Cargo hook gear of motor vehicle exhaustion system

An exhaust system and motor vehicle technology, applied in the directions of power plant, gas intake of power plant, vehicle components, etc., can solve problems such as axial movement, and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

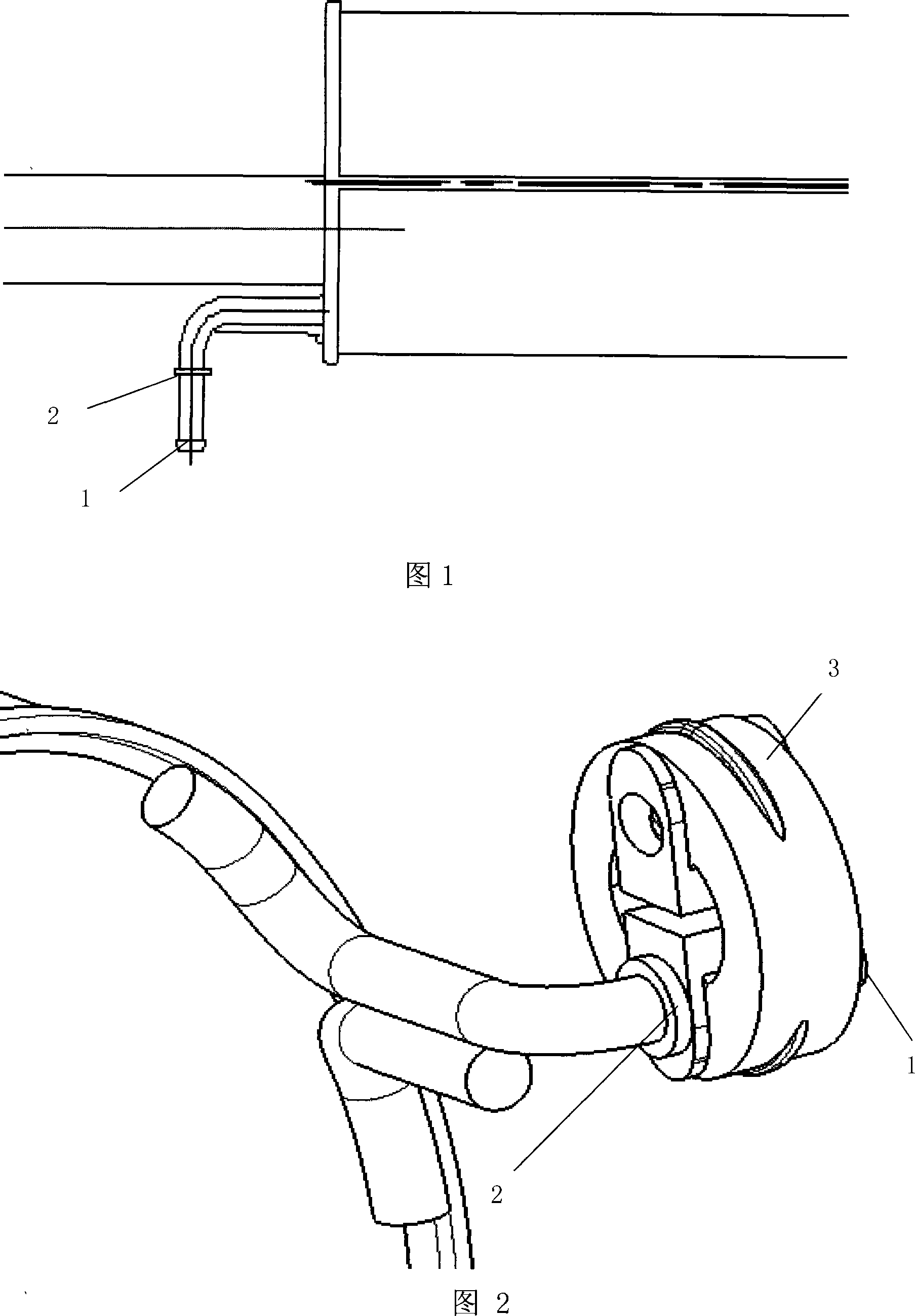

[0012] Embodiment 1: As shown in Figure 1, the structure adopted by the present invention is that the outer end of the hook welded on the exhaust system is provided with a header 1, and the middle section of the hook is formed into a circle by cold heading or welding. The ring boss 2 and the suspension part 3 are between the head 1 and the boss 2, and the outer diameter of the boss 2 is larger than the inner diameter of the suspension part 3. When the suspension parts such as rubber hanging blocks are installed on the welding hook, The suspension is limited between the outer end heading 1 of the hook and the boss 2. Since the outer diameter of the boss 2 is much larger than the inner diameter of the hanger, when the hanger moves to the boss, it is raised Taiwan blocked. Therefore, in this structure, the relative movement between the suspension part and the welding hook on the exhaust system is limited within a reasonable range to avoid interference between the exhaust system a...

Embodiment 2

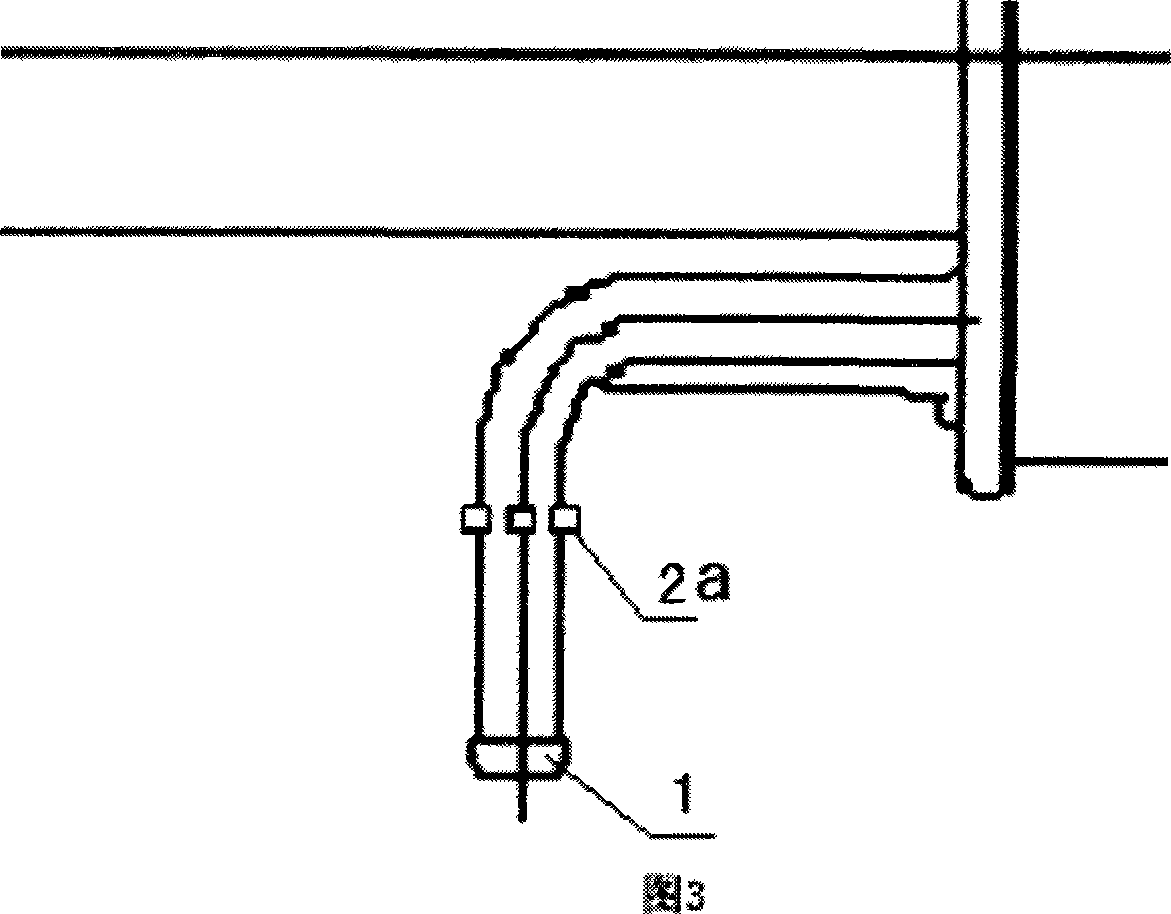

[0013] Embodiment 2: As shown in Figure 3, the boss 2 is a group (four in this embodiment) of independent bumps 2a formed on the middle hook of the hook by cold heading or welding. , the end face of each projection 2a close to the hook heading head is in a plane, so that the hanger 3 is finally limited in the hook.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com