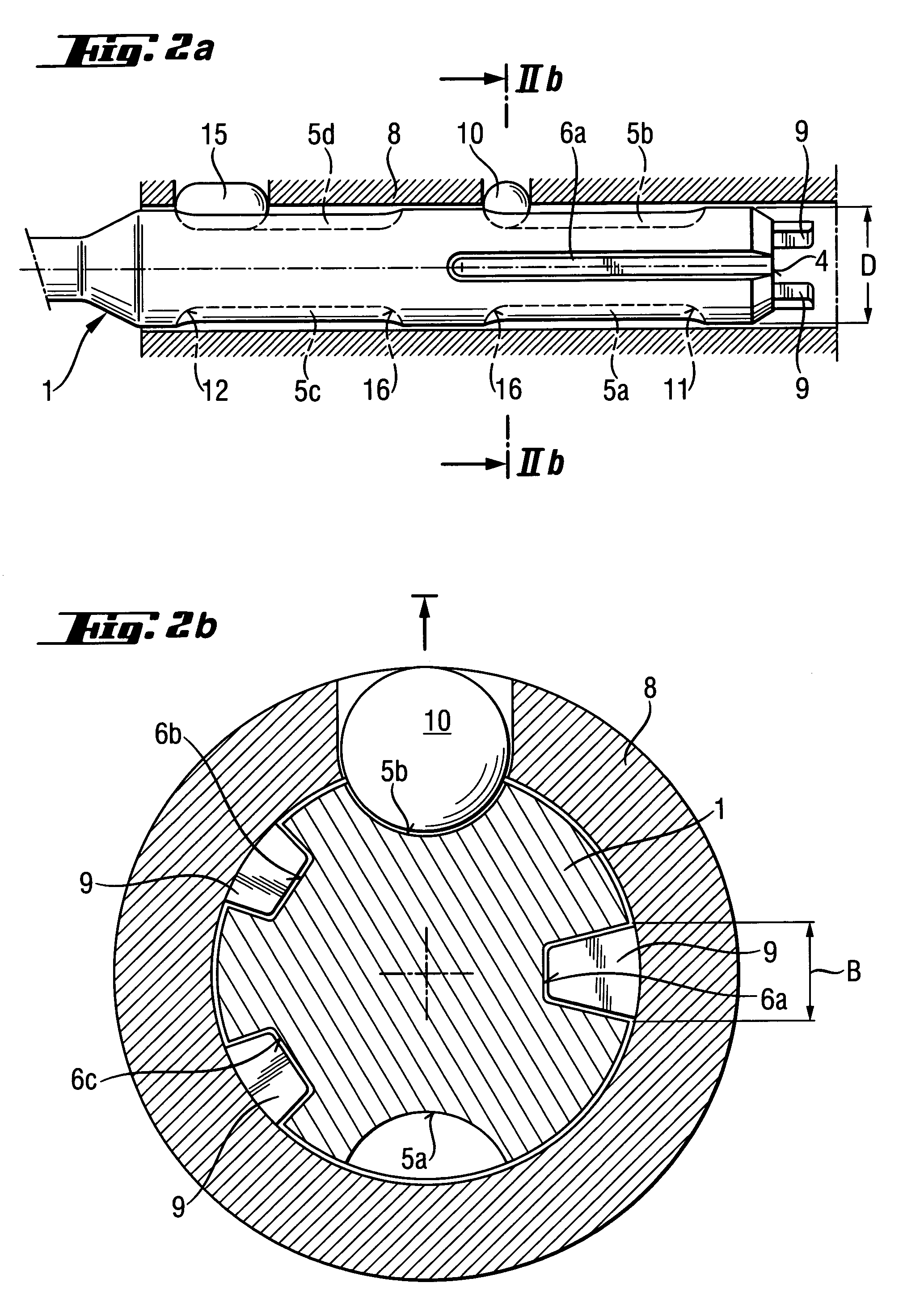

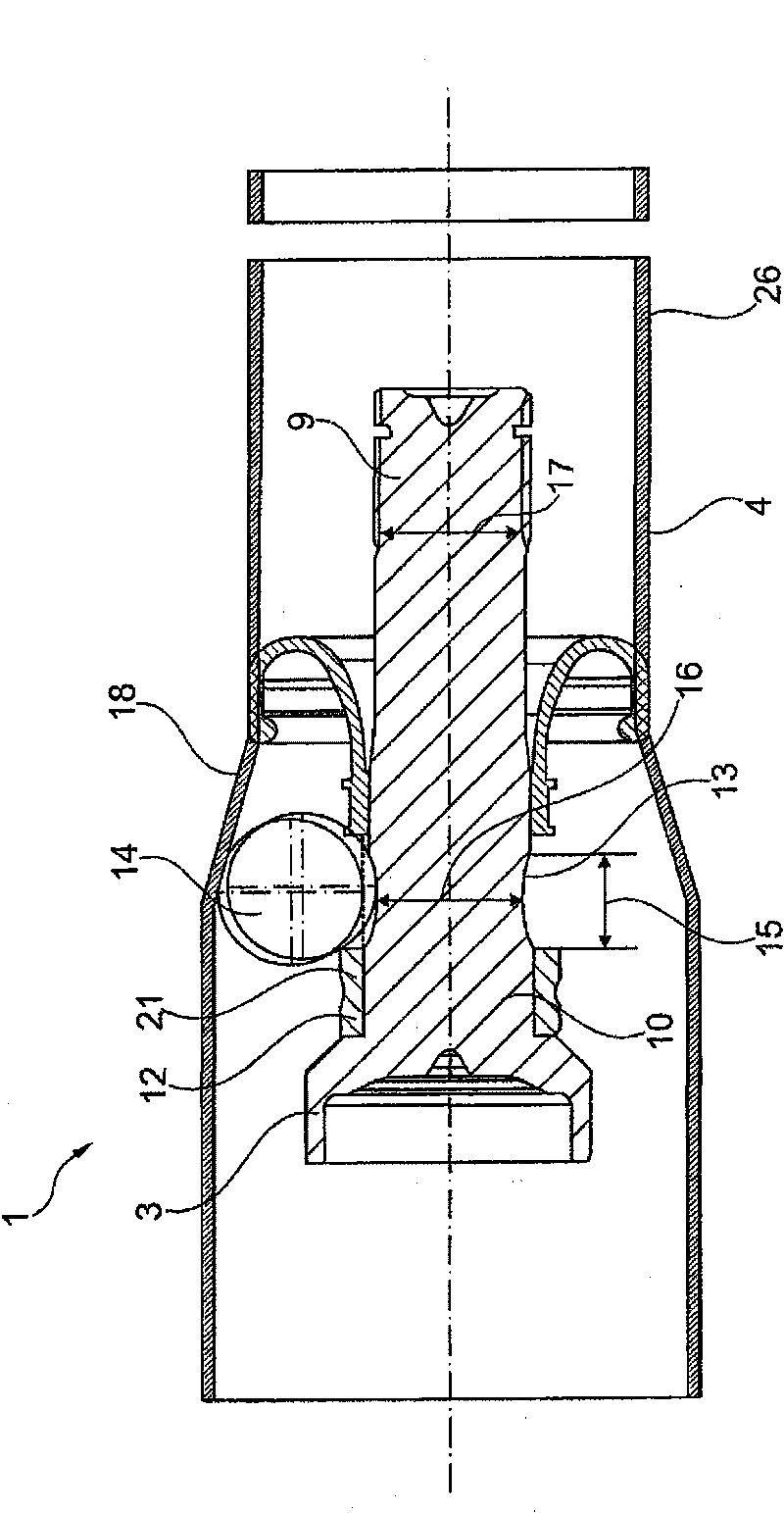

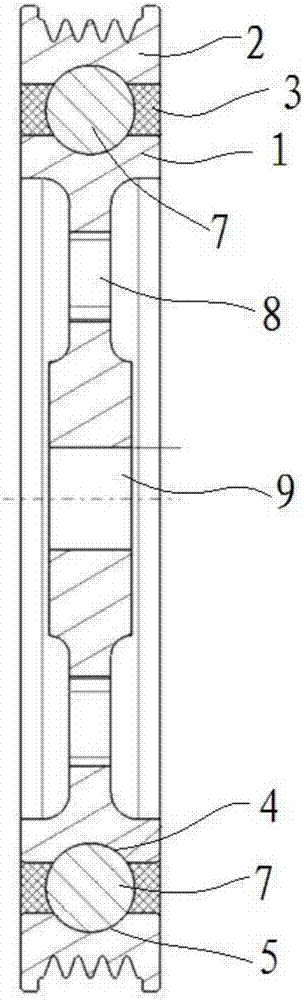

Shank for a rotary and/or percussion working tool

InactiveUS20050271487A1Increase torqueLimit axial displacementDrilling rodsTransportation and packagingGroove widthEngineering

A shank of a rotary-percussion working tool (2) has at least two, diametrically opposite locking grooves (5a, 5b) each having a locking shoulder (11) at an axial locking end (3) and spaced from a free end surface (4) of the shank (1), and an end shoulder (12) axially spaced from the locking shoulder (11) in a direction of a working tool-side end of the shank (1) and spaced from the axial locking end (3) of the shank (1) by a length (L) amounting at least to three times of a guide diameter (D) of the shank (1), and at least two entraining grooves (6a, 6b) mutually tangentially offset with respect to the locking grooves (5a, 5b), opening toward the free end surface (4), and having a tangential groove width (B) and at least one tangential, force application surface (7) extending over a contact length (K).

Owner:HILTI AG

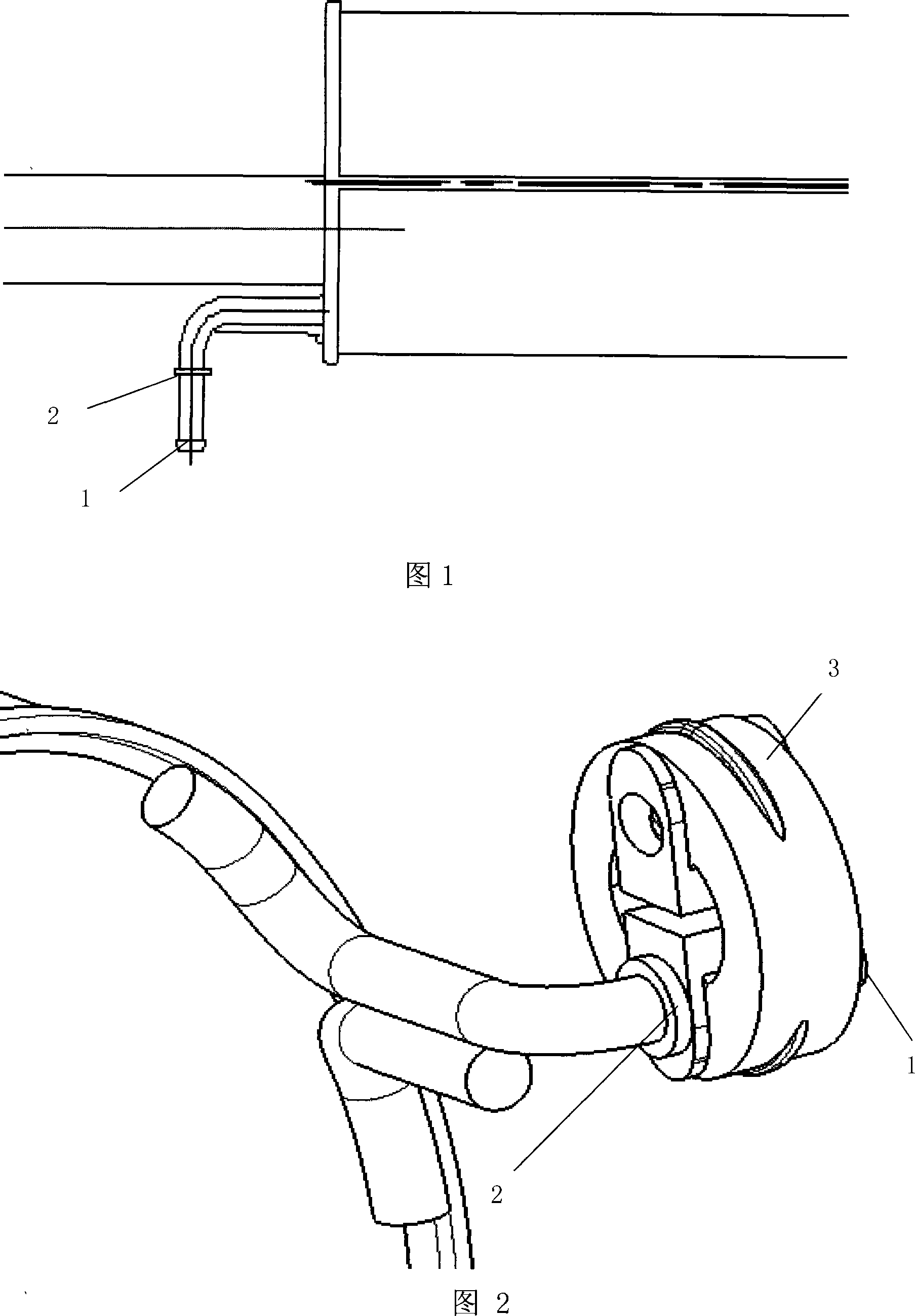

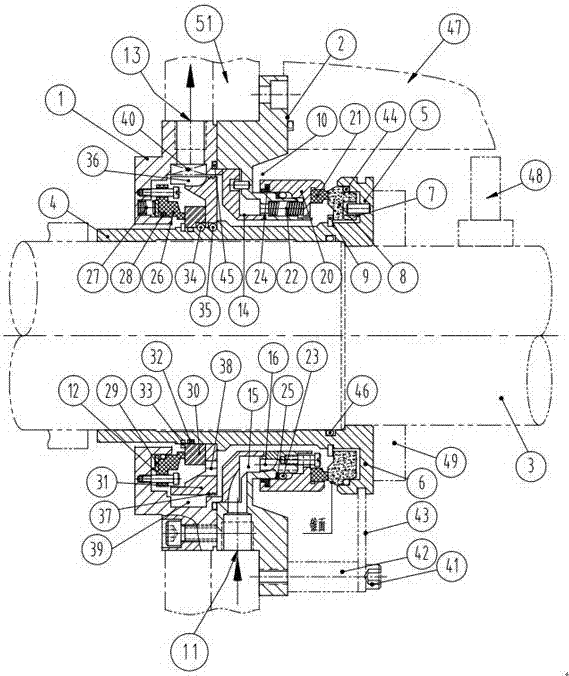

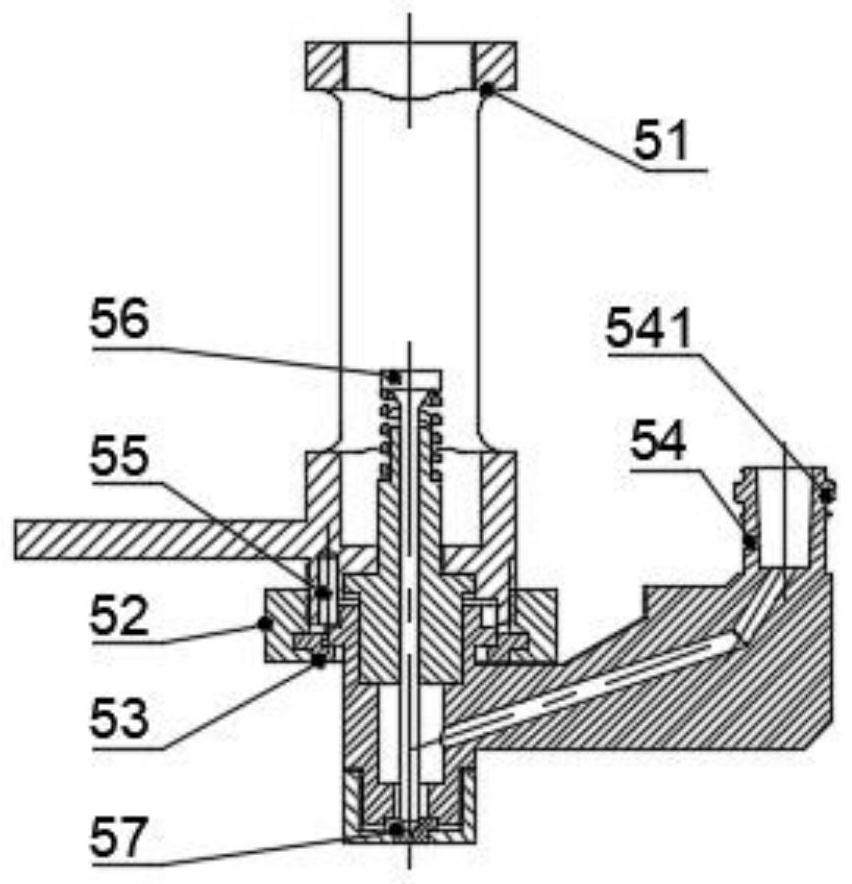

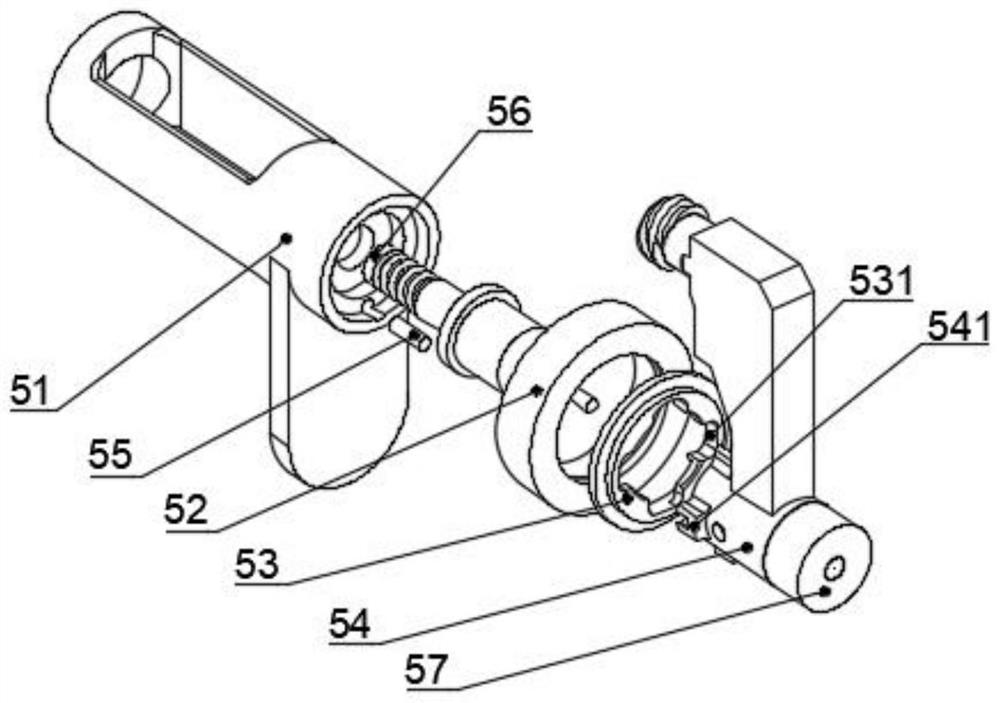

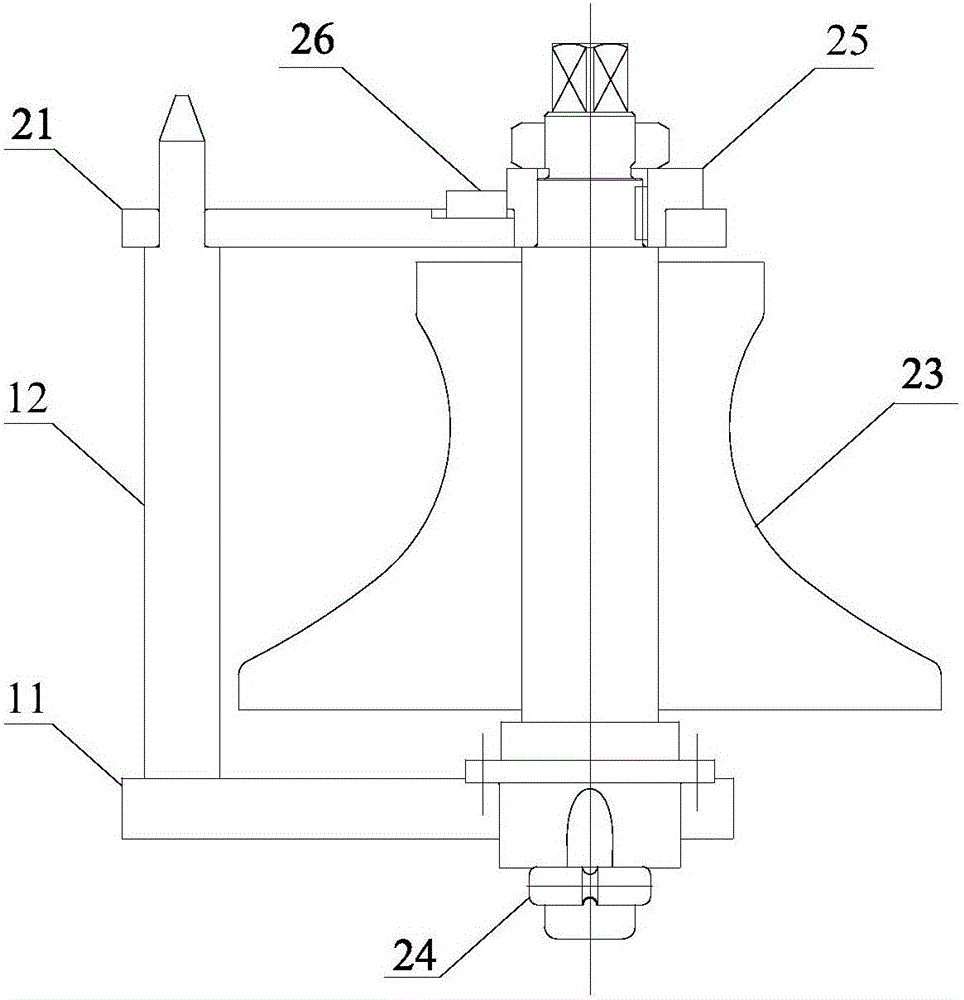

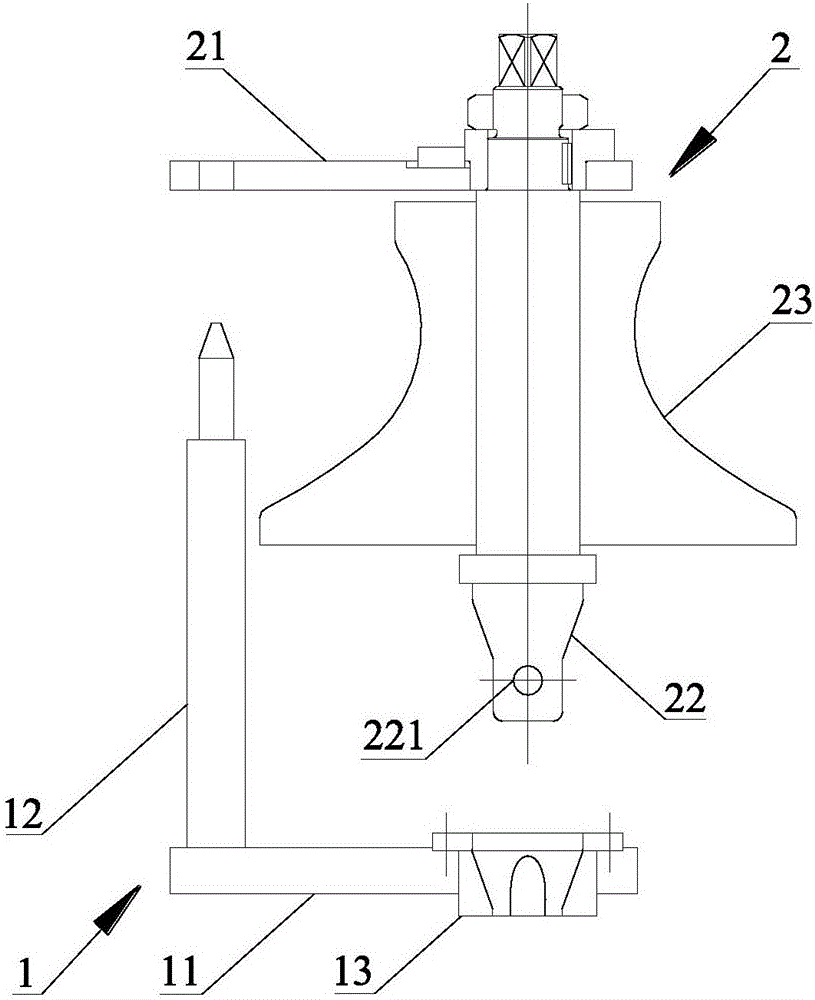

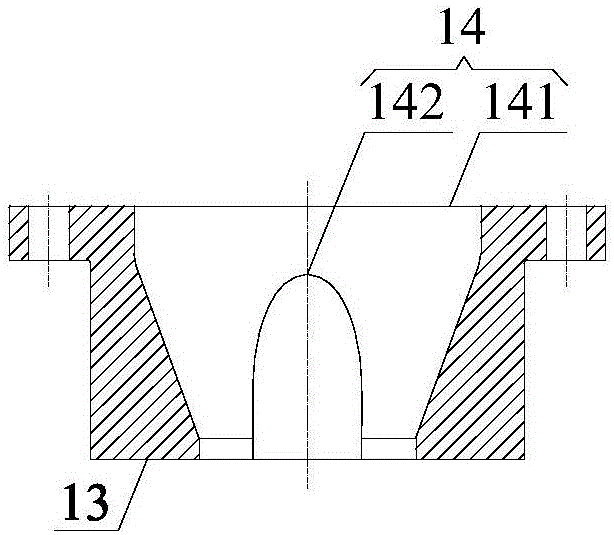

Exhaust gas bypass actuating mechanism and turbocharger with mechanism

ActiveCN108397279ASimple structureLimit axial displacementInternal combustion piston enginesTurbochargerEngineering

The invention relates to an exhaust gas bypass actuating mechanism of a supercharger. The exhaust gas bypass actuating mechanism comprises a pull rod, a rocking arm and a locking piece, wherein the pull rod is hinged to the rocking arm, the locking piece is elastic, one end of the locking piece is connected to the rocking arm, and the other end of the locking piece is fixed to the pull rod so as to stabilize the relative position between the pull rod and the rocking arm. According to the exhaust gas bypass actuating mechanism, the locking piece which is made of elastic materials is additionally arranged on the bypass actuating mechanism so as to generate axial pretightening force on the pull rod, so that the knocking problem is improved, and noise is reduced; the change of a bypass valve actuating mechanism is less, so that the cost is low; and the locking piece is suitable for various bypass actuating mechanisms of similar structures and has the advantage of high applicability.

Owner:ZHEJIANG YILI AUTO PARTS CO LTD

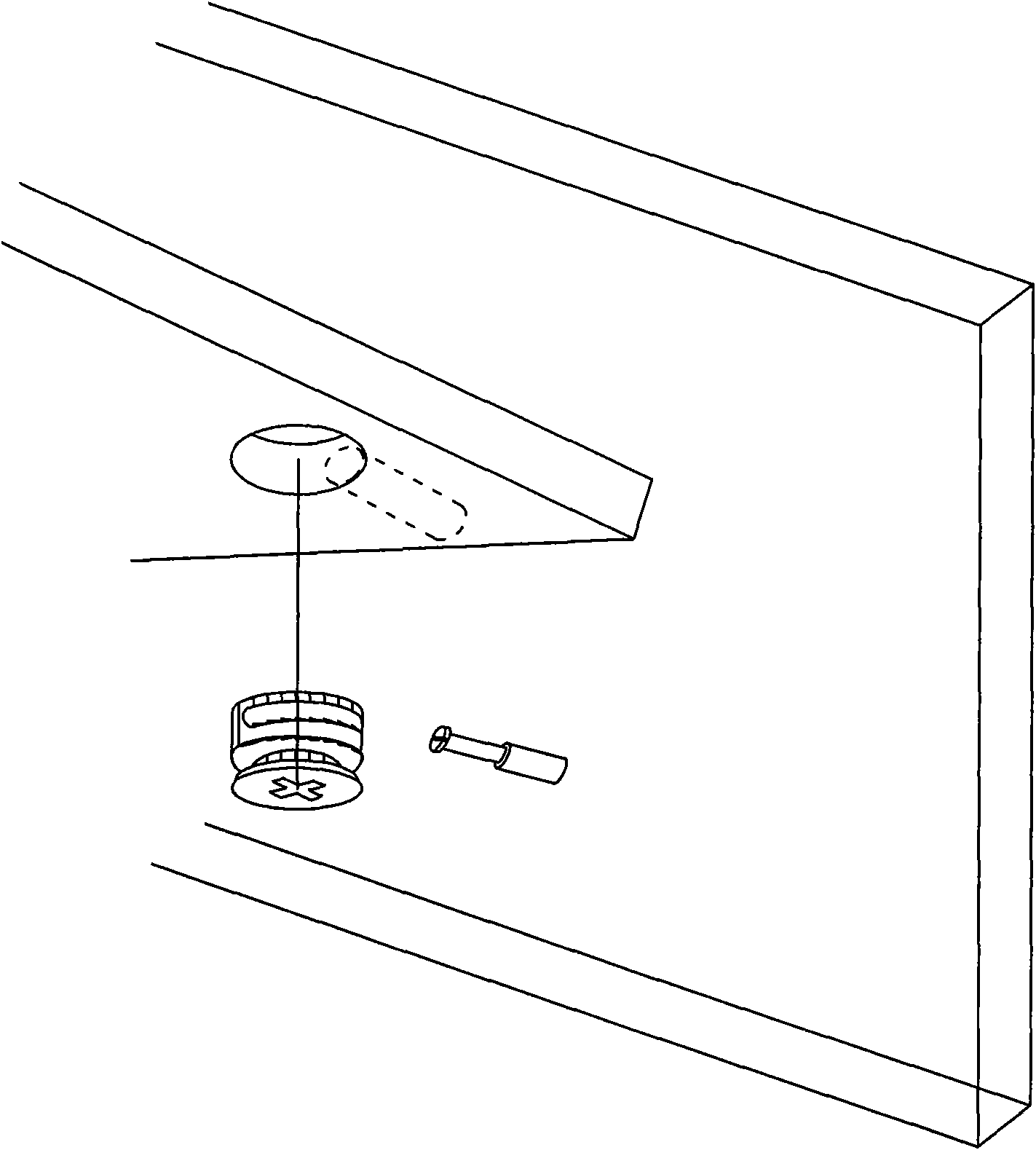

Connection fitting of household product

InactiveCN101672314AQuick assemblyAssembly is achieved quicklyBoltsSheet joiningEngineeringScrew thread

The invention relates to a connection fitting of a household product, which comprises a fitting body and a screw, wherein the screw comprises a screw head and a screw rod, and the screw rod is dividedinto a positioning section and a connecting section; a special-shaped channel in a racket shape is arranged on the fitting body and comprises a channel in a racket plate shape and a channel in a racket rod shape; a toothed body with an expansion function is arranged on the peripheral surface of the fitting body to form a first toothed surface, and at least a pair of positioning grooves and at least a pair of clamping strips which extend to two sides are respectively arranged symmetrically in the axial direction of the first toothed surface; two inner side surfaces of the channel in the racketrod shape on the fitting body form a second toothed surface; the distance between the two toothed surfaces is slightly smaller than the external diameter of the positioning section of the screw rod;a pair of inclined third toothed surfaces are formed between the second toothed surface and the back surface of the fitting body; and the integral gradient of each third toothed surface is matched with the external form of the bottom of the screw head, and the junction of each third toothed surface and the second toothed surface is slightly higher than the positioning section of the screw rod. Thefitting body can be fixed without using any screw thread, can be quickly assembled, and has high construction efficiency and firm connection.

Owner:刘家宇

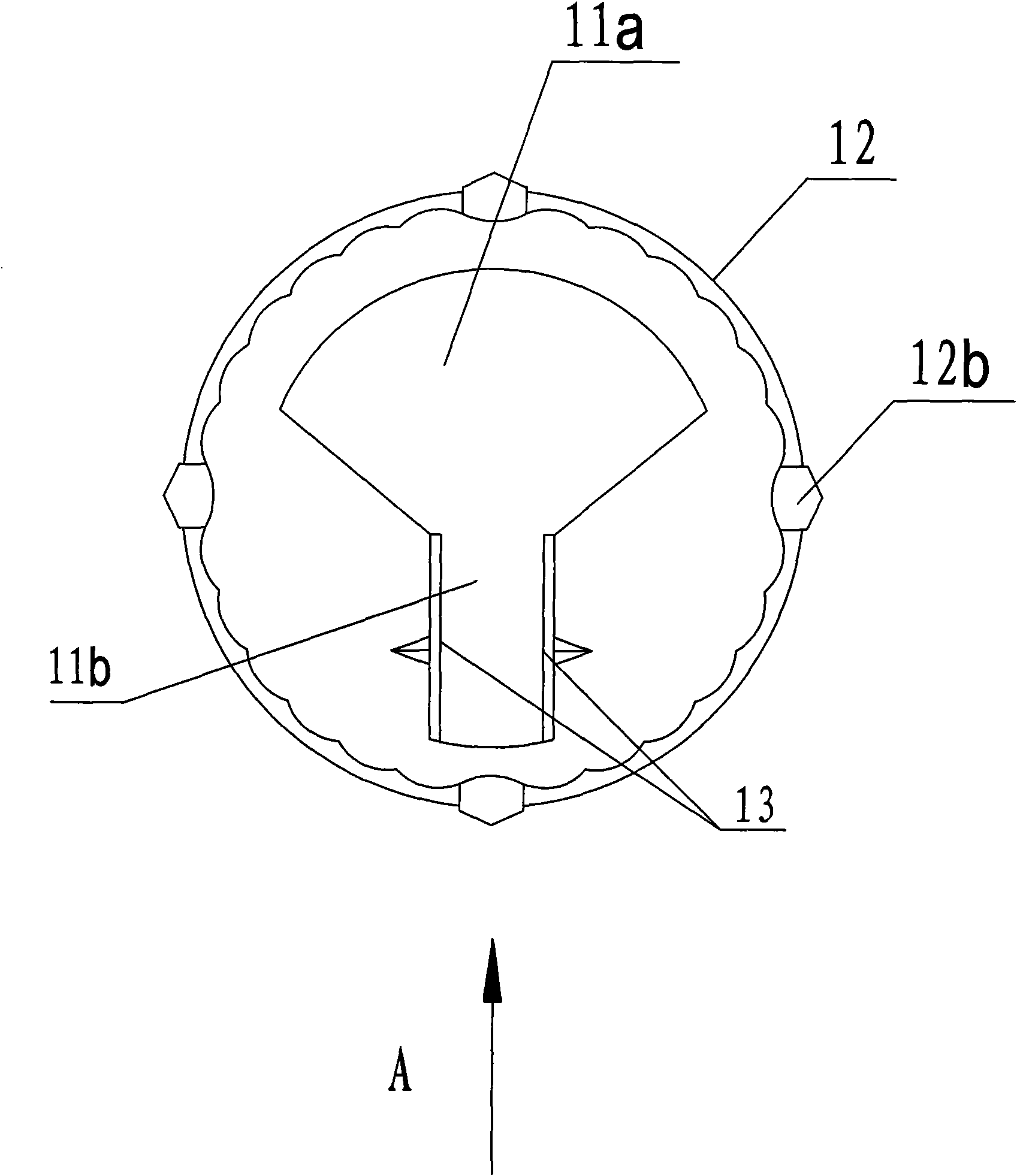

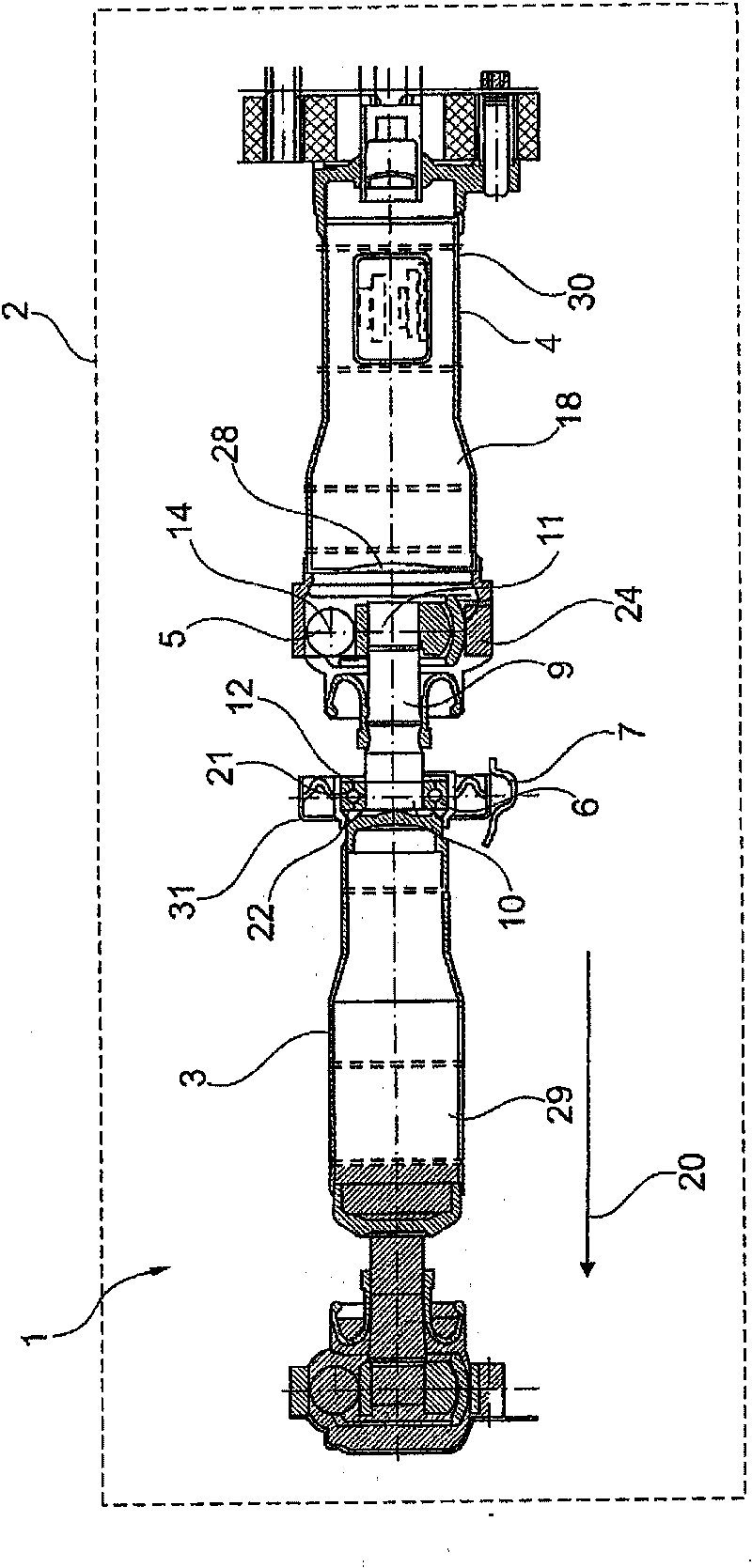

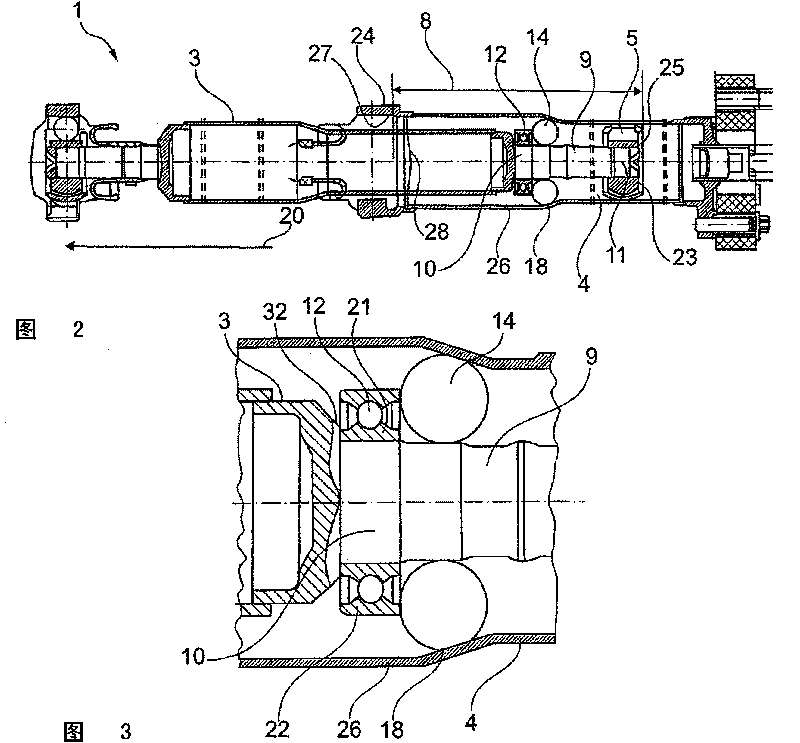

Longitudinal shaft assembly for a motor vehicle

ActiveCN101712278AReduce collision energyAvoid deflectionClutchesConnecting rodsConstant-velocity jointBall type

A longitudinal shaft assembly for a motor vehicle, comprising at least a first shaft and a second shaft, a ball-type constant velocity joint for connecting the first shaft to the second shaft and at least one central bearing for supporting the longitudinal shaft assembly with respect to a body of the motor vehicle.

Owner:GKN DRIVELINE DEUTSCHLAND GMBH

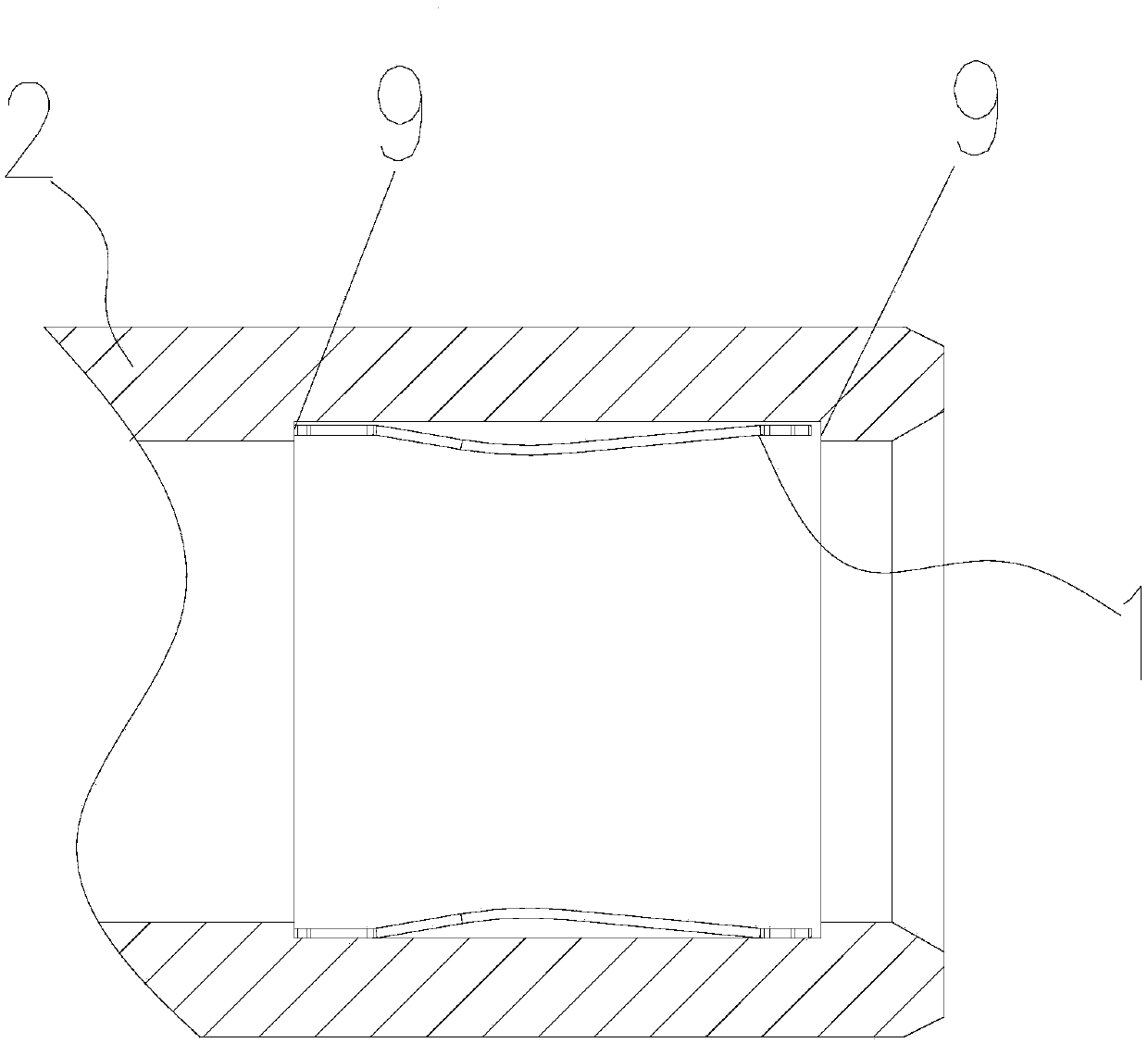

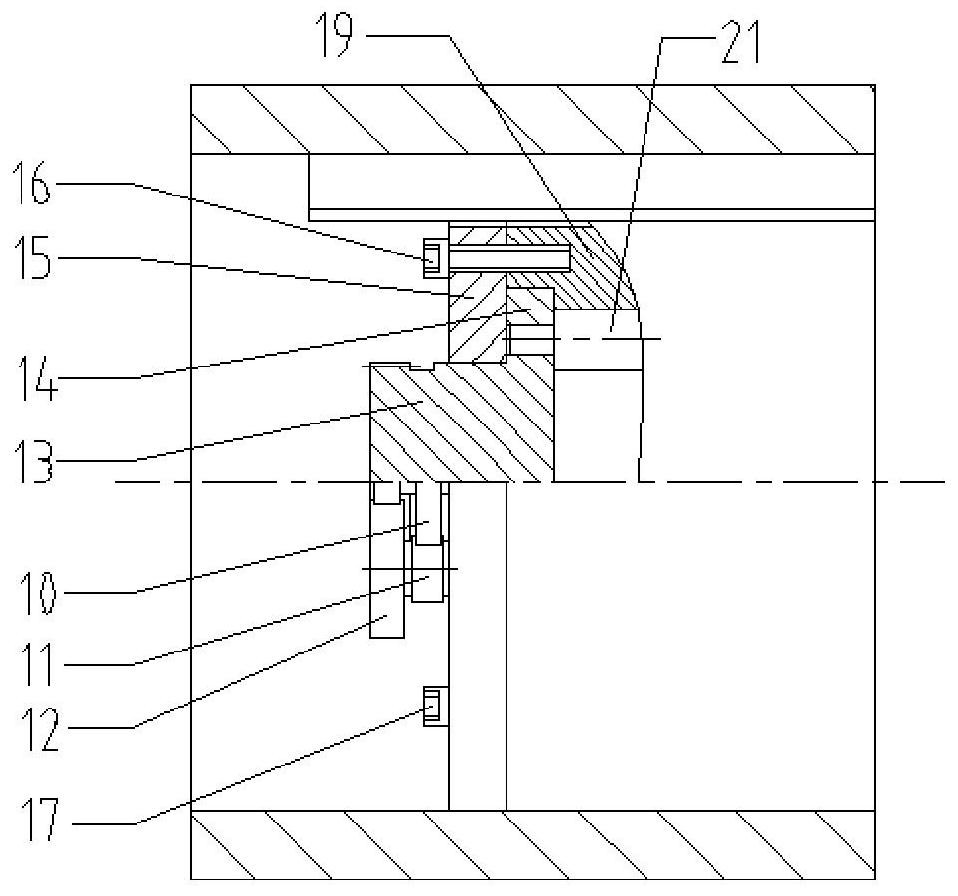

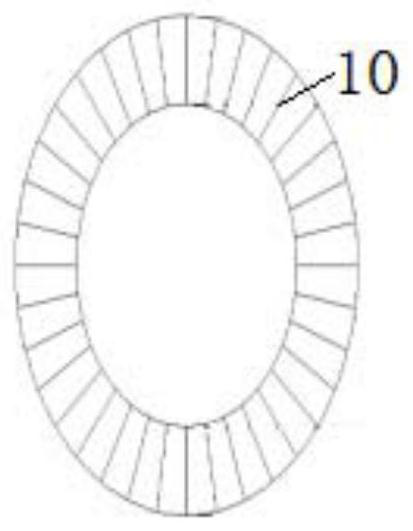

Crown spring mounting structure with good restriction and convenient disassembly

InactiveCN109638511AEasy charging connectionAvoid axial displacement and circumferential displacementSecuring/insulating coupling contact membersCoupling contact membersEngineeringAxial displacement

The invention belongs to the technical field of electric connectors and particularly relates to a crown spring mounting structure with good restriction and convenient disassembly. The crown spring mounting structure includes a crown spring and a sleeve. Elastic folding plates are uniformly distributed on the outer circumferential surfaces of the two ends of the crown spring. A plurality of throughholes are uniformly arranged on the cylinder surfaces of the two ends of the sleeve. The elastic folding plates are disposed in the through holes and have opposite folding directions. The free ends of the elastic folding plates are abutted against the walls of the through holes. The crown spring mounting structure has the beneficial effects that the axial displacement and the circumferential displacement of the crown spring in the sleeve can be avoided, the connection structure of the crown spring and the sleeve is firmly installed, which is convenient for charging connection; regardless of the diameter of the crown spring, the crown spring is convenient to disassemble and convenient to be taken out of the sleeve, thereby contributing to the maintenance of the crown spring; when the crownspring is maintained, the replacement of the connection structure of the sleeve and the crown spring can be avoided and the maintenance cost is saved.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

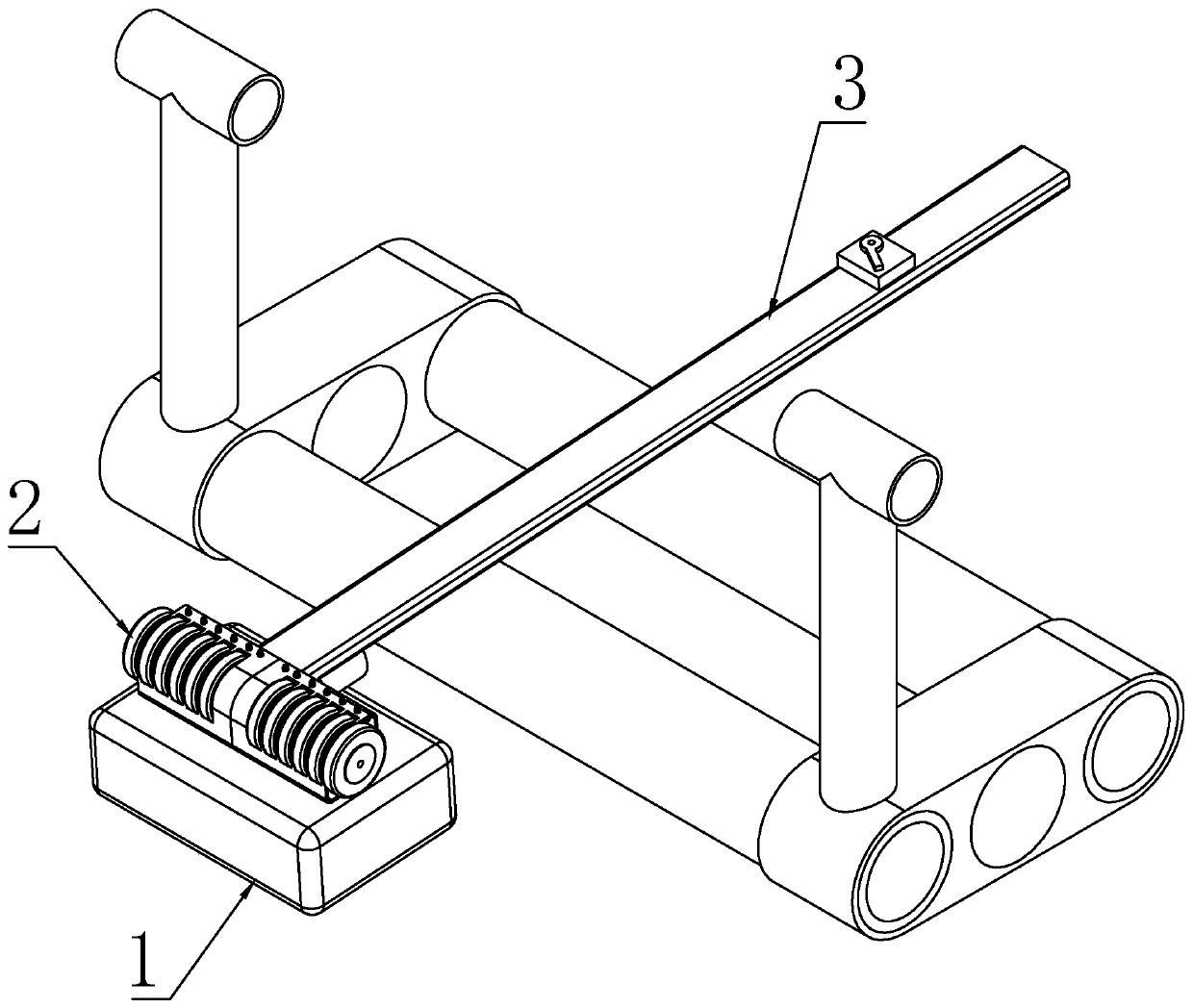

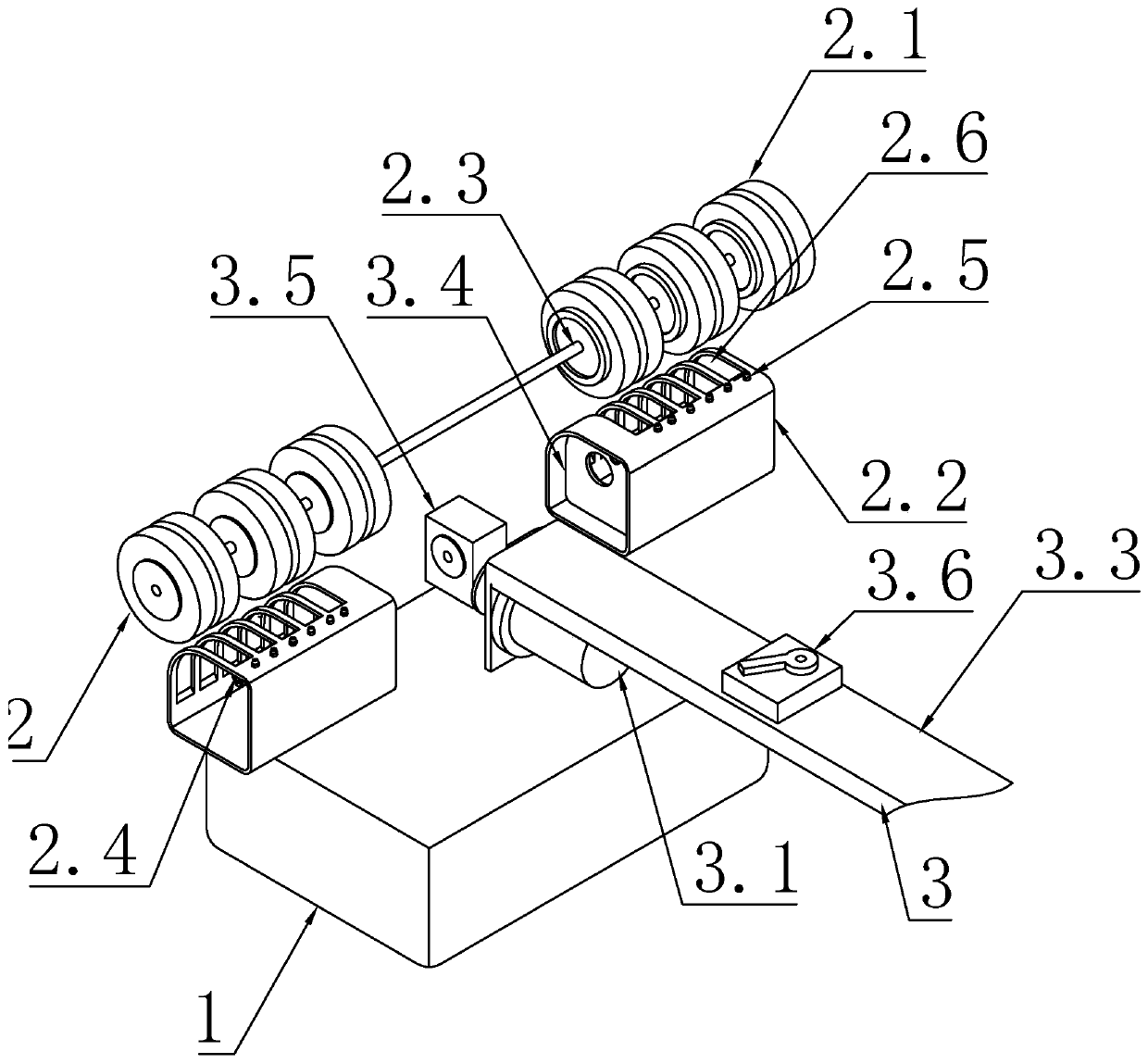

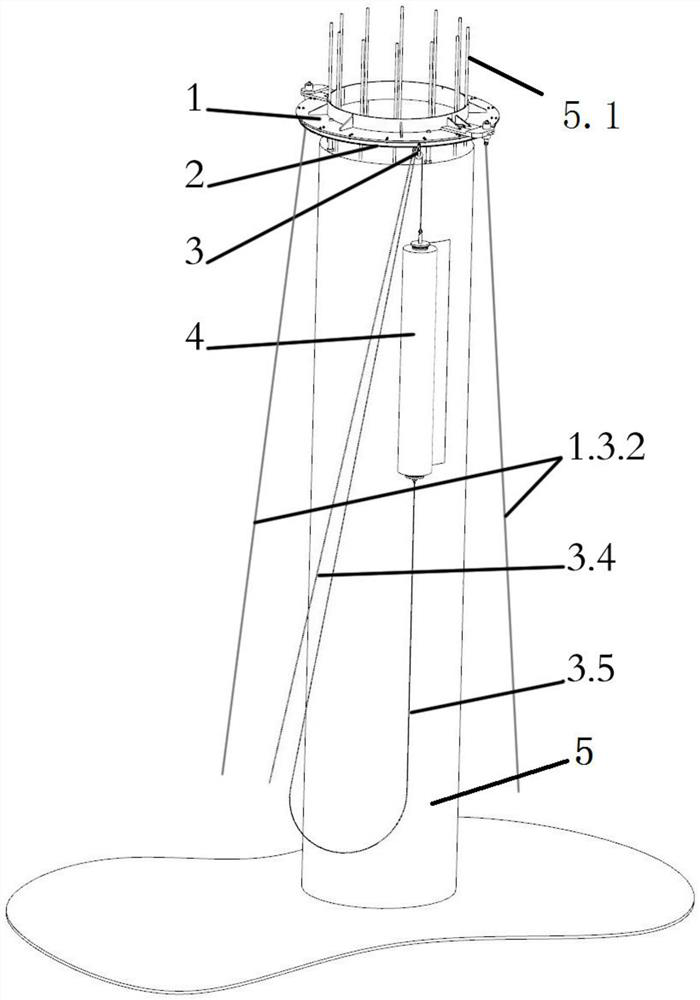

Aquatic netting washing machine for aquaculture net cages and washing method

PendingCN109848153AImprove cleaning efficiencyReduce energy wasteClimate change adaptationHollow article cleaningHydraulic motorBristle

The invention discloses an aquatic washing machine for aquaculture net cages. The aquatic netting washing machine includes floating bodies on the two sides of a net cage frame, wherein the floating bodies are provided with cleaning mechanisms for cleaning netting and driving mechanisms for driving the cleaning mechanisms to run; the cleaning mechanisms include casings, rollers and mounting shafts;hard bristles for cleaning the netting are arranged on the rollers; the rollers are rotatably arranged in the casings and driven to rotate by the mounting shafts; the surface of the netting is cleaned when the rollers rotate; the driving mechanisms include hydraulic motors, hydraulic conveying rods and plunger pumps; the hydraulic motors are connected with the mounting shafts and drive the mounting shafts to rotate; the hydraulic motors are connected with the plunger pumps through the hydraulic conveying rods; the plunger pumps supply water through the hydraulic conveying rods and drive the hydraulic motors to rotate; the upper ends of the casings are also provided with water tanks communicating with the hydraulic conveying rods; and a plurality of first high-pressure nozzles are arrangedon the water tanks at intervals. According to the aquatic netting washing machine for the aquaculture net cages and awashing method, aquatic washing can be carried out while the netting is put away,and the washing efficiency is high.

Owner:宁波久欣网络科技有限公司

Cargo hook gear of motor vehicle exhaustion system

InactiveCN101177121AAvoid interferenceSolve the problem of large amount of shakingPropulsion unit gas exhaustRelative motionRoad condition

The invention relates to an exhaust system hook structure with effective constraint to the displacement of a motor vehicle exhausting system, belonging to the field of the hook structures of the exhaust system. The outer end of the hook is provided with a heading (1); the inner side of the heading is provided with a hanging component (3). A boss (2) is arranged at the central section of the hook. The hanging component is arranged between the boss and the heading, and offers effective constraint to the axial movement of the hanging component and the hook, confining the relative motion of the hanging component and the welding hook of the exhaust system within a reasonable range, and thus resolving the problem of the large-amplitude sloshing of the welding hook and the hanging component of the exhaust system when the vehicle is turning or the road condition is bad, and preventing the interference of the exhaust system and the parts around during the process of movement.

Owner:CHERY AUTOMOBILE CO LTD

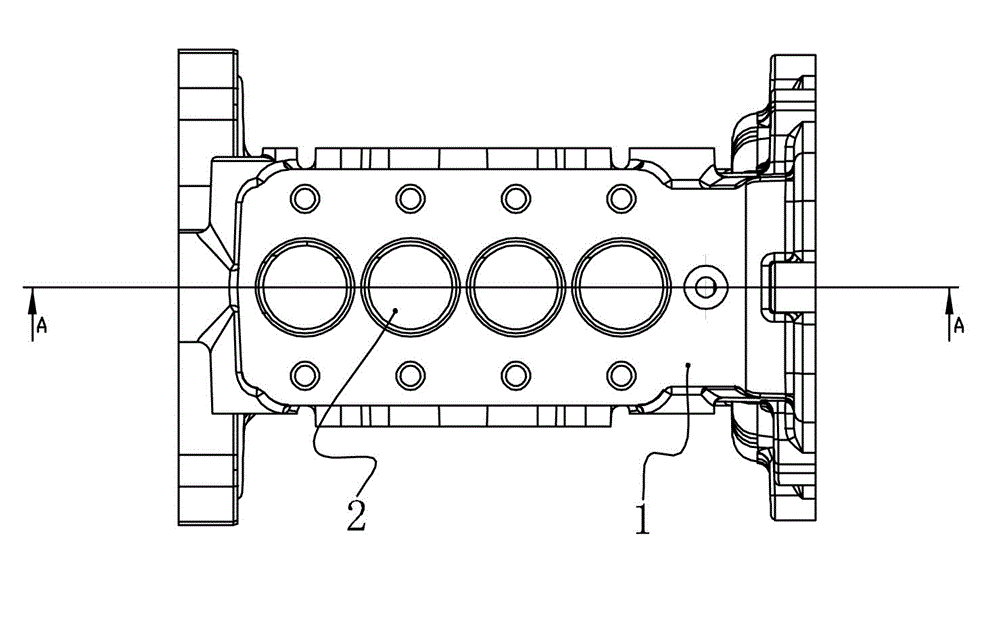

Oil groove sealing structure of fuel injection pump body

InactiveCN102878069APrevent oil spillsImprove sealingPositive displacement pump componentsLiquid fuel engine componentsInterference fitDie casting

The invention discloses an oil groove sealing structure of a fuel injection pump body. The oil groove sealing structure comprises a die-casting molded fuel injection pump body, a plunger hole is arranged at the top end of the pump body, an oil groove is arranged under the plunger hole, an oil inlet and a core pulling hole are opened on two opposite groove walls of the oil groove respectively, a step is formed in the hole of the core pulling hole, a plug matched with the step is arranged in the core pulling hole, and the plug and the core pulling hole are in interference fit. According to the oil groove sealing structure of the fuel injection pump body, the sealing effect is good, and oil leakage of the oil groove can be prevented.

Owner:CHONGQING BAIJI SIXING DIE CASTING

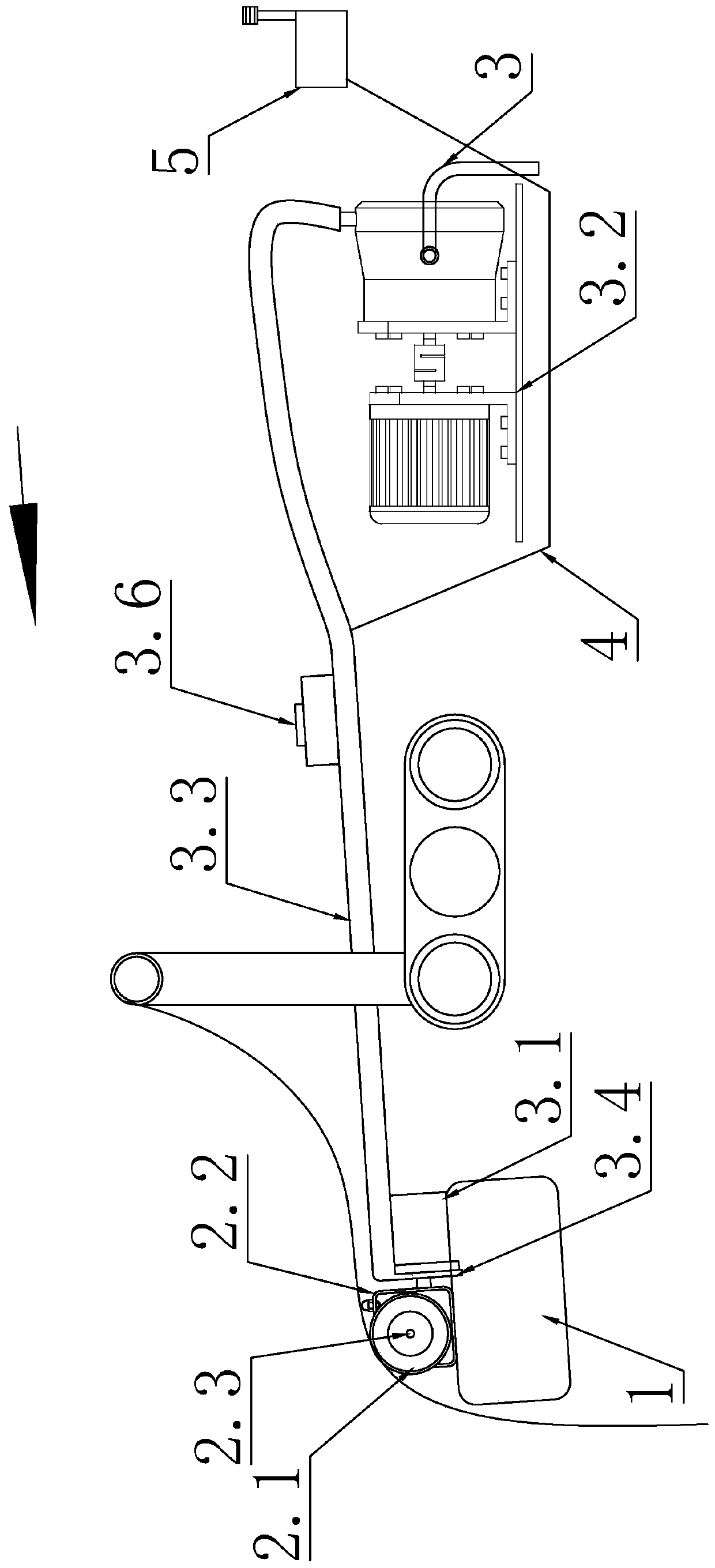

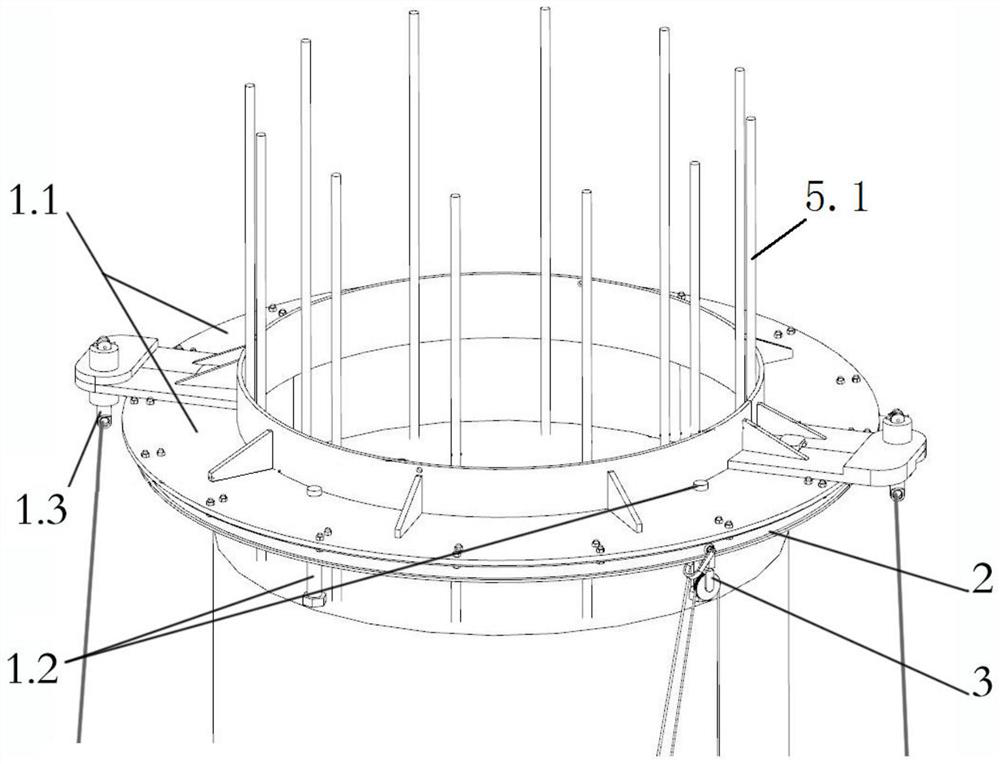

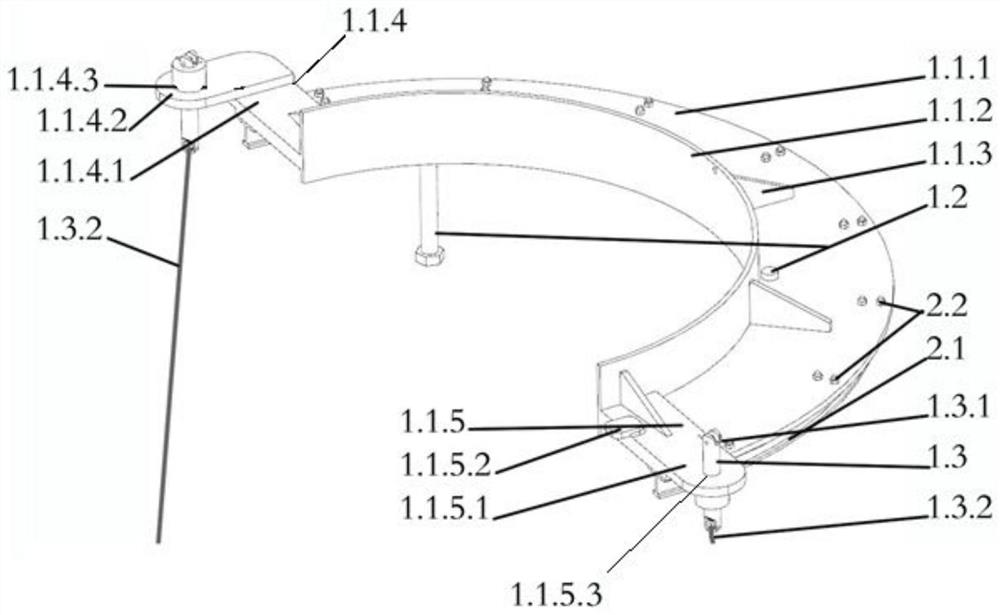

Pier column maintenance device and film covering construction method

PendingCN113756182AImprove lamination efficiencyImprove lamination qualityBridge structural detailsBridge erection/assemblyArchitectural engineeringPier

The invention relates to the field of buildings, and provides a pier column maintenance device and a film covering construction method. The pier column maintenance device comprises a rack fixed to a top of apier column, a lifting assembly slidably arranged on the rack in the circumferential direction of the pier column, and a maintenance film assembly which comprises a shaft rod and a maintenance film roll rotatably arranged on the shaft rod, wherein the shaft rod is connected with the lifting assembly; and the lifting assembly can lift or lower the maintenance film roll while sliding in the circumferential direction of the pier column so that the maintenance film roll can be wound around the pier column according to the spiral track. After the rack is hoisted at the top end of the pier column, a constructor can make the maintenance film spirally wind on the pier column on the ground through the lifting assembly, and therefore in the pier column maintenance film covering construction process, a crane does not need to be matched for construction, a support does not need to be erected, the construction period can be shortened, the construction cost can be reduced, high-altitude film covering operation of workers is avoided, and potential safety hazards of construction are eliminated.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

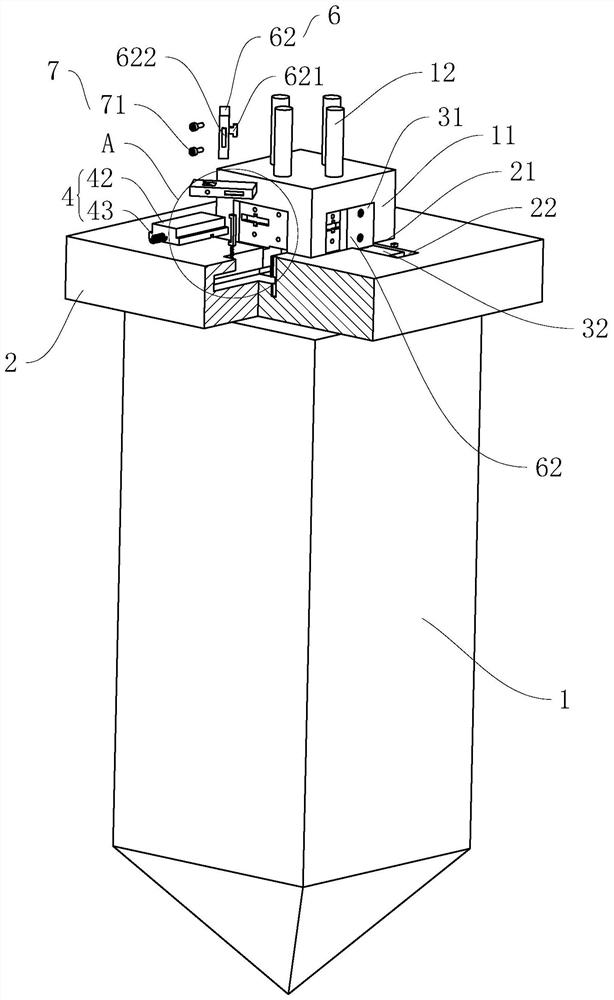

Pile foundation

ActiveCN112814007AEasy to transportEasy to assembleFoundation engineeringArchitectural engineeringStructural engineering

The invention relates to the building technology, and discloses a pile foundation. The pile foundation comprises a pile column and a base table, wherein a connecting column is integrally arranged on the pile column, a connecting table used for allowing the base table to be clamped in is formed between the connecting column and the pile column, an assembling hole is formed in the base table, the connecting column is arranged in the assembling hole in a penetrating mode, and a connecting mechanism is arranged between the connecting column and the base table and is used for fixing the base table and the pile column. According to the pile foundation, during transportation, the base table and the pile column can be disassembled, the disassembled base table and the pile column can be completely and horizontally placed on a transport vehicle, so that parts of the pile foundation are not prone to being bent and the like in the transportation process, and then the pile foundation is not prone to being damaged such as breakage; and meanwhile, during use, the base table can sleeve the connecting column, and is positioned and fixed through a connecting block, the assembly type structure is simple and convenient to install, the construction period can be shortened, and therefore, the effect of improving the construction efficiency is further achieved.

Owner:ZHEJIANG CHANHIGH MUNICIPAL GARDEN CONSTR CO LTD

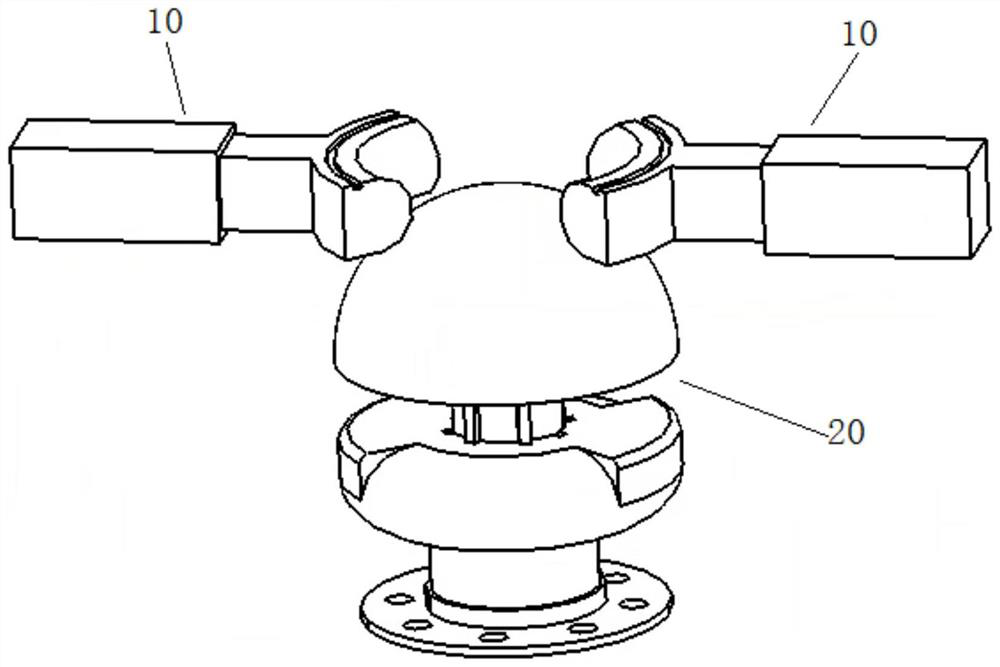

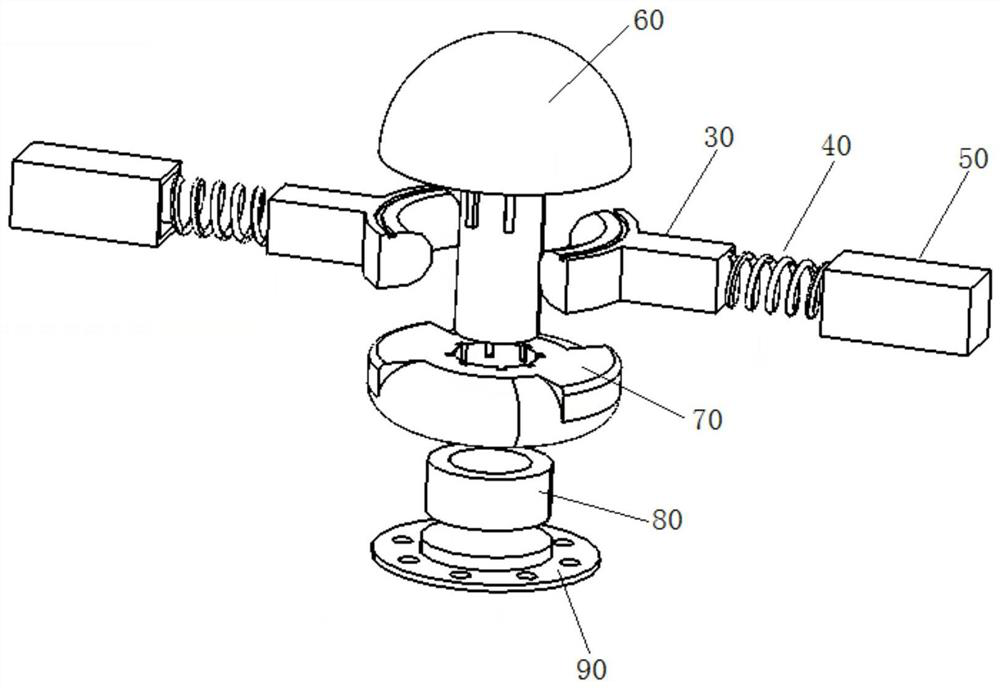

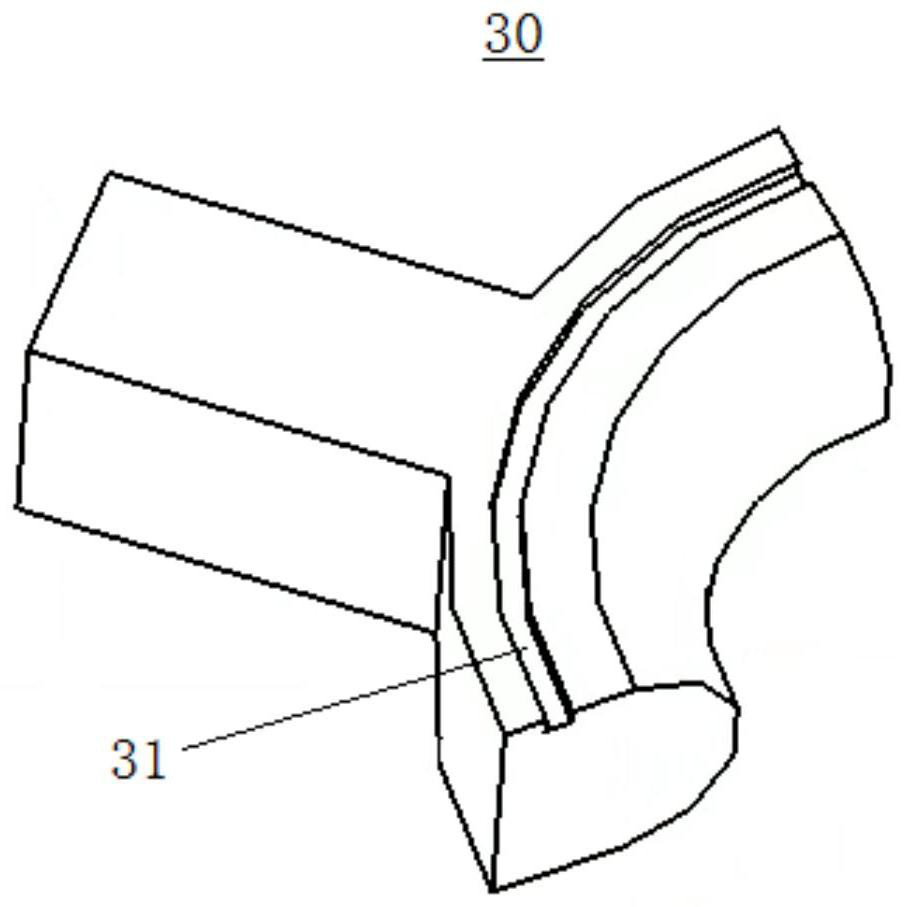

Quick-change locking mechanism for power battery

ActiveCN112277720ALimit axial displacementReliable separationCharging stationsElectric propulsion mountingPower batterySeparated state

The invention relates to a quick-change locking mechanism for a power battery. The quick-change locking mechanism comprises a fixing assembly and a locking assembly, wherein the fixing assembly comprises a push rod, a first elastic piece and a fixing block; s groove is formed in the upper surface of the end, close to the locking assembly, of the push rod; the locking assembly comprises a locking shaft and a sliding block; the locking shaft comprises a hemispheroid and a cylindrical shaft which are coaxially arranged; the sliding block is sleeved on the cylindrical shaft and is provided with ahorizontal table board and a cambered surface which form an angle with each other; in a locking state, the push rod is respectively clamped with the horizontal table top and a lower surface of the hemispheroid, and a lower edge of the hemispheroid is clamped in the groove of the push rod; in the separation state, the arc surface makes contact with the push rod, and the push rod slides on the arc surface to achieve separation. The mechanism is advantaged in that installation reliability of the locking mechanism can be improved, and the occupied space of the locking mechanism can be reduced through a simple structure.

Owner:DONGFENG MOTOR CORP HUBEI

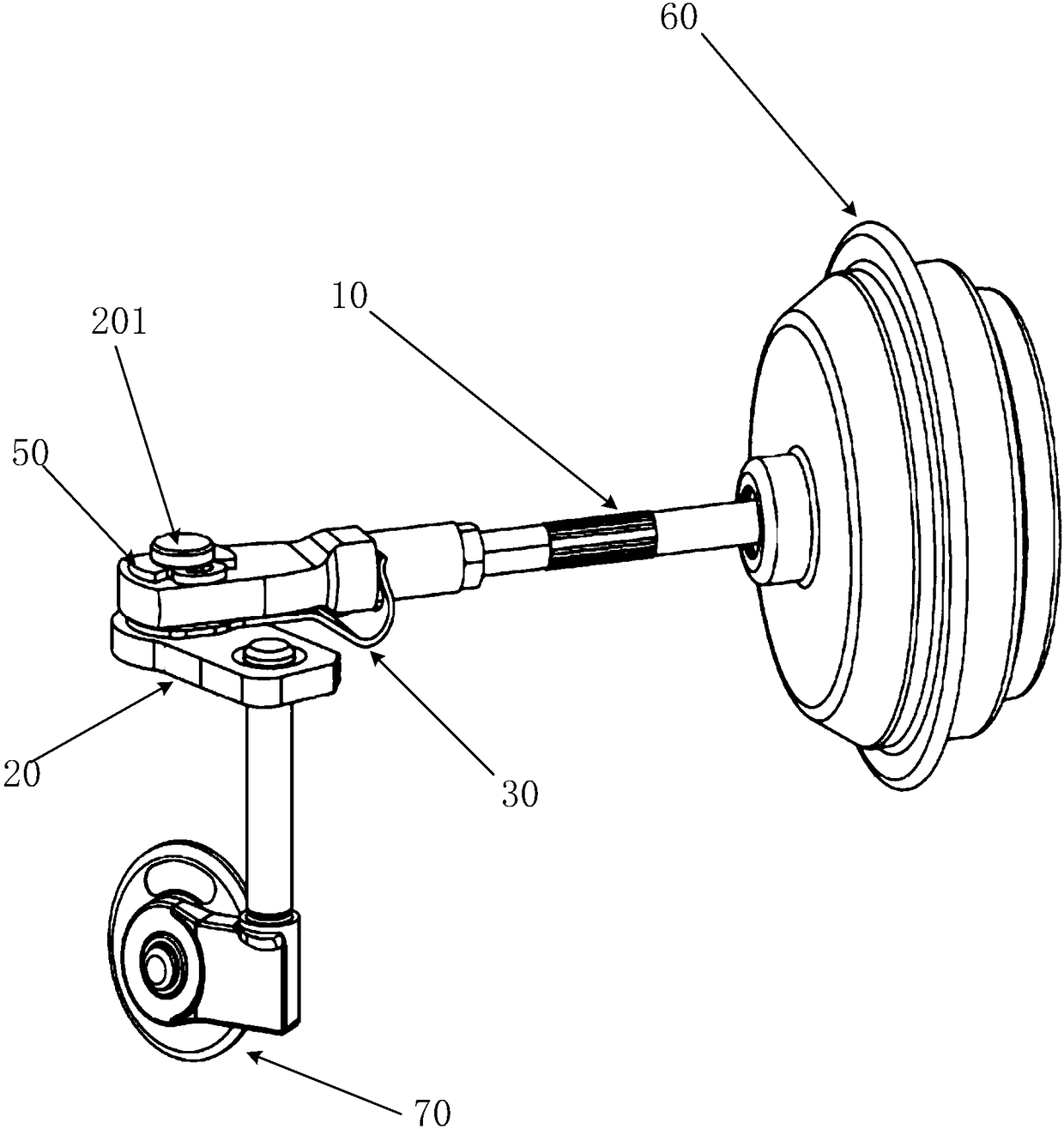

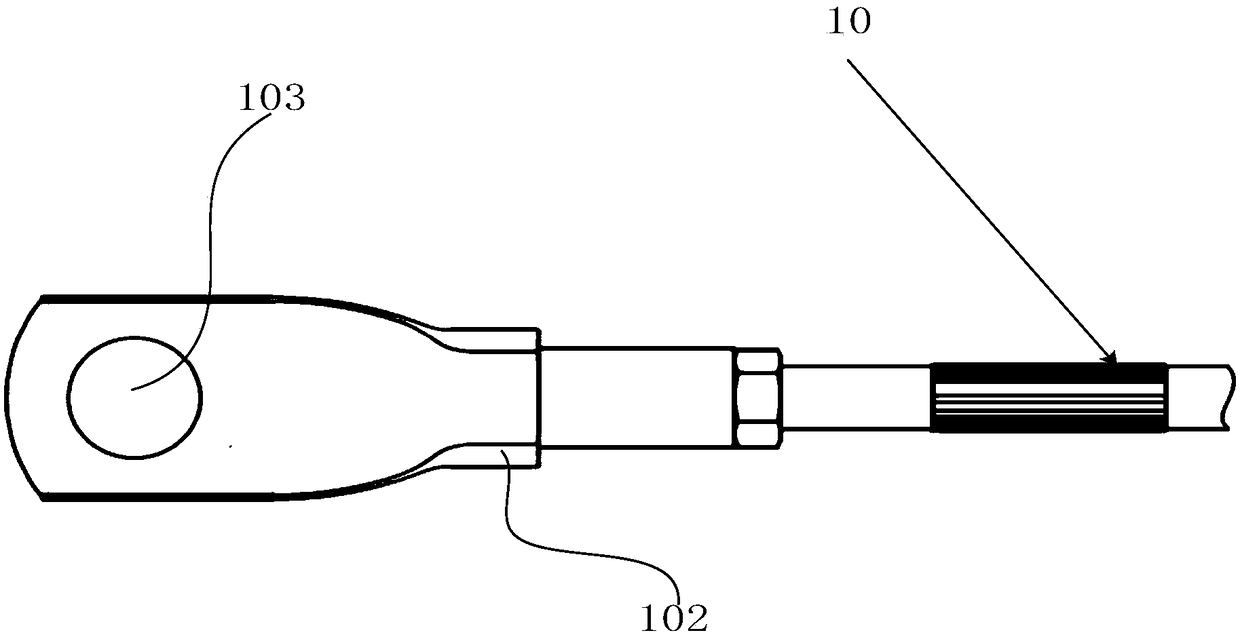

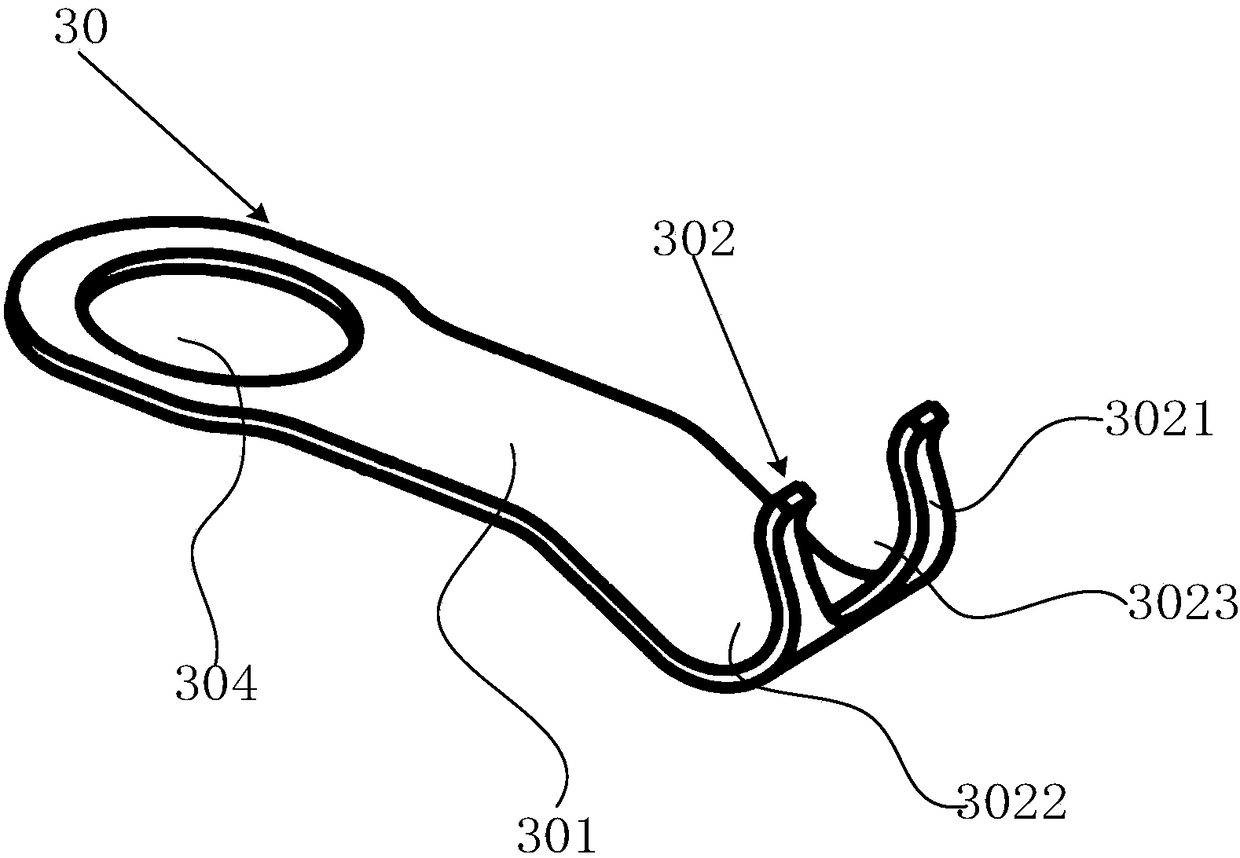

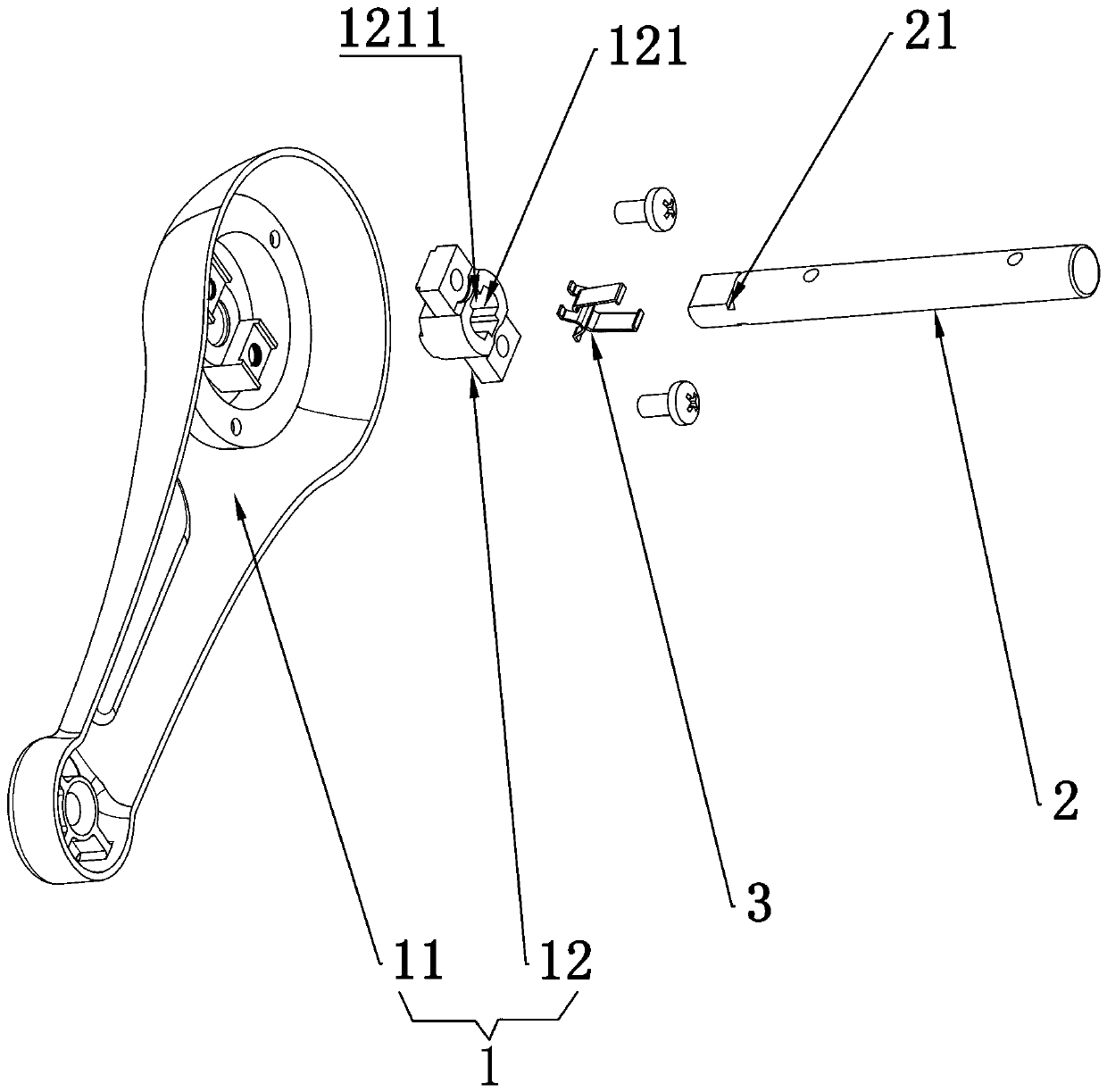

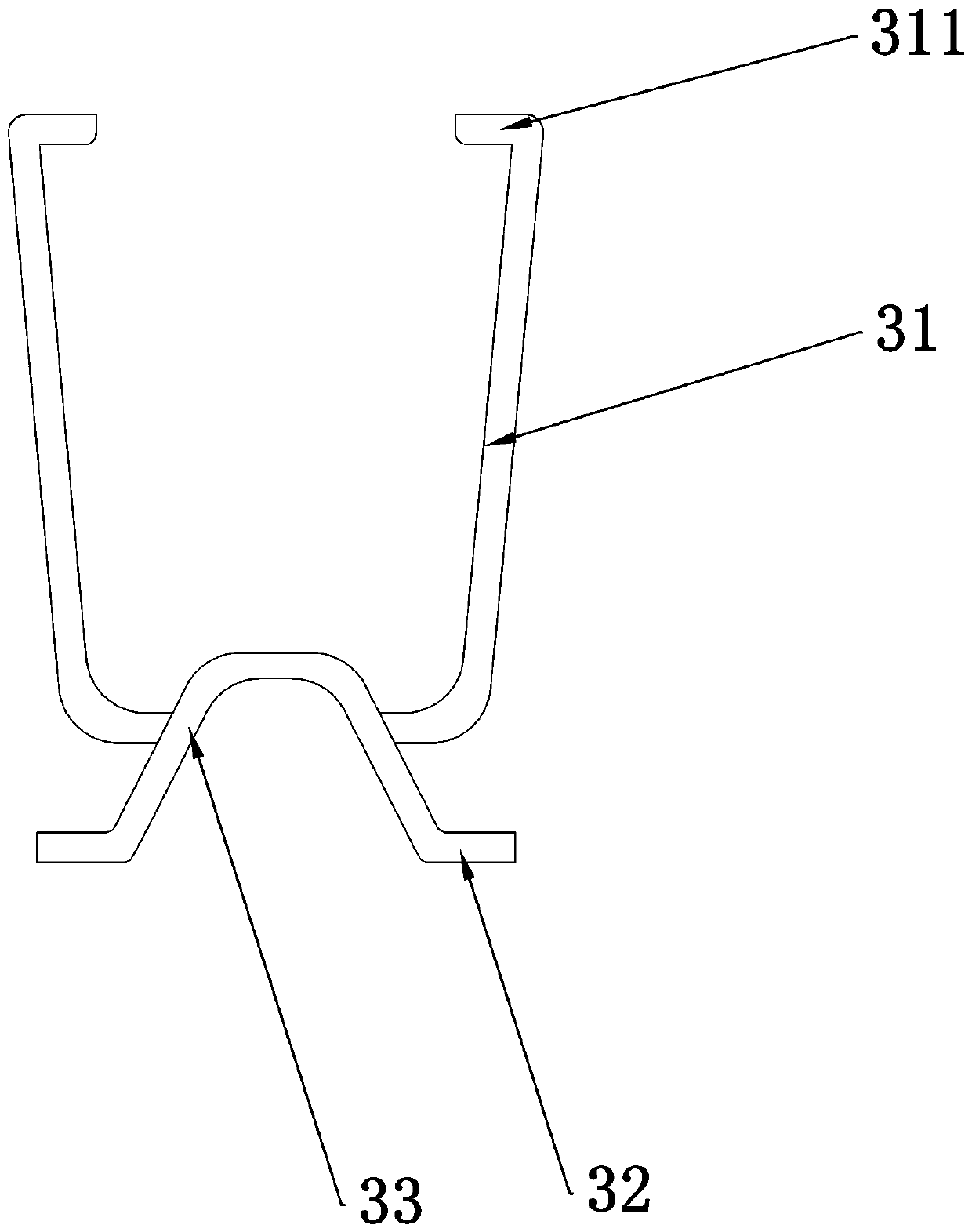

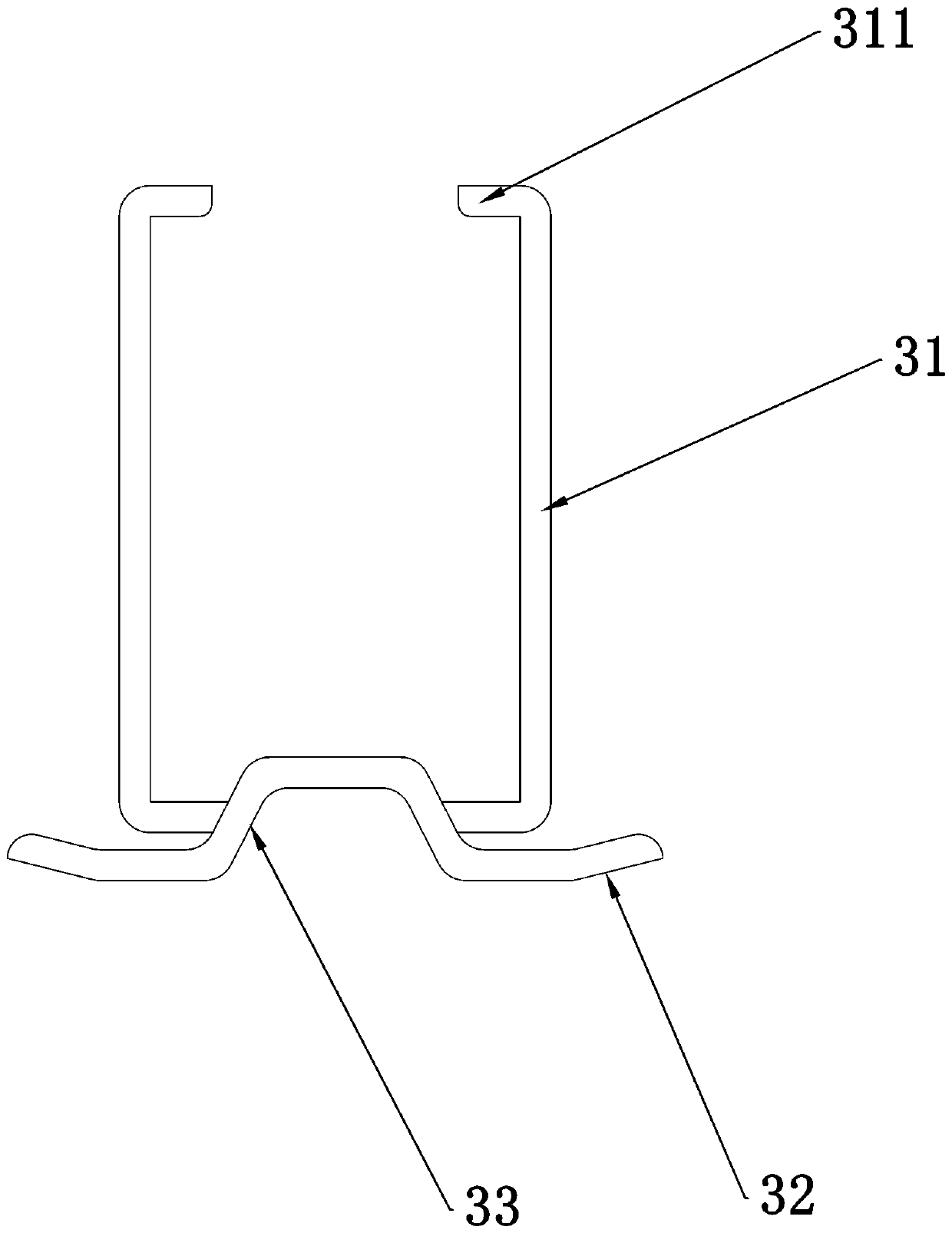

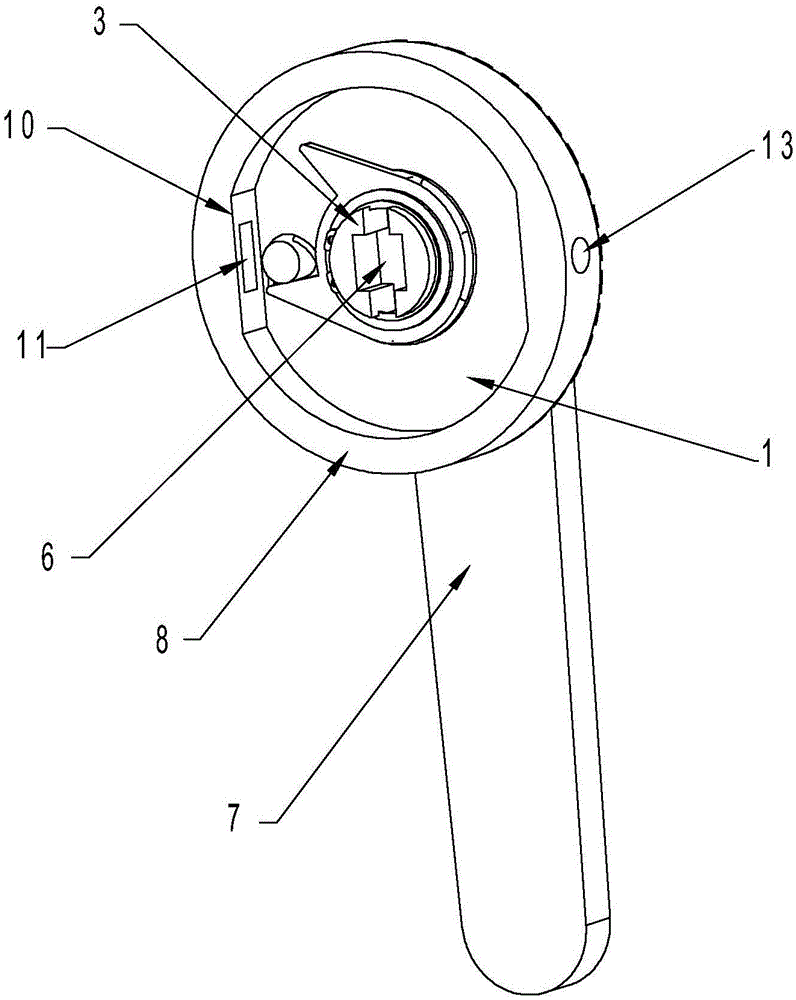

Hand cranking device of clothes hanger rack

PendingCN107780176AEasy assemblyReduce difficultyOther drying apparatusTextiles and paperLaundryClothes hanger

The invention discloses a hand cranking device of a clothes hanger rack. The hand cranking device comprises a handle assembly, a spindle and an elastic piece clamp, wherein the elastic piece clamp isin rotation stopping connection with the handle assembly and is in clamping connection with the spindle to limit axial displacement of the spindle relative to the handle assembly. According to the hand cranking device of the clothes hanger rack, the elastic piece clamp is in rotation stopping connection with the handle assembly and is in clamping connection with the spindle to limit axial displacement of the spindle relative to the handle assembly, so that the spindle is prevented from falling off the handle assembly, and the axial displacement of the spindle relative to the handle assembly islimited. The hand cranking device of the clothes hanger rack is simple to assemble, the difficulty of a production process is reduced, locking attachment by aid of a bolt and a screw is not needed for connection of the spindle and the handle assembly, the hand cranking device is more attractive and more practical after assembly and is stable in quality during use.

Owner:九牧智能厨卫(安徽)有限公司

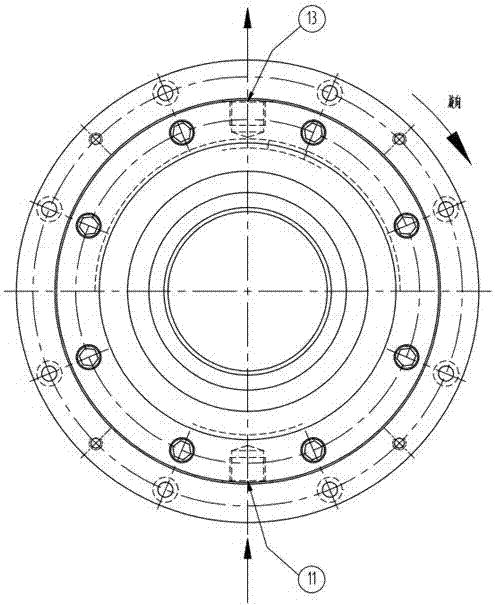

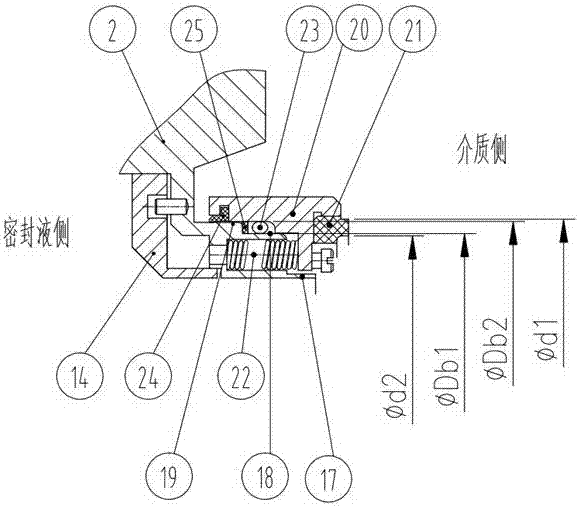

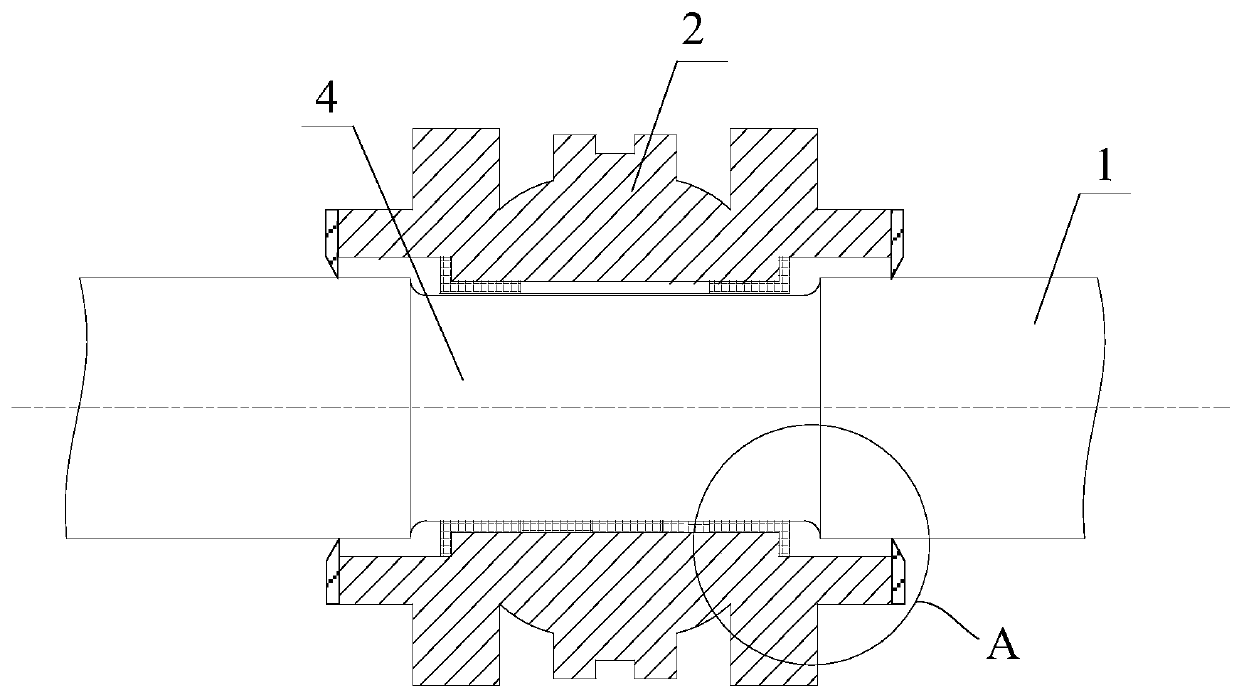

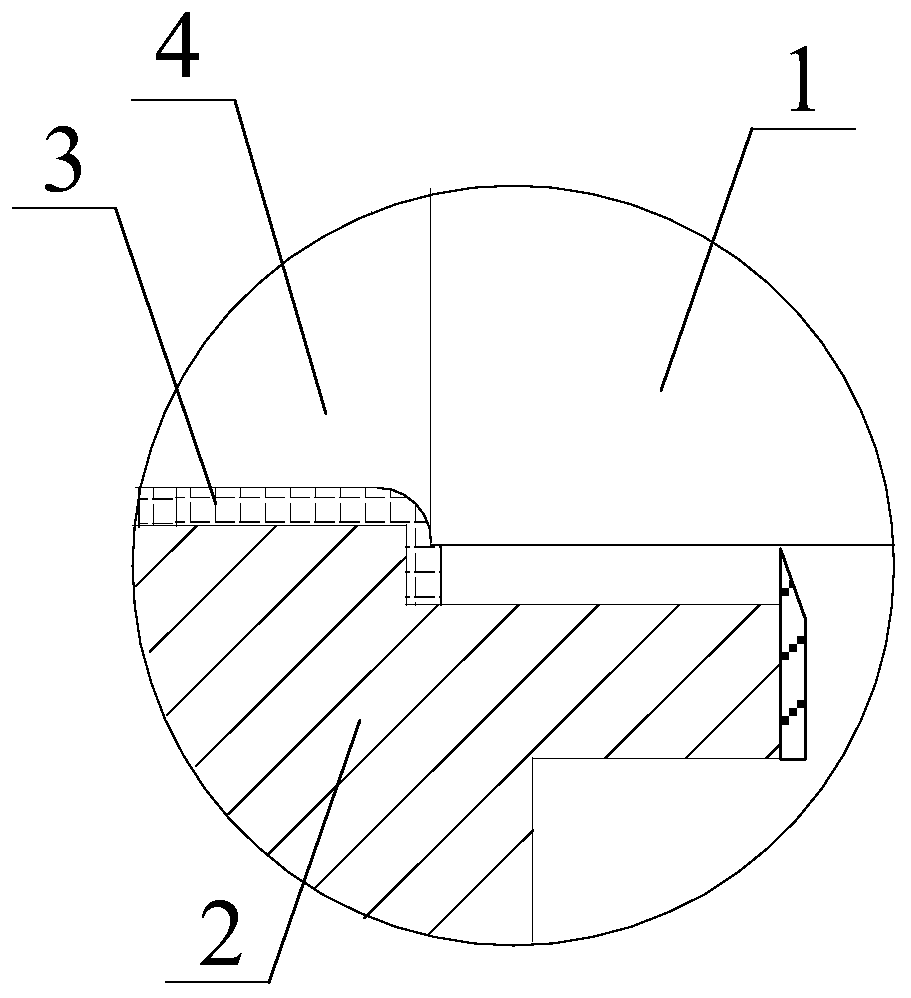

Mechanical sealing device for high-speed sand mill

PendingCN107355542AStrong sealing adaptabilityLiquid film stabilizationEngine sealsEngineeringMechanical engineering

The invention relates to a mechanical sealing device for a high-speed sand mill. The mechanical sealing device comprises an outer gland, an inner gland and a shaft sleeve. The shaft sleeve is sleeved with the outer gland and the inner gland. The outer gland and the inner gland are connected through a screw. An inner movable ring is arranged at the right end of the shaft sleeve. The right end of the inner gland is sleeved with an inner static ring assembly. The right end face of the inner static ring assembly is in fit with the left end face of the inner movable ring, and a main seal is formed. An inner movable ring assembly with which the shaft sleeve is sleeved is arranged in the gap between the shaft sleeve and the outer gland. The outer gland is provided with an outer static ring assembly. The left end face of the outer movable ring assembly is in fit with the right end face of the outer static ring assembly, and therefore a safe seal is formed. An isolation sleeve is arranged in the gap among the inner gland, the outer gland and the shaft sleeve. A sealing cavity is formed between the isolation sleeve and the inner gland and communicates with a liquid feeding hole, the sealing cavity communicates with an overflowing hole inside the inner gland, and therefore a liquid loop is formed. The mechanical sealing device is used for a device which is rotated at a high speed, a sealing end face is not likely to be damaged, and the service life is longer.

Owner:西安普力流体科技有限公司

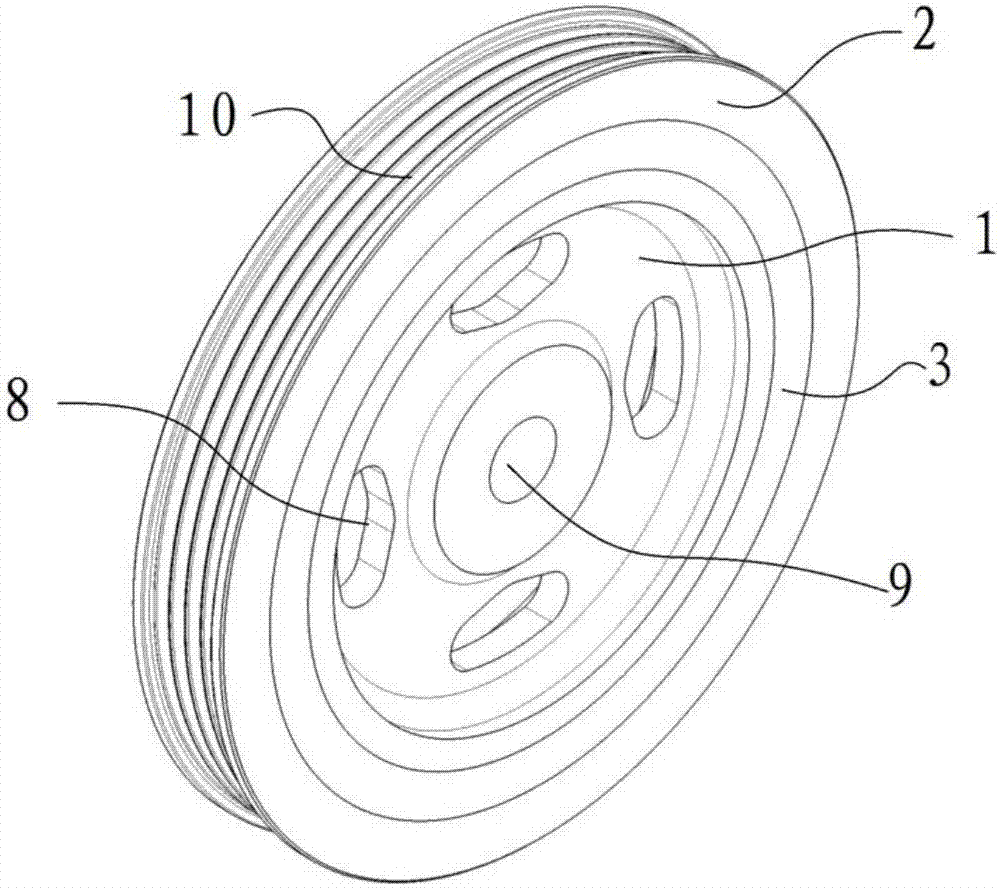

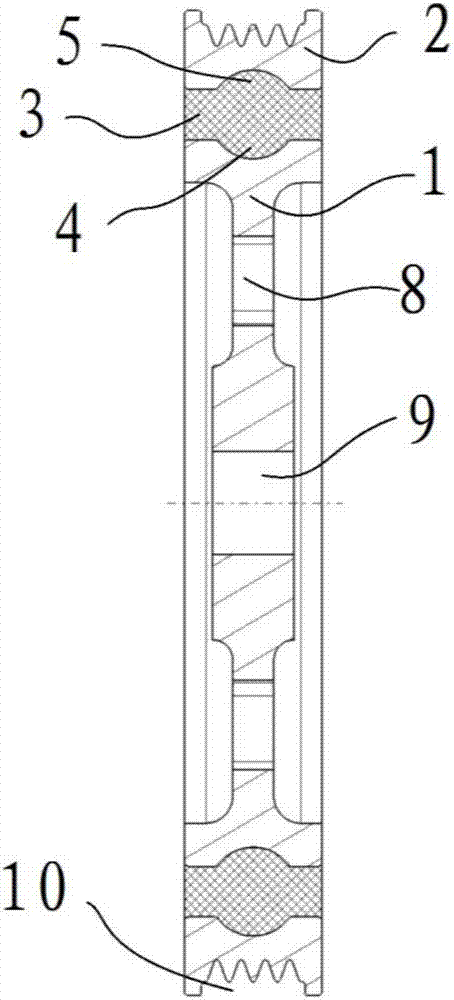

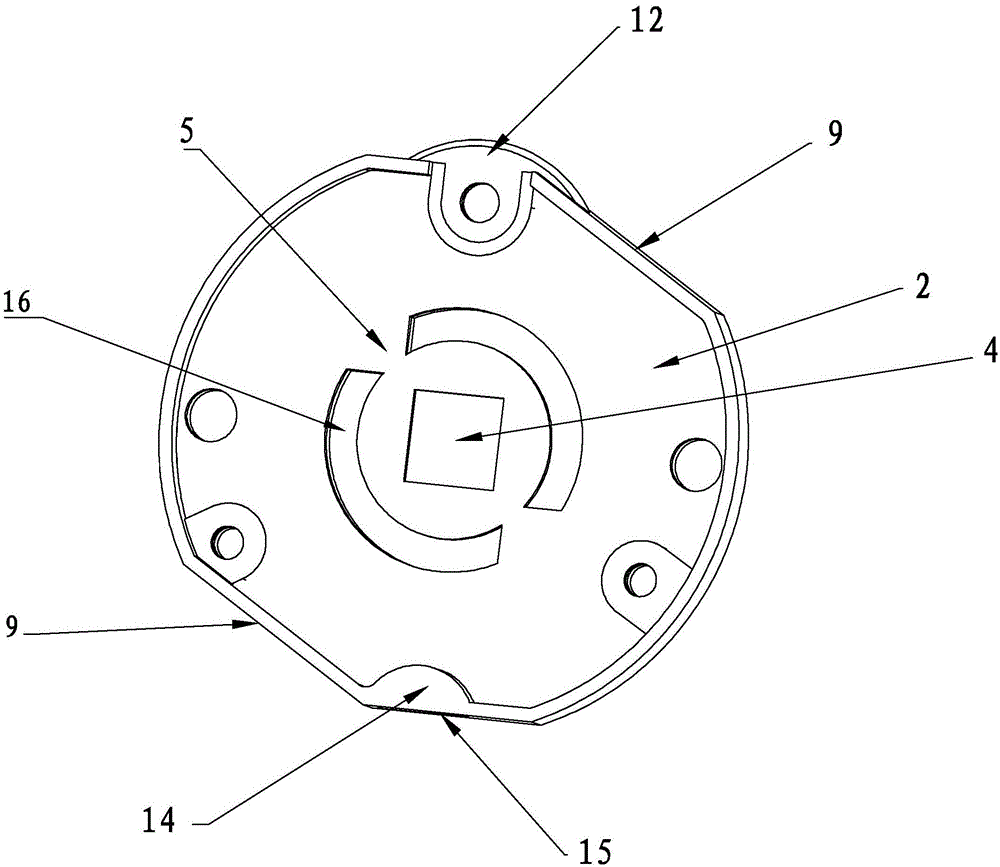

Vibration reduction belt wheel

InactiveCN107191576ALimit radialLimit axial displacementPortable liftingGearing elementsAxial displacementAccelerated aging

The invention discloses a vibration reduction belt wheel. The vibration reduction belt wheel comprises an inner belt wheel with a shaft hole, an outer belt wheel provided with a belt groove in the outer circumferential face annularly and a rubber layer arranged between the inner belt wheel and the outer belt wheel, a first arc-shaped groove is formed in the outer circumferential face of the inner belt wheel annularly, a second arc-shaped groove is formed in the inner circumferential face of the outer belt wheel, the first arc-shaped groove and the second arc-shaped groove are oppositely arranged to form a rolling way, and multiple balls are assembled in the rolling way. Compared with the prior art, the rolling way with the arc-shaped cross section is designed between the outer belt wheel and the inner belt wheel, the multiple balls are assembled in the rolling way, the runner layer equivalently serves as a holding support of the balls, and therefore the outer belt wheel and the inner belt wheel have rigid axial and radial limiting, radial loads and axial loads are borne at the same time, radial and axial displacement of the inner belt wheel and the outer belt wheel is effectively limited, accelerated aging caused by transmission errors and extra stress of rubber is avoided, and the running stability and reliability are improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

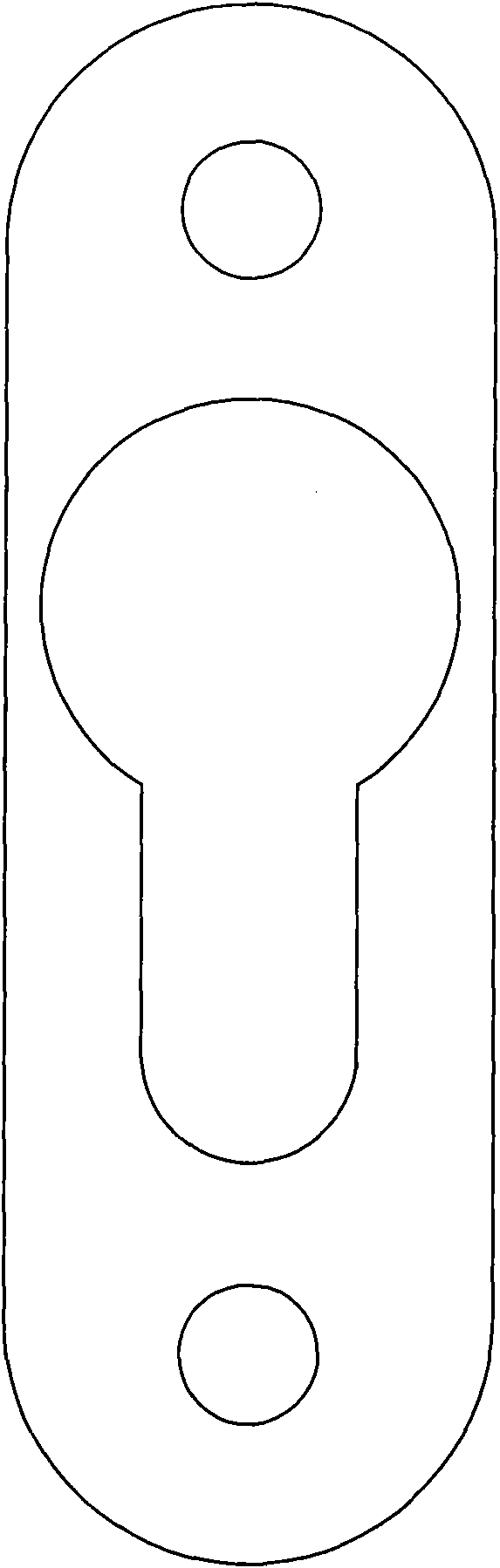

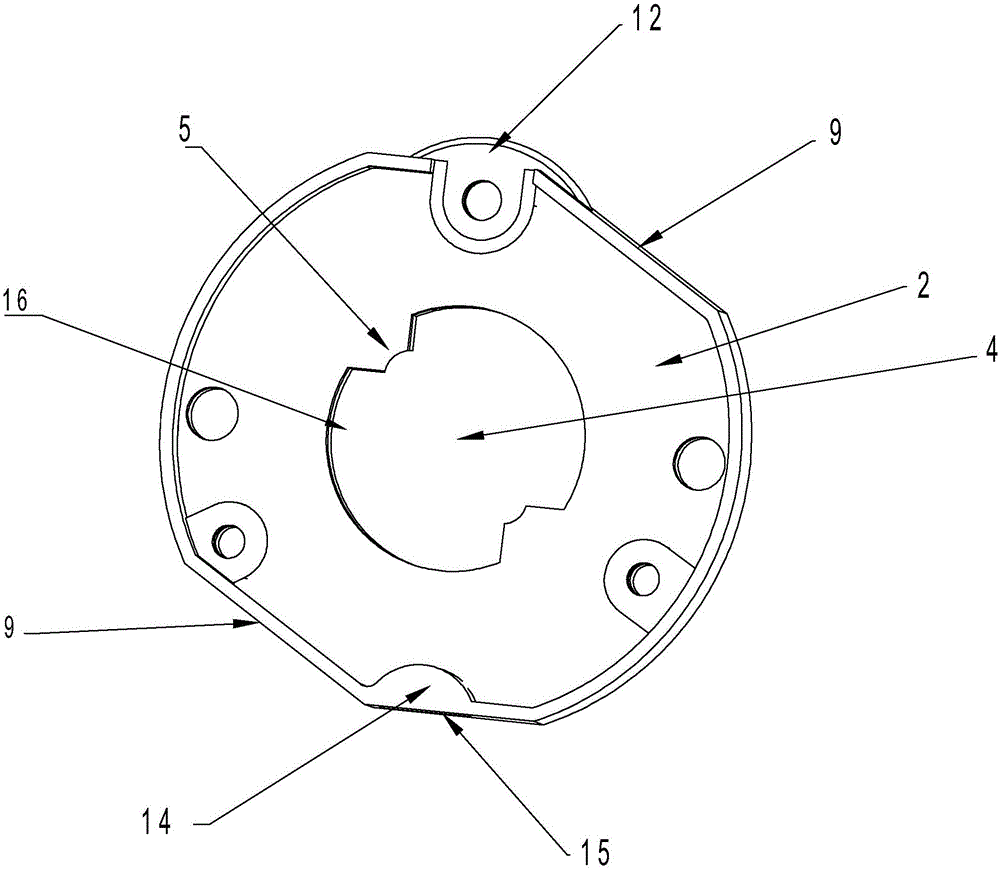

Fast-mounted door lock

InactiveCN105113853ALimit axial displacementRestrict mutual rotationBuilding locksHandle fastenersIndustrial engineering

The invention discloses a fast-mounted door lock which comprises an outer ring, an inner ring and a handle. The handle is inserted in the outer ring, a side wall is arranged on the edge of the outer ring, and the outer ring is arranged on the inner ring in a sleeving mode through the side wall. The outer ring is rotationally connected with the inner ring 2. A rotating clamping and connecting assembly is arranged between the outer ring and the inner ring and comprises a sliding clamping groove and a clamping block. The outer ring is arranged in a round shape, and horizontal tabletops are arranged on the inner side of the side wall. The sliding clamping groove is formed in the corresponding horizontal tabletop, notches matched with the horizontal tabletops are formed in the edge of the inner ring, and the clamping block is arranged at one end of the corresponding notch. The sliding clamping groove is arranged in one of the horizontal tabletops, the sliding clamping groove is provided with an opening facing a circle center, the sliding clamping groove is matched and connected with the clamping block in a clamping mode, a rotary buckling type opening and closing manner is adopted for the outer ring and the inner ring, operation is simple and convenient, and installation is convenient.

Owner:浙江永精锁业有限公司

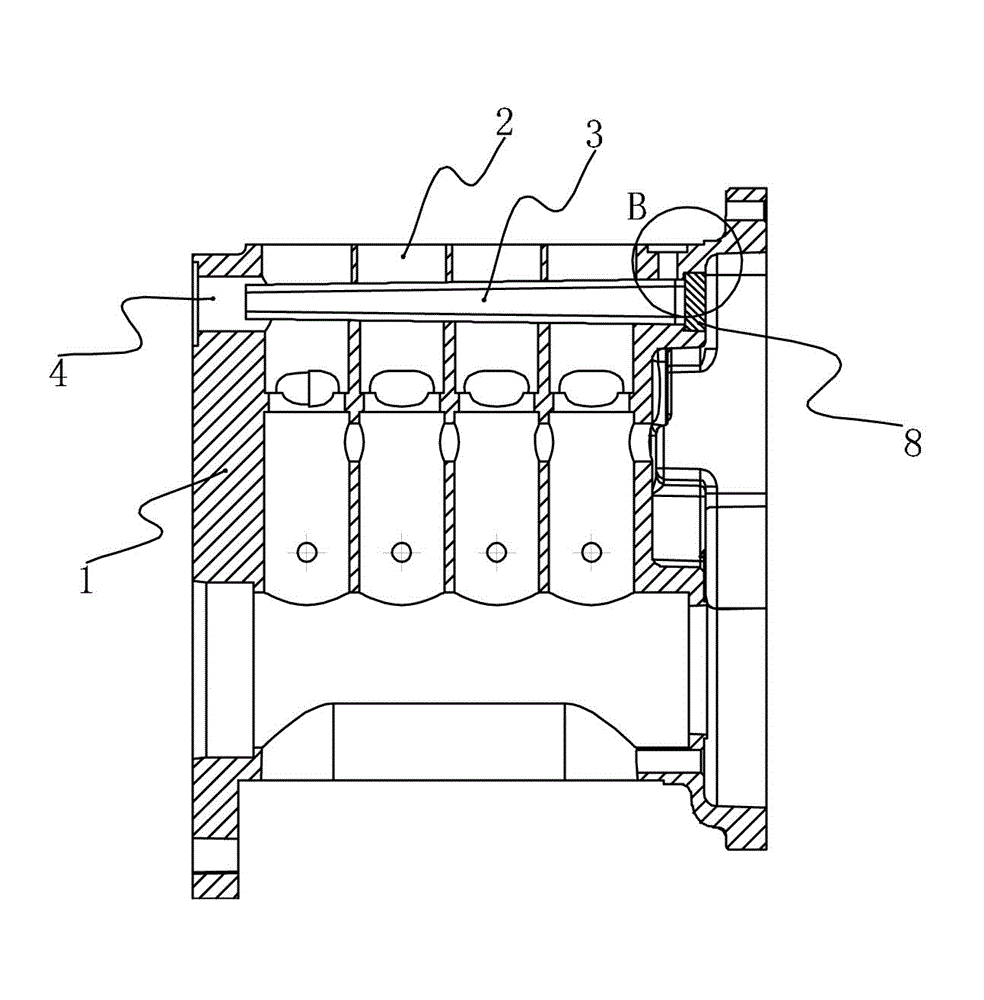

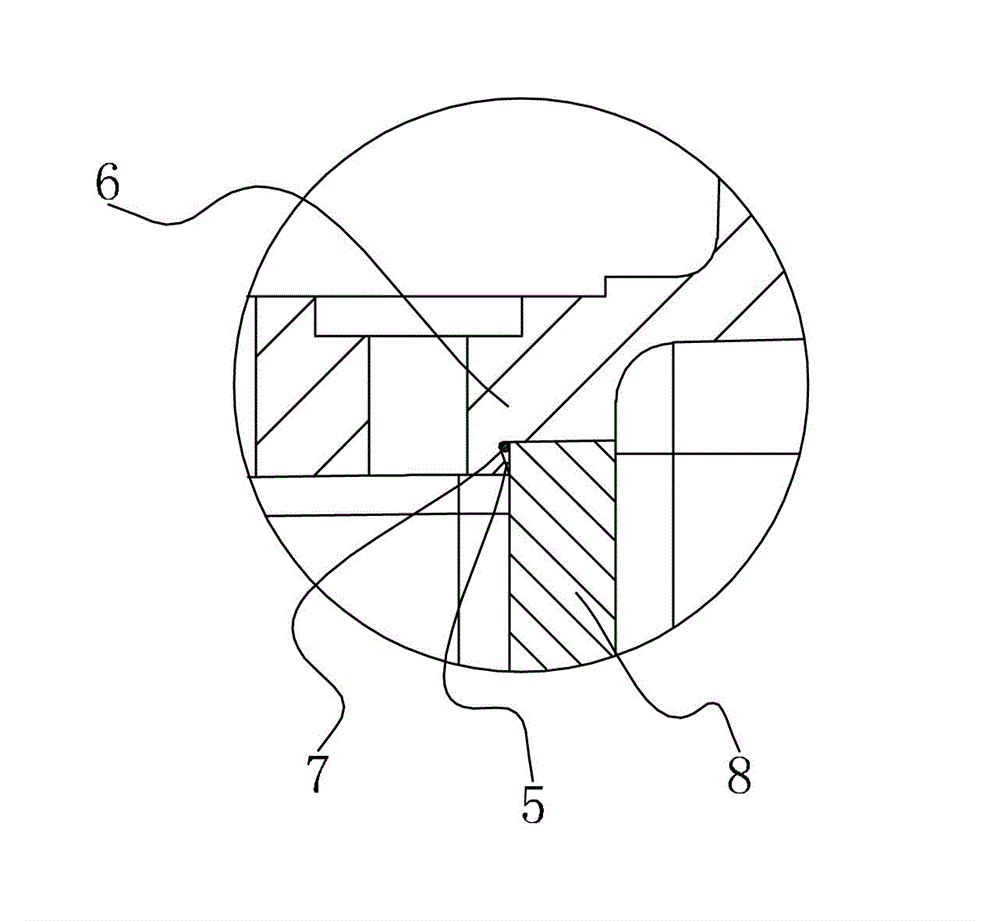

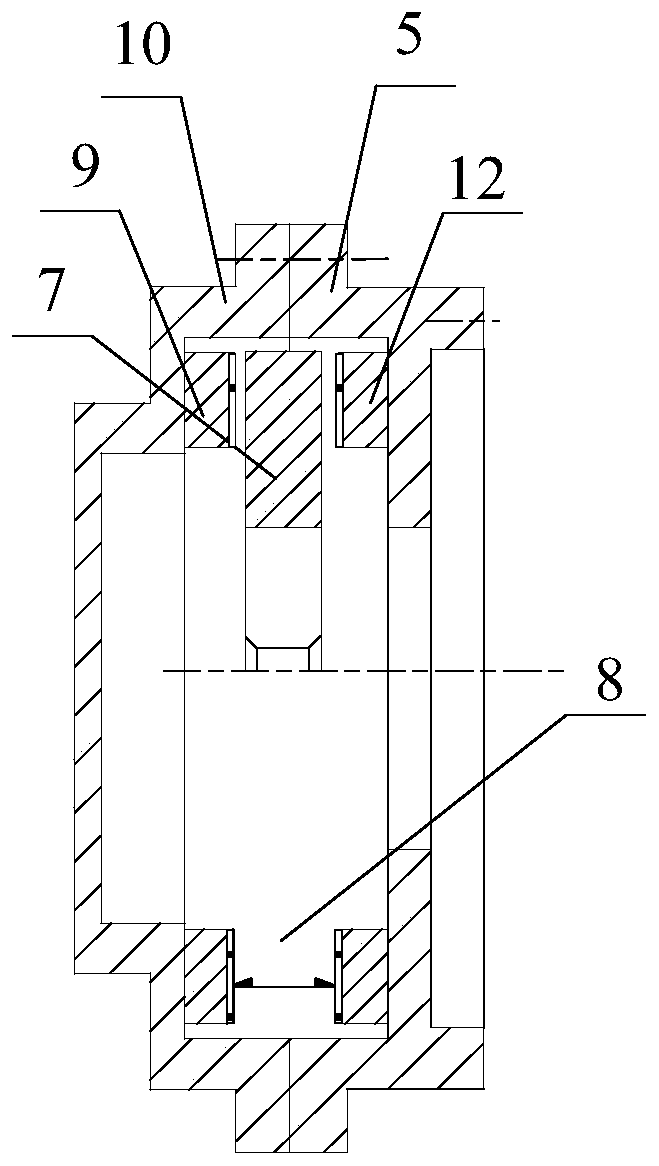

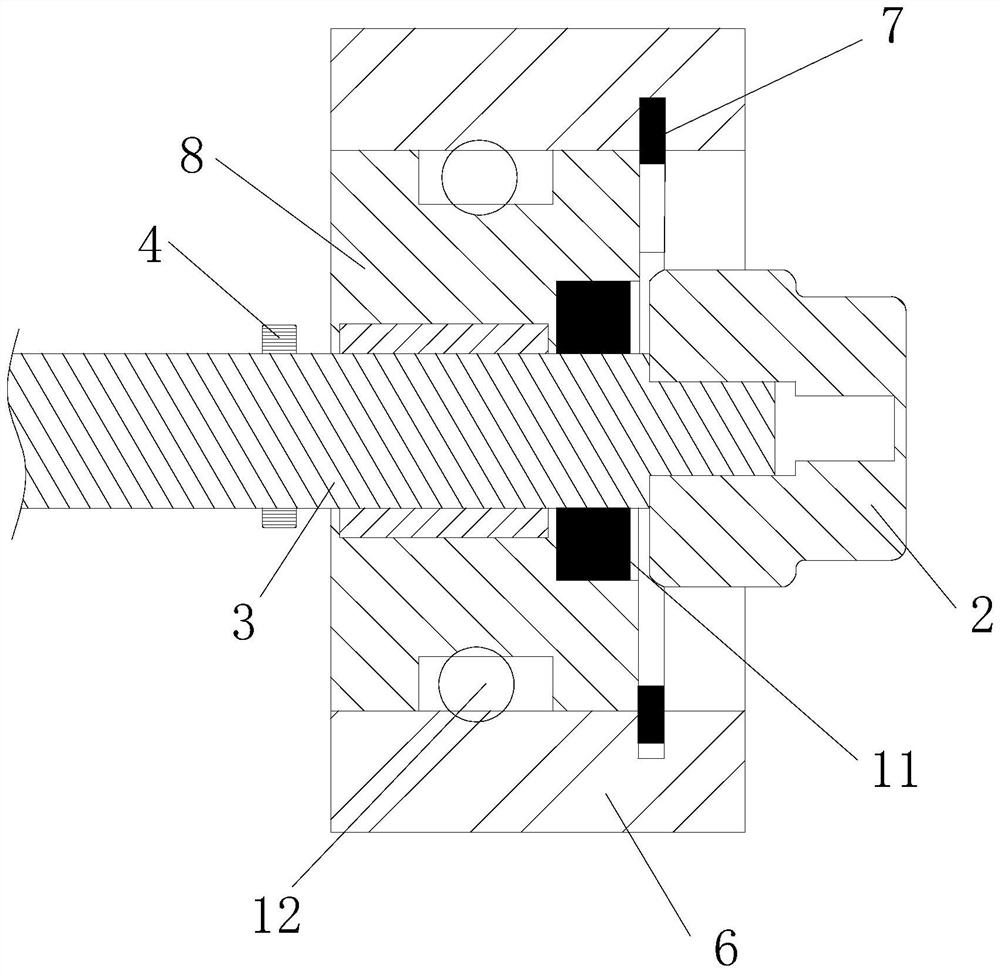

Motor rotor axial thrust device

PendingCN111327147AReduced Axial Shift ForceSafe and reliable operationSupports/enclosures/casingsAxial thrustPhysics

The invention discloses a pump motor rotor axial thrust device, which comprises a housing of the motor rotor axial thrust device composed of a front base (5) and a rear cover (10); thrust mechanism components which are arranged in the housing and comprise a rear cover pressure bearing ring (9) and a front base pressure bearing ring (12); and a thrust disc (7) which is arranged between the rear cover pressure bearing ring (9) and the front base pressure bearing ring (12). According to the invention, when the motor operates, the thrust disc enables the motor rotor to be at a designed working position in the axial direction; when the motor rotor is about to generate axial out-of-control large shifting, the two pressure bearing rings of the device can bear axial shifting force in different directions on the thrust disc, and the axial shifting amount of the motor rotor is limited to be within 0.8-1.0 mm.

Owner:上海正容工贸有限公司

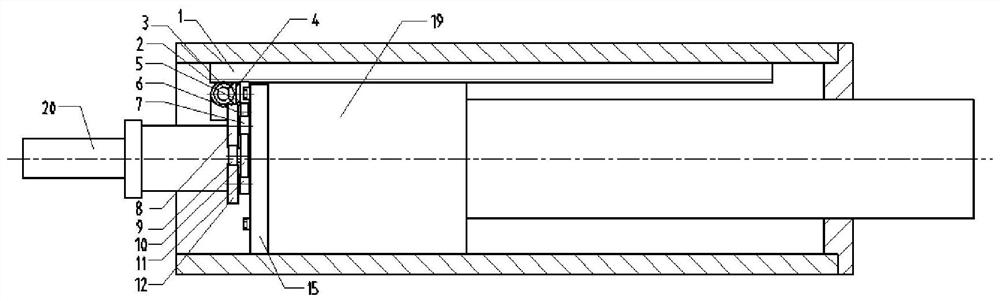

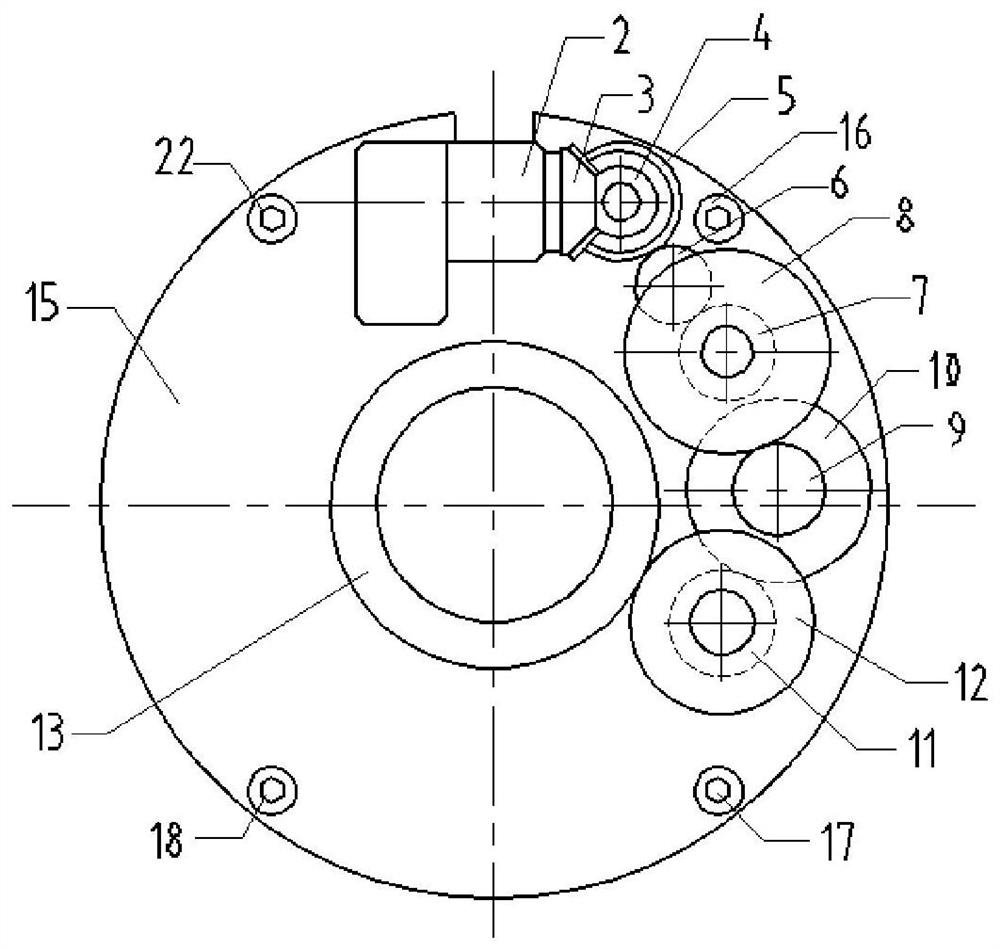

Gap adjusting mechanism for gear selecting component of gearbox and transmission

ActiveCN113803451AFlexible assemblyEase of mass productionGearingGearing controlCouplingElectric machinery

The invention is applicable to the technical field of transmissions, and provides a gap adjusting mechanism for a gear selecting component of a gearbox. The mechanism comprises a shell and a motor, and a coupler, a lead screw and a sealing block are arranged in the shell; an output shaft of the motor is in transmission connection with the lead screw through the coupler, the lead screw is in threaded connection with a sealing plug block, the sealing plug block is located in a concave hole in the shell, an elastic check ring is further installed between the sealing plug block and the coupler, the sealing plug block is in a circular ring shape, the concave hole is a round hole, external threads are arranged on the peripheral face of the sealing plug block, and internal threads matched with the external threads are arranged in the concave hole. The mechanism reduces the workload in the assembly process, and is beneficial to the batch production of the full-motor-driven transmission.

Owner:苏州赫行新能源汽车科技有限公司

Method for improving transmission precision of differential planetary roller screw actuator and synchronizing device

ActiveCN111779811AAvoid Cumulative Transmission ErrorsImprove real-time displacement accuracyGearingLinear displacementRoller screw

The invention relates to a method for improving the transmission precision of a differential planetary roller screw actuator and a synchronizing device. The method is characterized in that the constant lead of a lead screw in operation is ensured by establishing a fixed transmission ratio value of the lead of the lead screw and the rotation angle of a holder, so that the transmission precision ofthe actuator is improved; a set of ordinary gear train is additionally arranged between an actuator guide block and the lead screw holder, the gear train is fixed to the end face of a nut, the lower end face of a guide block is machined to be in a rack form and matched with the gear train, linear motion of the nut is converted into rotary motion of the lead screw holder, and therefore the rotationangle of the holder and linear displacement of the nut have the only determined relation.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

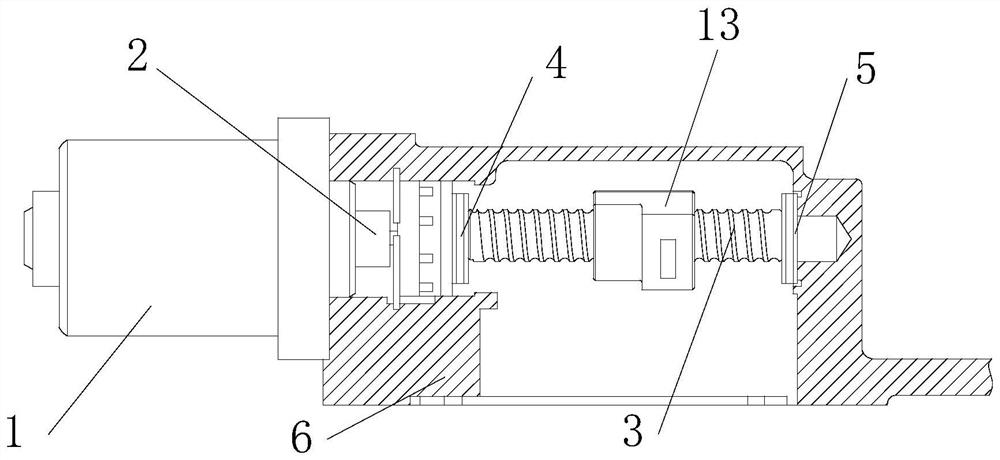

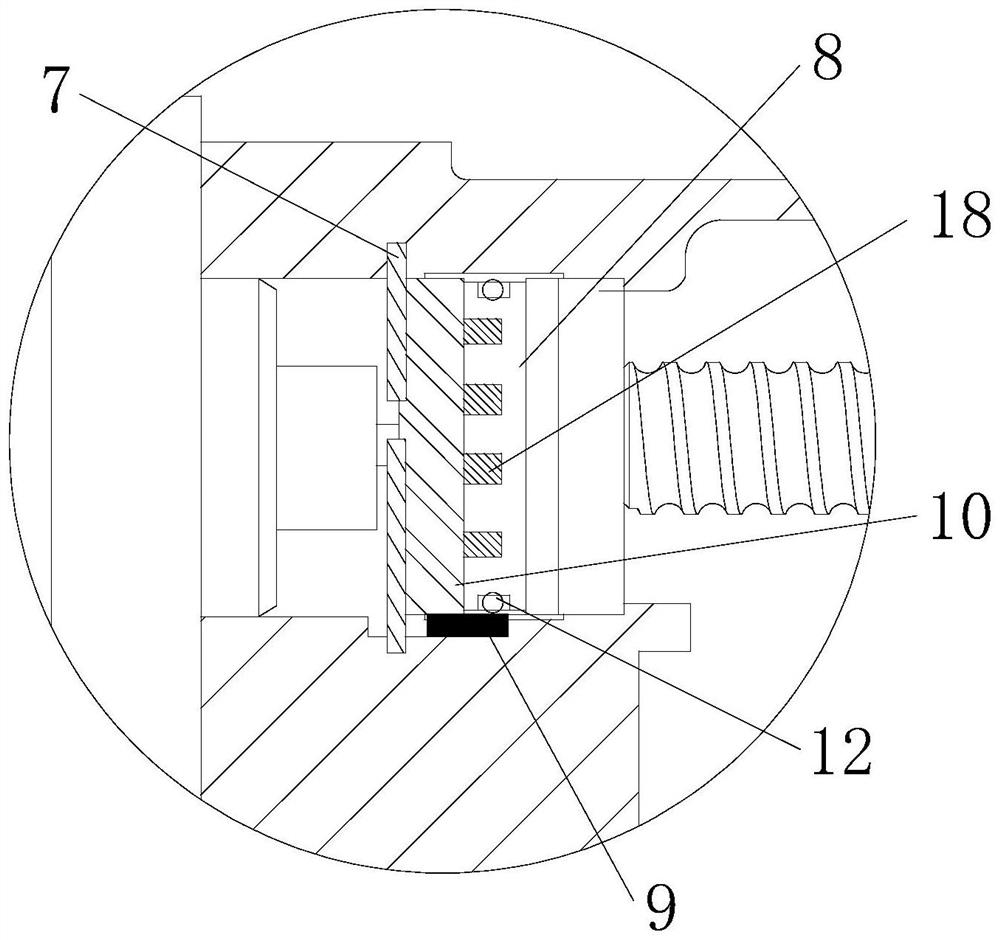

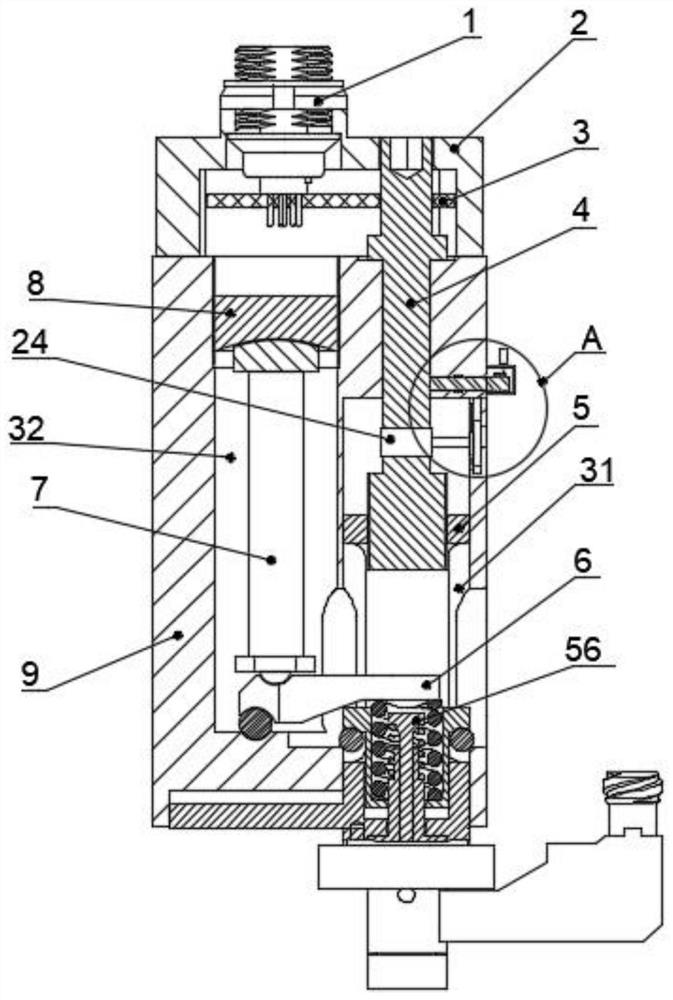

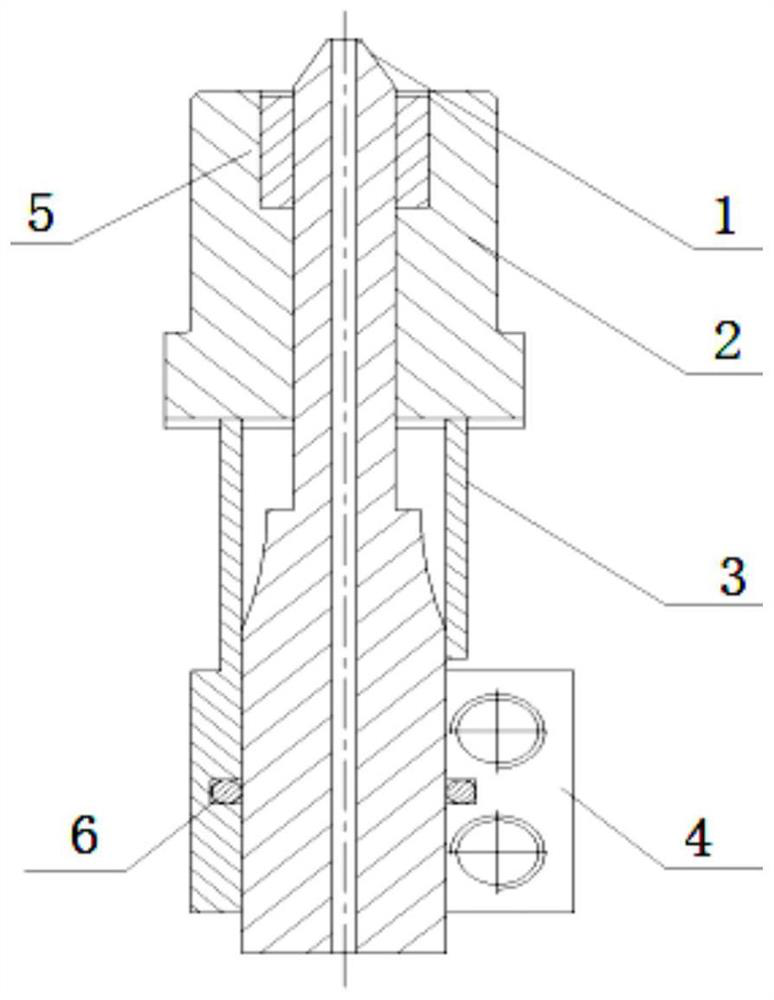

A New Type of Precision Piezoelectric Injection Valve

ActiveCN112387530BExtended Periodic Calibration IntervalsHigh precisionLiquid surface applicatorsCoatingsControl engineeringScrew thread

Owner:SHENZHEN TENSUN IND EQUIP

Rotatable separation rolling mill and separation method thereof

PendingCN106391719AQuick changeLimit axial displacementMetal rolling stand detailsMetal rolling arrangementsAxial displacementPulp and paper industry

The invention discloses a rotatable separation rolling mill and a separation method thereof. The rotatable separation rolling mill comprises a fixing rack and a roller rack, the roller rack comprises a shaft and a roller, the shaft is sleeved with the roller, an insertion hole is formed in the fixing rack, a limiting shaft extending in the radial direction is arranged at the second end of the shaft, and the second end of the shaft can be inserted into the insertion hole; and when the shaft is inserted into the insertion hole, the shaft is rotated, the limiting shaft can abut against the fixing rack, and therefore axial displacement of the roller rack is limited. When the rotatable separation rolling mill is installed and replaced, overall installation and rotation positioning can be carried out on the roller rack, and the installation and replacement process are rapider.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

High-pressure water jet spraying device carried on TBM and having sealing and anti-loosening functions

ActiveCN113182101AClosely connectedRealize the sealing and anti-loosening functionSpraying apparatusTunnelsHigh pressure waterWater spray

The invention provides a high-pressure water jet injection device carried on a TBM and having sealing and anti-loosening functions. A high-pressure water jet spraying device body is included and comprises a high-pressure hose, a water spray rod and a water spray rod flange. The high-pressure water jet spraying device carried on the TBM and having the sealing and anti-loosening functions is characterized in that the high-pressure water jet spraying device with the sealing and anti-loosening functions further comprises a sealing and anti-loosening structure of the high-pressure hose, a sealing and anti-loosening structure of a water spraying rod flange bolt and a sealing and anti-loosening structure of the water spraying rod screw pad and screw sleeve. The device can realize sealing and looseness prevention of the water jet spraying device through effective looseness prevention at a plurality of key parts, is simple to process and manufacture, convenient to assemble and disassemble, good in structural stability and capable of adapting to structural vibration in the TBM field tunneling process, ensures stable use of a water jet high-pressure sealing surface, improves the tunneling efficiency of the TBM on extremely hard rocks, and reduces tool abrasion and tool changing times, the cost is saved, the construction period is shortened, and meanwhile popularization of the high-pressure water jet assisted rock breaking TBM technology is accelerated.

Owner:YELLOW RIVER ENG CONSULTING

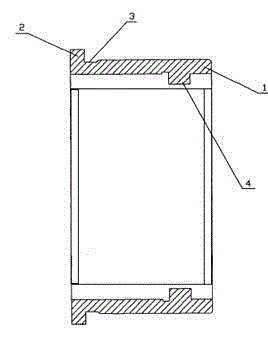

Bearing for high-voltage equipment switch

InactiveCN105526255ALimit axial displacementWon't fall offBearing componentsAxial displacementElectrical and Electronics engineering

The invention relates to a bearing for a high-voltage equipment switch. The bearing is characterized by comprising an outer ring, an inner ring, a roller pin, a supporting frame and a gasket, wherein the gasket is fixedly installed at one end of the bearing, a protruding step is arranged on the outer diameter part of the outer ring, and a boss capable of limiting the axial displacement of the roller pin is arranged on the inner surface of the end, towards the gasket, of the outer ring. According to the bearing, the axial displacement of the roller pin can be limited when the bearing works, even if the gasket falls offin the work process, the boss can prevent the roller pin from falling off from the inside of the bearing, and therefore, the bearing can work normally.

Owner:汪国伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com