A method and synchronization device for improving the transmission accuracy of a differential planetary roller screw actuator

A planetary roller and synchronous device technology, which is applied in the field of precision transmission, can solve the problems of control system oscillation and lack of real-time performance, and achieve the effects of preventing grease leakage, simplifying the difficulty of displacement control, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

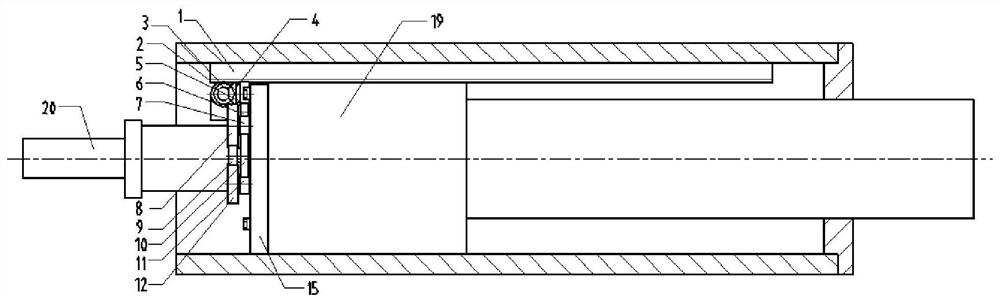

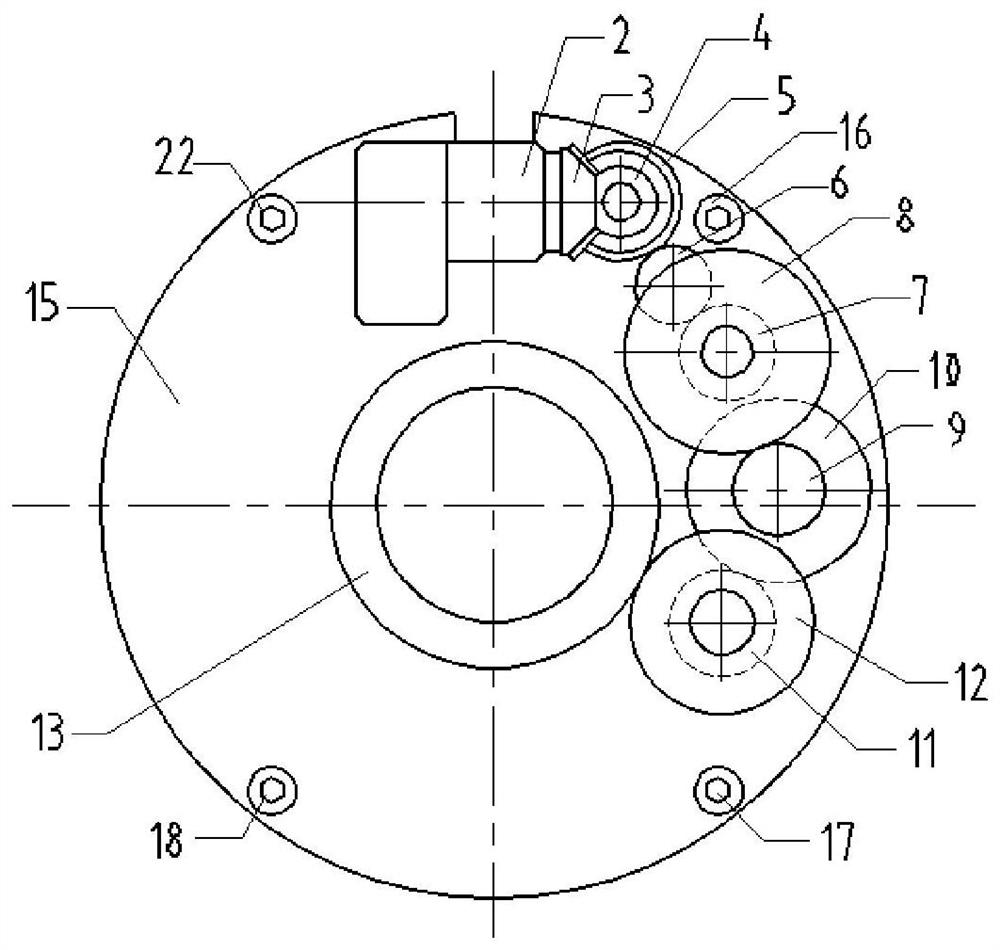

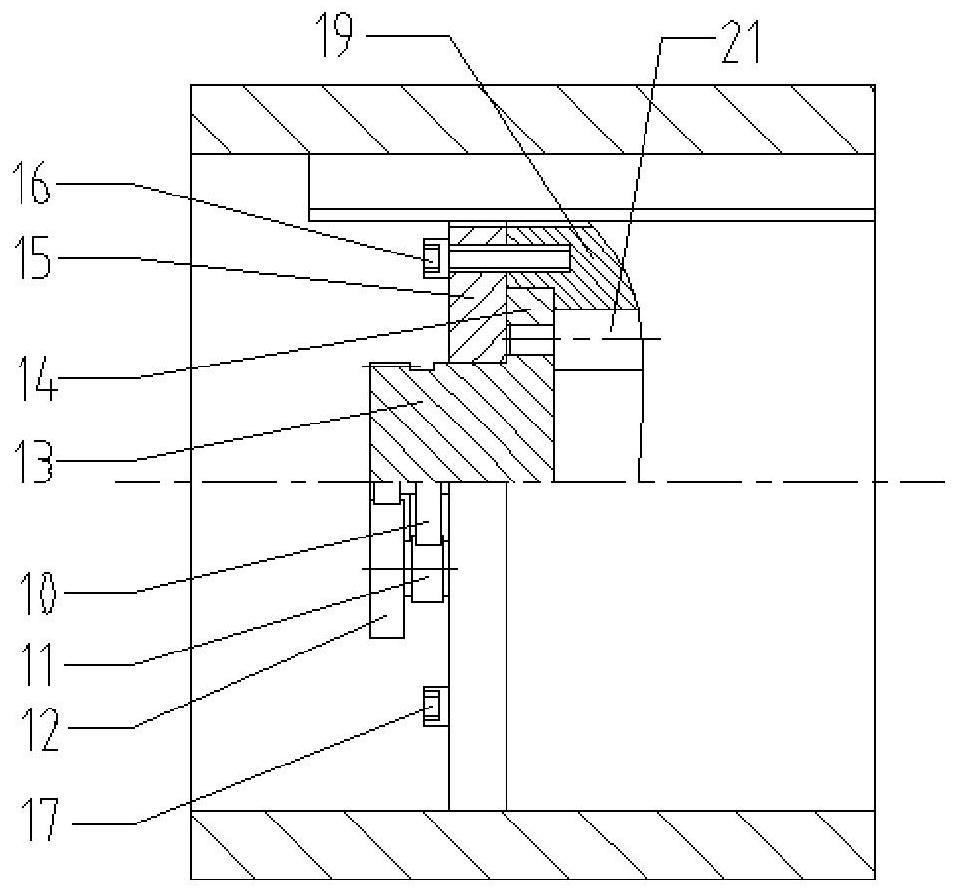

[0031] Below in conjunction with embodiment and appendix Figure 1-4 The present invention is further elaborated.

[0032] P=P s (1-ω c / ω s ) is the differential planetary roller screw transmission formula, where P is the lead of the screw pair, Ps is the lead of the screw 20, ω s is the screw speed, ω c is the cage speed, it can be seen from the formula, ω c s ,(1-ω c / ω s )c closer to ω s , the smaller the lead of the screw pair, that is, the differential planetary roller screw can be freed from the constraint of the screw pitch and achieve ultra-small lead. But when ω c When changing, the lead of the screw pair also changes, which increases the control difficulty of the actuator. The above formula may also be valid as P=P s (1-θ c / θ s ), θ c / θ s It is the ratio of the cage rotation angle to the screw rotation angle. This application establishes the lead P and θ by establishing c The fixed transmission ratio value to ensure that the P value is constant du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com