Method for improving transmission precision of differential planetary roller screw actuator and synchronizing device

A planetary roller and synchronous device technology, which is applied in the field of precision transmission, can solve the problems of control system oscillation and lack of real-time performance, and achieve the effects of preventing grease leakage, simplifying the difficulty of displacement control, and improving transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

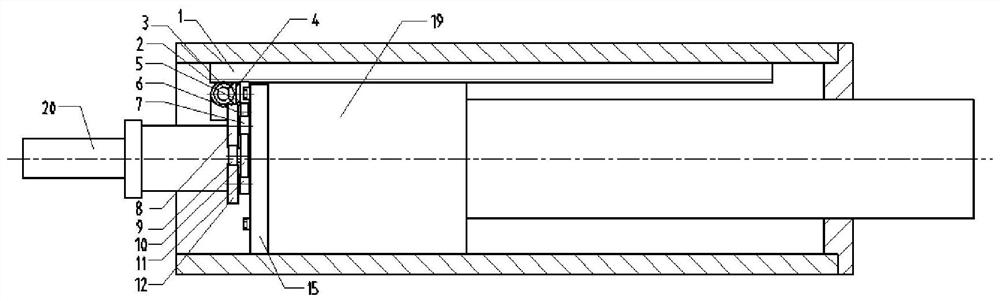

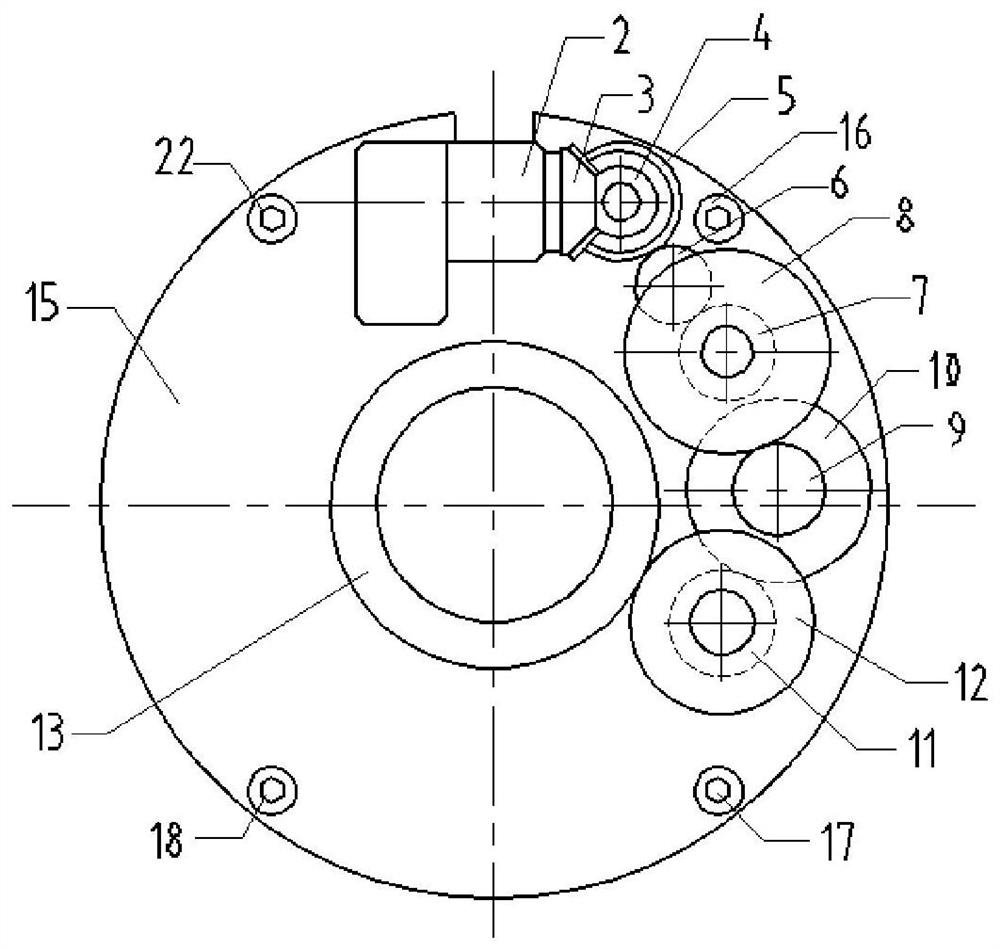

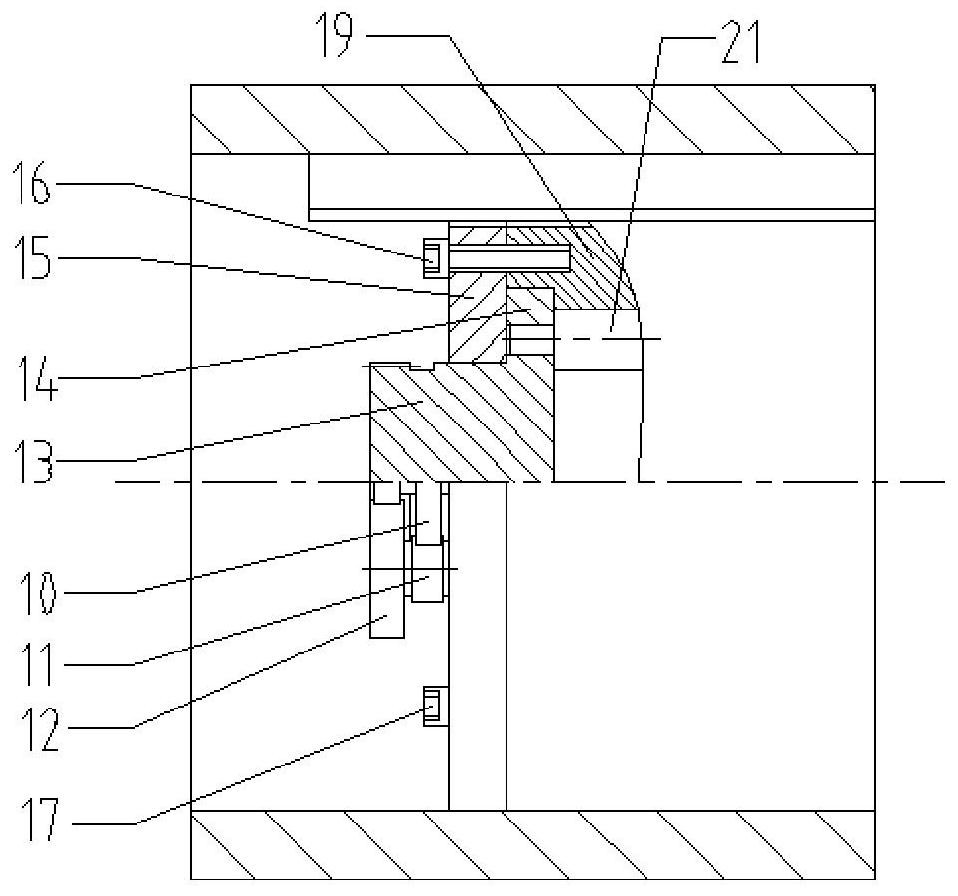

[0031] The following examples and attachments are combined Figure 1-4 The present invention is further explained.

[0032] P=P s (1-ω c / ω s ) Is the differential planetary roller screw transmission formula, where P is the lead of the screw pair, Ps is the lead of the screw 20, ω s Is the screw speed, ω c For the cage speed, it can be seen from the formula that ω c s ,(1-ω c / ω s ) c Closer to ω s , The smaller the lead of the screw pair, that is, the differential planetary roller screw can break away from the constraint of the screw pitch and realize the ultra-small lead. But when ω c When changing, the lead of the screw pair also changes, which increases the difficulty of controlling the actuator. The above formula may also be effective as P=P s (1-θ c / θ s ), θ c / θ s It is the ratio of the angle of the cage to the angle of the screw. This application establishes the lead P and θ c To ensure that the P value is constant during operation, thereby improving the transmission ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com